ASTM F1099M-98(2005)

(Specification)Standard Specification for Rat Guards, Ship's (Metric)

Standard Specification for Rat Guards, Ship's (Metric)

ABSTRACT

This specification covers the materials, dimensions, and assembly of steel and aluminum rat guards intended to prevent rats from boarding ships by way of mooring lines. Rat guards shall be classified into three types, namely: Type I, Type II, and Type III. Type I rat guards shall be made of the prescribed aluminum-alloy sheet metal; Type II rat guards shall be made of the prescribed galvanized sheet steel; and Type III rat guards shall be made of either of these specified materials. Types I and II rat guards shall be provided with the following: hinge bolt, guide and tie rope, and grommet. Type III rat guards shall consist of two half disks and two half tapered sleeves and the hinge bolt provided with each rat guard shall consist of a commercial hexagon head bolt, nut, and washer, all made of corrosion resistant steel. The dimensional requirements such as thickness of disk, sleeve, and guide for galvanized steel or aluminum sleeve of Type III rat guard are specified. Type I and Type II rat guard configurations and Type III rat guard assembly are detailed and illustrated.

SCOPE

1.1 This specification covers the materials, dimensions, and assembly of steel and aluminum rat guards.

1.2 Rat guards are intended to prevent rats from boarding ships by way of mooring lines.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F1099M – 98 (Reapproved 2005)

Standard Specification for

Rat Guards, Ship’s (Metric)

This standard is issued under the fixed designation F1099M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

TABLE 1 Mooring Line Combinations for Type I Rat Guards

1. Scope

Mooring Lines Diameter, mm Number of Lines

1.1 This specification covers the materials, dimensions, and

5 wire as required

assembly of steel and aluminum rat guards.

25-33 line 3 or more

1.2 Rat guards are intended to prevent rats from boarding

41-50 line 3

ships by way of mooring lines.

50-82 line 2

1.3 The values stated in SI units are to be regarded as the

standard.

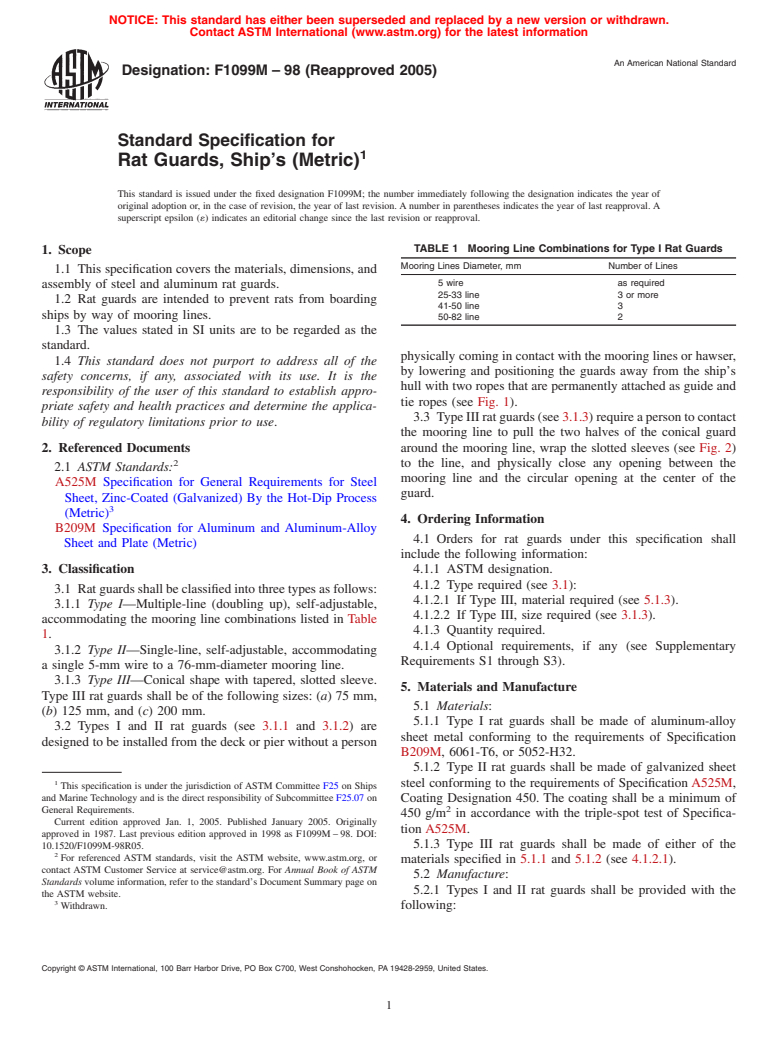

physically coming in contact with the mooring lines or hawser,

1.4 This standard does not purport to address all of the

by lowering and positioning the guards away from the ship’s

safety concerns, if any, associated with its use. It is the

hull with two ropes that are permanently attached as guide and

responsibility of the user of this standard to establish appro-

tie ropes (see Fig. 1).

priate safety and health practices and determine the applica-

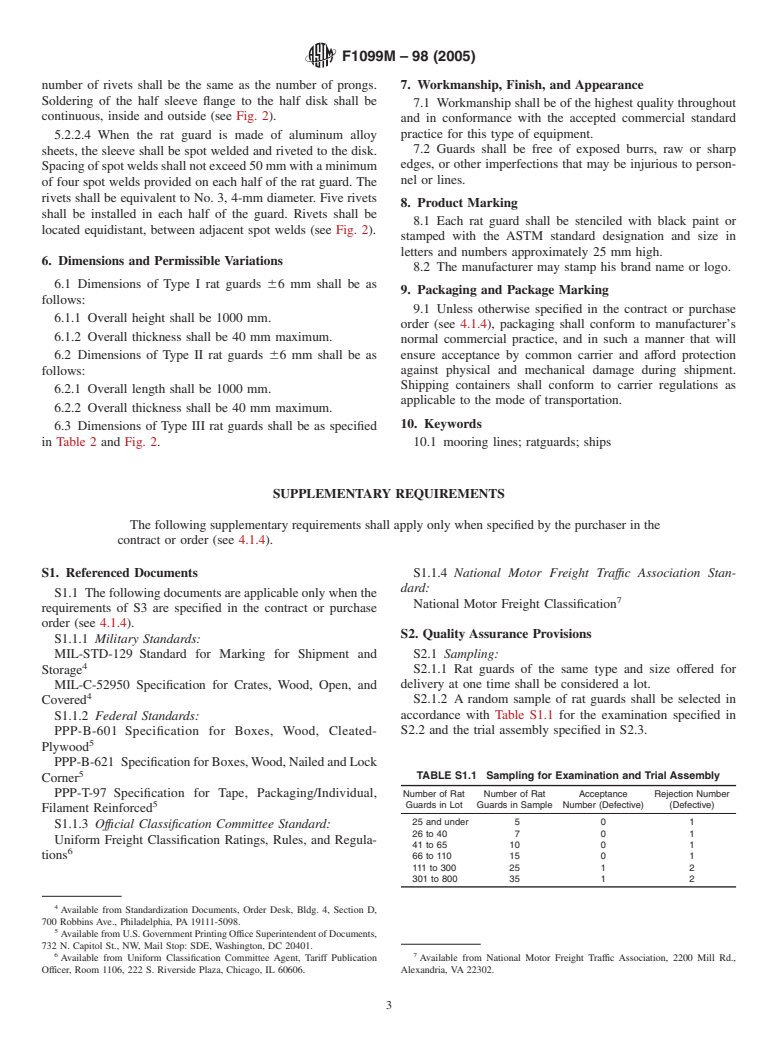

3.3 TypeIIIratguards(see3.1.3)requireapersontocontact

bility of regulatory limitations prior to use.

the mooring line to pull the two halves of the conical guard

2. Referenced Documents around the mooring line, wrap the slotted sleeves (see Fig. 2)

to the line, and physically close any opening between the

2.1 ASTM Standards:

mooring line and the circular opening at the center of the

A525M Specification for General Requirements for Steel

guard.

Sheet, Zinc-Coated (Galvanized) By the Hot-Dip Process

(Metric)

4. Ordering Information

B209M Specification for Aluminum and Aluminum-Alloy

4.1 Orders for rat guards under this specification shall

Sheet and Plate (Metric)

include the following information:

3. Classification 4.1.1 ASTM designation.

4.1.2 Type required (see 3.1):

3.1 Ratguardsshallbeclassifiedintothreetypesasfollows:

4.1.2.1 If Type III, material required (see 5.1.3).

3.1.1 Type I—Multiple-line (doubling up), self-adjustable,

4.1.2.2 If Type III, size required (see 3.1.3).

accommodating the mooring line combinations listed in Table

4.1.3 Quantity required.

1.

4.1.4 Optional requirements, if any (see Supplementary

3.1.2 Type II—Single-line, self-adjustable, accommodating

Requirements S1 through S3).

a single 5-mm wire to a 76-mm-diameter mooring line.

3.1.3 Type III—Conical shape with tapered, slotted sleeve.

5. Materials and Manufacture

Type III rat guards shall be of the following sizes: (a)75mm,

5.1 Materials:

(b) 125 mm, and (c) 200 mm.

5.1.1 Type I rat guards shall be made of aluminum-alloy

3.2 Types I and II rat guards (see 3.1.1 and 3.1.2) are

sheet metal conforming to the requirements of Specification

designed to be installed from the deck or pier without a person

B209M, 6061-T6, or 5052-H32.

5.1.2 Type II rat guards shall be made of galvanized sheet

steel conforming to the requirements of Specification A525M,

This specification is under the jurisdiction of ASTM Committee F25 on Ships

and Marine Technology and is the direct responsibility of Subcommittee F25.07 on

Coating Designation 450. The coating shall be a minimum of

General Requirements.

450 g/m in accordance with the triple-spot test of Specifica-

Current edition approved Jan. 1, 2005. Published January 2005. Originally

tion A525M.

approved in 1987. Last previous edition approved in 1998 as F1099M – 98. DOI:

5.1.3 Type III rat guards shall be made of either of the

10.1520/F1099M-98R05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

materials specified in 5.1.1 and 5.1.2 (see 4.1.2.1).

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.2 Manufacture:

Standards volume information, refer to the standard’s Document Summary page on

5.2.1 Types I and II rat guards shall be provided with the

the ASTM website.

Withdrawn. following:

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1099M – 98 (2005)

FIG. 2 Assembly of Type III Rat Guards

5.2.2 Type III Rat Guards—Type III rat guards shall consist

of two half disks and two half tapered sleeves. Both halves

shall be identical except one half shall be provided with a “U”

shaped sleeve.

5.2.2.1 The hinge bolt provided with each rat guard shall

consist of a commercial M 7 3 1 hexagon head bolt,

20-mm-long nut, and washer. All parts shall be corrosion-

resistant steel.

5.2.2.2 The galvanized steel or aluminum sleeve shall be

slotted as specified in Table 2 and Fig. 2, so that when the rat

guard is in place, it may be drawn tightly against the hawser,

with lashing. The formed sleeves shall be tapered to permit

nesting of the rat guards, for compact shipping.

5.2.2.3 When the rat guard is made of galvanized steel, the

sleeve shall be riveted and soldered to the disk with tinner’s

type rivets, No. 3, 4-mm diameter for each half sleeve. The

FIG. 1 Types I and II Rat Guard Configuration TABLE 2 Dimensions for Type III Rat Guards

Number of

Dimensions (see Thickness of Disk, Sleeve,

Prongs in

5.2.1.1 Hinge Bolt—An M 7 3 1 hexagon head bolt 20 mm Fig. 2), mm and Guide, mm

Complete

Size

long with elastic stop nut and washer. All parts shall be

Sleeve

Steel, Galvanized Aluminum

(See

corrosion-resistant steel. AB

Sheet Alloy Sheet

5.2.2.2)

5.2.1.2 Guide and Tie Rope—Polyester or nylon of good

75 75 1000 6 1.4 1.6

commercial quality, 6- or 9-mm diameter by 6 m long.

125 125 1300 10 1.4 1.6

5.2.1.3 Grommet—Good commercial quality brass and of

200 200 1300 16 1.4 1.6

size suitable for the guide and tie ropes.

F1099M – 98 (2005)

number of rivets shall be the same as the number of prongs. 7. Workmanship, Finish, and Appearance

Soldering of the half sleeve flange to the half disk shall be

7.1 Workmanship shall be of the highest quality throughout

continuous, inside and outside (see Fig. 2).

and in conformance with the accepted commercial standard

practice for this type of equipment.

5.2.2.4 When the rat guard is made of aluminum alloy

7.2 Guards shall be free of exposed burrs, raw or sharp

sheets, the sleeve shall be spot welded and riveted to the disk.

edges, or other imperfections that may be injurious to person-

Spacingofspotweldsshallnotexceed50mmwithaminimum

nel or lines.

of four spot welds provided on each half of the rat guard. The

rivets shall be equivalent to No. 3, 4-mm diameter. Five rivets

8. Product Marking

shall be installed in each half of the guard. Rivets shall be

8.1 Each rat guard shall be stenciled with black paint or

located equidistant, between adjacent spot welds (see Fig. 2).

stamped with the ASTM standard designation and size in

letters and numbers approximately 25 mm high.

6. Dimensions and Permissible Variations

8.2 The manufacturer may stamp his brand name or logo.

6.1 Dimensions of Type I rat guards 66 mm shall be as

9. Packaging and Package Marking

follows:

9.1 Unless otherwise specified in the contract or purchase

6.1.1 Overall height shall be 1000 mm.

order (see 4.1.4), packaging shall conform to manufacturer’s

6.1.2 Overall thickness shall be 40 mm maximum.

normal commercial practice, and in such a manner that will

6.2 Dimensions of Type II rat guards 66 mm shall be as ensure acceptance by common carrier and afford protection

against physical and mechanical damage during shipment.

follows:

Shipping containers shall conform to carrier regulations as

6.2.1 Overall length shall be 1000 mm.

applicable to the mode of transportation.

6.2.2 Overall thickness shall be 40 mm maximum.

10. Keywords

6.3 Dimensions of Type III rat guards shall be as specified

in Table 2 and Fig. 2. 10.1 mooring lines; ratguards; ships

SUPPLEMENTA

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.