ASTM C547-03

(Specification)Standard Specification for Mineral Fiber Pipe Insulation

Standard Specification for Mineral Fiber Pipe Insulation

SCOPE

1.1 This specification covers mineral fiber insulation produced to form hollow cylinders for standard pipe and tubing sizes. The mineral fiber pipe insulation may be molded or precision v-grooved, with one or more walls split longitudinally for use on pipe temperatures up to 1200°F (650°C).

1.2 For satisfactory performance, properly installed protective vapor retarders or barriers should be used on sub-ambient temperature applications to reduce movement of moisture through or around the insulation to the colder surface. Failure to use a vapor barrier can lead to insulation and system damage. Refer to Practice C 921 to aid material selection.

1.3 Flexible mineral fiber wrap products such as perpendicular-oriented fiber insulation rolls, non-precision or manually scored block or board, or flexible boards or blankets used as pipe insulation, are not covered by this specification.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 The following safety hazards caveat applies to the test methods portion, Section 11, only: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 547 – 03

Standard Specification for

1

Mineral Fiber Pipe Insulation

This standard is issued under the fixed designation C 547; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope C 302 Test Method for Density of Preformed Pipe-

2

Covering-Type Thermal Insulation

1.1 This specification covers mineral fiber insulation pro-

C 335 Test Method for Steady-State Heat Transfer Proper-

duced to form hollow cylinders for standard pipe and tubing

2

ties of Horizontal Pipe Insulation

sizes. The mineral fiber pipe insulation may be molded or

C 356 Test Method for Linear Shrinkage of Preformed

precision v-grooved, with one or more walls split longitudi-

High-Temperature Thermal Insulation Subjected to Soak-

nally for use on pipe temperatures up to 1200°F (650°C).

2

ing Heat

1.2 For satisfactory performance, properly installed protec-

C 390 Criteria for Sampling and Acceptance of Preformed

tive vapor retarders or barriers should be used on sub-ambient

2

Thermal Insulation Lots

temperature applications to reduce movement of moisture

C 411 Test Method for Hot-Surface Performance of High-

through or around the insulation to the colder surface. Failure

2

Temperature Thermal Insulation

to use a vapor barrier can lead to insulation and system

C 447 Practice for Estimating the Maximum Use Tempera-

damage. Refer to Practice C 921 to aid material selection.

2

ture of Insulations

1.3 Flexible mineral fiber wrap products such as

C 585 Practice for Inner and Outer Diameters of Rigid

perpendicular-oriented fiber insulation rolls, non-precision or

Thermal Insulation for Nominal Sizes of Pipe and Tubing

manually scored block or board, or flexible boards or blankets

2

(NPS System)

used as pipe insulation, are not covered by this specification.

C 612 Specification for Mineral Fiber Block and Board

1.4 The values stated in inch-pound units are to be regarded

2

Thermal Insulation

as the standard. The values given in parentheses are for

C 795 Specification for Thermal Insulation for Use in Con-

information only.

2

tact with Austenitic Stainless Steel

1.5 The following safety hazards caveat applies to the test

C 921 Practice for Determining the Properties of Jacketing

methods portion, Section 11, only: This standard does not

2

Materials for Thermal Insulation

purport to address all of the safety concerns, if any, associated

C 1045 Practice for Calculating Thermal Transmission

with its use. It is the responsibility of the user of this standard

2

Properties from Steady-State Heat Flux Measurements

to establish appropriate safety and health practices and

C 1058 Practice for Selecting Temperatures for Evaluating

determine the applicability of regulatory limitations prior to

2

and Reporting Thermal Properties of Thermal Insulation

use.

C 1104/C1104M Test Method for Determining the Water

2

2. Referenced Documents

Vapor Sorption of Unfaced Mineral Fiber Insulation

E 84 Test Method for Surface Burning Characteristics of

2.1 ASTM Standards:

3

Building Materials

C 167 Test Methods for Thickness and Density of Blanket

2

2.2 Other Standards:

or Batt Thermal Insulations

UL 723 Tests for Surface Burning of Building Materials,

C 168 Terminology Relating to Thermal Insulating Materi-

2

available from Underwriters Laboratories, 333 Pfingsten

als

Road, Northbrook, IL 60062–2026

C 177 Test Method for Steady-State Heat Flux Measure-

NFPA 255 Method of Tests of Surface Burning Character-

ments and Thermal Transmission Properties by Means of

2

istics of Building Materials, available from the National

the Guarded-Hot-Plate Apparatus

Fire Protection Association, Batterymarch Park, Quincy,

MA 02269

CAN/ULC-S102–M88 Standard Method ofTest for Surface

1

This specification is under the jurisdiction of ASTM Committee C16 on

Burning Characteristics of Building Materials andAssem-

Thermal Insulation and is the direct responsibility of Subcommittee C16.20 on

blies, available from Underwriters Laboratories of

Homogeneous Inorganic Thermal Insulations.

Current edition approved April 10, 2003. Published July 2003. Originally

approved in 1964. Last previous edition approved in 2000 as C 547 – 00.

2 3

Annual Book of ASTM Standards, Vol 04.06. Annual Book of ASTM Standards, Vol 04.07.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

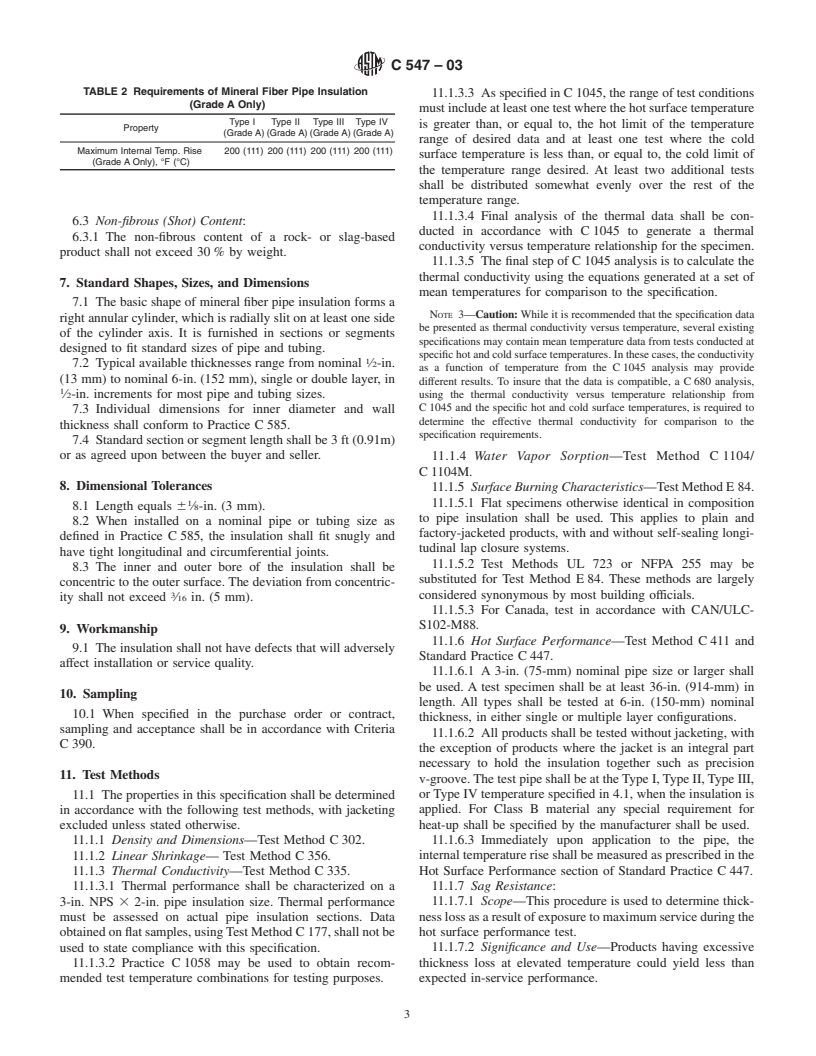

C547–03

products may lead to an exothermic reaction. This is dependent on

Canada, 7 Crouse Road, Scarborough, Ontario MIR3A9

t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.