ISO 6123-2:2015

(Main)Rubber or plastics covered rollers — Specifications — Part 2: Surface characteristics

Rubber or plastics covered rollers — Specifications — Part 2: Surface characteristics

ISO 6123-2:2015 establishes a classification of rubber or plastics covered rollers according to surface quality or imperfections and surface finish. A test method for the determination of surface roughness is also described.

Cylindres revêtus de caoutchouc ou de plastique — Spécifications — Partie 2: Caractéristiques de surface

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 6123-2

Third edition

2015-12-01

Rubber or plastics covered rollers —

Specifications —

Part 2:

Surface characteristics

Cylindres revêtus de caoutchouc ou de plastique — Spécifications —

Partie 2: Caractéristiques de surface

Reference number

©

ISO 2015

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

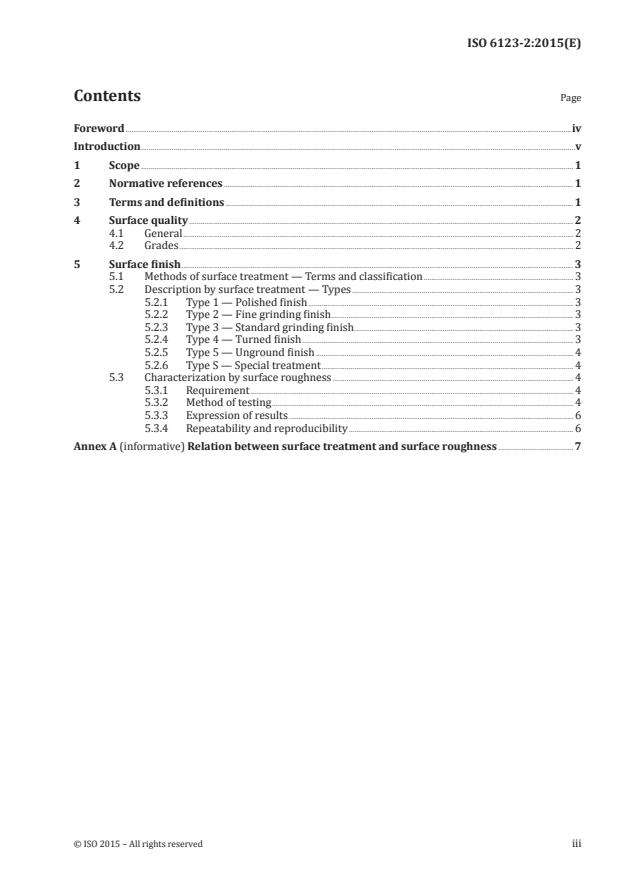

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Surface quality . 2

4.1 General . 2

4.2 Grades . 2

5 Surface finish . 3

5.1 Methods of surface treatment — Terms and classification . 3

5.2 Description by surface treatment — Types . 3

5.2.1 Type 1 — Polished finish . 3

5.2.2 Type 2 — Fine grinding finish . 3

5.2.3 Type 3 — Standard grinding finish . 3

5.2.4 Type 4 — Turned finish . 3

5.2.5 Type 5 — Unground finish . 4

5.2.6 Type S — Special treatment . 4

5.3 Characterization by surface roughness . 4

5.3.1 Requirement . 4

5.3.2 Method of testing . 4

5.3.3 Expression of results . 6

5.3.4 Repeatability and reproducibility . 6

Annex A (informative) Relation between surface treatment and surface roughness .7

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 45, Rubber and rubber products, Subcommittee

SC 4, Products (other than hoses).

This third edition cancels and replaces the second edition (ISO 6123-2:1988), of which it constitutes a

minor revision to update the normative references.

ISO 6123 consists of the following parts, under the general title Rubber or plastics covered rollers —

Specifications:

— Part 1: Requirements for hardness

— Part 2: Surface characteristics

— Part 3: Dimensional tolerances

iv © ISO 2015 – All rights reserved

Introduction

Covered rollers are cylindrical cores, generally of metal, with a cover of rubber or plastics or a particular

use. They are manufactured in a wide variety of sizes and hardness grades depending on the intended use.

INTERNATIONAL STANDARD ISO 6123-2:2015(E)

Rubber or plastics covered rollers — Specifications —

Part 2:

Surface characteristics

1 Scope

This part of ISO 6123 establishes a classification of rubber or plastics covered rollers according to

surface quality or imperfections and surface finish. A test method for the determination of surface

roughness is also described.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 3274, Geometrical Product Specifications (GPS) — Surface texture: Profile method — Nominal

characteristics of contact (stylus) instruments

ISO 4288, Geometrical Product Specifications (GPS) — Surface texture: Profile method — Rules and

procedures for the assessment of surface texture

ISO 23529, Rubber — General procedures for preparing and conditioning test pieces for physical test methods

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

arithmetical mean deviation of the profile

R

a

arithmetical mean of the absolute values of the profile departures within the sampling length, l

n

l

1 1

R = yx dx or approximately R ≈ y

∑

a ∫ a i

l 0 n

i=1

where n is the number of discrete profile deviations.

Note 1 to entry: The values of R in practice are determined within the evaluation length which includes several

a

sampling lengths. According to ISO 3274, the sampling length is equal to the cut-off.

3.2

ten point height of irregularities

R

z

average value of the absolute values of the heights of five highest profile peaks and the depths of five

deepest profile valleys within the sampling length

5 5

yy+

∑ ∑

pvii

i=1 i=1

R =

z

where

y is the height of the ith highest peak profile;

pi

y is the depth of the ith deepest profile valley.

vi

Note 1 to entry: Dependi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.