ISO 8085-1:2001

(Main)Polyethylene fittings for use with polyethylene pipes for the supply of gaseous fuels — Metric series — Specifications — Part 1: Fittings for socket fusion using heated tools

Polyethylene fittings for use with polyethylene pipes for the supply of gaseous fuels — Metric series — Specifications — Part 1: Fittings for socket fusion using heated tools

Raccords en polyéthylène pour utilisation avec des tubes en polyéthylène pour la distribution de combustibles gazeux — Série métrique — Spécifications — Partie 1: Raccords à emboîture à souder au moyen d'outils chauffés

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 8085-1

First edition

2001-09-01

Polyethylene fittings for use with

polyethylene pipes for the supply of

gaseous fuels — Metric series —

Specifications —

Part 1:

Fittings for socket fusion using heated

tools

Raccords en polyéthylène pour utilisation avec des tubes en polyéthylène

pour la distribution de combustibles gazeux — Série métrique —

Spécifications —

Partie 1: Raccords à emboîture à souder au moyen d'outils chauffés

Reference number

ISO 8085-1:2001(E)

©

ISO 2001

---------------------- Page: 1 ----------------------

ISO 8085-1:2001(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this

file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this

area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters

were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the unlikely event

that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2001

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic

or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's member body

in the country of the requester.

ISO copyright office

Case postale 56 � CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.ch

Web www.iso.ch

Printed in Switzerland

ii © ISO 2001 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 8085-1:2001(E)

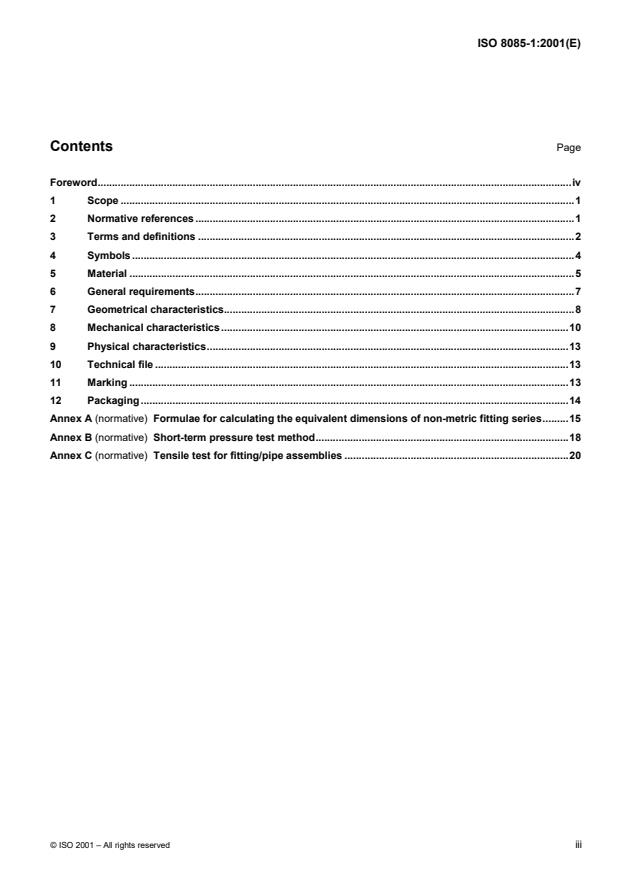

Contents Page

Foreword.iv

1 Scope .1

2 Normative references .1

3 Terms and definitions .2

4 Symbols .4

5 Material .5

6 General requirements.7

7 Geometrical characteristics.8

8 Mechanical characteristics .10

9 Physical characteristics.13

10 Technical file .13

11 Marking .13

12 Packaging.14

Annex A (normative) Formulae for calculating the equivalent dimensions of non-metric fitting series.15

Annex B (normative) Short-term pressure test method.18

Annex C (normative) Tensile test for fitting/pipe assemblies .20

© ISO 2001 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 8085-1:2001(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO

member bodies). The work of preparing International Standards is normally carried out through ISO technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

Draft International Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this part of ISO 8085 may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

International Standard ISO 8085-1 was prepared by Technical Committee ISO/TC 138, Plastics pipes, fittings and

valves for the transport of fluids, Subcommittee SC 4, Plastics pipes and fittings for the supply of gaseous fuels.

ISO 8085 consists of the following parts, under the general title Polyethylene fittings for use with polyethylene pipes

for the supply of gaseous fuels — Metric series — Specifications:

— Part 1: Fittings for socket fusion using heated tools

— Part 2: Spigot fittings for butt fusion, for socket fusion using heated tools and for use with electrofusion fittings

— Part 3: Electrofusion fittings

Annexes A, B and C form a normative part of this part of ISO 8085.

iv © ISO 2001 – All rights reserved

---------------------- Page: 4 ----------------------

INTERNATIONAL STANDARD ISO 8085-1:2001(E)

Polyethylene fittings for use with polyethylene pipes for the supply

of gaseous fuels — Metric series — Specifications —

Part 1:

Fittings for socket fusion using heated tools

1 Scope

This part of ISO 8085 specifies the requirements for polyethylene (PE) socket fusion fittings intended to be used

with PE pipes and fittings for the supply of gaseous fuels.

In addition, it specifies some general properties of the material from which these fittings are made.

This part of ISO 8085 also lays down requirements for dimensions and performance of such fittings.

It is applicable to socket fusion fittings designed to be fusion-jointed to PE pipes conforming to ISO 4437, and to

spigot fittings conforming to ISO 8085-2.

2 Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of

this part of ISO 8085. For dated references, subsequent amendments to, or revisions of, any of these publications

do not apply. However, parties to agreements based on this part of ISO 8085 are encouraged to investigate the

possibility of applying the most recent editions of the normative documents indicated below. For undated

references, the latest edition of the normative document referred to applies. Members of ISO and IEC maintain

registers of currently valid International Standards.

ISO 3:1973, Preferred numbers� Series of preferred numbers

ISO 497:1973, Guide to the choice of series of preferred numbers and of series containing more rounded values of

preferred numbers

ISO 1133:1997, Plastics� Determination of the melt mass-flow rate (MFR) and the melt volume-flow rate (MVR) of

thermoplastics

ISO 1167:1996, Thermoplastics pipes for the conveyance of fluids� Resistance to internal pressure� Test

method

ISO 1183 (all parts), Plastics — Methods for determining the density of non-cellular plastics

ISO 1872-1:1993, Plastics� Polyethylene (PE) moulding and extrusion materials� Part 1: Designation system

and basis for specifications

1)

ISO 3126:— , Plastics piping systems — Plastics piping components — Measurement and determination of

dimensions

1) To be published. (Revision of ISO 3126:1974)

© ISO 2001 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO 8085-1:2001(E)

ISO 4437:1997, Buried polyethylene (PE) pipes for the supply of gaseous fuels� Metric series� Specifications

ISO 6964:1986, Polyolefin pipes and fittings � Determination of carbon black content by calcination and

pyrolysis — Test method and basic specification

ISO 8085-2:2001, Polyethylene fittings for use with polyethylene pipes for the supply of gaseous fuels — Metric

series — Specifications — Part 2: Spigot fittings for butt fusion, for socket fusion using heated tools and for use

with electrofusion fittings

ISO 8085-3:2001, Polyethylene fittings for use with polyethylene pipes for the supply of gaseous fuels� Metric

series� Specifications — Part 3: Electrofusion fittings

ISO 9356:1989, Polyolefin pipe assemblies with or without jointed fittings — Resistance to internal pressure — Test

method

2)

ISO 9080:— , Plastics piping and ducting systems — Determination of the long-term hydrostatic strength of

thermoplastics materials in pipe form by extrapolation

ISO/TR 10837:1991, Determination of the thermal stability of polyethylene (PE) for use in gas pipes and fittings

ISO/TS 10839:2000, Polyethylene pipes and fittings for the supply of gaseous fuels — Code of practice for design,

handling and installation

ISO 12162:1995, Thermoplastics materials for pipes and fittings for pressure applications� Classification and

designation� Overall service (design) coefficient

ISO 13477:1997, Thermoplastics pipes for the conveyance of fluids� Determination of resistance to rapid crack

propagation (RCP)� Small-scale steady-state test (S4 test)

ISO 13478:1997, Thermoplastics pipes for the conveyance of fluids� Determination of resistance to rapid crack

propagation (RCP)� Full-scale test (FST)

ISO 13479:1997, Polyolefin pipes for the conveyance of fluids� Determination of resistance to crack propagation�

Test method for slow crack growth on notched pipes (notch test)

ISO 13951:2001, Plastics piping systems — Test method for the resistance of polyolefin pipe/pipe or pipe/fitting

assemblies to tensile loading

3)

ISO 18553:— , Method for the assessment of pigment or carbon black dispersion in polyolefin pipes, fittings and

compounds

ASTM D 4019-94, Standard Test Method for Moisture in Plastics by Coulometric Regeneration of Phosphorus

Pentoxide

3 Terms and definitions

For the purposes of this part of ISO 8085, the following terms and definitions apply.

3.1 Geometrical definitions

3.1.1

nominal diameter of a fitting

d

n

the nominal diameter of a fitting is taken as the nominal diameter of the corresponding pipe series

2) To be published. (Revision of ISO/TR 9080:1992)

3) To be published. (Revision of ISO 11420:1996 and ISO 13949:1997)

2 © ISO 2001 – All rights reserved

---------------------- Page: 6 ----------------------

ISO 8085-1:2001(E)

3.1.2

nominal wall thickness of a fitting

e

n

the nominal wall thickness of a fitting is taken as the nominal wall thickness of the corresponding pipe series

3.1.3

mean inside diameter

arithmetic mean of at least two inside diameters measured at right angles to each other in transverse planes

3.1.4

out-of-roundness of a socket

maximum inside diameter minus the minimum inside diameter of the socket, measured in the same plane, parallel

to the plane of the mouth

3.1.5

maximum out-of-roundness of a socket

greatest value of the out-of-roundness between the plane of the mouth and a plane separated from it by a distance

L (the socket reference length)

3.1.6

socket taper

included angle at the vertex of the triangle corresponding to the longitudinal cross-section of a cone based on the

mean socket-mouth diameter, the mean socket-root diameter and the reference length of the socket

3.1.7

standard dimension ratio of a fitting

SDR

the SDR value of a fitting is taken as being the same as that of the corresponding pipe series

d

n

SDR =

e

n

3.1.8

wall thickness of a fitting

E

wall thickness at any point of the body of the fitting which could be subjected to the full stress induced by the

pressure of the gas in the piping system

3.2 Material definitions

3.2.1

virgin material

thermoplastics material in a form such as granules or powder which has not been previously processed other than

for compounding and to which no reprocessable or recyclable materials have been added

3.2.2

reprocessable material

thermoplastics material prepared from clean unused rejected pipes, fittings or valves, produced in a manufacturer’s

plant by a process such as injection-moulding or extrusion, which will be reprocessed in the same plant

NOTE Such material may include trimmings from the production of such pipes, fittings and valves.

3.2.3

compound

homogenous mixture of base polymer (PE) and additives, e.g. anti-oxidants, pigments and UV-stabilizers, at

concentrations necessary for the particular application

© ISO 2001 – All rights reserved 3

---------------------- Page: 7 ----------------------

ISO 8085-1:2001(E)

3.3 Definitions related to material characteristics

3.3.1

lower confidence limit

�

lcl

quantity with the dimensions of stress, in megapascals, which can be considered as a property of the material and

represents the 97,5 % lower confidence limit of the mean long-term hydrostatic strength at 20 °C for 50 years

determined by pressurizing internally with water

3.3.2

overall service (design) coefficient

C

overall coefficient, with a value larger than 1,0, which takes into consideration service conditions as well as

properties of the components of a piping system other than those represented in the lower confidence limit

NOTE For gas applications, C can have any value equal to or greater than 2,0.

3.3.3

minimum required strength

MRS

the value of � rounded down to the next lower value in the R 10 series when � is less than 10 MPa, or to the

lcl lcl

next lower value in the R 20 series when� is greater than or equal to 10 MPa

lcl

NOTE The R 10 and R 20 series are the Renard number series as defined in ISO 3 and ISO 497.

3.3.4

melt mass-flow rate

MFR

value relating to the viscosity of molten thermoplastic material at a specified temperature and rate of shear

3.4 Definitions related to service conditions

3.4.1

gaseous fuel

4�

any fuel which is in the gaseous state at a temperature of +15 °C and a pressure of 1 bar

3.4.2

maximum operating pressure

MOP

maximum effective pressure of the gas in a piping system, expressed in bars, which is allowed in continuous use

NOTE It takes into account the physical and the mechanical characteristics of the components of a piping system and is

given by the equation:

20� MRS

MOP �

C��(SDR 1)

4 Symbols

The dimensions and symbols used in this part of ISO 8085 are shown in Figure 1, where

D is the mean inside diameter of the socket mouth, i.e. the mean diameter of the circle at the intersection of the

1

extension of the socket with the plane of the socket mouth.

5 2

4� 1 bar = 10 N/m =0,1 MPa

4 © ISO 2001 – All rights reserved

---------------------- Page: 8 ----------------------

ISO 8085-1:2001(E)

D is the mean inside diameter of the socket root, i.e. the mean diameter of the circle in a plane parallel to the

2

plane of the mouth and separated from it by a distance L which is the reference length of the socket.

D is the minimum bore, i.e. the minimum diameter of the flow channel through the body of the fitting.

3

L is the reference socket length, i.e. the theoretical minimum socket length used for calculation purposes.

L is the actual length of the socket from mouth to shoulder (if any).

1

L is the heated length of the fitting, i.e. the length of penetration of the heated tool into the socket.

2

L is the insertion depth, i.e. the depth of penetration of the heated pipe end into the socket.

3

NOTE L is also the depth of the “depth gauge” tool used in normal socket fusion jointing practice.

3

Figure 1 — Socket dimensions

5 Material

5.1 Technical data

The technical data referred to in Table 1 concerning the materials used shall be made available by the fitting

manufacturer.

Any change in the choice of materials affecting the quality shall require fresh type-testing of the fitting in

accordance with clause 8.

© ISO 2001 – All rights reserved 5

---------------------- Page: 9 ----------------------

ISO 8085-1:2001(E)

a

Table 1 — Characteristics of the PE compound

Property Units Requirement Test parameters Test method

3

Density W 930 (base polymer) 23 °C ISO 1183, ISO 1872-1

kg/m

Melt mass-flow rate g/10 min 190 °C/5 kg ISO 1133:1997

� 20 % of value declared by compound

(set of conditions T)

producer

b

Thermal stability minutes � 20 ISO/TR 10837

200 °C

Volatile-matter content mg/kg u 350 ISO 4437:1997, annex A

c

mg/kg u 300 ASTM D 4019

Water content

d

%(m/m) 2,0 % to 2,5 % ISO 6964

Carbon black content

d

grade u 3 ISO 18553

Carbon black dispersion

e

grade u 3 ISO 18553

Pigment dispersion

Resistance to gas h W 20 80 °C, 2 MPa ISO 4437:1997, annex B

constituents

Resistance to rapid crack

f

propagation (RCP):

Full-scale (FS) test: MPa The critical pressure in the FS test shall 0 °C ISO 13478

d > 250 mm be greater than or equal to the value of the

n

MOP of the system multiplied by 1,5

or

g

S4 test MPa The critical pressure in the S4 test shall be 0 °C ISO 13477

greater than or equal to the value of the MOP

of the system divided by 2,4, minus 0,72

h

(expressed in bars)

i

Resistancetoslowcrack h 165 80 °C, 8,0 bar ISO 13479

f

growth, e � 5mm

n

j

80 °C, 9,2 bar

a

Non-black compounds shall conform to the weathering requirements of ISO 4437.

b

Test may be carried out at 210 °C provided that there is a clear correlation with the results at 200 °C. In cases of dispute, the reference

temperature shall be 200 °C.

c

Only applicable if the compound does not conform to the requirement for volatile-matter content. In cases of dispute, the requirement

for water content shall apply.

d

For black compounds only.

e

Pigment dispersion method for non-black compounds only.

f

Only applicable to material in pipe form.

g

Shall be performed on pipe with a wall thicknessW 15 mm.

h

If this requirement is not met, then retesting using the full-scale (FS) test shall be performed (the calculation formula is still under study).

i

Test parameters for PE 80, SDR 11.

j

Test parameters for PE 100, SDR 11.

5.2 Compound

The compound from which the fitting is produced shall be polyethylene which shall be made by adding only those

additives necessary for the manufacture and end use of fittings conforming to this specification and for their fusion

jointing.

All additives shall be uniformly dispersed. The additives shall not have a negative influence on the performance

with respect to fusability.

6 © ISO 2001 – All rights reserved

---------------------- Page: 10 ----------------------

ISO 8085-1:2001(E)

5.3 Reprocessable material

Only clean reprocessable material generated from a manufacturer’s own production of fittings to this specification

may be used, and it shall be derived from the same resin as used for the relevant production.

5.4 Characteristics of the compound

The fittings shall be made of

a) virgin material,

b) reprocessable material or

c) a combination of virgin and reprocessable material.

The PE compound from which the fitting is manufactured shall conform to the requirements given in Table 1.

5.5 Classification

PE compounds shall be classified by MRS as specified in Table 2.

Table 2 — Classification of PE compounds

� (20 °C, 50 years, 97,5 %) MRS

lcl

Designation

MPa

MPa

8,00u� u 9,99

PE 80 8,0

lcl

10,00u� u 11,19

PE 100 10,0

lcl

The classification shall be established by the producer of the compound using the ISO 9080 extrapolation method

and stated in accordance with ISO 12162.

5.6 Compatibility

Conformity to clause 8 shall be established by the fitting manufacturer to ensure compatibility of the fittings with PE

pipes conforming to ISO 4437. The PE pipe compound(s) used for this demonstration, the fusion condition(s) and

the tooling shall be as detailed in the fitting manufacturer's technical file (see clause 10).

6 General requirements

6.1 Multiple connections

If a fitting includes one or more spigot ends, these shall conform to the relevant product standard.

6.2 Appearance of the fitting

When viewed without magnification, the internal and external surfaces shall be smooth, clean and free from

scoring, cavities and other surface defects which might prevent conformity to this part of ISO 8085.

© ISO 2001 – All rights reserved 7

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.