ISO/DIS 7121

(Main)Metal ball valves for general-purpose industrial applications

Metal ball valves for general-purpose industrial applications

Robinets à tournant sphérique pour les applications industrielles générales

General Information

RELATIONS

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD ISO/DIS 7121

ISO/TC 153/SC 1 Secretariat: AFNOR

Voting begins on: Voting terminates on:

2003-11-25 2004-04-26

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION • МЕЖДУНАРОДНАЯ ОРГАНИЗАЦИЯ ПО СТАНДАРТИЗАЦИИ • ORGANISATION INTERNATIONALE DE NORMALISATION

Metal ball valves for general-purpose industrial applicationsRobinets à tournant sphérique pour les applications industrielles générales

[Revision of first edition (ISO 7121:1986)]

ICS 23.060.20

In accordance with the provisions of Council Resolution 15/1993 this document is circulated in

the English language only.Conformément aux dispositions de la Résolution du Conseil 15/1993, ce document est distribué

en version anglaise seulement.To expedite distribution, this document is circulated as received from the committee secretariat.

ISO Central Secretariat work of editing and text composition will be undertaken at publication

stage.Pour accélérer la distribution, le présent document est distribué tel qu'il est parvenu du

secrétariat du comité. Le travail de rédaction et de composition de texte sera effectué au

Secrétariat central de l'ISO au stade de publication.THIS DOCUMENT IS A DRAFT CIRCULATED FOR COMMENT AND APPROVAL. IT IS THEREFORE SUBJECT TO CHANGE AND MAY NOT BE

REFERRED TO AS AN INTERNATIONAL STANDARD UNTIL PUBLISHED AS SUCH.IN ADDITION TO THEIR EVALUATION AS BEING ACCEPTABLE FOR INDUSTRIAL, TECHNOLOGICAL, COMMERCIAL AND USER PURPOSES, DRAFT

INTERNATIONAL STANDARDS MAY ON OCCASION HAVE TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN NATIONAL REGULATIONS.© International Organization for Standardization, 2003

---------------------- Page: 1 ----------------------

ISO/DIS 7121

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall

not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the

unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

Copyright noticeThis ISO document is a Draft International Standard and is copyright-protected by ISO. Except as permitted

under the applicable laws of the user's country, neither this ISO draft nor any extract from it may be

reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, photocopying,

recording or otherwise, without prior written permission being secured.Requests for permission to reproduce should be addressed to either ISO at the address below or ISO's

member body in the country of the requester.ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

ii ISO 2003 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 7121

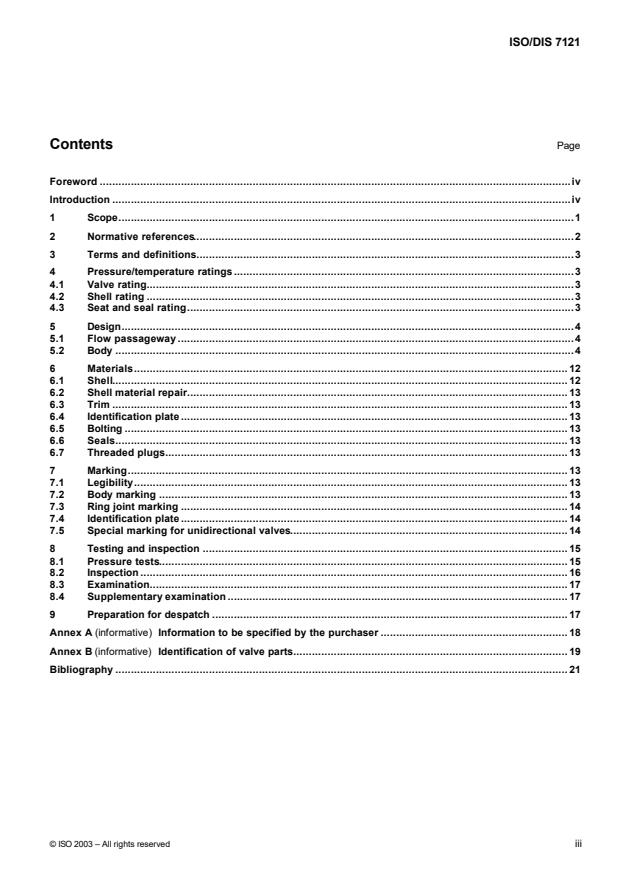

Contents Page

Foreword .......................................................................................................................................................iv

Introduction ...................................................................................................................................................iv

1 Scope..................................................................................................................................................1

2 Normative references..........................................................................................................................2

3 Terms and definitions.........................................................................................................................3

4 Pressure/temperature ratings .............................................................................................................3

4.1 Valve rating.........................................................................................................................................3

4.2 Shell rating .........................................................................................................................................3

4.3 Seat and seal rating............................................................................................................................3

5 Design.................................................................................................................................................4

5.1 Flow passageway ...............................................................................................................................4

5.2 Body ...................................................................................................................................................4

6 Materials........................................................................................................................................... 12

6.1 Shell.................................................................................................................................................. 12

6.2 Shell material repair.......................................................................................................................... 13

6.3 Trim .................................................................................................................................................. 13

6.4 Identification plate ............................................................................................................................ 13

6.5 Bolting .............................................................................................................................................. 13

6.6 Seals................................................................................................................................................. 13

6.7 Threaded plugs................................................................................................................................. 13

7 Marking............................................................................................................................................. 13

7.1 Legibility........................................................................................................................................... 13

7.2 Body marking ................................................................................................................................... 13

7.3 Ring joint marking ............................................................................................................................ 14

7.4 Identification plate ............................................................................................................................ 14

7.5 Special marking for unidirectional valves......................................................................................... 14

8 Testing and inspection ..................................................................................................................... 15

8.1 Pressure tests................................................................................................................................... 15

8.2 Inspection ......................................................................................................................................... 16

8.3 Examination...................................................................................................................................... 17

8.4 Supplementary examination ............................................................................................................. 17

9 Preparation for despatch .................................................................................................................. 17

Annex A (informative) Information to be specified by the purchaser ............................................................ 18

Annex B (informative) Identification of valve parts........................................................................................ 19

Bibliography ................................................................................................................................................. 21

© ISO 2003 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 7121

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO

member bodies). The work of preparing International Standards is normally carried out through ISO technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards adopted

by the technical committees are circulated to the member bodies for voting. Publication as an International

Standard requires approval by at least 75 % of the member bodies casting a vote.Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights.

ISO shall not be held responsible for identifying any or all such patent rights.ISO 7121 was prepared by Technical Committee ISO/TC 153, Valves, Subcommittee SC 1, Design, manufacture,

marking and testing.This second edition cancels and replaces the first edition (ISO 7121:1986), which has been technically revised.

iv © ISO 2003 – All rights reserved---------------------- Page: 4 ----------------------

ISO/DIS 7121

Introduction

The purpose of this International Standard is the establishment, in ISO format, of basic requirements and practices

for flanged, butt-welding, socket welding, and threaded, end steel ball valves having flow passageways identified

as full bore, reduced bore, and double reduced bore suitable for general purpose applications. Flanged end Class

designated valves have flanges in accordance with ASME B16.5. Flanged end PN designated valves have flanges

in accordance with EN 1092-1. Valves with ends threaded may have threads to either ISO 7-1 or ASME B1.20.1.

© ISO 2003 – All rights reserved v---------------------- Page: 5 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 7121

Metal ball valves for general-purpose industrial applications

1 Scope

This International Standard specifies the requirements for a series of metal ball valves suitable for general purpose

industrial applications.It covers valves of the nominal sizes :

¾ DN 8 ; 10 ; 15 ; 20 ; 25 ; 32 ; 40 ; 50 ; 65 ; 80 ; 100 ; 125 ; 150 ; 200 ; 250 ; 300 ; 350 ; 400 ; 450 ; 500 (NPS ¼

; 3/8 ; ½ ; ¾ ; 1 ; 1¼ ; 1½ ; 2 ; 2½ ; 3 ; 4 ; 5 ; 6 ; 8 ; 10 ; 12 ; 14 ; 16 ; 18 ; 20) ;

2) 3)and applies for pressure designations :

¾ Class 150 ; 300 ; 600 ; 900 and PN 10 ; 16 ; 25 ; 40 ; 63 ; 100.

It includes provisions for valve characteristics as follows :

¾ flanged and butt-welded ends : in sizes 15 £ DN £ 500 (½ £ NPS £ 20) ;

¾ socket welding ends : in sizes 8 £ DN £ 100 (¼ £ NPS £ 4) ;

¾ threaded ends : in sizes 8 £ DN £ 50 (¼ £ NPS £ 2) ;

¾ body seat openings designated as full bore, reduced bore, and double reduced bore ;

¾ materials ;¾ testing and inspection.

1) See ISO 6708 and ASME B16.34.

2) See ISO 7268 or EN 1333.

3) See ASME B16.34.

4) Valve characteristics are not necessarily available in all nominal sizes for all pressure designations, e.g., Class 900 applies

only for reduced bore body seat openings.© ISO 2003 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/DIS 7121

2 Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of

this International Standard. For dated references, subsequent amendments to, or revisions of, any of these

publications do not apply. However, parties to agreements based on this International Standard are encouraged to

investigate the possibility of applying the most recent editions of the normative documents indicated below. For

undated references, the latest edition of the normative document referred to (including amendments) applies.

Members of ISO and IEC maintain registers of currently valid International Standards.

ISO 7-1, Pipe threads where pressure-tight joints are made on the threads – Part 1: Dimensions, tolerances and

designationISO 7-2, Pipe threads where pressure-tight joints are made on the thread – Part 2: Verification by means of limit

gaugesISO 261, ISO general purpose metric screw threads – General plan

ISO 228-1, Pipe threads where pressure-tight joints are not made on the threads - Part 1 : dimensions, tolerances

and designationISO 228-2, Pipe threads where pressure-tight joints are not made on the threads. Part 2 : verification by means of

limit gaugesISO 965-2, ISO general purpose metric screw threads – Tolerances – Part 2: Limits of sizes for general purpose

external and internal screw threads – Medium qualityISO 4032, Hexagon nuts, style 1 – Product grades A and B

ISO 4033, Hexagon nuts, style 2 – Product grades A and B

ISO 4034, Hexagon nuts – Product grade C

ISO 5208, Industrial valves – Pressure testing of valves

ISO 5209, General purpose industrial valves – Marking

ISO 5752, Metal valves for use in flanged pipe systems – Face-to-face and centre-to-face dimensions

ISO 10497, Testing of valves – Fire type-testing requirementsEN 1092-1, Flanges and their joints – Circular flanges for pipes, valves, fittings and accessories, PN designated –

Part 1: Steel flangesEN 12982, Industrial valves - End-to-end and centre-to-end dimensions for butt welding end valves

EN 1515-1, Flanges and their joints – Bolting – Part 1: Selection of boltingASME B1.1, Unified inch screw threads (UN and UNR thread form)

ASME B1.20.1, Pipe threads, general purpose (inch)

ASME B16.5, Pipe flanges and flanged fittings

ASME B16.10, Face-to-face and end-to-end dimensions of valves

ASME B16.34, Valves - Flanged, threaded and welding end

ASME B18.2.2, Square and hex nuts

2 © ISO 2003 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/DIS 7121

MSS-SP-55, Quality standard for steel castings for valves, flanges and fittings and other piping components —

Visual method for evaluation of surface irregularities3 Terms and definitions

For the purposes of this International Standard, the following terms and definitions apply.

3.1service pressure/temperature rating

the lesser of the shell or seat pressure/temperature rating

3.2

anti-static design

a design that provides for electrical continuity between the body, ball and stem of the valve

3.3anti-blow-out design

a design that ensures the valve stem cannot be blown out of the body in the event of the gland being removed

while the valve is under pressure4 Pressure/temperature ratings

4.1 Valve rating

The service pressure/temperature rating applicable to valves specified in this International Standard shall be the

lesser of the shell rating, 4.2 or the seat rating, 4.3.4.2 Shell rating

4.2.1 The pressure/temperature ratings applicable to the valve pressure containing shell (the pressure boundary

elements, e.g., body, body cap, trunnion cap, cover, body inserts) shall be in accordance with that specified in the

pressure/temperature tables of either ASME B16.34, Standard Class for Class designated valves or EN 1092-1 for

PN designated valves4.2.2 The temperature for a corresponding shell pressure rating is the maximum temperature that is permitted for

the pressure containing shell of the valve. In general, this maximum temperature is that of the contained fluid. The

use of a pressure rating corresponding to a temperature other than that of the contained fluid is the responsibility of

the user. For temperatures below the lowest temperature listed in the pressure/temperature Tables (see 4.2.1), the

service pressure shall be no greater than the pressure for the lowest listed temperature. Consideration should be

given to the loss of ductility and impact strength of many materials at low temperature.

4.3 Seat and seal rating4.3.1 Non-metallic elements, e.g. seat, seals or stem seals may impose restrictions on the applied

pressure/temperature rating. Any such restriction shall be shown on the valve identification plate in accordance

with 7.4.4.3.2 The design shall be such that, when either polytetrafluoroethylene (PTFE) or reinforced PTFE is used for

seats, the minimum valve pressure/temperature rating shall be as specified in Table 1. Designs using these seating

materials that have pressure/temperature ratings less than those shown in Table 1 are not in compliance with this

standard.4.3.3 Seat ratings for other seat materials shall be the manufacturer’s standard. However, the assigned valve

service pressure/temperature rating shall not exceed that of the valve shell.© ISO 2003 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO/DIS 7121

Table 1 — Minimum seat pressure/temperature rating

a a

PTFE seats Reinforced PTFE seats

bar bar

Temperature

Floating ball Trunnion Floating ball Trunnion

DN £ 50 50 < DN £ 100 DN > 100 DN > 50 DN £ 50 50 < DN £ 100 DN > 100 DN > 50

NPS £ 2 2 < NPS £ 4 NPS > 4 NPS > 2 NPS £ 2 2 < NPS £ 4 NPS > 4 NPS > 2

-29 to 38 69,0 51,0 19,7 51,0 75,9 51,0 19,7 51,0

50 63,6 47,1 18,2 47,1 70,4 47,8 18,4 47,8

75 53,3 39,2 15,2 39,2 59,9 40,4 15,6 40,4

100 43,0 31,3 12,1 31,3 49,4 33,1 12,8 33,1

125 32,7 23,3 9,1 23,3 38,9 25,8 10,0 25,8

150 22,4 15,4 6,1 15,4 28,3 18,4 7,2 18,4

175 12,1 7,5 3,0 7,5 17,8 11,1 4,4 11,1

200 – – – – 7,3 3,7 1,6 3,7

205 – – – – 5,2 2,3 1,0 2,3

NOTE For a given PN or Class designation, the assigned valve pressure/temperature ratings are not to exceed the

shell ratings, see 4.2.Polytetrafluoroethylene seats.

Consult manufacturer for maximum design temperature rating of the valve seats.

5 Design

5.1 Flow passageway

The flow passageway includes the circular seat opening in the ball (the port) and the body runs leading thereto.

The body runs are the intervening elements that link the seat opening to the end connection e.g. to the thread end,

weld end or socket end or to the end-flange. Collectively, the flow passageway through the ball port and body runs

is referred to as the flow passageway. The ball port is categorized in this standard as full-bore, reduced-bore, and

double reduced-bore. The minimum effective diameter for each category shall be such that a hypothetical cylinder,

having a diameter shown in Table 2, can be passed through.5.2 Body

5.2.1 Body wall thickness

5.2.1.1 The minimum valve body wall thickness, t , shall be as specified in Table 3, except that for

butt-welding end valves the welding ends for connection to pipe shall be in accordance with the requirements of

Figure 1.4 © ISO 2003 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/DIS 7121

Table 2 — Cylindrical diameter for categorizing bore size

Minimum bore diameter

Double

Reduced reduced

Full bore

Nominal bore bore Nominal

size PN 10, 16, 25 and 40 PN 63 PN 100 PN - all PN - all size

DN Class 150 and 300 — Class 600 Class - all Class - all NPS

8 6 6 6 6 NA ¼

10 9 9 9 6 NA 3/8

15 11 11 11 8 NA ½

20 17 17 17 11 NA ¾

25 23 24 24 17 14 1

32 30 30 30 23 18 1¼

40 37 37 37 27 23 1½

50 49 49 49 36 30 2

65 62 62 62 49 41 2½

80 74 75 75 55 49 3

100 98 98 98 74 62 4

150 148 148 148 98 74 6

200 198 196 194 144 100 8

250 245 245 241 186 151 10

300 295 293 291 227 202 12

350 325 322 318 266 230 14

400 375 371 365 305 250 16

450 430 423 421 335 305 18

500 475 467 453 375 335 20

NOTE 1 NA signifies that valves having this configuration are not within the scope of this International Standard.

NOTE 2 For Class 900, only valves having reduced port are within the scope of this International Standard

5.2.1.2 The minimum thickness requirements are applicable to and are measured from internally wetted

surfaces, i.e., up to the point where body seals are effective.5.2.1.3 Local areas having less than minimum wall thickness are acceptable provided that all of the following

conditions are satisfied :¾ the area of sub-minimum thickness can be enclosed by a circle, the diameter of which is not greater than

0,35 dt ; where d is the minimum bore diameter given in Table 2 and t is the minimum wall thickness given

in Table 3 ;¾ the measured thickness is not less than 0,75 t ;

¾ enclosed circles are separated from each other by an edge to edge distance of not less than 1,75 dt .

5.2.1.4 The manufacturer, taking into account such factors as component bolting or thread assembly loads,

rigidity needed for component alignment, other valve design details and the specified operating conditions, is

responsible for determining if larger wall thickness is required.© ISO 2003 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO/DIS 7121

5.2.2 Flanged ends

5.2.2.1 Body end flanges shall comply with the requirements of ASME B16.5 for Class designated valves and

EN 1092-1 for PN designated valves. Raised face end flanges shall be provided unless otherwise specified by the

purchaser.5.2.2.2 Face-to-face dimensions for flanged end valves shall be in accordance with ASME B16.10 for Class

designated valves or ISO 5752, Basic Series 1, 14, and 27 for PN designated valves, with an applicable tolerance,

for DN £ 250 of ± 2 mm and for DN ³ 300 of ± 4 mm.Table 3 — Valve body wall thickness

PN 10 and 16 25 and 40 63 100 - PN

Class 150 300 - 600

900 Class

Minimum valve body wall thickness, t

Nominal Nominal

size size

Full Reduced Double Full Reduced Double Full Reduced Double Full Reduced Double Reduced

DN NPSbore bore reduced bore bore reduced bore bore reduced bore bore reduced bore

bore bore bore bore

8 2,7 2,7 NA 2,9 2,9 NA 2,7 2,7 NA 3,1 3,1 NA 3,4 ¼

3/8

10 2,9 2,9 NA 3,0 2,9 NA 2,9 2,9 NA 3,4 3,3 NA 3,8

15 3,1 3,1 NA 3,2 3,2 NA 3,1 3,1 NA 3,6 3,6 NA 4,1 ½

20 3,4 3,4 NA 3,7 3,7 NA 3,5 3,5 NA 4,1 4,1 NA 5,8 ¾

25 3,9 3,8 3,8 4,1 4,1 4,1 4,0 4,0 4,0 4,7 4,6 4,6 6,0 1

32 4,3 4,2 4,2 4,7 4,6 4,6 4,4 4,3 4,3 5,1 5,0 5,0 6,4 1¼

40 4,7 4,5 4,5 5,2 5,0 5,0 4,8 4,7 4,7 5,5 5,4 5,4 5,8 1½

50 5,5 5,3 5,3 6,2 5,9 5,9 5,6 5,5 5,5 6,3 6,0 6,0 7,0 2

65 5,7 5,6 5,6 6,7 6,5 6,5 6,5 6,3 6,3 6,7 6,4 6,4 7,9 2½

80 6 5,9 5,9 7,1 6,9 6,9 7,2 7,0 7,0 7,6 7,2 7,2 9,4 3

100 6,3 6,3 6,3 7,6 7,6 7,6 8,2 7,9 7,9 9,2 8,7 8,7 11,8 4

150 7,1 6,9 6,9 9,3 8,9 8,9 10,1 9,8 9,8 12,6 11,8 11,8 16,3 6

200 7,9 7,7 7,7 10,9 10,4 10,4 12,5 12,0 12,0 15,7 14,7 14,7 20,5 8

250 8,7 8,4 8,4 12,55 12,0 12,0 14,5 13,5 13,5 18,9 17,6 17,6 24,9 10

300 9,5 9,2 9,2 14,2 13,5 13,5 16,5 15,5 15,5 22,3 20,7 20,7 29,1 12

350 10 9,6 9,6 15,2 14,4 14,4 17,8 16,8 16,8 24,1 22,5 22,5 31,8 14

400 10,8 10,4 10,4 16,8 16 16 19,8 18,6 18,6 27,3 25,4 25,4 36,0 16

450 11,7 11,1 11,1 18,7 17,3 17,3 21,7 20,4 20,4 31,1 28,9 28,9 42,0 18

500 12,4 11,9 11,9 20,2 18,8 18,8 24,0 22,5 22,5 33,2 30,8 30,8 44,3 20

NOTE NA signifies that valves having this configuration are not within the scope of this international standard.

For Class 900, only valves having reduced ball ports are within the scope of this inte rnational standard.

6 © ISO 2003 – All rights reserved---------------------- Page: 11 ----------------------

ISO/DIS 7121

Figure 1a) — Welding end for connection to pipe Figure 1b) — Welding end for connection to pipe

of wall thickness T £ 22 mm of wall thickness T > 22 mmKeys

A nominal outside diameter of welding end (see Table 4)

B nominal inside diameter of pipe (see Table 4)

T nominal wall thickness of pipe (see Table 4)

NOTE 1 The inside and outside surfaces of valve welding ends are machine finished overall. The contour within the

envelope is at the option of the manufacturer unless specifically ordered otherwise.

NOTE 2 Intersections should be slightly rounded.NOTE 3 Valves minimum wall thickness equal to 3 mm or less may have ends cut square or slightly chamfered.

NOTE 4 For nominal outside diameters and wall thickness of standard steel pipe, see ISO 4200 or ASME B36.10.

NOTE 5 Linear dimensions and tolerances shown are in millimetres.Figure 1 — Welding ends

Table 4 — Welding ends

15 20 25 32 40 50 65 80 100 150 200 250 300 350 400 450 500

Nominal size, DN

Nominal size, NPS ½ ¾ 1 1¼ 1½ 2 2½ 3 4 6 8 10 12 14 16 18 20

A, mm diameter 22 28 35 44 50 62 78 91 117 172 223 278 329 362 413 464 516

tolerance + 2,5/ – 1,0 + 4/ – 1

B, mm tolerance + 1/ – 1 + 2/ – 2 + 3/ – 2

5.2.2.3 End flanges shall be either cast or forged integral with the body or end piece of a split body design, or

attached by welding by a qualified welder using an accepted welding procedure, provided that all such flanges on

valves larger than DN 50 shall be butt-welded. Any heat treatment necessary to ensure that the material is suitable

for the full range of service temperature shall be performed.5.2.2.4 End flange facing finish shall be in accordance with ASME B16.5 for Class designated valves or

EN 1092-1 for PN designated valves unless otherwise specified by the purchaser.© ISO 2003 – All rights reserved 7

---------------------- Page: 12 ----------------------

ISO/DIS 7121

5.2.3 Butt-welding ends

5.2.3.1 Butt-welding ends shall be in accordance with the details shown in Figure 1 and Table 4, unless

otherwise specified by the purchaser.5.2.3.2 End-to-end dimensions for Class designated valves shall be in accordance with ASME B16.10 for

either the long or short pattern or for PN designated valves shall be in accordance with EN 12982.

5.2.4 Socket welding ends5.2.4.1 The socket bore axis shall coincide with the end entry axis. Socket end faces shall be perpendicular to

the socket bore axis. The socket bore diameter and its depth shall be as specified in Table 5.

5.2.4.2 The minimum socket wall thickness, extending over the full socket depth shall be as specified in

Table 6.5.2.4.3 End to end dimensions for socket welding end valves shall be established by the manufacturer.

Table 5 — Socket diameter and deptha b

Diameter Depth

DN NPS

8 14,1 9,5

10 17,5 9,5 3/8

15 21,7 10 ½

20 27,0 13 ¾

25 33,8 13 1

32 42,5 13 1¼

40 48,6 13 1½

50 61,1 16 2

65 73,8 16 2½

80 89,7 16 3

100 115,1 19 4

The applicable diametral tolerance is :

¾ For DN = 50, + 0,5 mm /- 0 ;

¾ For DN > 50, + 0,7 mm /- 0.

The depth dimension is a minimum value.

5.2.5 Threaded ends

5.2.5.1 The threaded end thread axis shall coincide with the end entry axis. The minimum wall thickness at the

threaded end shall be as specified in Table 6. An approximate 45° lead-in chamfer, having an approximate depth of

one-half the thread pitch, shall be applied at each threaded end.5.2.5.2 The end threads shall be either taper or parallel pipe threads meeting the applicable requirements of

ISO 7-1, ISO 228-1 or ASME B1.20.1, with threads gauged in accordance with the requirements of ISO 7-2,

ISO 228-2 or ASME B1.20.1 as applicable. The required pipe thread shall be specified in the purchase order.

5.2.5.3 End to end dimensions for threaded end valves shall be established by the manufacturer.

8 © ISO 2003 – All rights reserved---------------------- Page: 13 ----------------------

ISO/DIS 7121

Table 6 — Socket and threaded end wall thickness

PN 10, 16, 25 and 40 63 and 100 — PN

Class 150 and 300 600 900 Class

Minimum wall thickness

DN NPS

8 3,0 3,3 4,1

10 3,0 3,6 4,3 3/8

15 3,3 4,1 5,3 ½

20 3,6 4,3 6,1 ¾

25 3,8 5,1 6,9 1

32 3,8 5,3 7,1 1¼

40 4,1 5,6 7,9 1½

50 4,6 6,1 9,7 2

65 5,6 7,6 10,4 2½

80 6,4 8,6 12,2 3

100 7,5 10,1 14,3 4

5.2.6 Body openings

Trunnion mounted valves that employ upstream sealing seats shall be fitted with a test plug, DN 15 (NPS ½) or

smaller, having threads in accordance with 5.2.5.2 in order to complete the closure tightness test. Other tapped

openings, for any purpose, are permitted only when specified by the purchaser.5.2.7 Anti-static design

When specified in the purchase order, valves shall incorporate an anti-static feature that ensures electrical

continuity between stem and body of valves DN £ 50 and between ball, stem and body of larger valves. The

anti-static feature shall have electrical continuity across the discharge path with a resistance not exceeding

10 ohms from a power source not exceeding 12 V d.c. when type tested on a new, dry, as-built valve after pressure

testing and cycling of the valve at least five times.5.2.8 Anti-blow-out stem

The valve design shall be such that the stem seal retaining dev

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.