ASTM E868-82(2005)

(Test Method)Standard Test Methods for Conducting Performance Tests on Mechanical Conveying Equipment Used in Resource Recovery Systems (Withdrawn 2005)

Standard Test Methods for Conducting Performance Tests on Mechanical Conveying Equipment Used in Resource Recovery Systems (Withdrawn 2005)

SIGNIFICANCE AND USE

These test methods may be used to measure the equipment performance.

These test methods are applicable when the conveying equipment is of sufficient length and is accessible for taking the samples and measuring the speed, or when the discharge is accessible to collect a sample in a given length of time. Not all pieces of equipment in a processing plant may be accessible; therefore, the input or total of inputs to adjacent upstream equipment/output or total of outputs of adjacent downstream equipment may be used to determine the throughput of the conveying equipment in question. Judgement must be used to determine any loss of material or changes in bulk density.

SCOPE

1.1 These test methods include descriptions for conducting and reporting throughput and electrical power tests on mechanical conveying equipment for municipal solid waste and recovered products from resource recovery systems. Other aspects of performance testing such as spillage, conveyor tracking, dusting, slippage, transfer points, etc., should be considered in the interpretation of the results. These test methods can be used on equipment handling raw refuse, processed refuse, magnetic scrap metals, nonferrous scrap metals, mixed glass, and residues or tailings. These test methods may also be used for materials in other industries.

1.2 These test methods cover mechanical conveying equipment including apron, belt, drag, flight, screw, slat, and vibrating conveyors and bucket elevators.

1.3 These test methods are applicable specifically to the resource recovery industry since municipal solid wastes are heterogeneous mixtures and the composition and bulk densities vary considerably depending on many factors. Because of the varying composition of municipal solid waste, a number of samples must be taken to determine accurately the performance of the mechanical conveying equipment.

1.4 Test methods for determining the approximate as-conveyed bulk density of the material and for determining the electrical horsepower input of the equipment motors are also included.

1.5 It is intended that the tests be made and reported by personnel trained in the proper application and use of the various instruments and methods involved.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For hazard statement, see Section .

WITHDRAWN RATIONALE

These test methods include descriptions for conducting and reporting throughput and electrical power tests on mechanical conveying equipment for municipal solid waste and recovered products from resource recovery systems.

Formerly under the jurisdiction of Committee D34 on Waste Management, these test methods were withdrawn in February 2013. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E868 − 82(Reapproved 2005)

Standard Test Methods for

Conducting Performance Tests on Mechanical Conveying

Equipment Used in Resource Recovery Systems

This standard is issued under the fixed designation E868; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 These test methods include descriptions for conducting

bility of regulatory limitations prior to use. For hazard

and reporting throughput and electrical power tests on me-

statement, see Section 7.

chanical conveying equipment for municipal solid waste and

recovered products from resource recovery systems. Other

2. Referenced Documents

aspects of performance testing such as spillage, conveyor

2.1 ASTM Standards:

tracking, dusting, slippage, transfer points, etc., should be

E380 Practice for Use of the International System of Units

considered in the interpretation of the results. These test

(Si) (the Modernized Metric System) (Withdrawn 1997)

methods can be used on equipment handling raw refuse,

E856 Definitions of Terms and Abbreviations Relating to

processed refuse, magnetic scrap metals, nonferrous scrap

Physical and Chemical Characteristics of Refuse Derived

metals, mixed glass, and residues or tailings. These test

Fuel (Withdrawn 2011)

methods may also be used for materials in other industries.

2.2 Other Standard:

1.2 These test methods cover mechanical conveying equip-

No. 550 Classification and Definitions of Bulk Materials

ment including apron, belt, drag, flight, screw, slat, and

vibrating conveyors and bucket elevators.

3. Terminology

1.3 These test methods are applicable specifically to the

3.1 Definitions:

resource recovery industry since municipal solid wastes are

3.1.1 oversize bulky waste (OBW)—items whose large size

heterogeneousmixturesandthecompositionandbulkdensities

precludes or complicates processing or sampling.

vary considerably depending on many factors. Because of the

3.1.2 performance test—atestdevisedtopermitobservation

varying composition of municipal solid waste, a number of

and measurement of the performance of a system or unit of

samplesmustbetakentodetermineaccuratelytheperformance

equipment operating under prescribed load conditions.

of the mechanical conveying equipment.

3.2 Fordefinitionsofothertermsusedinthesetestmethods,

1.4 Test methods for determining the approximate as-

refer to Definitions E856. For an explanation of the metric

conveyed bulk density of the material and for determining the

system including symbols and conversion factors, refer to

electrical horsepower input of the equipment motors are also

Practice E380.

included.

4. Summary of Test Methods

1.5 It is intended that the tests be made and reported by

personnel trained in the proper application and use of the

4.1 The conveying equipment performance can be calcu-

various instruments and methods involved.

lated by determining the volume or weight of a representative

sample of material on the conveying equipment and measuring

1.6 The values stated in SI units are to be regarded as the

its speed. Another method for calculating the conveying

standard. The values given in parentheses are for information

equipment performance is to measure the infeed or discharge

only.

weight or volume in a given length of time. The minimum

1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

These test methods are under the jurisdiction of ASTM Committee D34 on Standards volume information, refer to the standard’s Document Summary page on

Waste Management and are the direct responsibility of Subcommittee D34.01.02 on the ASTM website.

Sampling Techniques. The last approved version of this historical standard is referenced on

Current edition approved Feb. 1, 2005. Published March 2005. Originally www.astm.org.

approved in 1982. Last previous edition approved in 1999 as E868-82(1999). DOI: Available from Conveyor Equipment Manufacturers Association, 1000 Ver-

10.1520/E0868-82R05. mont Ave., N.W, Washington, DC 20005.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E868 − 82 (2005)

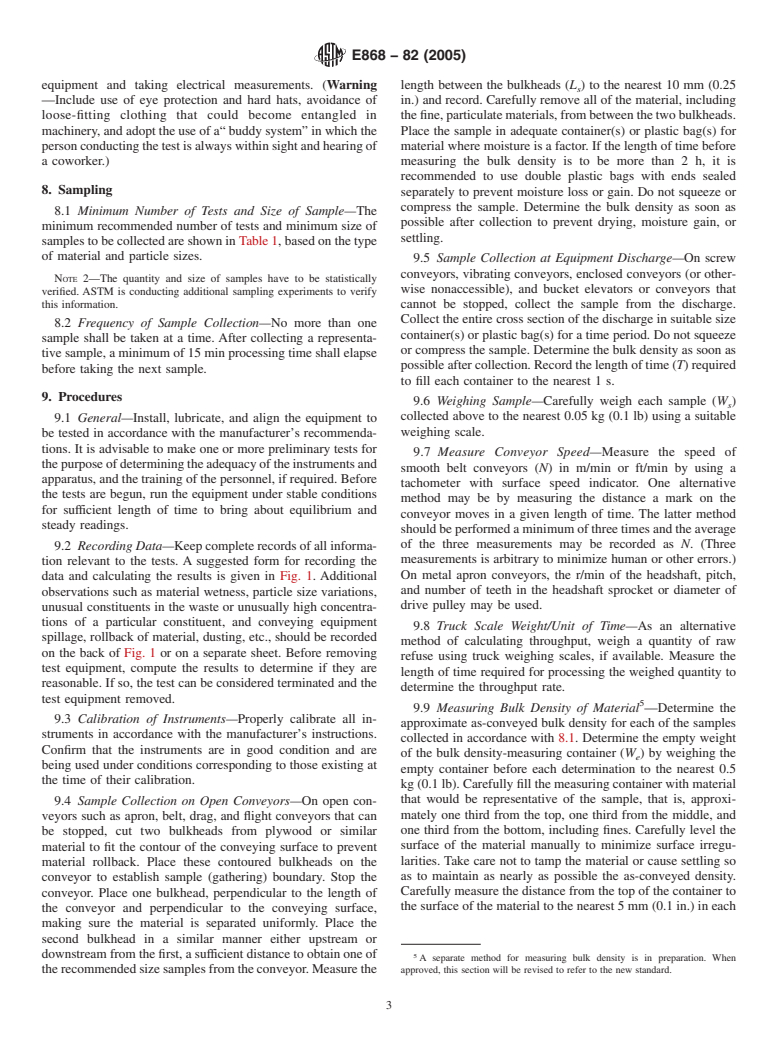

recommended number of test runs and size of samples are size. Suitable handles may be attached to the exterior of the

provided for various types of materials (see Table 1). container to aid in subsequent handling.

4.2 The material flow rate may be reported in any unit;

NOTE 1—Alternatively, containers of other dimensions may be em-

ployed provided the base area is known and sides are perpendicular.

sample calculations are given only for selected (common)

Dimensions of the container shall be a minimum of two times the largest

units.

particle size.

4.3 Motor wattage (or amperage and voltage) may be

6.3 Bulk Density Measuring Rod—A round or square rod,

measured and used to calculate the electrical power consump-

approximately 50 mm (2 in.) in diameter or square by 600 mm

tion.

(2 ft) long, calibrated in 5-mm (0.1-in.) intervals starting from

one end. The end should be cut off square to prevent sinking

5. Significance and Use

into sample.

5.1 These test methods may be used to measure the equip-

6.4 Tachometer or Speed Indicator—A tachometer with

ment performance.

linear speed indicator or surface speed indicator. Indicator may

5.2 These test methods are applicable when the conveying

be hand type with digital readout.

equipmentisofsufficientlengthandisaccessiblefortakingthe

6.5 Wattmeter—Industrial analyzer or individual wattmeter

samples and measuring the speed, or when the discharge is

to provide two wattmeter indications for three-phase power.

accessible to collect a sample in a given length of time. Not all

Meters may be analog or digital type.

pieces of equipment in a processing plant may be accessible;

therefore, the input or total of inputs to adjacent upstream

7. Safety Hazards

equipment/output or total of outputs of adjacent downstream

7.1 These test methods may involve the use of hazardous

equipment may be used to determine the throughput of the

materials, operations, and equipment. It is the responsibility of

conveying equipment in question. Judgement must be used to

whomever uses this standard to establish appropriate safety

determine any loss of material or changes in bulk density.

practices and to determine the applicability of regulatory

6. Apparatus limitations prior to use.

6.1 Ammeter/Voltmeter—Multimeter or individual meters to 7.2 Due to the origins of municipal solid waste, common

permit reading the maximum current and voltage anticipated. sense dictates that some precautions should be observed when

Meters may be the snap-on type with analog or digital readout. conducting tests. Recommended hygienic practices include use

of gloves when handling the waste, wearing dust masks

6.2 Bulk Density-Measuring Container—An open-top con-

(NIOSH-approved type), and washing hands before eating or

tainer constructed of suitable materials such as plywood or

smoking.

plastic and having the following internal dimensions: 300 mm

wide by 300 mm long (1 by 1 ft) and 600 mm (2 ft) high may 7.3 Safety precautions should be taken when measuring

be used for material normally smaller than 150 mm (6 in.) in conveyor speeds or collecting samples near open, moving

TABLE 1 Minimum Number of Test Runs and Sample Sizes for Performance Determination

Normal Top Particle Size, mm Number of Test Sample Size,

Type Description

3 3

(in.) Runs m (ft )

Raw refuse (as discarded) municipal solid waste; residential, 900 (36) max in any one 8 1.5 (50)

commer- cial, and industrial dimension

(excludes oversize bulky waste)

Processed Refuse primary screen undersize 200 (8) 8 0.1 (2)

primary screen oversize 900 (36) max in any one 8 1.5 (50)

dimension

first-stage shredded refuse 300 (12) 8 0.25 (8)

air-classified heavy fraction 300 (12) 8 0.25 (8)

air-classified light fraction 300 (12) 8 0.25 (8)

second-stage shredded light fraction 100 (4) 8 0.25 (1)

screened air-classified light fraction 50 (2) 8 0.25 (1)

densified refuse-derived fuel 40 (1 ⁄2 ) 8 0.25 (1)

3 1

pulverized or powdered RDF 10 ( ⁄8 ) 8 0.25 ( ⁄2)

Magnetic scrap first-stage shredded metal 300 (12) 8 0.25 (1)

light-gage iron scrap after air 300 (12) 8 0.25 (1)

classification

shredded or nuggetized iron scrap 25 (1) 8 0.25 (1)

Nonferrous scrap metal aluminum can stock 100 (4) 8 0.25 (1)

shredded aluminum scrap 50 (2) 8 0.25 (1)

other nonferrous metals 50 (2) 8 0.25 (1)

Mixed glass coarse cullet glass 75 (3) 8 0.25 (1)

fine cullet glass 6 ( ⁄4) 8 0.25 (1)

E868 − 82 (2005)

equipment and taking electrical measurements. (Warning length between the bulkheads (L ) to the nearest 10 mm (0.25

s

—Include use of eye protection and hard hats, avoidance of in.) and record. Carefully remove all of the material, including

loose-fitting clothing that could become entangled in thefine,particulatematerials,frombetweenthetwobulkheads.

machinery, and adopt the use of a“ buddy system” in which the Place the sample in adequate container(s) or plastic bag(s) for

personconductingthetestisalwayswithinsightandhearingof material where moisture is a factor. If the length of time before

a coworker.) measuring the bulk density is to be more than 2 h, it is

recommended to use double plastic bags with ends sealed

8. Sampling

separately to prevent moisture loss or gain. Do not squeeze or

compress the sample. Determine the bulk density as soon as

8.1 Minimum Number of Tests and Size of Sample—The

possible after collection to prevent drying, moisture gain, or

minimum recommended number of tests and minimum size of

settling.

samples to be collected are shown in Table 1, based on the type

of material and particle sizes.

9.5 Sample Collection at Equipment Discharge—On screw

conveyors, vibrating conveyors, enclosed conveyors (or other-

NOTE 2—The quantity and size of samples have to be statistically

wise nonaccessible), and bucket elevators or conveyors that

verified. ASTM is conducting additional sampling experiments

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.