ISO 484-2:2015

(Main)Shipbuilding — Ship screw propellers — Manufacturing tolerances — Part 2: Propellers of diameter between 0,80 and 2,50 m inclusive

Shipbuilding — Ship screw propellers — Manufacturing tolerances — Part 2: Propellers of diameter between 0,80 and 2,50 m inclusive

ISO 484-2:2015 defines manufacturing tolerances of ship screw propellers of a diameter between 0,80 m and 2,50 m. NOTE Some deviations for the tolerance are permitted in certain cases subject to the discretion of the customer or of the designer and the customer.

Construction navale — Hélices de navires — Tolérances de fabrication — Partie 2: Hélices de diamètre compris entre 0,80 et 2,50 m inclus

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 484-2

Second edition

2015-12-01

Shipbuilding — Ship screw propellers

— Manufacturing tolerances —

Part 2:

Propellers of diameter between 0,80

and 2,50 m inclusive

Construction navale — Hélices de navires — Tolérances de

fabrication —

Partie 2: Hélices de diamètre compris entre 0,80 et 2,50 m inclus

Reference number

©

ISO 2015

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

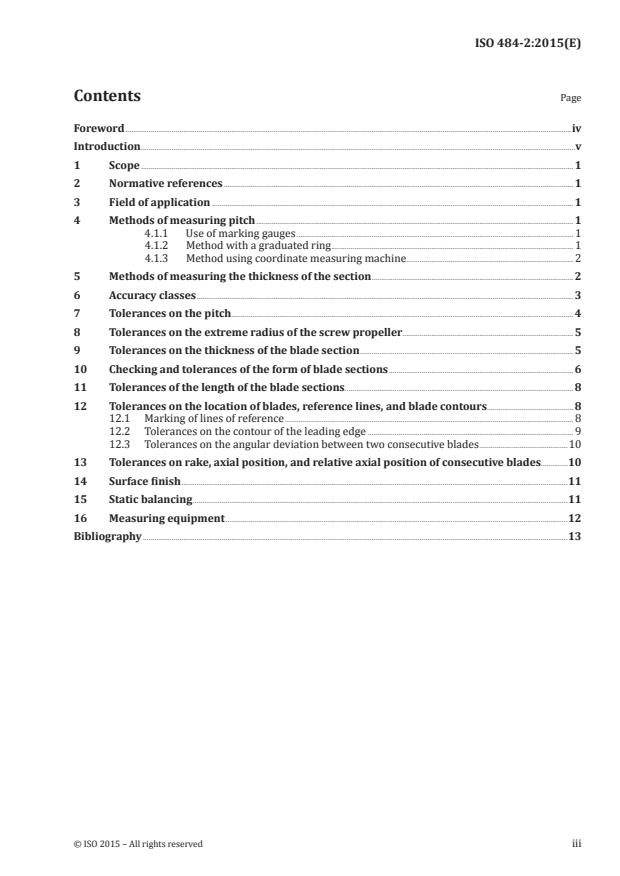

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Field of application . 1

4 Methods of measuring pitch . 1

4.1.1 Use of marking gauges . 1

4.1.2 Method with a graduated ring . 1

4.1.3 Method using coordinate measuring machine. 2

5 Methods of measuring the thickness of the section . 2

6 Accuracy classes . 3

7 Tolerances on the pitch . 4

8 Tolerances on the extreme radius of the screw propeller. 5

9 Tolerances on the thickness of the blade section . 5

10 Checking and tolerances of the form of blade sections . 6

11 Tolerances of the length of the blade sections. 8

12 Tolerances on the location of blades, reference lines, and blade contours .8

12.1 Marking of lines of reference . 8

12.2 Tolerances on the contour of the leading edge . 9

12.3 Tolerances on the angular deviation between two consecutive blades .10

13 Tolerances on rake, axial position, and relative axial position of consecutive blades.10

14 Surface finish .11

15 Static balancing .11

16 Measuring equipment .12

Bibliography .13

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 8, Ships and marine technology, Subcommittee

SC 3, Piping and machinery.

This second edition cancels and replaces the first edition (ISO 484-2:1981), which has been

technically revised.

ISO 484 consists of the following parts, under the general title Shipbuilding — Ship screw propellers —

Manufacturing tolerances:

— Part 1: Propellers of diameter greater than 2,50 m

— Part 2: Propellers of diameter between 0,80 m and 2,50 m inclusive

iv © ISO 2015 – All rights reserved

Introduction

The propeller manufacturer is at liberty to use any equipment and method that enables the tolerances

to be verified to the required accuracy.

INTERNATIONAL STANDARD ISO 484-2:2015(E)

Shipbuilding — Ship screw propellers — Manufacturing

tolerances —

Part 2:

Propellers of diameter between 0,80 and 2,50 m inclusive

1 Scope

This part of ISO 484 defines manufacturing tolerances of ship screw propellers of a diameter between

0,80 m and 2,50 m.

NOTE Some deviations for the tolerance are permitted in certain cases subject to the discretion of the

customer or of the designer and the customer.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 1302, Geometrical Product Specifications (GPS) — Indication of surface texture in technical product

documentation

ISO 1940-1:2003, Mechanical vibration — Balance quality requirements for rotors in a constant (rigid)

state — Part 1: Specification and verification of balance tolerances

3 Field of application

This part of ISO 484 applies to monobloc, built-up, and controllable pitch propellers.

4 Methods of measuring pitch

4.1 The principle of one method of measurement consists in setting out along a helicoidal line of

radius, r, a certain length, PQ, corresponding to the desired angle, α, and in measuring the difference, h, in

the heights of the points P and Q with respect to a reference plane (see Figure 1).

The length PQ shall be set out using one of the methods described in 4.1.1, 4.1.2 or 4.1.3.

NOTE Other methods giving the required accuracy may be used if necessary.

4.1.1 Use of marking gauges

The length PQ shall be set out by means of marking gauges.

4.1.2 Method with a graduated ring

The length PQ shall be set out by means of angle, α, on a part of a graduated ring of suitable radius

(see Figure 1).

A

4.1.3 Method using coordinate measuring machine

The height coordinates are taken at defined measuring points by means of coordinate measuring

machine and they are related to each other (determination of height differences needed for pitch

evaluation). Both cartesian coordinate system (x, y, z) and polar coordinate system (α, r, h) can be

applied alternatively in order to define measuring points P and Q.

5 Methods of measuring the thickness of the section

5.1 The thickness of a cylindrical section at a point S shall be measured along direction SV (see

Figure 2) on the plane tangent to the coaxial cylinder and perpendicular to the pitch line of the pressure

side of the section (and only along direction SU perpendicular to the pressure side surface or direction S

parallel to the propeller axis when defined in this way on the drawings).

P

B

Q

Key

1 small graduated ring

2 large graduated ring

Figure 1 — Pitch measurement

2 © ISO 2015 – All rights reserved

r

α

h

T

V

U

S

U

V T S

S

S

S

S

S

Key

1 pressure side

2 suction side

3 cylindrical section

4 line of maximum thickness of section perpendicular to the pressure side

5 developed section perpendicular to the pressure side

6 developed cylindrical section

7 pressure side

Figure 2 — Thickness measurement

5.2 The maximum thickness at each radius shall be determined by means of a pair of outside callipers

or from the profile obtained by plotting the thickness at various points: S, S , S , S , etc.

1 2 3

6 Accuracy classes

The accuracy class shall be selected by the customer. The indications in Table 1 serve as guidance

in this choice.

Table 1 — Accuracy of manufacturing

Class Manufacturing accuracy

S Very high accuracy

I High accuracy

II Medium accuracy

III Wide tolerances

7 Tolerances on the pitch

Table 2 — Pitch tolerances

Class

Designation of pitch

S I II III

a) Local pitch ±1,5 % ±2 % ±3 %

—

with a minimum of ±10 mm ±15 mm ±20 mm

b) Mean pitch per radius of

±1 % ±1,5 % ±2 % ±5 %

each blade

with a minimum of ±7,5 mm ±10 mm ±15 mm ±25 mm

c) Mean pitch per blade ±0,75 % ±1 % ±1,5 % ±4 %

with a minimum of ±5 mm ±7,5 mm ±10 mm ±20 mm

d) Mean pitch for propeller ±0,5 % ±0,75 % ±1 % ±3 %

with a minimum of ±4 mm ±5 mm ±7,5 mm ±15 mm

NOTE The tolerances of Table 2 are expressed as percentages of the design pitch

corresponding to the radius for designations a) and b) and the mean design pitch for

designations c) and d).

7.1 Pitch shall be measured at least at the radii indicated in Table 3. By agreement between the

interested parties, different radii may be measured.

Table 3 — Pitch measurement locations

Class Radii

S and I A section near the hub – 0,4 R – 0,5 R – 0,6 R – 0,7 R – 0,8 R – 0,9 R – 0,95 R

II and III A section near the hub – 0,5 R – 0,7 R – 0,9 R

7.2 The measurement of local pitches for Class S and Class I is further controlled as described in Clause 10.

7.3 The tolerances on the local pitch and on the mean pitch of each radius of each blade given in

Table 2, a) and b) are increased by 50 % for sections at 0,4 R or less.

7.4 Should the propeller manufacturer wish to compensate for an error on the pitch (inside or outside

the tabulated tolerances) by means of an alteration in the propeller diameter, he may do so only with the

customer’s agreement.

7.5 The design pitch is the pitch of the reference line as defined below.

The design pitch line of a section is a helical reference line for the section in question of which the

section ordinates for the face and the back are given.

It could be a line joining the nose and tail of the section or any other conveniently placed helical line.

7.6 The local pitch at a point B (Figure 1) is determined by measuring the difference in height between

two points, P and Q, situated at equal distances from point B and on either side of the latter (BP = BQ)

and by multiplying the difference in height by . This shall be compared with the local pitch as

α

calculated from the face offsets for the same points.

There shall be four pitch measurements for Class S, three for Class I, and two for Class II. These

measurements shall be consecutive (the initial point

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.