ISO 4779:2021

(Main)Chain components for lifting purposes - Forged eye hook with point and latch - Grade 4, stainless steel, solution annealed

Chain components for lifting purposes - Forged eye hook with point and latch - Grade 4, stainless steel, solution annealed

This document specifies the requirements for forged eye hooks with point and latch of grade 4 from stainless steel and solution annealed for use preferably as a component in chain slings of welded construction of grade 4 from stainless steel and solution annealed. IMPORTANT - For other applications, e.g. steel wire rope slings or textile slings, it is important that the hook design is checked to ensure its fitness for a safe use. NOTE 1 The grade for the hook according to this document is taken from the grade of the sling chain according to ISO 1835. Both (sling chains and hooks) have identical scopes and values for the working load limit, WLL, according to Table 2 and values for the mechanical requirements according to Table 3. Thus, the direct correlation of hooks to the sling chain is given by the WLL and especially the code system on the product body itself. The grade of the hook does not define any values of the tensile strength of the hook material. For further information, see Annex B. The range of the nominal diameter, dn, of the associated sling chain according to ISO 1835 is from 4 mm to 22 mm. Hooks according to this document are for use in the temperature range –100 °C to +400 °C. These hooks are solution annealed in the finished condition and can therefore be used without restrictions with regard to the corrosion resistance of the steels according to 5.1. NOTE 2 The term “eye hook with point and latch” is taken from ISO 1837:2003, Figure 5.

Éléments de chaînes de levage — Crochets de levage forgés en acier à bec et à œil — Grade 4, acier inoxydable, recuit d’homogénéisation

General Information

Relations

Overview

ISO 4779:2021 specifies requirements for forged eye hooks with point and latch - Grade 4, stainless steel, solution annealed, intended primarily as components in welded chain slings (grade 4). The standard covers material, manufacture, heat treatment, dimensions, mechanical properties, testing, marking and certificates for hooks matched to round steel sling chains with nominal diameters from 4 mm to 22 mm. Hooks manufactured to ISO 4779 are suitable for service temperatures from –100 °C to +400 °C and are solution annealed to ensure corrosion resistance.

Keywords: ISO 4779:2021, forged eye hook, grade 4, stainless steel, solution annealed, lifting chain components, working load limit (WLL).

Key topics and requirements

- Scope and application: Hooks are intended preferably for welded chain slings of grade 4; alternative uses (wire rope or textile slings) require design verification for safe use.

- Material: Austenitic stainless steels with molybdenum and resistance to intergranular corrosion (e.g., X6CrNiMoTi17-12-2 / 1.4571 / S31635) are specified.

- Manufacture and heat treatment:

- Drop-forged in one piece, free from harmful surface defects.

- Solution annealed (approx. 1 020 °C to 1 120 °C) and rapidly cooled; surface pickling/passivation required after heat treatment.

- Dimensions and designation: Dimension limits are given (Table 1) and calculation bases are in Annex A. Hooks are designated by nominal chain diameter and grade (e.g., 10-4).

- Mechanical properties & WLL: Working Load Limit (WLL) values correspond directly to the sling chain grade per ISO 1835; mechanical test requirements (test force, elongation, breaking force, deformation) are specified.

- Testing & inspection: Type, manufacturing and end tests include dimensional checks, surface/penetrant tests, tensile testing and inspection criteria; personnel qualification and test certification are required.

- Marking & documentation: Product body coding and certificates (type test and manufacturer’s) are required for traceability.

Applications and users

- Primary users: lifting equipment manufacturers, chain-sling fabricators, forging shops, QA/inspection teams, procurement/specification engineers, and lifting/safety officers.

- Practical applications: Components for chain slings used in material handling, offshore, chemical and food industries where corrosion resistance and high temperature performance are required.

- Practical notes: Always verify hook compatibility (geometry, WLL, attachment type) when substituting between sling types; rely on the product code/WLL for direct correlation to chain grade.

Related standards

- ISO 1835 - Round steel short link chains for lifting (Grade 4)

- ISO 1837 - Lifting hooks - Nomenclature

- ISO 16143-2 - Stainless steels - Corrosion-resistant semi-finished products

- ISO 3452-1, ISO 7500-1, ISO 8539, ISO 13385-1, EN 10228-2 - referenced for testing, NDT and calibration

For specification or procurement, reference ISO 4779:2021 to ensure forged eye hooks meet recognized international requirements for safety, corrosion resistance and traceability.

Frequently Asked Questions

ISO 4779:2021 is a standard published by the International Organization for Standardization (ISO). Its full title is "Chain components for lifting purposes - Forged eye hook with point and latch - Grade 4, stainless steel, solution annealed". This standard covers: This document specifies the requirements for forged eye hooks with point and latch of grade 4 from stainless steel and solution annealed for use preferably as a component in chain slings of welded construction of grade 4 from stainless steel and solution annealed. IMPORTANT - For other applications, e.g. steel wire rope slings or textile slings, it is important that the hook design is checked to ensure its fitness for a safe use. NOTE 1 The grade for the hook according to this document is taken from the grade of the sling chain according to ISO 1835. Both (sling chains and hooks) have identical scopes and values for the working load limit, WLL, according to Table 2 and values for the mechanical requirements according to Table 3. Thus, the direct correlation of hooks to the sling chain is given by the WLL and especially the code system on the product body itself. The grade of the hook does not define any values of the tensile strength of the hook material. For further information, see Annex B. The range of the nominal diameter, dn, of the associated sling chain according to ISO 1835 is from 4 mm to 22 mm. Hooks according to this document are for use in the temperature range –100 °C to +400 °C. These hooks are solution annealed in the finished condition and can therefore be used without restrictions with regard to the corrosion resistance of the steels according to 5.1. NOTE 2 The term “eye hook with point and latch” is taken from ISO 1837:2003, Figure 5.

This document specifies the requirements for forged eye hooks with point and latch of grade 4 from stainless steel and solution annealed for use preferably as a component in chain slings of welded construction of grade 4 from stainless steel and solution annealed. IMPORTANT - For other applications, e.g. steel wire rope slings or textile slings, it is important that the hook design is checked to ensure its fitness for a safe use. NOTE 1 The grade for the hook according to this document is taken from the grade of the sling chain according to ISO 1835. Both (sling chains and hooks) have identical scopes and values for the working load limit, WLL, according to Table 2 and values for the mechanical requirements according to Table 3. Thus, the direct correlation of hooks to the sling chain is given by the WLL and especially the code system on the product body itself. The grade of the hook does not define any values of the tensile strength of the hook material. For further information, see Annex B. The range of the nominal diameter, dn, of the associated sling chain according to ISO 1835 is from 4 mm to 22 mm. Hooks according to this document are for use in the temperature range –100 °C to +400 °C. These hooks are solution annealed in the finished condition and can therefore be used without restrictions with regard to the corrosion resistance of the steels according to 5.1. NOTE 2 The term “eye hook with point and latch” is taken from ISO 1837:2003, Figure 5.

ISO 4779:2021 is classified under the following ICS (International Classification for Standards) categories: 53.020.30 - Accessories for lifting equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 4779:2021 has the following relationships with other standards: It is inter standard links to ISO 4779:1986. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO 4779:2021 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 4779

Second edition

2021-08

Chain components for lifting

purposes — Forged eye hook with

point and latch — Grade 4, stainless

steel, solution annealed

Éléments de chaînes de levage — Crochets de levage forgés en acier à

bec et à œil — Grade 4, acier inoxydable, recuit d’homogénéisation

Reference number

©

ISO 2021

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2021 – All rights reserved

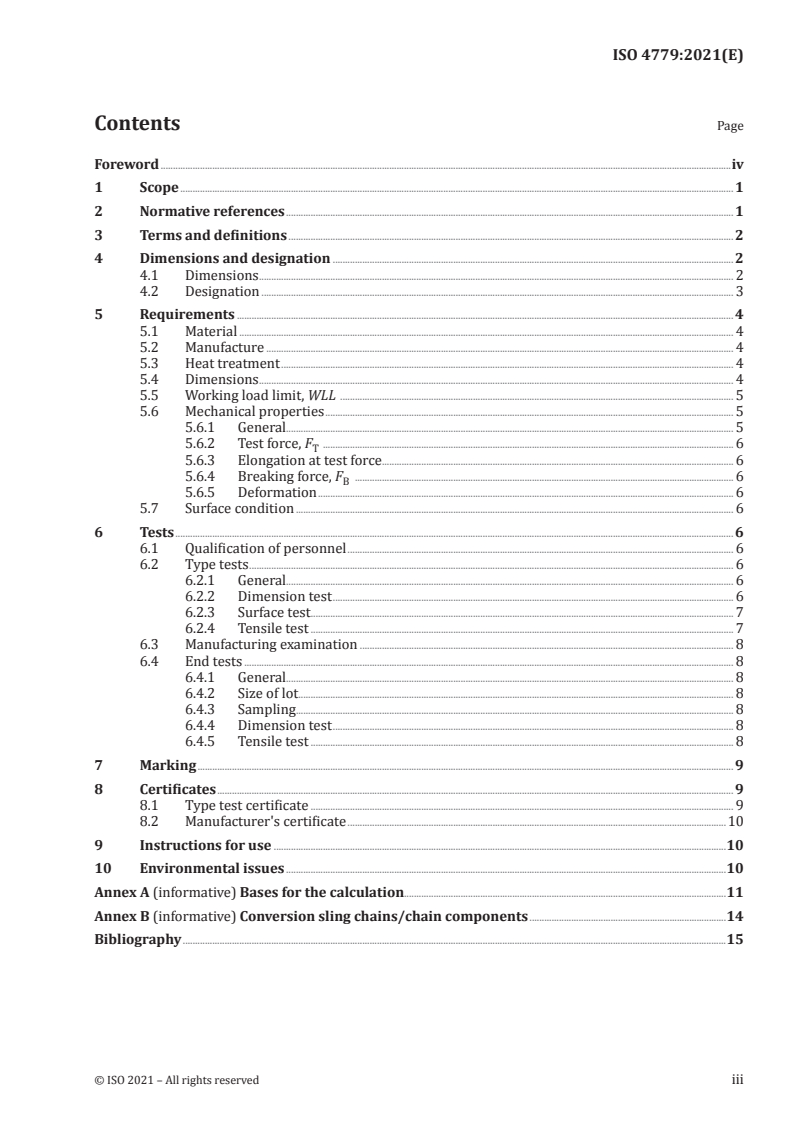

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Dimensions and designation . 2

4.1 Dimensions . 2

4.2 Designation . 3

5 Requirements . 4

5.1 Material . 4

5.2 Manufacture . 4

5.3 Heat treatment . 4

5.4 Dimensions . 4

5.5 Working load limit, WLL . 5

5.6 Mechanical properties . 5

5.6.1 General. 5

5.6.2 Test force, F . 6

T

5.6.3 Elongation at test force . . 6

5.6.4 Breaking force, F . 6

B

5.6.5 Deformation . 6

5.7 Surface condition . 6

6 Tests . 6

6.1 Qualification of personnel . 6

6.2 Type tests . 6

6.2.1 General. 6

6.2.2 Dimension test . 6

6.2.3 Surface test. 7

6.2.4 Tensile test . 7

6.3 Manufacturing examination . 8

6.4 End tests . 8

6.4.1 General. 8

6.4.2 Size of lot . . 8

6.4.3 Sampling. 8

6.4.4 Dimension test . 8

6.4.5 Tensile test . 8

7 Marking . 9

8 Certificates . 9

8.1 Type test certificate . 9

8.2 Manufacturer's certificate .10

9 Instructions for use .10

10 Environmental issues .10

Annex A (informative) Bases for the calculation.11

Annex B (informative) Conversion sling chains/chain components .14

Bibliography .15

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/ iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 111, Round steel link chains, chain slings,

components and accessories, Subcommittee SC 3, Components and accessories.

This second edition cancels and replaces the first edition (ISO 4779:1986), which has been technically

revised.

The main changes compared to the previous edition are as follows:

— limitation of the materials used to stainless steels;

— corresponding adaptation of the alloy elements and heat treatment;

— reduction of the sizes, corresponding to the related nominal chain sizes;

— including detailed formulae base for calculation of dimensions, working load limits and mechanical

requirements in Annex A.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

iv © ISO 2021 – All rights reserved

INTERNATIONAL STANDARD ISO 4779:2021(E)

Chain components for lifting purposes — Forged eye hook

with point and latch — Grade 4, stainless steel, solution

annealed

1 Scope

This document specifies the requirements for forged eye hooks with point and latch of grade 4 from

stainless steel and solution annealed for use preferably as a component in chain slings of welded

construction of grade 4 from stainless steel and solution annealed.

IMPORTANT — For other applications, e.g. steel wire rope slings or textile slings, it is important

that the hook design is checked to ensure its fitness for a safe use.

NOTE 1 The grade for the hook according to this document is taken from the grade of the sling chain according

to ISO 1835. Both (sling chains and hooks) have identical scopes and values for the working load limit, WLL,

according to Table 2 and values for the mechanical requirements according to Table 3. Thus, the direct correlation

of hooks to the sling chain is given by the WLL and especially the code system on the product body itself. The

grade of the hook does not define any values of the tensile strength of the hook material. For further information,

see Annex B.

The range of the nominal diameter, d , of the associated sling chain according to ISO 1835 is from 4 mm

n

to 22 mm.

Hooks according to this document are for use in the temperature range –100 °C to +400 °C.

These hooks are solution annealed in the finished condition and can therefore be used without

restrictions with regard to the corrosion resistance of the steels according to 5.1.

NOTE 2 The term “eye hook with point and latch” is taken from ISO 1837:2003, Figure 5.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 1835, Round steel short link chains for lifting purposes — Medium tolerance sling chains — Grade 4,

stainless steel

ISO 1837, Lifting hooks — Nomenclature

ISO 3452-1, Non-destructive testing — Penetrant testing — Part 1: General principles

ISO 7500-1, Metallic materials — Calibration and verification of static uniaxial testing machines — Part 1:

Tension/compression testing machines — Calibration and verification of the force-measuring system

ISO 8539, Forged steel lifting components for use with Grade 8 chain

ISO 13385-1, Geometrical product specifications (GPS) — Dimensional measuring equipment — Part 1:

Design and metrological characteristics of callipers

ISO 16143-2, Stainless steels for general purposes — Part 2: Corrosion-resistant semi-finished products,

bars, rods and sections

EN 10228-2, Non-destructive testing of steel forgings - Part 2: Penetrant testing

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 1837, ISO 8539 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https:// www .electropedia .org/

— ISO Online browsing platform: available at https:// www .iso .org/ obp

3.1

nominal size

combination of numerical values without units for designation and ordering purposes, which indicates

the nominal diameter of the associated round steel link chain and the grade of the forged component

EXAMPLE 10-4

3.2

test force

F

T

force applied to the hook during the tensile test

4 Dimensions and designation

4.1 Dimensions

The bases for calculation of the values for the dimension limits listed in Table 1 are given in Annex A.

The corresponding dimension letters are shown in Figure 1. The specified values are absolute limits.

The geometry of the hook is not specified in detail. Therefore, Figure 1 specifies only where the

dimension values according to Table 1 are measured.

2 © ISO 2021 – All rights reserved

Key

A bar diameter D seat diameter L inner length

B point hight E eye dimension M outer length, see 5.6.3

C throat opening H seat hight W seat width

Figure 1 — Dimensions of hooks

Preferred nominal sizes are given in Table 1, column 1. Other nominal sizes may be used, provided the

corresponding dimensions are calculated in accordance with Annex A.

Table 1 — Dimension limits

Dimensions in millimetres

1 2 3 4 5 6 7 8 9 10

A B C C D E H L W

Nominal

size

max min min max min min max max max

4 - 4 10 12 11 14 15 10 17 62 12

6 - 4 15 17 16 21 22 15 26 93 17

8 - 4 21 23 22 27 30 20 34 124 23

10 - 4 26 29 27 35 38 25 44 157 29

13 - 4 33 38 35 45 49 33 56 202 38

16 - 4 41 47 43 55 60 40 69 248 46

18 - 4 46 52 48 61 67 45 77 277 52

20 - 4 51 58 54 69 75 50 86 311 58

22 - 4 56 64 59 75 82 55 94 340 64

4.2 Designation

The designation of the hook shall be in accordance with the general format given in Figure 2.

Figure 2 — General format

5 Requirements

5.1 Material

The steel used shall be austenitic stainless steels with molybdenum and shall be resistant against

intergranular corrosion.

NOTE 1 For example the steel with the ISO name X6CrNiMoTi17-12-2 respectively with the ISO number 4571

316-35-I according to ISO 15510.

NOTE 2 The resistance against pitting corrosion will be increased by alloying with molybdenum.

After solution annealing, intergranular corrosion is unlikely at a service temperature of +400 °C and

with an extra low carbon content of the steel. T

...

The ISO 4779:2021 standard specifies the requirements for forged eye hooks with a point and latch made of grade 4 stainless steel that has been solution annealed. These hooks are intended to be used as components in chain slings of welded construction also made of grade 4 stainless steel and solution annealed. However, it is important to check the hook design for other applications, such as steel wire rope slings or textile slings, to ensure its safety. The grade of the hook is determined by the grade of the sling chain it is used with, and they have the same working load limit and mechanical requirements. The nominal diameter of the associated sling chain can range from 4 mm to 22 mm. These hooks can be used in temperatures ranging from -100 °C to +400 °C and have good corrosion resistance. The term "eye hook with point and latch" refers to a specific design of hooks.

아래 기사를 한국어로 요약하시오: 기사 제목: ISO 4779:2021 - 들어올리기 용 체인 부품 - 포지트 및 락셋을 갖춘 단조 아이 훅 - 4급, 스테인리스 스틸, 솔루션 앤닐 처리 기사 내용: 이 문서는 주로 스테인리스 스틸 솔루션 앤닐 처리로 제조된 4급의 포지트 및 락셋을 갖춘 단조 아이 훅의 요구 사항을 명시한다. 이 훅은 4급의 스테인리스 스틸 솔루션 앤닐 처리 용접된 체인 슬링의 구성 요소로 사용되며, 다른 용도(예: 강철 와이어 로프 슬링이나 직물 슬링)의 경우 훅 디자인을 확인하여 안전한 사용 여부를 확인하는 것이 중요하다. 이 문서에 따른 훅의 등급은 ISO 1835에 따른 체인 슬링의 등급에서 가져온 것이다. 체인 슬링과 훅은 표 2에 따른 작동 하중 한도(WLL) 및 표 3에 따른 기계적 요구 사항 값과 범위가 동일하다. 따라서 훅과 체인 슬링은 WLL 및 제품 몸체의 코드 시스템을 통해 직접적인 상관 관계를 가진다. 훅의 등급은 훅 재료의 인장 강도 값을 정의하지 않는다. 자세한 정보는 부록 B를 참조하십시오. ISO 1835에 따른 연관된 슬링 체인의 명목 직경(dn) 범위는 4mm에서 22mm까지이다. 이 문서에 따른 훅은 -100°C에서 +400°C의 온도 범위에서 사용할 수 있다. 이러한 훅은 완성 상태에서 솔루션 앤닐 처리되며, 따라서 스틸의 부식 저항성에 제한 없이 사용할 수 있다. "포지트 및 락셋을 갖춘 단조 아이 훅"이라는 용어는 ISO 1837:2003의 도면 5에서 가져온 것이다.

記事を日本語で要約してください: 記事のタイトル:ISO 4779:2021 - 牽引用チェーン部品 - ポイントとラッチを備えた鍛造アイフック - 4級、ステンレス鋼、ソリューションアンニーリング処理 記事内容:この文書は、主にステンレス鋼製でソリューションアンニーリング処理を施した4級の鍛造アイフックの要件を規定しています。これらのフックは、ステンレス鋼製でソリューションアンニーリング処理を施した4級の溶接チェーンスリングの構成部品として使用されることが意図されていますが、他の用途(例:鋼ワイヤーロープスリングやテキスタイルスリング)の場合は、フックのデザインを確認して安全性を確保することが重要です。本文書によるフックの等級は、ISO 1835に基づくスリングチェーンの等級から取得されます。スリングチェーンとフックは、作業荷重限界(WLL)に関して表2に基づき、機械的要件に関して表3に基づく価値と範囲が同じです。したがって、フックとスリングチェーンは、WLLおよび製品本体のコードシステムによって直接的な関連性を持ちます。フックの等級は、フック材料の引張強度の値を定義しません。詳細については、付録Bを参照してください。ISO 1835に基づく関連するスリングチェーンの名義直径(dn)の範囲は、4mmから22mmまでです。この文書によるフックは、-100℃から+400℃の温度範囲で使用することができます。これらのフックは仕上げ状態でソリューションアンニーリング処理されており、鋼の耐食性に制限なく使用することができます。"ポイントとラッチを備えた鍛造アイフック"という用語は、ISO 1837:2003の図5から取られています。

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...