oSIST prEN 15681-2:2007

(Main)Glass in building - Basic alumino silicate glass products - Part 2: Evaluation of conformity/Product standard

Glass in building - Basic alumino silicate glass products - Part 2: Evaluation of conformity/Product standard

This European Standard covers the evaluation of conformity and the factory production control of basic alumino silicate glass products for use in buildings.

Note: For glass products with electrical wiring or connections for, e.g. alarm or heating purposes, other directives, e.g. Low Voltage Directive, may apply.

Glas im Bauwesen - Basiserzeugnisse aus Alumo-Silicatglas - Teil 2: Konformitätsbewertung/Produktnorm

Verre dans la construction - Produits de base verre alumino silicaté - Partie 2 : Evaluation de la conformité/Norme de produit

La présente Norme européenne couvre l'évaluation de la conformité et le contrôle de la production en usine pour les produits verriers alumino-silicatés de base en usage dans la construction.

NOTE Pour les produits verriers équipés d'un câblage ou de branchements électriques pour les besoins d'alarme ou de chauffage par exemple, d’autres directives telles que la Directive sur les Courants Faibles peuvent s’appliquer.

Steklo v gradbeništvu - Osnovni izdelki iz aluminij-silikatnega stekla - 2. del: Ovrednotenje skladnosti/standard za izdelek

General Information

- Status

- Not Published

- Public Enquiry End Date

- 30-Aug-2007

- Withdrawal Date

- 17-Apr-2011

- Technical Committee

- STV - Steklo, svetloba in razsvetljava v gradbeništvu

- Current Stage

- 98 - Abandoned project (Adopted Project)

- Start Date

- 18-Apr-2011

- Due Date

- 23-Apr-2011

- Completion Date

- 18-Apr-2011

- Directive

- 89/106/EEC - Construction products

Overview

prEN 15681-2 - "Glass in building - Basic alumino silicate glass products - Part 2: Evaluation of conformity/Product standard" (CEN draft, 2007) defines how manufacturers evaluate conformity and manage factory production control for basic alumino silicate glass used in buildings. It focuses on ensuring declared performance characteristics, durability during an economically reasonable working life, and the information and marking needed for regulatory compliance (including provisions related to the EU Construction Products Directive and CE marking).

Keywords: prEN 15681-2, basic alumino silicate glass, evaluation of conformity, factory production control, glass in building, CE marking, durability, product standard.

Key topics and requirements

- Scope and definitions: Applies to basic alumino silicate glass products as defined in prEN 15681-1; excludes electrical aspects subject to other directives (e.g. Low Voltage Directive).

- Performance characteristics: Sets out which characteristics must be determined (measured, calculated or generally accepted values), including density, hardness, Young’s modulus, refractive index, emissivity, light and solar transmittance, thermal conductivity and U‑value calculation inputs.

- Safety and resistance testing: References harmonized EN test methods for:

- Fire resistance and reaction to fire (EN 13501 series)

- Bullet, explosion and burglar resistance (EN 1063, EN 13541, EN 356)

- Impact (pendulum) resistance (EN 12600)

- Sound reduction (EN 12758)

- Luminous and solar properties (EN 410)

- Evaluation of conformity: Describes procedures for initial type testing, factory production control (FPC), initial inspection of the factory, and continuous surveillance/assessment.

- Factory Production Control (Annex A): Organizational and control system requirements, testing tables, and rules for proxy testing.

- Marking & documentation: Product marking, performance identification papers and information required for CE marking and declaration of conformity (Annex ZA covers Construction Products Directive alignment).

Applications and users

Who uses prEN 15681-2:

- Glass manufacturers and quality managers establishing FPC and declaring product performance.

- Test laboratories performing initial type testing and supporting conformity reports.

- Specifiers, façade engineers and architects who rely on declared glass properties (thermal, optical, mechanical, fire and safety characteristics).

- Certification bodies and notified bodies assessing conformity and CE marking dossiers. Practical applications include safety glazing, fire‑resistant or security glazing, energy‑efficient façades, acoustic glazing and any building application where certified glass performance and documented production control are required.

Related standards

- prEN 15681-1 (Definitions and general physical/mechanical properties)

- EN 410 (luminous and solar characteristics)

- EN 673 (U‑value calculation)

- EN 12600, EN 1063, EN 356, EN 13541 (impact, bullet, burglar, explosion)

- EN 13501 series (fire classification)

- prEN 13474 (glass pane design)

For manufacturers and specifiers working with basic alumino silicate glass, prEN 15681-2 provides the conformity framework that links product testing, factory control and regulatory marking to ensure consistent, documented performance in building applications.

Frequently Asked Questions

oSIST prEN 15681-2:2007 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Glass in building - Basic alumino silicate glass products - Part 2: Evaluation of conformity/Product standard". This standard covers: This European Standard covers the evaluation of conformity and the factory production control of basic alumino silicate glass products for use in buildings. Note: For glass products with electrical wiring or connections for, e.g. alarm or heating purposes, other directives, e.g. Low Voltage Directive, may apply.

This European Standard covers the evaluation of conformity and the factory production control of basic alumino silicate glass products for use in buildings. Note: For glass products with electrical wiring or connections for, e.g. alarm or heating purposes, other directives, e.g. Low Voltage Directive, may apply.

oSIST prEN 15681-2:2007 is classified under the following ICS (International Classification for Standards) categories: 81.040.20 - Glass in building. The ICS classification helps identify the subject area and facilitates finding related standards.

oSIST prEN 15681-2:2007 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/135. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase oSIST prEN 15681-2:2007 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2007

Steklo v gradbeništvu - Osnovni izdelki iz aluminij-silikatnega stekla - 2. del:

Ovrednotenje skladnosti/standard za izdelek

Glass in building - Basic alumino silicate glass products - Part 2: Evaluation of

conformity/Product standard

Glas im Bauwesen - Basiserzeugnisse aus Alumo-Silicatglas - Teil 2:

Konformitätsbewertung/Produktnorm

Verre dans la construction - Produits de base verre alumino silicaté - Partie 2 :

Evaluation de la conformité/Norme de produit

Ta slovenski standard je istoveten z: prEN 15681-2

ICS:

81.040.20 Steklo v gradbeništvu Glass in building

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

DRAFT

NORME EUROPÉENNE

EUROPÄISCHE NORM

May 2007

ICS 81.040.20

English Version

Glass in building - Basic alumino silicate glass products - Part 2:

Evaluation of conformity/Product standard

Glas im Bauwesen - Basiserzeugnisse aus Alumo-

Silicatglas - Teil 2: Konformitätsbewertung/Produktnorm

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee CEN/TC 129.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations which

stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other language

made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the

same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,

Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are aware and to

provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without notice and

shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2007 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 15681-2:2007: E

worldwide for CEN national Members.

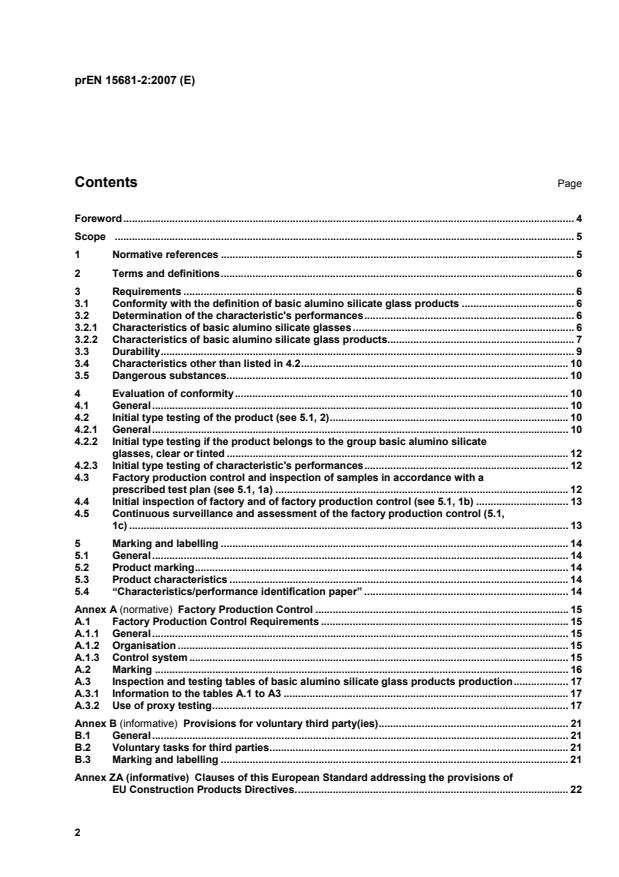

Contents Page

Foreword. 4

Scope . 5

1 Normative references . 5

2 Terms and definitions. 6

3 Requirements . 6

3.1 Conformity with the definition of basic alumino silicate glass products . 6

3.2 Determination of the characteristic's performances. 6

3.2.1 Characteristics of basic alumino silicate glasses . 6

3.2.2 Characteristics of basic alumino silicate glass products. 7

3.3 Durability. 9

3.4 Characteristics other than listed in 4.2. 10

3.5 Dangerous substances. 10

4 Evaluation of conformity. 10

4.1 General. 10

4.2 Initial type testing of the product (see 5.1, 2). 10

4.2.1 General. 10

4.2.2 Initial type testing if the product belongs to the group basic alumino silicate

glasses, clear or tinted . 12

4.2.3 Initial type testing of characteristic's performances. 12

4.3 Factory production control and inspection of samples in accordance with a

prescribed test plan (see 5.1, 1a) . 12

4.4 Initial inspection of factory and of factory production control (see 5.1, 1b) . 13

4.5 Continuous surveillance and assessment of the factory production control (5.1,

1c) . 13

5 Marking and labelling . 14

5.1 General. 14

5.2 Product marking. 14

5.3 Product characteristics . 14

5.4 “Characteristics/performance identification paper” . 14

Annex A (normative) Factory Production Control . 15

A.1 Factory Production Control Requirements . 15

A.1.1 General. 15

A.1.2 Organisation . 15

A.1.3 Control system . 15

A.2 Marking . 16

A.3 Inspection and testing tables of basic alumino silicate glass products production. 17

A.3.1 Information to the tables A.1 to A3 . 17

A.3.2 Use of proxy testing. 17

Annex B (informative) Provisions for voluntary third party(ies). 21

B.1 General. 21

B.2 Voluntary tasks for third parties. 21

B.3 Marking and labelling . 21

Annex ZA (informative) Clauses of this European Standard addressing the provisions of

EU Construction Products Directives. 22

ZA.1 Scope and relevant characteristics. 22

ZA.2 Procedure(s) for the attestation of conformity of basic alumino silicate glass

products. 24

ZA.2.1 System(s) of attestation of conformity . 24

ZA.2.2 EC Certificate and Declaration of conformity . 26

ZA.3 CE marking and labelling . 28

Bibliography . 30

Foreword

This document (prEN 15681-2:2007) has been prepared by Technical Committee CEN/TC 129 “Glass

in building”, the secretariat of which is held by NBN.

This document is currently submitted to the CEN Enquiry.

This document has been prepared under a mandate given to CEN by the European Commission and

the European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this

document.

Scope

This European Standard covers the evaluation of conformity and the factory production control of

basic alumino silicate glass products for use in buildings.

Note: For glass products with electrical wiring or connections for, e.g. alarm or heating purposes, other directives,

e.g. Low Voltage Directive, may apply.

1 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

EN 356, Glass in Building - Security glazing - Testing and classification of resistance against manual

attack

EN 410, Glass in Building - Determination of luminous and solar characteristics of glazing

EN 673, Glass in Building - Determination of thermal transmittance (U-value) – Calculation method

EN 1063, Glass in Building - Security glazing – Testing and classification of resistance against bullet

attack

EN 12600, Glass in Building - Pendulum test - Impact test method and classification for flat glass

EN 12758, Glass in Building - Glazing and airborne sound insulation – Product descriptions and

determination of properties

EN 12898, Glass in Building - Determination of the emissivity

prEN 13474, Glass in building – Design of glass panes

EN 13501-1, Fire classification of construction products and building elements – Part 1: Classification

using test data from fire reaction to fire tests

EN 13501-2, Fire classification of construction products and building elements - Part 2: Classification

using data from fire resistance tests, excluding ventilation services

EN 13501-5, Fire classification of construction products and building elements – Part 5: Classification

using data from fire exposure roof tests

EN 13541, Glass in Building - Security glazing - Testing and classification of resistance against

explosion pressure

prEN 15681-1, Glass in Building – Basic alumino silicate glass products – Part 1: Definitions and

general physical and mechanical properties

2 Terms and definitions

For the purposes of this document, the terms and definitions given in prEN BAluS-1 and the following

apply.

3.1

initial type testing

determination of the performance of a product (characteristic, durability), on the basis of either actual

tests or other procedures (such as conventional, standardised, tabulated or general accepted values;

standardised or recognised calculation methods; test reports when made available), in accordance

with this document that demonstrates compliance with this document.

3.2

test report

document that covers the results of tests undertaken on a representative sample of the product from

production or on a prototype design of the product.

3.3

product description

document that details the relevant parameters, e.g. process conditions, structure, etc., for defining a

product that complies with the standard. It includes specific reference(s) to characteristics that are

modified by the production process.

3.4

significant change

variation in performance beyond the permitted tolerance for the characteristic.

3 Requirements

3.1 Conformity with the definition of basic alumino silicate glass products

Products shall conform to the definition and fulfil the requirements of basic alumino silicate glass

products as defined in prEN 15681-1.

3.2 Determination of the characteristic's performances

3.2.1 Characteristics of basic alumino silicate glasses

Basic alumino silicate glass products are made in accordance with prEN 15681-1. The characteristics

listed in table 1, concern generally accepted values, calculated values or measured values.

Table 1 — Necessary information on characteristics of basic alumino silicate glasses

Characteristic Symbol Unit

General accepted values:

- density ρ kg/m³

- hardness HK GPa

0,1/20

- Young's modulus E Pa

- Poisson's ratio µ Dimensionless

ƒ

- characteristic bending strength Pa

g,k

- resistance against sudden temperature changes and temperature K

differentials

- specific heat capacity J/(kg*K)

c

-1

- coefficient of linear expansion K

α

- thermal conductivity W/(m*K)

λ

- mean refractive index to visible radiation Dimensionless

n

- emissivity Dimensionless

ε

Measured values:

- light transmittance τ Dimensionless

ν

- solar direct transmittance Dimensionless

τ

e

Calculated values:

- total solar energy transmittance g Dimensionless

3.2.2 Characteristics of basic alumino silicate glass products

If the basic alumino silicate glass manufacturer wishes to claim that any performance characteristic is

independent of the production equipment used then the factory production control system shall be in

accordance with this document including his specific process control conditions.

3.2.2.1 Safety in the case of fire - Resistance to fire

Fire resistance shall be determined and classified in accordance with EN 13501-2.

Note: EN 357 may be used as a classification reference specific to fire resistant glazed elements.

3.2.2.2 Safety in the case of fire - Reaction to fire

Reaction to fire shall be determined and classified according to EN 13501-1.

Basic alumino silicate glass products are products/materials that do not require to be tested for

reaction to fire (e.g. Products/materials of Classes A1* according to Commission Decision 96/603/EC,

as amended 2000/605/EC).

3.2.2.3 Safety in the case of fire - External fire behaviour

Where the manufacturer wishes to declare external fire performance (e.g. when subject to regulatory

requirements), the product shall be tested and classified in accordance with EN 13501-5.

3.2.2.4 Safety in use - Bullet resistance: shatter properties and resistance to attack

Bullet resistance shall be determined and classified in accordance with EN 1063.

3.2.2.5 Safety in use - Explosion resistance: impact behaviour and resistance to impact

Explosion resistance shall be determined and classified in accordance with EN 13541.

3.2.2.6 Safety in use - Burglar resistance: shatter properties and resistance to attack

Burglar resistance shall be determined and classified in accordance with EN 356.

3.2.2.7 Safety in use - Pendulum body impact resistance: shatter properties (safe

breakability) and resistance to impact

Pendulum body impact resistance shall be determined and classified in accordance with EN 12600.

3.2.2.8 Safety in use - Mechanical resistance: Resistance against sudden temperature

changes and temperature differentials

The resistance against sudden temperature changes and temperature differentials is a generally

accepted value that is given in prEN 15681-1 and shall be ensured by compliance with this document.

3.2.2.9 Safety in use - Mechanical resistance: Resistance against wind, snow, permanent

load and/or imposed loads of the glass unit

The mechanical resistance of basic alumino silicate glass is a characteristic value that is given in

prEN BAluS-1 and shall be ensured by compliance with this document.

As long as on the concerned construction or building site no part of prEN 13474 is applicable then the

current method of determining mechanical resistance in the country of destination shall be applied.

The manufactured or supplied thickness of glass shall conform to the ordered thickness.

3.2.2.10 Protection against noise - Direct airborne sound reduction

The sound reduction index shall be determined in accordance with EN 12758.

3.2.2.11 Energy conservation and heat retention - Thermal properties

The thermal transmittance value (U-value) shall be determined by calculation in accordance with

EN 673 with:

emissivity ε: using the value the emissivity as given in prEN 15681-1.

nominal thickness of the glass panes

3.2.2.12 Energy conservation and heat retention - Radiation properties: Light

transmittance and reflectance

The light transmittance and reflectance shall be determined in accordance with EN 410.

3.2.2.13 Energy conservation and heat retention - Radiation properties: Solar energy

characteristics

The solar energy transmittance and reflectance shall be determined in accordance with EN 410.

3.3 Durability

When products conform to the definition of basic alumino silicate glass products as 4.1, the

characteristic's performances in 4.2 are ensured during an economically reasonable working life.

The durability of glass products, including their characteristics, shall be ensured by the following:

Compliance with this document

Compliance with instructions from the glass product manufacturer or supplier

The manufacturer shall supply specific installation instructions or make reference to appropriate

technical specifications.

Note 1: The durability of glass products depends on:

building and construction movements due to various actions;

building and construction vibrations due to various actions;

deflection and racking of the glass support due to various actions;

glass support design (e.g. drainage of infiltrated water in the rebate, prevention of direct contact

between glass support members and glass);

accuracy of glass support and glass support member dimensions;

quality of the assembling of glass support members up to a glass support;

quality of installation of the glass support into or onto the buildings or constructions;

glass support expansion due to adsorbed moisture from the air or other sources;

the quality of installation of the glass product into or onto its support.

3.4 Characteristics other than listed in 4.2

Optical and visual characteristics shall comply with prEN 15681-1.

Dimensional tolerances: shall comply with prEN 15681-1.

3.5 Dangerous substances

Materials used in products shall not release any dangerous substances in excess of the maximum

permitted levels specified in a relevant European Standard for the material or permitted in the national

regulations of the member state of destination.

4 Evaluation of conformity

4.1 General

Evaluation of conformity in accordance with this document shall be a result of Factory Production

Control and Initial Type Testing in accordance with this document.

1) Factory production control;

This shall include the following:

a) Inspection of samples taken at the factory in accordance with a prescribed test plan;

b) Initial inspection of the factory and of factory production control;

c) Continuous surveillance and assessment of the factory production control.

2) Initial type testing of the product;

Note: There may be a need to involve a third party with 1b), 1c) and/or 2), for the purpose of regulatory marking

(see Annex ZA).

4.2 Initial type testing of the product (see 5.1, 2)

4.2.1 General

All the product’s characteristics shall be initial type tested to verify they are in conformity with the

requirements of this document. In addition instead of performing any actual testing, initial type testing

may make use of:

generally accepted and/or conventional and/or standardised values, in the Clause 2 referenced

standards, or in publications that are referred to in these standards;

standardised calculation methods and recognised calculation methods in the Clause 2 referenced

standards, or in publications that are referred to in these standards;

test report(s) on the basis of 5.2.1.2 when made available except for the characteristics listed in

5.2.2.

where components are used whose characteristics have already been determined, by the

component manufacturer, on the basis of conformity with other product standards, these

characteristics need not be reassessed providing they remain unchanged by the manufacturing

process;

release of dangerous substances may be assessed indirectly by controlling the content of the

substance concerned;

durability may be assessed indirectly by controlling the production processes according to this

document;

Note 1: Products CE marked in accordance with appropriate harmonised European specifications may be

presumed to have the performances stated with the CE marking.

Note 2: There may be a need to involve a third party for the purpose of regulatory marking (see Annex ZA).

When actual testing is required then the Initial Type Testing (ITT) shall be undertaken on a sample

representative of the product taken from direct production or a prototype, any plant and/ or line.

Whenever a change occurs in the raw material or the production process (subject to the definition of

the family), which would change significantly one or more of the characteristics, the type tests shall be

repeated for the appropriate characteristics.

4.2.1.1 Multiple lines/sites

If a manufacturer operates more than one line and/or site, the following can reduce the requirement

for multiple Initial Type Testing (ITT):

i) The manufacturers’ technical file for a product shall specifically covers all sites and/or

lines of the same manufacturer ,

ii) The manufacturer shall establish a direct relationship between production control, initial

type testing and on-going internal audit testing,

iii) The manufacturer has a responsible individual designated to ensure product compliance

based on:

The operation of a consistent Factory Production Control system on all applicable

sites and/or lines,

The manufacturer having obtained evidence that shows the product to be

consistent, with respect to both product characteristics and intended use

characteristics,

The manufacturer has in place an internal auditing scheme, including product

consistency.

1 The terms ‘manufacturer’ and ‘producer’ are understood as being synonyms (see CPD working document

NBCPD/ 02/019-issued 24 April 2002 – page1)

4.2.1.2 Historic Data

Tests previously performed in accordance with the provisions of this document (same product, same

characteristic(s), same or more onerous test method, sampling method and attestation of conformity)

may be taken into account.

4.2.2 Initial type testing if the product belongs to the group basic alumino silicate glasses,

clear or tinted

Initial type testing to establish if a product conforms to the definition of basic alumino silicate glass,

may be economised as much as possible. For that purpose appropriate available test reports in

accordance with 5.2.1.2 are equivalent to actual testing and may be used instead of actual testing.

The initial type testing concerns the product aspects as listed in table 2.

Table 2 — Product aspects to be checked if product belongs to group basic alumino silicate

glasses

No. Product aspect

1 Chemical composition

2 Thickness

3 Light transmittance (distinction clear glass from tinted glass)

4.2.3 Initial type testing of characteristic's performances

All characteristics in 4.2.2 shall be subject to initial type testing in accordance with 5.2.1.

4.3 Factory production control and inspection of samples in accordance with a

prescribed test plan (see 5.1, 1a)

Factory production control means the permanent internal control of production exercised by the

manufacturer.

All elements, requirements and provisions adopted by the manufacturer shall be documented in a

systematic manner in the form of written policies and procedures. This production control system

documentation shall ensure a common understanding of quality assurance and enable the

achievement of the required product characteristics and the effective operation of the production

control system to be checked.

Factory production control shall be according to Annex A of this document.

Note 1: A factory production control system similar to EN ISO 9001 made product specific to this document is

deemed to satisfy the requirements of this clause.

Note 2: There may be a need to involve a third party for the purpose of regulatory marking (see Annex ZA).

Annex A of this document also summarizes the tests to be carried out by the manufacturer as part of

the production control in the factory, and as further testing of samples taken at the factory in

accordance with a prescribed test plan.

4.4 Initial inspection of factory and of factory production control (see 5.1, 1b)

The initial inspection of the factory and of the factory production control shall be limited to the

parameters listed in table 3 in conjunction with Annex A.

Note: There may be a need to involve a third party for the purpose of regulatory marking (see Annex ZA).

Table 3 — Characteristics of interest for the Factory Production Control

No. Characteristic Interested parameter related to the For details,

characteristic refer to

a Resistance to fire - checking incoming materials Annex A

Reaction to fire - chemical composition

External fire behavior - product control after manufacture

- labelling outgoing glass product

b Release of dangerous substances - checking incoming materials Annex A

c Bullet resistance - checking incoming materials Annex A

Explosion resistance - chemical composition

Burglar resistance - product control after manufacturing

Pendulum body impact resistance - labelling outgoing glass product

Resistance against sudden temperature

changes and temperature differentials

Wind, snow, permanent and imposed load

resistance of the glass unit

d Direct airborne sound reduction - checking incoming materials Annex A

Thermal properties - chemical composition

Radiation properties: - product control after manufacture

– light transmittance and reflection

- labelling outgoing glass product

– solar energy characteristic

4.5 Continuous surveillance and assessment of the factory production control (5.1,

1c)

The continuous surveillance and assessment of the factory production control shall cover the

parameters listed in Table 3 in conjunction with Annex A.

Note: There may be a need to involve a third party for the purpose of regulatory marking (see Annex ZA).

The frequency of production surveillance shall be twice per year for new production facilities or for

facilities that do not already have an established factory production control system in accordance with

this document.

When assessment of FPC fails to identify major non-conformances during four successive

assessments, the frequency can be reduced to once a year.

When a major non-conformance is recorded, the inspection shall be repeated within two months. The

frequency of production surveillance shall return to, or remain at twice a year. When the repeated

inspection also results in a major non-conformance, then the production shall be subject within two

months to a repeated initial inspection of the factory and of the factory production control together with

a surveillance inspection. When this repeated initial inspection and surveillance inspection also results

in a major non-conformance then the products are considered as no longer conforming to this

document.

5 Marking and labelling

5.1 General

All voluntary marking and/or labelling shall comply with Annex B 3.

Care shall be taken to ensure that any voluntary marking and/or labelling does not cause confusion

with respect to the mandatory requirements.

Note: All marking and/or labelling of product to demonstrate compliance with the regulatory requirement is

detailed in Annex ZA.

5.2 Product marking

There is no requirement to mark basic alumino silicate glass products.

5.3 Product characteristics

The manufacturer or his agent shall organise a system of references that allows for the following:

the identification of exactly which characteristics have to be assessed (see 4.2.2);

those characteristics that will be assessed;

th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...