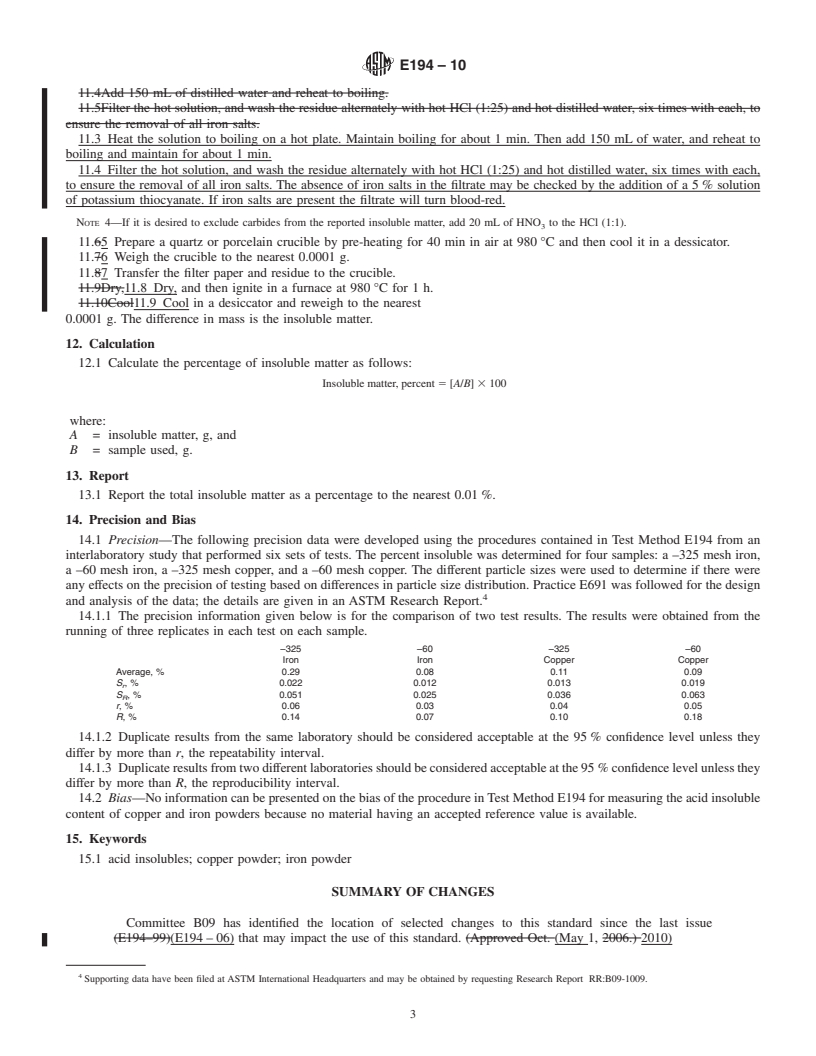

ASTM E194-10

(Test Method)Standard Test Method for Acid-Insoluble Content of Copper and Iron Powders

Standard Test Method for Acid-Insoluble Content of Copper and Iron Powders

SIGNIFICANCE AND USE

The purpose of this test method is to determine the amount of gangue, refractory, inert, etc., materials, that may adversely affect compacting tools and sintered properties of components formed from copper and iron powders.

The insoluble matter consists of those nonmetallic substances that do not dissolve in the mineral acid used to dissolve the metal. In copper powder, which is treated with nitric acid, the acid-insoluble matter includes silica, insoluble silicates, alumina, clays, and other refractory materials that may be introduced either as impurities in the raw material or from the furnace lining, fuel, etc.; lead sulfate may also be present. In iron powder, which is treated with hydrochloric acid, the insoluble matter may include carbides in addition to the substances listed above. The test method excludes insoluble material that is volatile at the ignition temperature specified.

SCOPE

1.1 This test method covers the determination of the mineral-acid-insoluble matter content of copper and iron powders in amounts under 1.0 %.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E194 − 10

StandardTest Method for

1

Acid-Insoluble Content of Copper and Iron Powders

This standard is issued under the fixed designation E194; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 4.2 The insoluble matter consists of those nonmetallic

2

substances that do not dissolve in the mineral acid used to

1.1 This test method covers the determination of the

dissolve the metal. In copper powder, which is treated with

mineral-acid-insoluble matter content of copper and iron pow-

nitric acid, the acid-insoluble matter includes silica, insoluble

ders in amounts under 1.0 %.

silicates, alumina, clays, and other refractory materials that

1.2 This standard does not purport to address all of the

may be introduced either as impurities in the raw material or

safety problems, if any, associated with its use. It is the

from the furnace lining, fuel, etc.; lead sulfate may also be

responsibility of the user of this standard to establish appro-

present. In iron powder, which is treated with hydrochloric

priate safety and health practices and determine the applica-

acid, the insoluble matter may include carbides in addition to

bility of regulatory limitations prior to use.

thesubstanceslistedabove.Thetestmethodexcludesinsoluble

material that is volatile at the ignition temperature specified.

2. Referenced Documents

3

5. Interferences

2.1 ASTM Standards:

B215 Practices for Sampling Metal Powders

5.1 Any metallic tin present in the copper powder will be

E50 Practices for Apparatus, Reagents, and Safety Consid-

converted into the insoluble tin oxide by the nitric acid

erations for Chemical Analysis of Metals, Ores, and

treatment; in such cases, provision shall be made for the

Related Materials

determination of tin oxide and the appropriate correction

E691 Practice for Conducting an Interlaboratory Study to

applied.

Determine the Precision of a Test Method

6. Apparatus

3. Summary of Test Method

6.1 Apparatus and reagents shall conform to the require-

3.1 The sample is dissolved in the appropriate acid: nitric

ments prescribed in Practices E50.

acid (HNO ) for copper, hydrochloric acid (HCl) for iron. The

3

6.2 Hot Plate.

insoluble matter is filtered out and ignited in a furnace at

6.3 Muffle Furnace, capable of operating at 980 °C.

980 °C for 1 h.

6.4 Casseroles (non-metallic), 250 mL and 750 mL.

4. Significance and Use

6.5 Glass Funnel.

4.1 The purpose of this test method is to determine the

6.6 Quart or Porcelain Crucible.

amount of gangue, refractory, inert, etc., materials, that may

6.7 Desiccator.

adversely affect compacting tools and sintered properties of

components formed from copper and iron powders.

6.8 Analytical Balance, having a sensitivity of 0.1 mg.

6.9 Filter Paper, Whatman No. 541 or one of equivalent

pore size and ash content.

1

This test method is under the jurisdiction of ASTM Committee B09 on Metal

Powders and Metal Powder Productsand is the direct responsibility of Subcommit-

6.10 Vapor Collection System, suitable to provide adequate

tee B09.02 on Base Metal Powders.

operator protection from chemical vapors resulting from the

Current edition approved May 1, 2010. Published June 2010. Originally

approved in 1962. Last previous edition approved in 2006 as E194 – 06. DOI: acid digestion steps and muffle furnace ignition steps.

10.1520/E0194-10.

2

Based on the method developed by the Metal Powder Association (now the

7. Reagents

Metal Powder Producers Association of the Metal Powder Industries Federation)

7.1 Hydrochloric Acid HCl (1:1).

and described in MPIF Standard 06, “Determination of Acid Insoluble Matter in

Iron and Copper Powders,” which is a standard of the MPIF.

7.2 Hydrochloric Acid HCl (1:25).

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7.3 Nitric Acid (HNO ).

3

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 7.4 Nitric Acid HNO (1:1).

3

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E194 − 10

7.5 Ammonium Iodide (NH I). IRON POWDER

4

7.6 Potassium Thiocyanate (5%).

11. Procedure

8. Sampling

11.1 Transfer5gofthe sample, weighed to the nearest

0.0001 g, to a 750 mL covered casserole.

8.1 The metal powder shall be sampled in accordance with

Practices B215.

NOTE 3—Some operators report better reproducibility when increasing

8.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E194–06 Designation: E194 – 10

Standard Test Method for

1

Acid-Insoluble Content of Copper and Iron Powders

This standard is issued under the fixed designation E194; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

2

1.1 This test method covers the determination of the mineral-acid-insoluble matter content of copper and iron powders in

amounts under 1.0 %.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

3

2.1 ASTM Standards:

B215 Practices for Sampling Metal Powders

E50 PracticesforApparatus,Reagents,andSafetyConsiderationsforChemicalAnalysisofMetals,Ores,andRelatedMaterials

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Summary of Test Method

3.1 The sample is dissolved in the appropriate acid: nitric acid (HNO ) for copper, hydrochloric acid (HCl) for iron. The

3

insoluble matter is filtered out and ignited in a furnace at 980 °C for 1 h.

4. Significance and Use

4.1 The purpose of this test method is to determine the amount of gangue, refractory, inert, etc., materials, that may adversely

affect compacting tools and sintered properties of components formed from copper and iron powders.

4.2 The insoluble matter consists of those nonmetallic substances that do not dissolve in the mineral acid used to dissolve the

metal. In copper powder, which is treated with nitric acid, the acid-insoluble matter includes silica, insoluble silicates, alumina,

clays, and other refractory materials that may be introduced either as impurities in the raw material or from the furnace lining, fuel,

etc.; lead sulfate may also be present. In iron powder, which is treated with hydrochloric acid, the insoluble matter may include

carbides in addition to the substances listed above. The test method excludes insoluble material that is volatile at the ignition

temperature specified.

5. Interferences

5.1 Any metallic tin present in the copper powder will be converted into the insoluble tin oxide by the nitric acid treatment; in

such cases, provision shall be made for the determination of tin oxide and the appropriate correction applied.

6. Apparatus

6.1 Apparatus and reagents shall conform to the requirements prescribed in Practices E50.

6.2 Hot Plate.

6.3 Muffle Furnace, capable of operating at 980 °C.

6.4 Casseroles (non-metallic), 250 mL and 750 mL.

6.5 Glass Funnel.

6.6 Quart or Porcelain Crucible.

1

This test method is under the jurisdiction of ASTM Committee B09 on Metal Powders and Metal Powder Products and is the direct responsibility of Subcommittee

B09.02 on Base Metal Powders.

Current edition approved Oct.May 1, 2006.2010. Published October 2006.June 2010. Originally approved in 1962. Last previous edition approved in 19992006 as

E194–99.E194 – 06. DOI: 10.1520/E0194-106.

2

BasedonthemethoddevelopedbytheMetalPowderAssociation(nowtheMetalPowderProducersAssociationoftheMetalPowderIndustriesFederation)anddescribed

in MPIF Standard 06, “Determination of Acid Insoluble Matter in Iron and Copper Powders,” which is a standard of the MPIF.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E194 – 10

6.7 Desiccator.

6.8 Analytical Balance, having a sensitivity of 0.1 mg.

6.9 Filter Paper, Whatman No. 541 or one of equivalent pore size and ash content.

6.10 Vapor Collection System, suitable to provide adequate operator protection from chemical vapors resulting from the acid

digestion steps and muffle furnace ignition steps.

7. Reagents

7.1 Hydrochloric Acid HCl (1:1).

7.2 Hydrochloric Acid HCl (1:25).

7.3 Nitric Acid (HNO ).

3

7.4 Nitric Acid HNO (1:1).

3

7.5 Ammonium Iodide (NH I).

4

7.6 Potassium Thio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.