ASTM D1552-08(2014)e1

(Test Method)Standard Test Method for Sulfur in Petroleum Products (High-Temperature Method)

Standard Test Method for Sulfur in Petroleum Products (High-Temperature Method)

SIGNIFICANCE AND USE

4.1 This test method provides a means of monitoring the sulfur level of various petroleum products and additives. This knowledge can be used to predict performance, handling, or processing properties. In some cases the presence of sulfur compounds is beneficial to the product and monitoring the depletion of sulfur can provide useful information. In other cases the presence of sulfur compounds is detrimental to the processing or use of the product.

SCOPE

1.1 This test method covers three procedures for the determination of total sulfur in petroleum products including lubricating oils containing additives, and in additive concentrates. This test method is applicable to samples boiling above 177°C (350°F) and containing not less than 0.06 mass % sulfur. Two of the three procedures use iodate detection; one employing an induction furnace for pyrolysis, the other a resistance furnace. The third procedure uses IR detection following pyrolysis in a resistance furnace.

1.2 Petroleum coke containing up to 8 mass % sulfur can be analyzed.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D1552 − 08(Reapproved 2014)

Standard Test Method for

Sulfur in Petroleum Products (High-Temperature Method)

This standard is issued under the fixed designation D1552; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Footnotes were updated editorially in September 2014.

1. Scope Measurement System Performance

D6792 Practice for Quality System in Petroleum Products

1.1 This test method covers three procedures for the deter-

and Lubricants Testing Laboratories

mination of total sulfur in petroleum products including

lubricating oils containing additives, and in additive concen-

3. Summary of Test Method

trates. This test method is applicable to samples boiling above

3.1 Iodate Detection System—The sample is burned in a

177°C(350°F)andcontainingnotlessthan0.06mass %sulfur.

stream of oxygen at a sufficiently high temperature to convert

Two of the three procedures use iodate detection; one employ-

about 97 % of the sulfur to sulfur dioxide. A standardization

ing an induction furnace for pyrolysis, the other a resistance

factor is employed to obtain accurate results. The combustion

furnace. The third procedure uses IR detection following

products are passed into an absorber containing an acid

pyrolysis in a resistance furnace.

solution of potassium iodide and starch indicator. A faint blue

1.2 Petroleum coke containing up to 8 mass % sulfur can be

color is developed in the absorber solution by the addition of

analyzed.

standard potassium iodate solution. As combustion proceeds,

bleaching the blue color, more iodate is added. The amount of

1.3 The values stated in SI units are to be regarded as the

standard iodate consumed during the combustion is a measure

standard. The values given in parentheses are for information

of the sulfur content of the sample.

only.

1.4 This standard does not purport to address all of the 3.2 IR Detection System—The sample is weighed into a

safety concerns, if any, associated with its use. It is the special ceramic boat which is then placed into a combustion

responsibility of the user of this standard to establish appro- furnace at 1371°C (2500°F) in an oxygen atmosphere. Most

priate safety and health practices and determine the applica-

sulfur present is combusted to SO which is then measured

bility of regulatory limitations prior to use. with an infrared detector after moisture and dust are removed

by traps. A microprocessor calculates the mass percent sulfur

2. Referenced Documents

from the sample weight, the integrated detector signal and a

predeterminedcalibrationfactor.Boththesampleidentification

2.1 ASTM Standards:

number and mass percent sulfur are then printed out. The

D1193 Specification for Reagent Water

calibration factor is determined using standards approximating

D1266 Test Method for Sulfur in Petroleum Products (Lamp

the material to be analyzed.

Method)

D4057 Practice for Manual Sampling of Petroleum and

4. Significance and Use

Petroleum Products

4.1 This test method provides a means of monitoring the

D6299 Practice for Applying Statistical Quality Assurance

sulfur level of various petroleum products and additives. This

and Control Charting Techniques to Evaluate Analytical

knowledge can be used to predict performance, handling, or

processing properties. In some cases the presence of sulfur

This test method is under the jurisdiction of ASTM Committee D02 on

compounds is beneficial to the product and monitoring the

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

depletion of sulfur can provide useful information. In other

Subcommittee D02.03 on Elemental Analysis.

cases the presence of sulfur compounds is detrimental to the

Current edition approved June 15, 2014. Published July 2014. Originally

approved in 1958. Last previous edition approved in 2008 as D1552–08. DOI: processing or use of the product.

10.1520/D1552-08R14E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 5. Interferences

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1 For the iodate systems, chlorine in concentrations less

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. than 1 mass % does not interfere. The IR system can tolerate

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D1552 − 08 (2014)

somewhat higher concentrations. Nitrogen when present in

excessof0.1mass %mayinterferewiththeiodatesystems;the

extent of such interference may be dependent on the type of

nitrogen compound as well as the combustion conditions.

Nitrogen does not interfere with the IR system. The alkali and

alkaline earth metals, as well as zinc, phosphorus, and lead, do

not interfere with either system.

6. Apparatus

6.1 Combustion and Iodate Detection System:

6.1.1 Furnaces—Twomajortypesareavailable,theprimary

difference being the manner in which the necessary high

temperatures are obtained. These two types are as follows:

6.1.1.1 Induction Type, which depends upon the high-

frequency electrical induction method of heating. This assem-

bly shall be capable of attaining a temperature of at least

1482°C (2700°F) in the sample combustion zone, under the FIG. 1 Combustion Tube

conditions set forth in 9.1 and shall be equipped with an

additional induction coil located above the combustion zone,

substantially as shown in Fig. 1.

6.1.1.2 The furnace work coil should have a minimum all reagents shall conform to the specifications of the Commit-

outputof500 W;theminimuminputratingofthefurnacemust

tee onAnalytical Reagents of theAmerican Chemical Society,

be 1000 W. With the correct amount of iron chips, weighed to where such specifications are available. Other grades may be

60.05 g, the maximum plate current will be between 350 and

used, provided it is first ascertained that the reagent is of

450 mA. (Warning—This type of furnace is capable of sufficiently high purity to permit its use without lessening the

inflicting high frequency burns and high-voltage shocks. In

accuracy of the determination.

addition to other precautions, maintain all guards properly.)

7.2 Purity of Water—Unless otherwise indicated, references

(Warning—Disconnect the furnace from the power line when-

to water shall be understood to mean reagent water as defined

ever electrical repairs or adjustments are made.)

by Type II or III of Specification D1193.

6.1.1.3 Resistance Type, capable of maintaining a tempera-

7.3 Alundum (Al O )or Magnesium Oxide (Com-Aid).

2 3

ture of at least 1371°C (2500°F).

6.1.2 Absorber, as described in Test Method D1266.

7.4 Anhydrone (Magnesium Perchlorate). (Warning—In

addition to other precautions, handle magnesium perchlorate

NOTE 1—Also suitable for use with either type of furnace is an

with care.Avoid contacting it with acid and organic materials.

automatic titrator, specifically designed for iodometry. This combines the

functions of absorption and titration to a predetermined end point. Reactions with fuel may be violent.)

6.1.3 Buret, standard 25-mL or automatic types available

7.5 Hydrochloric Acid (3 + 197)—Dilute 30 mL of concen-

from the manufacturers of the specific combustion units, are

tratedhydrochloricacid(HCl,relativedensity1.19)to2Lwith

suitable (Note 1).

water. (Warning—Poison. Corrosive. May be fatal if swal-

lowed. Liquid and vapor cause severe burns.)

6.2 Combustion and IR Detection System, comprised of

automatic balance, oxygen flow controls, drying tubes, com-

7.6 Oxygen (Extra Dry)—The oxygen shall be at least

bustion furnace, infrared detector and microprocessor. The

99.5 % pure and show no detectable sulfur by blank determi-

furnace shall be capable of maintaining a nominal operating

nation. (Warning—Oxygen vigorously accelerates combus-

temperature of 1350°C (2460°F).

tion.)

6.3 Miscellaneous Apparatus—Specific combustion assem-

7.7 Phosphorus Pentoxide—(P O ).

2 5

blies require additional equipment such as crucibles, combus-

7.8 Potassium Alum (Aluminum Potassium Sulfate).

tion boats, crucible lids, boat pushers, separator disks, com-

bustion tubes, sample inserters, oxygen flow indicator, and 7.9 Potassium Iodate, Standard Solution (0.06238 N), 1 mL

of this solution is equivalent to 1 mg S)—Dissolve 2.225 g of

oxygen drying trains. The additional equipment required is

potassium iodate (KIO ) that has been dried at about 180°C to

dependentonthetypeoffurnaceusedandisavailablefromthe

constantweight,inwateranddiluteto1L.Thoroughlymixthe

manufacturer of the specific combustion unit. To attain the

solution.

lower sulfur concentration given in Section 1, the ceramics

used with the induction furnace assembly shall be ignited in a

muffle furnace at 1371°C (2500°F) for at least 4 h before use.

Reagent Chemicals, American Chemical Society Specifications, American

6.4 Sieve, 60-mesh (250-mm).

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

listed by the American Chemical Society, see Annual Standards for Laboratory

7. Reagents and Materials

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

7.1 Purity of Reagents—Reagent grade chemicals shall be

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

used in all tests. Unless otherwise indicated, it is intended that MD.

´1

D1552 − 08 (2014)

7.10 Potassium Iodate, Standard Solution (0.006238 N),

1 mL of this solution is equivalent to 0.1 mg S)—Measure

exactly 100 mL of KIO solution (0.06238 N) into a 1–L

volumetric flask, and dilute to volume with water. Thoroughly

mix the solution.

7.11 Potassium Iodate, Standard Solution (0.01248 N),

1 mL of this solution is equivalent to 0.2 mg S)—Measure

exactly 200 mL of KIO solution (0.06238 N) into a 1-L

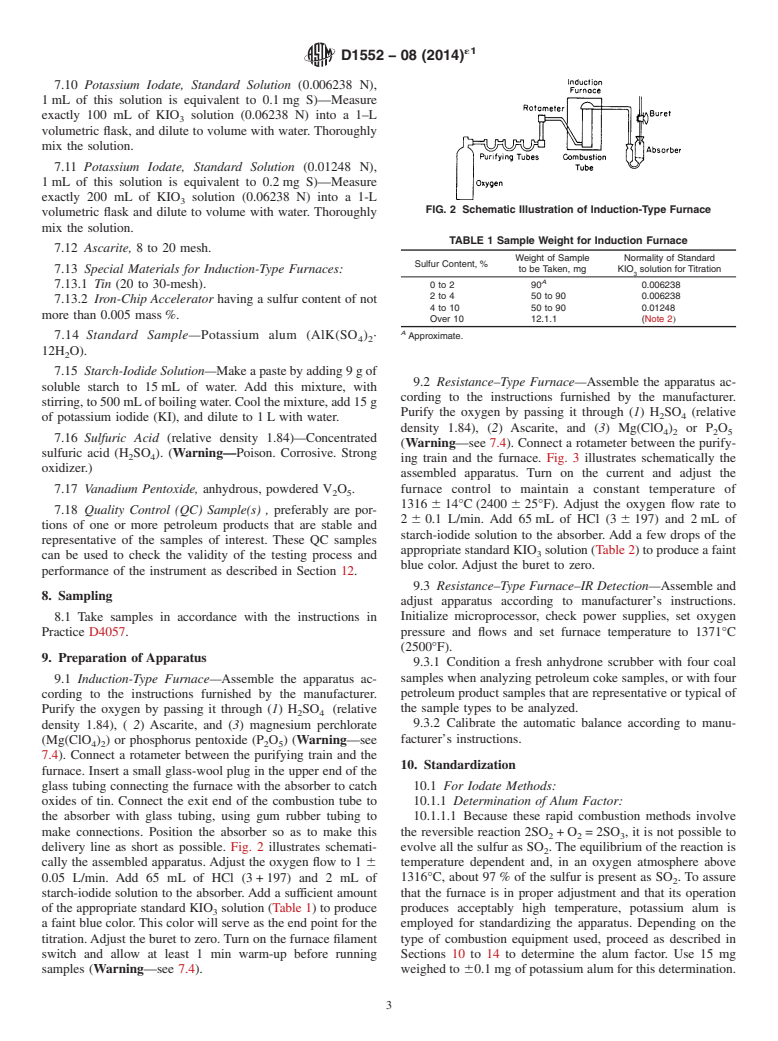

FIG. 2 Schematic Illustration of Induction-Type Furnace

volumetric flask and dilute to volume with water. Thoroughly

mix the solution.

TABLE 1 Sample Weight for Induction Furnace

7.12 Ascarite, 8 to 20 mesh.

Weight of Sample Normality of Standard

Sulfur Content, %

to be Taken, mg KIO solution for Titration

7.13 Special Materials for Induction-Type Furnaces:

A

7.13.1 Tin (20 to 30-mesh). 0to2 90 0.006238

2 to 4 50 to 90 0.006238

7.13.2 Iron-Chip Accelerator having a sulfur content of not

4 to 10 50 to 90 0.01248

more than 0.005 mass %.

Over 10 12.1.1 (Note 2)

A

7.14 Standard Sample—Potassium alum (AlK(SO ) · Approximate.

4 2

12H O).

7.15 Starch-Iodide Solution—Make a paste by adding9gof

9.2 Resistance–Type Furnace—Assemble the apparatus ac-

soluble starch to 15 mL of water. Add this mixture, with

cording to the instructions furnished by the manufacturer.

stirring,to500 mLofboilingwater.Coolthemixture,add15 g

Purify the oxygen by passing it through (1)H SO (relative

2 4

of potassium iodide (KI), and dilute to 1 L with water.

density 1.84), (2) Ascarite, and (3) Mg(ClO ) or P O

4 2 2 5

7.16 Sulfuric Acid (relative density 1.84)—Concentrated

(Warning—see 7.4). Connect a rotameter between the purify-

sulfuric acid (H SO ). (Warning—Poison. Corrosive. Strong

2 4

ing train and the furnace. Fig. 3 illustrates schematically the

oxidizer.)

assembled apparatus. Turn on the current and adjust the

7.17 Vanadium Pentoxide, anhydrous, powdered V O . furnace control to maintain a constant temperature of

2 5

1316 6 14°C (2400 6 25°F). Adjust the oxygen flow rate to

7.18 Quality Control (QC) Sample(s) , preferably are por-

2 6 0.1 L/min. Add 65 mL of HCl (3 6 197) and 2 mL of

tions of one or more petroleum products that are stable and

starch-iodide solution to the absorber. Add a few drops of the

representative of the samples of interest. These QC samples

appropriate standard KIO solution (Table 2) to produce a faint

can be used to check the validity of the testing process and

blue color. Adjust the buret to zero.

performance of the instrument as described in Section 12.

9.3 Resistance–Type Furnace–IR Detection—Assemble and

8. Sampling

adjust apparatus according to manufacturer’s instructions.

Initialize microprocessor, check power supplies, set oxygen

8.1 Take samples in accordance with the instructions in

Practice D4057. pressure and flows and set furnace temperature to 1371°C

(2500°F).

9. Preparation of Apparatus

9.3.1 Condition a fresh anhydrone scrubber with four coal

samples when analyzing petroleum coke samples, or with four

9.1 Induction-Type Furnace—Assemble the apparatus ac-

petroleum product samples that are representative or typical of

cording to the instructions furnished by the manufacturer.

the sample types to be analyzed.

Purify the oxygen by passing it through (1)H SO (relative

2 4

9.3.2 Calibrate the automatic balance according to manu-

density 1.84), ( 2) Ascarite, and (3) magnesium perchlorate

facturer’s instructions.

(Mg(ClO ) ) or phosphorus pentoxide (P O)(Warning—see

4 2 2 5

7.4). Connect a rotameter between the purifying train and the

10. Standardization

furnace. Insert a small glass-wool plug in the upper end of the

glass tubing connecting the furnace with the absorber to catch 10.1 For Iodate Methods:

oxides of tin. Connect the exit end of the combustion tube to 10.1.1 Determination of Alum Factor:

the absorber with glass tubing, using gum rubber tubing to 10.1.1.1 Because these rapid combustion methods involve

make connections. Position the absorber so as to make this the reversible reaction 2SO +O = 2SO , it is not possible to

2 2 3

delivery line as short as possible. Fig. 2 illustrates schemati- evolve all the sulfur as SO . The equilibrium of the reaction is

cally the assembled apparatus. Adjust the oxygen flow to 1 6 temperature dependent and, in an oxygen atmosphere above

0.05 L/min. Add 65 mL of HCl (3 + 197) and 2 mL of 1316°C, about 97 % of the sulfur is present as SO . To assure

starch-iodide solution to the absorber. Add a sufficient amount that the furnace is in proper adjustment and that its operation

of the appropriate standard KIO solution (Table 1) to produce produces acceptably high temperature, potassium alum is

a faint blue color. This color will serve as the end point for the employed for standardizing the apparatus. Depending on the

titration.Adjust the buret to zero. Turn on the furnace filament type of combustion equipment used, proceed as described in

switch and allow at least 1 min warm-up before running Sections 10 to 14 to determine the alum factor. Use 15 mg

samples (Warnin

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D1552 − 08 (Reapproved 2014) D1552 − 08 (Reapproved 2014)

Standard Test Method for

Sulfur in Petroleum Products (High-Temperature Method)

This standard is issued under the fixed designation D1552; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Footnotes were updated editorially in September 2014.

1. Scope

1.1 This test method covers three procedures for the determination of total sulfur in petroleum products including lubricating

oils containing additives, and in additive concentrates. This test method is applicable to samples boiling above 177°C (350°F) and

containing not less than 0.06 mass % sulfur. Two of the three procedures use iodate detection; one employing an induction furnace

for pyrolysis, the other a resistance furnace. The third procedure uses IR detection following pyrolysis in a resistance furnace.

1.2 Petroleum coke containing up to 8 mass % sulfur can be analyzed.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D1266 Test Method for Sulfur in Petroleum Products (Lamp Method)

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

D6792 Practice for Quality System in Petroleum Products and Lubricants Testing Laboratories

3. Summary of Test Method

3.1 Iodate Detection System—The sample is burned in a stream of oxygen at a sufficiently high temperature to convert about

97 % of the sulfur to sulfur dioxide. A standardization factor is employed to obtain accurate results. The combustion products are

passed into an absorber containing an acid solution of potassium iodide and starch indicator. A faint blue color is developed in the

absorber solution by the addition of standard potassium iodate solution. As combustion proceeds, bleaching the blue color, more

iodate is added. The amount of standard iodate consumed during the combustion is a measure of the sulfur content of the sample.

3.2 IR Detection System—The sample is weighed into a special ceramic boat which is then placed into a combustion furnace

at 1371°C (2500°F) in an oxygen atmosphere. Most sulfur present is combusted to SO which is then measured with an infrared

detector after moisture and dust are removed by traps. A microprocessor calculates the mass percent sulfur from the sample weight,

the integrated detector signal and a predetermined calibration factor. Both the sample identification number and mass percent sulfur

are then printed out. The calibration factor is determined using standards approximating the material to be analyzed.

4. Significance and Use

4.1 This test method provides a means of monitoring the sulfur level of various petroleum products and additives. This

knowledge can be used to predict performance, handling, or processing properties. In some cases the presence of sulfur compounds

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.03 on Elemental Analysis.

Current edition approved June 15, 2014. Published July 2014. Originally approved in 1958. Last previous edition approved in 2008 as D1552–08. DOI:

10.1520/D1552-08R14.10.1520/D1552-08R14E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D1552 − 08 (2014)

is beneficial to the product and monitoring the depletion of sulfur can provide useful information. In other cases the presence of

sulfur compounds is detrimental to the processing or use of the product.

5. Interferences

5.1 For the iodate systems, chlorine in concentrations less than 1 mass % does not interfere. The IR system can tolerate

somewhat higher concentrations. Nitrogen when present in excess of 0.1 mass % may interfere with the iodate systems; the extent

of such interference may be dependent on the type of nitrogen compound as well as the combustion conditions. Nitrogen does not

interfere with the IR system. The alkali and alkaline earth metals, as well as zinc, phosphorus, and lead, do not interfere with either

system.

6. Apparatus

6.1 Combustion and Iodate Detection System:

6.1.1 Furnaces—Two major types are available, the primary difference being the manner in which the necessary high

temperatures are obtained. These two types are as follows:

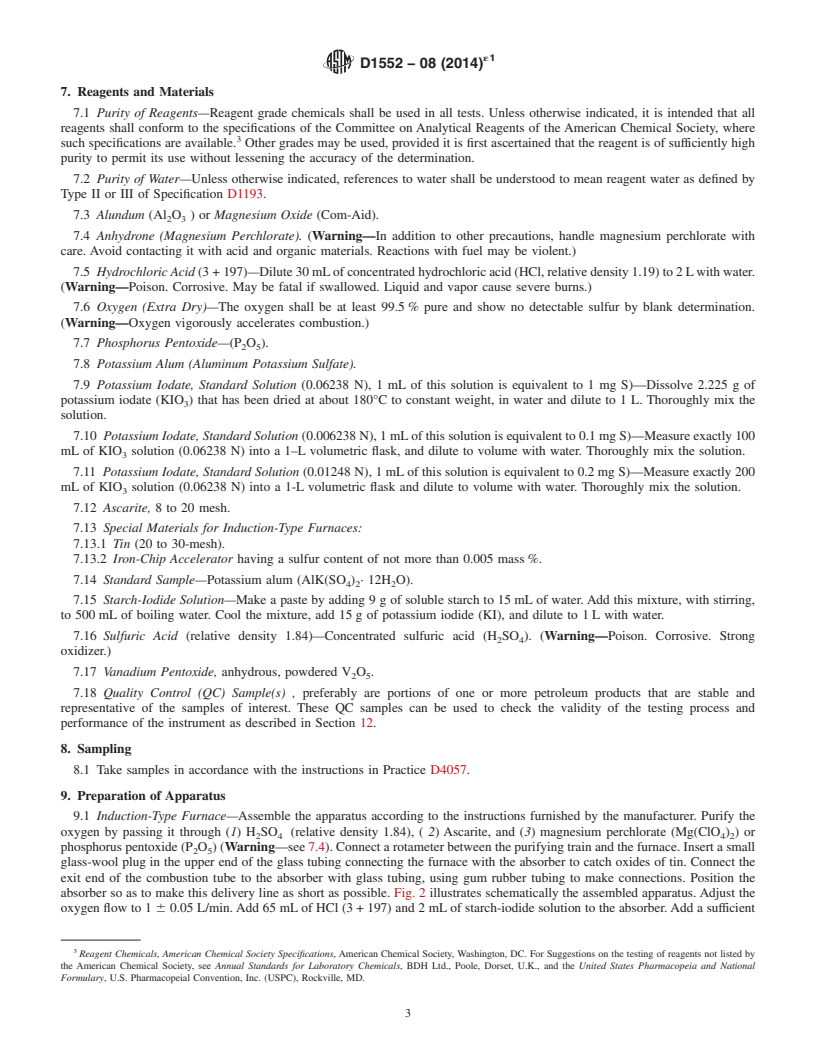

6.1.1.1 Induction Type, which depends upon the high-frequency electrical induction method of heating. This assembly shall be

capable of attaining a temperature of at least 1482°C (2700°F) in the sample combustion zone, under the conditions set forth in

9.1 and shall be equipped with an additional induction coil located above the combustion zone, substantially as shown in Fig. 1.

6.1.1.2 The furnace work coil should have a minimum output of 500 W; the minimum input rating of the furnace must be 1000

W. With the correct amount of iron chips, weighed to 60.05 g, the maximum plate current will be between 350 and 450 mA.

(Warning—This type of furnace is capable of inflicting high frequency burns and high-voltage shocks. In addition to other

precautions, maintain all guards properly.) (Warning—Disconnect the furnace from the power line whenever electrical repairs or

adjustments are made.)

6.1.1.3 Resistance Type, capable of maintaining a temperature of at least 1371°C (2500°F).

6.1.2 Absorber, as described in Test Method D1266.

NOTE 1—Also suitable for use with either type of furnace is an automatic titrator, specifically designed for iodometry. This combines the functions of

absorption and titration to a predetermined end point.

6.1.3 Buret, standard 25-mL or automatic types available from the manufacturers of the specific combustion units, are suitable

(Note 1).

6.2 Combustion and IR Detection System, comprised of automatic balance, oxygen flow controls, drying tubes, combustion

furnace, infrared detector and microprocessor. The furnace shall be capable of maintaining a nominal operating temperature of

1350°C (2460°F).

FIG. 1 Combustion Tube

6.3 Miscellaneous Apparatus—Specific combustion assemblies require additional equipment such as crucibles, combustion

boats, crucible lids, boat pushers, separator disks, combustion tubes, sample inserters, oxygen flow indicator, and oxygen drying

trains. The additional equipment required is dependent on the type of furnace used and is available from the manufacturer of the

specific combustion unit. To attain the lower sulfur concentration given in Section 1, the ceramics used with the induction furnace

assembly shall be ignited in a muffle furnace at 1371°C (2500°F) for at least 4 h before use.

6.4 Sieve, 60-mesh (250-mm).

´1

D1552 − 08 (2014)

7. Reagents and Materials

7.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

7.2 Purity of Water—Unless otherwise indicated, references to water shall be understood to mean reagent water as defined by

Type II or III of Specification D1193.

7.3 Alundum (Al O ) or Magnesium Oxide (Com-Aid).

2 3

7.4 Anhydrone (Magnesium Perchlorate). (Warning—In addition to other precautions, handle magnesium perchlorate with

care. Avoid contacting it with acid and organic materials. Reactions with fuel may be violent.)

7.5 Hydrochloric Acid (3 + 197)—Dilute 30 mL of concentrated hydrochloric acid (HCl, relative density 1.19) to 2 L with water.

(Warning—Poison. Corrosive. May be fatal if swallowed. Liquid and vapor cause severe burns.)

7.6 Oxygen (Extra Dry)—The oxygen shall be at least 99.5 % pure and show no detectable sulfur by blank determination.

(Warning—Oxygen vigorously accelerates combustion.)

7.7 Phosphorus Pentoxide—(P O ).

2 5

7.8 Potassium Alum (Aluminum Potassium Sulfate).

7.9 Potassium Iodate, Standard Solution (0.06238 N), 1 mL of this solution is equivalent to 1 mg S)—Dissolve 2.225 g of

potassium iodate (KIO ) that has been dried at about 180°C to constant weight, in water and dilute to 1 L. Thoroughly mix the

solution.

7.10 Potassium Iodate, Standard Solution (0.006238 N), 1 mL of this solution is equivalent to 0.1 mg S)—Measure exactly 100

mL of KIO solution (0.06238 N) into a 1–L volumetric flask, and dilute to volume with water. Thoroughly mix the solution.

7.11 Potassium Iodate, Standard Solution (0.01248 N), 1 mL of this solution is equivalent to 0.2 mg S)—Measure exactly 200

mL of KIO solution (0.06238 N) into a 1-L volumetric flask and dilute to volume with water. Thoroughly mix the solution.

7.12 Ascarite, 8 to 20 mesh.

7.13 Special Materials for Induction-Type Furnaces:

7.13.1 Tin (20 to 30-mesh).

7.13.2 Iron-Chip Accelerator having a sulfur content of not more than 0.005 mass %.

7.14 Standard Sample—Potassium alum (AlK(SO ) · 12H O).

4 2 2

7.15 Starch-Iodide Solution—Make a paste by adding 9 g of soluble starch to 15 mL of water. Add this mixture, with stirring,

to 500 mL of boiling water. Cool the mixture, add 15 g of potassium iodide (KI), and dilute to 1 L with water.

7.16 Sulfuric Acid (relative density 1.84)—Concentrated sulfuric acid (H SO ). (Warning—Poison. Corrosive. Strong

2 4

oxidizer.)

7.17 Vanadium Pentoxide, anhydrous, powdered V O .

2 5

7.18 Quality Control (QC) Sample(s) , preferably are portions of one or more petroleum products that are stable and

representative of the samples of interest. These QC samples can be used to check the validity of the testing process and

performance of the instrument as described in Section 12.

8. Sampling

8.1 Take samples in accordance with the instructions in Practice D4057.

9. Preparation of Apparatus

9.1 Induction-Type Furnace—Assemble the apparatus according to the instructions furnished by the manufacturer. Purify the

oxygen by passing it through (1) H SO (relative density 1.84), ( 2) Ascarite, and (3) magnesium perchlorate (Mg(ClO ) ) or

2 4 4 2

phosphorus pentoxide (P O ) (Warning—see 7.4). Connect a rotameter between the purifying train and the furnace. Insert a small

2 5

glass-wool plug in the upper end of the glass tubing connecting the furnace with the absorber to catch oxides of tin. Connect the

exit end of the combustion tube to the absorber with glass tubing, using gum rubber tubing to make connections. Position the

absorber so as to make this delivery line as short as possible. Fig. 2 illustrates schematically the assembled apparatus. Adjust the

oxygen flow to 1 6 0.05 L/min. Add 65 mL of HCl (3 + 197) and 2 mL of starch-iodide solution to the absorber. Add a sufficient

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, DC. For Suggestions on the testing of reagents not listed by

the American Chemical Society, see Annual Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

´1

D1552 − 08 (2014)

FIG. 2 Schematic Illustration of Induction-Type Furnace

amount of the appropriate standard KIO solution (Table 1) to produce a faint blue color. This color will serve as the end point

for the titration. Adjust the buret to zero. Turn on the furnace filament switch and allow at least 1 min warm-up before running

samples (Warning—see 7.4).

9.2 Resistance–Type Furnace—Assemble the apparatus according to the instructions furnished by the manufacturer. Purify the

oxygen by passing it through (1) H SO (relative density 1.84), (2) Ascarite, and (3) Mg(ClO ) or P O (Warning—see 7.4).

2 4 4 2 2 5

Connect a rotameter between the purifying train and the furnace. Fig. 3 illustrates schematically the assembled apparatus. Turn on

the current and adjust the furnace control to maintain a constant temperature of 1316 6 14°C (2400 6 25°F). Adjust the oxygen

flow rate to 2 6 0.1 L/min. Add 65 mL of HCl (3 6 197) and 2 mL of starch-iodide solution to the absorber. Add a few drops of

the appropriate standard KIO solution (Table 2) to produce a faint blue color. Adjust the buret to zero.

9.3 Resistance–Type Furnace–IR Detection—Assemble and adjust apparatus according to manufacturer’s instructions. Initialize

microprocessor, check power supplies, set oxygen pressure and flows and set furnace temperature to 1371°C (2500°F).

9.3.1 Condition a fresh anhydrone scrubber with four coal samples when analyzing petroleum coke samples, or with four

petroleum product samples that are representative or typical of the sample types to be analyzed.

9.3.2 Calibrate the automatic balance according to manufacturer’s instructions.

10. Standardization

10.1 For Iodate Methods:

10.1.1 Determination of Alum Factor:

10.1.1.1 Because these rapid combustion methods involve the reversible reaction 2SO + O = 2SO , it is not possible to evolve

2 2 3

all the sulfur as SO . The equilibrium of the reaction is temperature dependent and, in an oxygen atmosphere above 1316°C, about

97 % of the sulfur is present as SO . To assure that the furnace is in proper adjustment and that its operation produces accept

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.