ASTM D4869/D4869M-16

(Specification)Standard Specification for Asphalt-Saturated Organic Felt Underlayment Used in Steep Slope Roofing

Standard Specification for Asphalt-Saturated Organic Felt Underlayment Used in Steep Slope Roofing

ABSTRACT

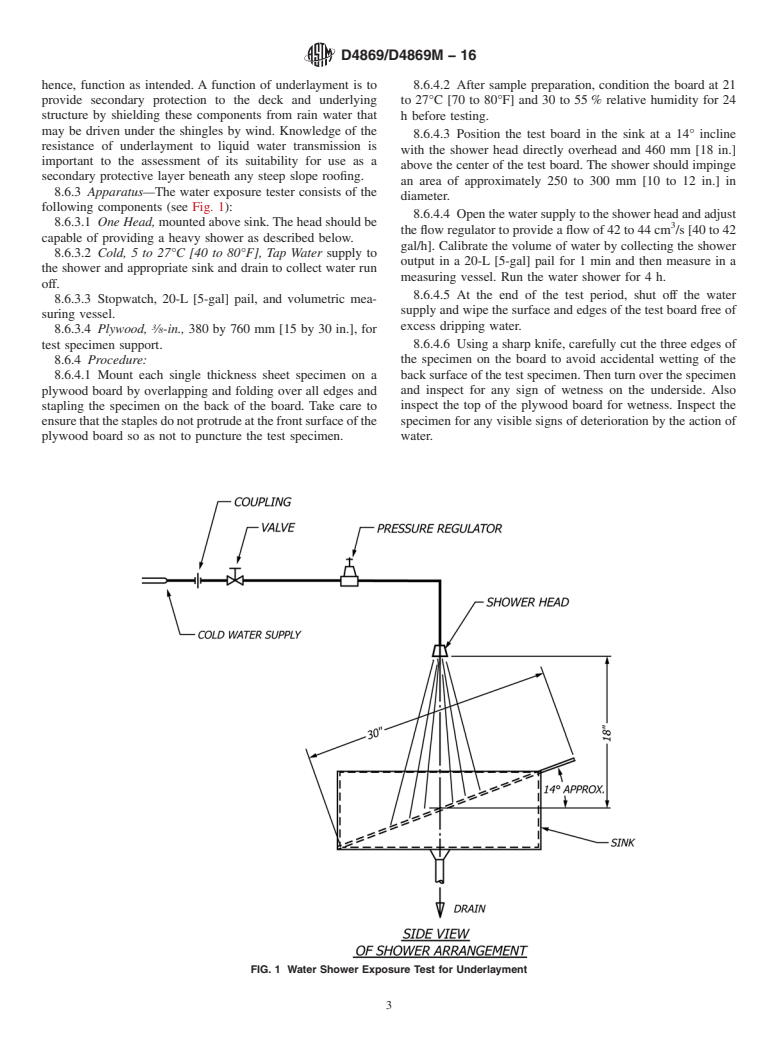

This specification covers asphalt-saturated organic felt for use as an underlayment in steep slope roofing. The objective of this specification is to provide a finished product that will lie flat and resist wrinkling, puckering, and shrinking when left exposed to the sun, rain, frost, or dew for a period of two weeks after application. In the process of manufacture, a single thickness of organic dry felt shall be uniformly saturated with an asphaltic saturant and the felt shall be produced principally from organic fibers. The surface of the felt shall be uniform and relatively smooth and upon splitting or tearing on the bias, the felt shall appear free of lumps or particles of foreign substances. The material shall conform to the prescribed physical requirements such as tear strength, pliability, loss on heating, liquid water transmission, breaking strength, and dimensional stability, and to the specified dimension and mass requirements such as roll width, roll area, net mass of saturated felt, net mass of desaturated felt, saturation, moisture, and saturating efficiency. The finished product shall not crack nor be so sticky as to cause tearing or other damage upon being unrolled. The following tests shall be taken: (1) determination of saturation percent of felt, (2) determination of resistance to liquid water transmission using water shower exposure test, and (3) test for dimensional stability to low and high humidity. The water shower exposure test for underlayment is illustrated.

SCOPE

1.1 This specification covers asphalt-saturated organic felt for use as an underlayment with steep slope roofing.

1.2 The objective of this specification is to provide a finished product that will lie flat and resist wrinkling, puckering, and shrinking when left exposed to the sun, rain, frost, or dew for a period of two weeks after application.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 The following safety hazards caveat pertains only to the test method portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4869/D4869M −16

StandardSpecification for

Asphalt-Saturated Organic Felt Underlayment Used in Steep

1

Slope Roofing

This standard is issued under the fixed designation D4869/D4869M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D6136 Test Method for Kerosine Number of Unsaturated

(Dry) Felt by Vacuum Method

1.1 This specification covers asphalt-saturated organic felt

F1087 Test Method for Linear Dimensional Stability of a

for use as an underlayment with steep slope roofing.

Gasket Material to Moisture

1.2 The objective of this specification is to provide a

finished product that will lie flat and resist wrinkling,

3. Terminology

puckering, and shrinking when left exposed to the sun, rain,

3.1 Definitions—For definitions of terms used in this

frost, or dew for a period of two weeks after application.

specification, refer to Terminology D1079.

1.3 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

4. Classification

each system may not be exact equivalents; therefore, each

4.1 Asphalt-saturated felts covered by this specification are

system shall be used independently of the other. Combining

of four types:

values from the two systems may result in non-conformance

4.1.1 Type I—#8 Underlayment,

with the standard.

4.1.2 Type II—#13 Underlayment,

1.4 The following safety hazards caveat pertains only to the

4.1.3 Type III—#20 Underlayment, and

test method portion, Section 8, of this specification: This

4.1.4 Type IV—#26 Underlayment.

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user

5. Materials and Manufacture

of this standard to establish appropriate safety and health

5.1 In the process of manufacture, a single thickness of

practices and determine the applicability of regulatory limita-

organic dry felt shall be uniformly saturated with an asphaltic

tions prior to use.

saturant.

2. Referenced Documents

5.2 The felt shall be produced principally from organic

2

fibers. The surface of the felt shall be uniform and relatively

2.1 ASTM Standards:

smooth. Upon splitting or tearing on the bias, the felt shall

D70 Test Method for Density of Semi-Solid Bituminous

appear free of lumps or particles of foreign substances.

Materials (Pycnometer Method)

D146 Test Methods for Sampling and Testing Bitumen-

6. Physical Requirements

Saturated Felts and Woven Fabrics for Roofing and

Waterproofing

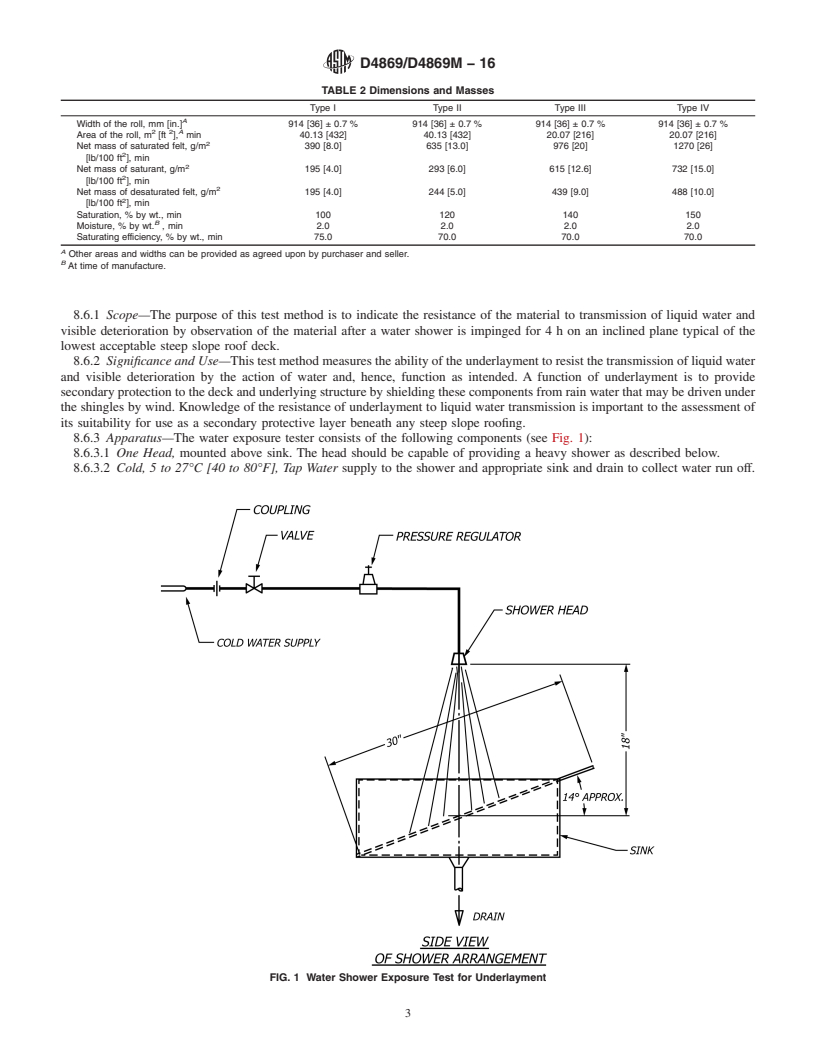

6.1 The material shall conform to the physical requirements

D1079 Terminology Relating to Roofing and Waterproofing

in accordance with Table 1 and the dimensions and masses in

D1922 Test Method for Propagation Tear Resistance of

accordance with Table 2.

Plastic Film and Thin Sheeting by Pendulum Method

6.2 The finished product shall not crack nor be so sticky as

to cause tearing or other damage upon being unrolled at

temperatures between 0 and 60°C [32 and 140°F].

1

This specification is under the jurisdiction of ASTM Committee D08 on

6.3 The finished product shall pass the water shower expo-

Roofing and Waterproofing and is the direct responsibility of Subcommittee D08.02

on Steep Roofing Products and Assemblies.

sure test in accordance with 8.6, indicating resistance to liquid

Current edition approved Jan. 1, 2016. Published January 2016. Originally

water transmission.

approved in 2002. Last previous edition approved in 2015 as D4869/D4869M – 15.

DOI: 10.1520/D4869_D4869M-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 7. Workmanship, Finish, and Appearance

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7.1 The felt shall be thoroughly and uniformly saturated,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. and shall show no unsaturated spots at any point upon cutting

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4869/D4869M−16

TABLE 1 Physical Requirements

Type I Type II Type III Type IV

Tear strength, 23 ± 2°C [73 ± 4°F] min, N [lbf] 2.0 2.0 4.0 4.0

(both cross and with direction of sheet) [0.45] [0.45] [0.90] [0.90]

Pliability at 23 ± 2°C [73 ± 4°F]. Ten strips 12.7 mm 12.7 mm 19.1 mm 19.1 mm

tested shall not crack when bent 90° at a [0.50 in.] [0.50 in.] [0.75 in.] [0.75 in.]

uniform speed over a rounded corner of

radius in table for each type.

Loss on heating at 105°C [221°F] for 5 h max, % 6 6 6 6

Liquid water transmission test Pass Pass

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4869/D4869M − 15 D4869/D4869M − 16

Standard Specification for

Asphalt-Saturated Organic Felt Underlayment Used in Steep

1

Slope Roofing

This standard is issued under the fixed designation D4869/D4869M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers asphalt-saturated organic felt for use as an underlayment with steep slope roofing.

1.2 The objective of this specification is to provide a finished product that will lie flat and resist wrinkling, puckering, and

shrinking when left exposed to the sun, rain, frost, or dew for a period of two weeks after application.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.4 The following safety hazards caveat pertains only to the test method portion, Section 8, of this specification:This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D70 Test Method for Density of Semi-Solid Bituminous Materials (Pycnometer Method)

D146 Test Methods for Sampling and Testing Bitumen-Saturated Felts and Woven Fabrics for Roofing and Waterproofing

D228 Test Methods for Sampling, Testing, and Analysis of Asphalt Roll Roofing, Cap Sheets, and Shingles Used in Roofing and

Waterproofing

D1079 Terminology Relating to Roofing and Waterproofing

D1922 Test Method for Propagation Tear Resistance of Plastic Film and Thin Sheeting by Pendulum Method

D6136 Test Method for Kerosine Number of Unsaturated (Dry) Felt by Vacuum Method

F1087 Test Method for Linear Dimensional Stability of a Gasket Material to Moisture

3. Terminology

3.1 Definitions—For definitions of terms used in this specification, refer to Terminology D1079.

4. Classification

4.1 Asphalt-saturated felts covered by this specification are of four types:

4.1.1 Type I—#8 Underlayment,

4.1.2 Type II—#13 Underlayment,

4.1.3 Type III—#20 Underlayment, and

4.1.4 Type IV—#26 Underlayment.

5. Materials and Manufacture

5.1 In the process of manufacture, a single thickness of organic dry felt shall be uniformly saturated with an asphaltic saturant.

1

This specification is under the jurisdiction of ASTM Committee D08 on Roofing and Waterproofing and is the direct responsibility of Subcommittee D08.02 on Steep

Roofing Products and Assemblies.

Current edition approved Jan. 1, 2015Jan. 1, 2016. Published February 2015January 2016. Originally approved in 2002. Last previous edition approved in 20112015 as

ε1

D4869 – 05 (2011)D4869/D4869M – 15. . DOI: 10.1520/D4869_D4869M-15.10.1520/D4869_D4869M-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4869/D4869M − 16

5.2 The felt shall be produced principally from organic fibers. The surface of the felt shall be uniform and relatively smooth.

Upon splitting or tearing on the bias, the felt shall appear free of lumps or particles of foreign substances.

6. Physical Requirements

6.1 The material shall conform to the physical requirements in accordance with Table 1 and the dimensions and masses in

accordance with Table 2.

6.2 The finished product shall not crack nor be so sticky as to cause tearing or other damage upon being unrolled at temperatures

between 0 and 60°C [32 and 140°F].

6.3 The finished product shall pass the water shower exposure test in accordance with 8.6, indicating resistance to liquid water

transmission.

7. Workmanship, Finish, and Appearance

7.1 The felt shall be thoroughly and uniformly saturated, and shall show no unsaturated spots at any point upon cutting 50-mm

[2-in.] wide s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.