ISO/DIS 20908

(Main)Tyre sound emission test -- Methods of drum

Tyre sound emission test -- Methods of drum

Titre manque

General Information

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD

ISO/DIS 20908

ISO/TC 31 Secretariat: ANSI

Voting begins on: Voting terminates on:

2021-04-08 2021-07-01

Tyre sound emission test — Methods of drum

ICS: 83.160.10; 17.140.30

THIS DOCUMENT IS A DRAFT CIRCULATED

FOR COMMENT AND APPROVAL. IT IS

THEREFORE SUBJECT TO CHANGE AND MAY

NOT BE REFERRED TO AS AN INTERNATIONAL

STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS

BEING ACCEPTABLE FOR INDUSTRIAL,

This document is circulated as received from the committee secretariat.

TECHNOLOGICAL, COMMERCIAL AND

USER PURPOSES, DRAFT INTERNATIONAL

STANDARDS MAY ON OCCASION HAVE TO

BE CONSIDERED IN THE LIGHT OF THEIR

POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN

Reference number

NATIONAL REGULATIONS.

ISO/DIS 20908:2021(E)

RECIPIENTS OF THIS DRAFT ARE INVITED

TO SUBMIT, WITH THEIR COMMENTS,

NOTIFICATION OF ANY RELEVANT PATENT

RIGHTS OF WHICH THEY ARE AWARE AND TO

PROVIDE SUPPORTING DOCUMENTATION. ISO 2021

---------------------- Page: 1 ----------------------

ISO/DIS 20908:2021(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2021 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 20908:2021(E)

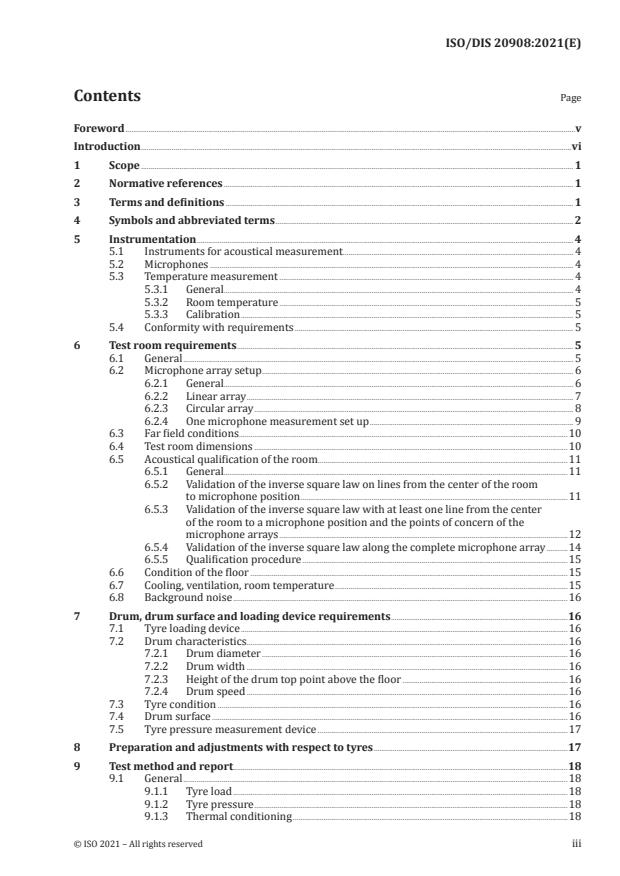

Contents Page

Foreword ..........................................................................................................................................................................................................................................v

Introduction ................................................................................................................................................................................................................................vi

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 1

4 Symbols and abbreviated terms ........................................................................................................................................................... 2

5 Instrumentation .................................................................................................................................................................................................... 4

5.1 Instruments for acoustical measurement........................................................................................................................ 4

5.2 Microphones ............................................................................................................................................................................................. 4

5.3 Temperature measurement ......................................................................................................................................................... 4

5.3.1 General...................................................................................................................................................................................... 4

5.3.2 Room temperature ......................................................................................................................................................... 5

5.3.3 Calibration ............................................................................................................................................................................. 5

5.4 Conf ormity with requirements ................................................................................................................................................. 5

6 Test room requirements ............................................................................................................................................................................... 5

6.1 General ........................................................................................................................................................................................................... 5

6.2 Microphone array setup .................................................................................................................................................................. 6

6.2.1 General...................................................................................................................................................................................... 6

6.2.2 Linear array .......................................................................................................................................................................... 7

6.2.3 Circular array ...................................................................................................................................................................... 8

6.2.4 One microphone measurement set up .......................................................................................................... 9

6.3 Far field conditions ...........................................................................................................................................................................10

6.4 Test room dimensions ...................................................................................................................................................................10

6.5 Acoustical qualification of the room ..................................................................................................................................11

6.5.1 General...................................................................................................................................................................................11

6.5.2 Validation of the inverse square law on lines from the center of the roomto microphone position ...........................................................................................................................................11

6.5.3 Validation of the inverse square law with at least one line from the center

of the room to a microphone position and the points of concern of themicrophone arrays ......................................................................................................................................................12

6.5.4 Validation of the inverse square law along the complete microphone array ...........14

6.5.5 Qualification procedure ..........................................................................................................................................15

6.6 Condition of the floor .....................................................................................................................................................................15

6.7 Cooling, ventilation, room temperature .........................................................................................................................15

6.8 Background noise ..............................................................................................................................................................................16

7 Drum, drum surface and loading device requirements ............................................................................................16

7.1 Tyre loading device ..........................................................................................................................................................................16

7.2 Drum characteristics .......................................................................................................................................................................16

7.2.1 Drum diameter ...............................................................................................................................................................16

7.2.2 Drum width .......................................................................................................................................................................16

7.2.3 Height of the drum top point above the floor ......................................................................................16

7.2.4 Drum speed .......................................................................................................................................................................16

7.3 Tyre condition ......................................................................................................................................................................................16

7.4 Drum surface .........................................................................................................................................................................................16

7.5 Tyre pressure measurement device ..................................................................................................................................17

8 Preparation and adjustments with respect to tyres .....................................................................................................17

9 Test method and report ..............................................................................................................................................................................18

9.1 General ........................................................................................................................................................................................................18

9.1.1 Tyre load ..............................................................................................................................................................................18

9.1.2 Tyre pressure ...................................................................................................................................................................18

9.1.3 Thermal conditioning ...............................................................................................................................................18

© ISO 2021 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 20908:2021(E)

9.1.4 Speed range .......................................................................................................................................................................18

9.2 Data processing ...................................................................................................................................................................................18

9.2.1 Data pre-treatment .....................................................................................................................................................18

9.2.2 Normalization with respect to distance ....................................................................................................19

9.2.3 Emulation of Fast time weighting ..................................................................................................................19

9.2.4 Normalization with respect to number of tyres, tyre masking effect, andvehicle impact..................................................................................................................................................................19

9.2.5 Normalization with respect to speed ..........................................................................................................20

9.2.6 Correlation with outdoor measurement ..................................................................................................21

9.2.7 Adjustment of the reported value ..................................................................................................................21

10 Test report ................................................................................................................................................................................................................21

11 Validation method and alignment coefficient to outdoor measurement ...............................................24

11.1 Correlation with outdoor reference measurement using ISO 13325 method ..............................24

11.2 Alignment process ............................................................................................................................................................................25

11.3 Correction coefficients ..................................................................................................................................................................26

11.3.1 Correction coefficients calculation ................................................................................................................26

11.3.2 Correlation coefficient calculation ................................................................................................................26

11.3.3 Correction coefficients usage .............................................................................................................................27

11.4 Measurement stability among time ...................................................................................................................................27

12 Measurement uncertainty .......................................................................................................................................................................27

Annex A (informative) Measurement uncertainty — Framework for analysis according to

ISO/IEC Guide 98-3 ..........................................................................................................................................................................................29

Annex B (informative) Normalization with respect to number of tyres, tyre masking effect,

and vehicle impact ...........................................................................................................................................................................................32

Bibliography .............................................................................................................................................................................................................................38

iv © ISO 2021 – All rights reserved---------------------- Page: 4 ----------------------

ISO/DIS 20908:2021(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 31, Tyres, rims and valves.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.© ISO 2021 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO/DIS 20908:2021(E)

Introduction

The external sound emission of a tyre is one out of a multitude of requirements that need to be considered

by manufacturers during design and development of tyres. For health and environmental protection

reasons, the sound emission should be reduced under all relevant driving conditions. To meet all these

demands, an efficient test site is needed that can be operated the whole year round independent of

weather conditions or other outside factors. In many countries, the meteorological conditions are so

adverse that outdoor testing on a classical proving ground is only possible in a very limited timeframe.

Furthermore, performing sound emission tests on various test tracks highly increases the uncertainty

and multiplies the workload for a manufacturer.This ISO standard gives specifications for an indoor noise test bench and a test procedure that delivers

precise results for indoor testing, comparable to a certified type approval test track. The results

are intended to be within the run-to-run variation of the actual valid exterior noise test described

in ISO 13325:2019, which is the test standard used for type approval of tyres. An indoor test bench

requires tight specifications for the equipment and set up, such as the acoustical treatment of the walls

and the ceiling, the microphone array, the roller bench, the adjustment of the tire load on the roller

bench. Special treatment needs to ensure that all rolling sound components of the tire are comparable

to the rolling sound on a road surface as specified in ISO 10844 and as applied in type approvals. This

ISO 20908 standard provides all necessary specifications and procedures to ensure comparability

between todays common and well accepted testing on outdoor test tracks with future indoor facilities.

It incorporates all relevant International Standards for equipment, measurement uncertainty, and test

procedures.The current outdoor method (described in ISO 13325:2019) requests the vehicle to move at various

speeds in between 2 microphones. This imposes to the tyre a high rotation speed which is at the source

of sound emission, by creating tyre parts movements, slip and shocks against the track surface. As a

vehicle movement is not possible in a semi-anechoic room, the rotation of a drum is used to create tyre

rotation similar to the one observed on track. In order to create excitation similar to the one created

on the track, the drum is coated with a surface similar to the one of the tracks. Finally, the vehicle

trajectory between the microphones is simulated by a line of microphones, signals of each microphone

being used to estimate the noise level of the car moving between microphonesThe results are intended to be within the run-to-run variation of the actual valid exterior noise test

described in ISO 13325:2019.vi © ISO 2021 – All rights reserved

---------------------- Page: 6 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 20908:2021(E)

Tyre sound emission test — Methods of drum

1 Scope

This document specifies methods for measuring tyre-to-road sound emissions from tyres fitted on rig

applying the tyre on a rotating drum under coast-by conditions — i.e. when the tyre is in free-rolling,

non-powered operation.The specifications are intended to achieve a correlation between results of testing the exterior noise of

tyres in a semi anechoic chamber and outdoor testing as described in ISO 13325.This document is applicable to passenger cars and light commercial vehicles tyres of class C1 and C2, as

defined in ISO 3833. It is not intended to be used to determine the sound contribution of tyres applying

a torque, nor for the determination of traffic sound nuisance at a given location.

2 Normative referencesThe following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 4223-1, Definitions of some terms used in the tyre industry—Part1: Pneumatic tyres

ISO 3745, Acoustics — Determination of sound power levels and sound energy levels of noise sources using

sound pressure — Precision methods for anechoic rooms and hemi-anechoic roomsISO 10844, Acoustics — Specification of test tracks for measuring noise emitted by road vehicles and

their tyresISO 13325:2019, Tyres — Coast-by methods for measurement of tyre-to-road sound emission

ISO 26101, Acoustics — Test methods for the qualification of free-field environments

IEC 60942, Electroacoustics — Sound calibratorsIEC 61672-1, Electroacoustics — Sound level meters — Part 1: Specifications

IEC 61672-3, Electroacoustics — Sound level meters — Part 3: Periodic tests

ISO/IEC Guide 98-3, Uncertainty of measurement — Part 3: Guide to the expression of uncertainty in

measurementISO 4223-1, Definitions of some terms used in the tyre industry — Part 1: Pneumatic tyres

IEC 60651:2001, Sound level metersISO 362-3:2016, Measurement of noise emitted by accelerating road vehicles — Engineering method —

Part 3: Indoor testing M and N categories3 Terms and definitions

For the purposes of this document, the terms and definitions in ISO 4223-1 and the following symbols

and abbreviated terms apply.© ISO 2021 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO/DIS 20908:2021(E)

3.1

classes of tyre

C1 Passenger car tyres

C2 Commercial vehicle tyres with LI in single formation lower or equal to 121 and speed category

symbol higher or equal to “N”3.2

category of tyres

normal tyre, as defined by ISO 4223-1 3.1.1

snow tyre, as defined by ISO 4223-1 3.1.3

severe snow use tyre, as defined by ISO 4223-1traction tyre, as defined by ISO 4223-1 3.1.5

Special use, as defined by ISO 4223-1 3.1.2traction tyre, as defined by ISO 4223-1 3.1.8

3.3

LI (load index)

numerical code associated with the maximum load a tyre can carry at the speed indicated by its speed

symbol under the service conditions specified by the tyre manufacturerNote 1 to entry: In cases where the LI consists of two numbers, reference shall be made to the first number. For

tyres where the load index is not available, reference shall be made to the maximum load marked on the tyre

sidewall.3.4

rig

device applying a load to tyre and measuring it during the test.

4 Symbols and abbreviated terms

Table 1 — Symbols used and corresponding clauses

Symbol Unit Clause Designation

x, y, z m 6.2.1 Axis of Cartesian coordinate system

m m 6.2.1 Number of a microphone

xy,,z

m 6.2.1 Coordinates of the microphone number m

mm m

Number of array microphones in positive and negative x-directions,

MM, 6.2.1

respectively

M 6.2.1 Total number of the microphones in the array

m 6.2.2 Distance from linear microphone array to the vertical tire mid-plane

array

Height of linear microphone array above the tire contact patch center

m 6.2.2

array

(drum top)

Distance from microphone to track center as defined in ISO 13325;

Y m 6.2.2

CBY

Reference distance for SPL correction in ISO 20908

Height of microphones above the ground as defined in ISO 13325; Ref-

m 6.2.2

CBY

erence height for definition of array microphones height in ISO 20908

Spacing of linear array microphones in x-direction;

Δx m 6.2.2 Reference distance for definition of coordinates of circular array

microphones

Δx Maximum allowed value of Δx

m 6.2.2

max

Lengths of linear microphone array in positive and negative x-direc-

ll,

m 6.2.2

arrayarray

tions, respectively

2 © ISO 2021 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/DIS 20908:2021(E)

Table 1 (continued)

Symbol Unit Clause Designation

+ −

Minimal acceptable value of l and l

m 6.2.2

arraymin

array array

Reference distance for definition of l and α

L m 6.2.2

arraymin arraymin

CBY

m 6.2.3 Radius of the base circle of the circular microphone array

array

Signed angle between projection of the microphone number m of the

α 6.2.3

circular array onto the xy-plane and the y-axis

Angles spanned by the circular array in the xy-plane in positive and

αα,

6.2.3

arrayarray

negative x-directions, respectively

+ −

6.2.3 Minimal acceptable value of α and α

arraymin

array array

D m 6.3 The largest expected size of acoustic source on the tire

The wavelength of sound wave in the air at the highest frequency of

λ m 6.3

min

concern

SPL 6.5 Sound Pressure Level

r 6.5 Distance from the acoustic source to the m-th microphone of the array

Distance from the acoustic source to the central microphone of the

r 6.5

array

Relative Sound Pressure Level decay at microphone number m with

ΔLx 6.5

respect to the central microphone

Q N 9.1.1 Test load for the tyre

Reference load, corresponding to max load associated with tyre

Q N 9.1.1

load index

kPa 9.1.2 Test inflation pressure

P kPa 9.1.2 Reference pressure

n 9.1.4 Number of test speeds

v km/h 9.1.4 Value of the i-th test speed

pt()

Pa 9.2.1 Time-signal of the m-t microphone

pt() Pa 9.2.1 A-filtered time signal of the m-th microphone

Px Pa 9.2.1 Mean square value of pt()

T s 9.2.1 Averaging time for mean square calculation

X m 9.2.2 Distance-corrected x-coordinate of the microphone 𝑚

corr 2

PX Pa 9.2.2 Distance corrected mean-square pressure of the microphone m

A m

Distance-corrected mean-square pressure of the microphone m with

corr 2

PX Pa 9.2.3

FA m

emulation of Fast time weighting through exponential weighting in X

C 9.2.4 Coefficient for tyre impact on sound propagation

9.2.4 Coefficient for vehicle impact on sound propagation

L dB(A) 9.2.4 Representative SPL (test result) at speed v

i i

Pa 9.2.4 Reference acoustic pressure for dB scale

km/h 9.2.6 Reference speed for test results interpolation

ref

Interpolated value of SPL at the speed v

dB(A) 9.2.5

ref

dB(A) 9.2.5 Mean value of representative SPLs

v 9.2.5 Decimal logarithm of the test speed v

∗i i

Mean value of v

9.2.5

© ISO 2021 – All rights reserved 3

---------------------- Page: 9 ----------------------

ISO/DIS 20908:2021(E)

Table 1 (continued)

Symbol Unit Clause Designation

Slope of the regression line L vs. v

a 9.2.5

i ∗i

L 9.2.5 Interpolated value of SPL at a speed v

Slope of the regression line L vs. L

M 11.3

Rtracki Rdrumi

Shift at origin of the regression line L vs. L

Q 11.3

Rtracki Rdrumi

2 Correlation coefficient of the regression line L vs. L

11.3

Rtracki Rdrumi

dB(A) 9.2.6 Interpolated value corrected for lab alignment with outdoor

raligned

dB(A) 9.2.5 Final test result

5 Instrumentation

5.1 Instruments for acoustical measurement

The sound pressure level meter or equivalent measuring system (including microphone and acquisition

system), shall meet the minimum requirements of a Class 1 instrument in accordance with IEC 61672-1.

Alternatively, IEC 60651 may be used.The measurements shall be made using the “A” frequency weighting.

The calibration of the sound pressure level meter shall be checked and adjusted in accordance with the

manufacturer’s instructions or with a standard sound source (e.g. pistonphone) at the beginning of the

measurements and rechecked and recorded at the end of them. The calibration device shall meet the

requirements of Class 1 in accordance with IEC 60942.If the sound pressure level meter indications obtained from these calibrations differ by more than

0.5 dB during a series of measurements, the test shall be considered invalid. Any deviation shall be

recorded in the test report.NOTE The tests of IEC 61672-3 cover only a limited subset of the specifications in IEC 61672-1 for which the

scope is large (temperature range, frequency requirements up to 20 kHz, etc.). It is economically not feasible to

verify the whole IEC 61672-1 requirements on each item of a computerized data acquisition systems model.

5.2 MicrophonesThe microphones setup will be described in the §6.2 “Microphone array setup”. In the vicinity of the

microphones, there shall be no obstacle that could influence the acoustical field.

5.3 Temperature measurement5.3.1 General

For air temperature measurement, the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.