ISO 16065-2:2014

(Main)Pulps — Determination of fibre length by automated optical analysis — Part 2: Unpolarized light method

Pulps — Determination of fibre length by automated optical analysis — Part 2: Unpolarized light method

ISO 16065-2:2014 specifies a method for determining fibre length by automated optical analysis using unpolarized light. The method is applicable to all kinds of pulp. However, fibrous particles shorter than 0,2 mm are not regarded as fibres for the purposes of ISO 16065-2:2014 and, therefore, are not included in the results.

Pâtes — Détermination de la longueur de fibre par analyse optique automatisée — Partie 2: Méthode de la lumière non polarisée

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 16065-2

Second edition

2014-01-15

Pulps — Determination of fibre length

by automated optical analysis —

Part 2:

Unpolarized light method

Pâtes — Détermination de la longueur de fibre par analyse optique

automatisée —

Partie 2: Méthode de la lumière non polarisée

Reference number

©

ISO 2014

© ISO 2014

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2014 – All rights reserved

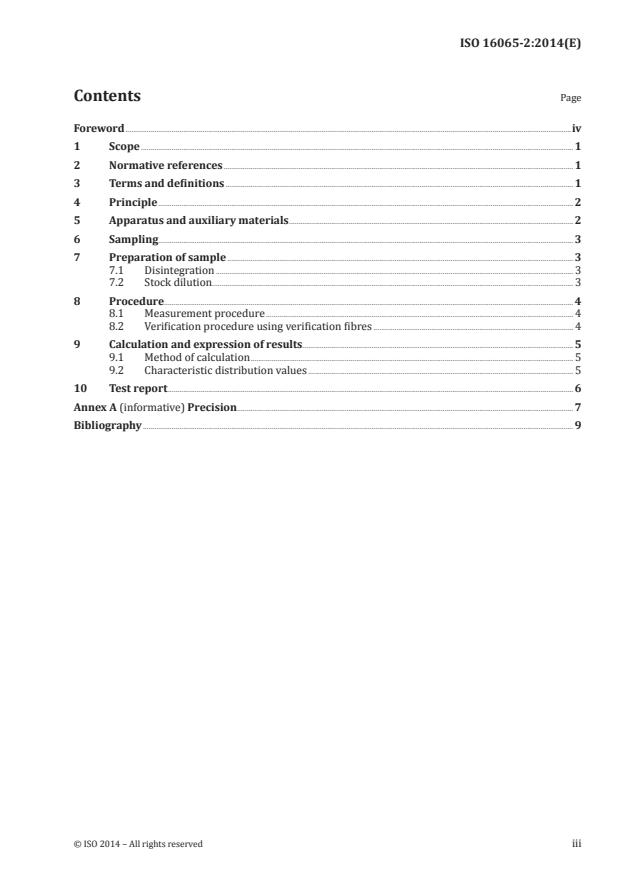

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Principle . 2

5 Apparatus and auxiliary materials . 2

6 Sampling . 3

7 Preparation of sample . 3

7.1 Disintegration . 3

7.2 Stock dilution. 3

8 Procedure. 4

8.1 Measurement procedure . 4

8.2 Verification procedure using verification fibres . 4

9 Calculation and expression of results . 5

9.1 Method of calculation . 5

9.2 Characteristic distribution values . 5

10 Test report . 6

Annex A (informative) Precision . 7

Bibliography . 9

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of any

patent rights identified during the development of the document will be in the Introduction and/or on

the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 6, Paper, board and pulps.

ISO 16065 consists of the following parts, under the general title Pulps — Determination of fibre length

by automated optical analysis:

— Part 1: Polarized light method

— Part 2: Unpolarized light method

This second edition cancels and replaces the first edition (ISO 16065–2:2007), of which it constitutes a

minor revision with the following changes:

— a new precision statement that complies with the requirements of ISO/TR 24498 has been added.

iv © ISO 2014 – All rights reserved

INTERNATIONAL STANDARD ISO 16065-2:2014(E)

Pulps — Determination of fibre length by automated

optical analysis —

Part 2:

Unpolarized light method

1 Scope

This part of ISO 16065 specifies a method for determining fibre length by automated optical analysis

using unpolarized light.

The method is applicable to all kinds of pulp. However, fibrous particles shorter than 0,2 mm are not

regarded as fibres for the purposes of this part of ISO 16065 and, therefore, are not included in the

results.

NOTE ISO 16065-1 deals with the determination of fibre length using polarized light.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 638, Paper, board and pulps — Determination of dry matter content — Oven-drying method

ISO 4119, Pulps — Determination of stock concentration

ISO 5263-1, Pulps — Laboratory wet disintegration — Part 1: Disintegration of chemical pulps

ISO 5263-2, Pulps — Laboratory wet disintegration — Part 2: Disintegration of mechanical pulps at 20 °C

ISO 5263-3, Pulps — Laboratory wet disintegration — Part 3: Disintegration of mechanical pulps at > 85 °C

ISO 7213, Pulps — Sampling for testing

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

unpolarized light

light composed of light waves whose planes of vibration are randomly oriented

3.2

mean length

L

total length of all fibres counted divided by the number of fibres

Note 1 to entry: See Formula (3).

3.3

length-weighted mean length

L

l

average of the length-weighted fibre-length distribution

Note 1 to entry: See Formula (4).

3.4

mass-weighted fibre length

L

w

average of the mass-weighted fibre-length distribution

Note 1 to entry: See Formula (5).

4 Principle

The fibres suspended in the water are routed through a measuring cell, where the lengths of the

individual fibres are measured. A suitable unpolarized light source is used to create the high-contrast

image between the fibres and the background. The numerical and weighted average fibre lengths and

fibre-length distributions of the pulp are calculated.

5 Apparatus and auxiliary materials

Ordinary laboratory equipment and the following are required.

5.1 Fibre-length analyser, consisting of a measurement section and a sample transport system.

The measurement section consists of a measuring cell, through which the fibres in the water are drawn.

There is a uniform unpolarized light source on one side of the cell and a sensitive detector [for example, a

charge coupled device (CCD) camera] on the same or on the opposite side of the measuring cell. The flow

orientates the fibres into a focal depth no thicker than 0,5 mm normal to the sample flow. The sample

flow can be stopped when the CCD camera takes a picture. The detector indicates the fibre length from

the image of the fibre. The analyser shall have a resolution that is equal to or better than 100 µm over

the range 0 mm to 7 mm, and an accuracy of at least 0,01 mm.

5.1.1 Measuring system, constructed so that air bubbles and non-fibrous particles greater than 0,2 mm

do not have any effect on the results.

5.2 Disintegrator, as described in ISO 5263-1, ISO 5263-2, or ISO 5263-3.

5.3 Verification fibres, made of rayon with suggested lengths of about 0,5 mm, 3,0 mm, and 7,0 mm,

with an accuracy of 0,01 mm.

The fibres shall be provided by the producer of the analyser, together with statistical data showing the

mean length and the length distribution of each type of verification fibre.

1)

5.4 Reference pulp , a commercial reference pulp is available. A quantity of pulp for which the length-

weighted fibre length has previously been determined, using this part of ISO 16065.

NOTE In-house reference pulp can also be used.

1) Reference pulp is available, for example, from the device supplier or the National Institute of Science &

Technology, Gaithersburg, MD, USA (NIST). The reference pulp is provided in sheet form. This information is given

for the convenience of users of this document and does not constitute an endorsement by ISO of this product.

2 © ISO 2014 – All rights reserved

5.5 Dilution water, free of non-fibrous material and air bubbles greater than 5 µm, and having an

evaporation residue less than 50 mg/l.

Non-fibrous particles can be removed from the water by filtering (pore size of 5 µm) and the air bubbles

can be removed by the application of heat, vacuum, and/or a settling time.

6 Sampling

If the test is being made to evaluate a pulp lot, the sample shall be selected in accordance with ISO 7213. If

the test is made on another type of sample, report the source of the sample and, if possible, the sampling

procedure used.

From the sample received, select the specimens so that they are representative of the whole sample.

7 Preparation of sample

7.1 Disintegration

If the sample is in dried form, determine the dry matter content, in accordance with ISO 638. If the

sample is in slush form, determine the stock concentration, in accordance with ISO 4119.

NOTE It is preferable to measure the never-dried pulps without disintegration, because excessive

disintegration can generate fines and reduce the fibre length in some pulps.

7.1.1 Dry pulp samples

If the sample is in dried form, tear the specimens into pieces before soaking. Tear the pieces evenly

throughout the thickness of the pulp sheet. By visual assessment, ensure that the fibres are properly

separated. Do not cut the sample, as this will cause fibre shortening. Soak the specimen, according to

the relevant part of ISO 5263.

Disintegrate the specimens, if required (see the note in 7.1), using the apparatus described in the relevant

part of ISO 5263. If the disintegrator described in ISO 5263 is used, the soaking time, the oven-dry mass

of the pulp, the amount of water to be used in the disintegration, and the number of revolutions are

specified in the relevant part of ISO 5263. Use the dilution water (5.5). For the removal of latency from

the mechanical pulps, follow the recommendations given in ISO 5263-3.

For the pulps containing the fibre bundles [e.g. Canadian high-freeness thermo-mechanical pulp (TMP)

and chemithermo-mechanical pulp (CTMP)], it can be difficult to measure the fibre length, since the fibre

bundles can plug the flow cell. If plugging occurs, then screening is recommended to remove the fibre

bundles. Screening can bias the results since it removes the fibre bundles, which preferentially contain

the longer fibres. After screening, ensure that the fibres are completely separated and fully dispersed.

WARNING — Very long fibres (e.g. hemp, cotton, and flax) can require some special sample

preparation techniques if they are so long that part of the fibres are outside the measuring

window, or if they cause blocking of the fibre-orientating cell.

7.1.2 Wet pulp samples

D

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.