ASTM A1022-01

(Specification)Standard Specification for Deformed and Plain Stainless Steel Wire and Welded Wire for Concrete Reinforcement

Standard Specification for Deformed and Plain Stainless Steel Wire and Welded Wire for Concrete Reinforcement

SCOPE

1.1 This specification covers stainless steel wire and welded wire reinforcement produced from hot-rolled stainless steel rod. The stainless steel wire is cold-worked, drawn or rolled, plain (non-deformed) or deformed or a combination of deformed and plain. It is used as concrete reinforcement for applications requiring resistance to corrosion and/or controlled magnetic permeability. Common wire sizes and dimensions are found in this specification. Actual wire sizes are not restricted to those shown in the tables.

1.2 Supplement S1 describes high strength wire, which shall be furnished when specifically ordered. It shall be permissible to furnish high strength wire in place of regular wire if mutually agreed to by the purchaser and supplier.

1.2.1 A supplementary requirement (S2) of an optional nature is provided. It shall apply only when specified by the purchaser. In order to obtain a corrosion tested or controlled magnetic permeability product, steel conforming to Supplementary Requirement S2 should be ordered.

1.3 The values stated in either inch-pound units or SI units are to be regarded as standard. Within the text the inch-pound units are shown in parentheses. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values may result in nonconformance with the specification.

1.4 The chemical composition of the steel (stainless grade) shall be selected for suitability to the application involved by agreement between the manufacturer and the purchaser. Use Specification A 276 for chemical requirements. The UNS designations are to be included with the type number and noted in brackets, i.e. austenitic stainless steels as Type 304 [S30400], 304L [S30403], 316 [S31600], 316L [S31603], 316N [S31651], 316LN [S31653] and duplex stainless steels, Types 2205 [S32205] and 329 [S32900].Note 1—Only austenitic and duplex stainless steels are usually recommended for use as reinforcement in concrete because of their high corrosion resistance. Austenitic stainless steels have good general corrosion resistance, strength characteristics which can be improved by cold working, good toughness and ductility properties at low temperatures, and low magnetic permeability. Duplex stainless steels have generally a corrosion resistance greater than that of most austenitic steels and are magnetic. Other stainless steels with different chemical compositions than the series and types mentioned above, may be used for less restrictive applications.

1.5 Wire for welded wire reinforcement is generally manufactured at 520 MPa (75 ksi) yield strength level. Other strength levels shall be by agreement between the purchaser and manufacturer. Note 2—The term used to refer to yield strength levels are the same as those in ASTM Standards for welded wire reinforcement.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: A 1022 – 01

Standard Specification for

Deformed and Plain Stainless Steel Wire and Welded Wire

for Concrete Reinforcement

This standard is issued under the fixed designation A 1022; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

working, good toughness and ductility properties at low temperatures, and

1. Scope

low magnetic permeability. Duplex stainless steels have generally a

1.1 This specification covers stainless steel wire and welded

corrosion resistance greater than that of most austenitic steels and are

wire reinforcement produced from hot-rolled stainless steel

magnetic. Other stainless steels with different chemical compositions than

rod. The stainless steel wire is cold-worked, drawn or rolled,

the series and types mentioned above, may be used for less restrictive

plain (non-deformed) or deformed or a combination of de- applications.

formed and plain. It is used as concrete reinforcement for

1.5 Wire for welded wire reinforcement is generally manu-

applications requiring resistance to corrosion and/or controlled

factured at 520 MPa (75 ksi) yield strength level. Other

magnetic permeability. Common wire sizes and dimensions are

strength levels shall be by agreement between the purchaser

found in this specification. Actual wire sizes are not restricted

and manufacturer.

to those shown in the tables.

NOTE 2—The term used to refer to yield strength levels are the same as

1.2 SupplementS1describeshighstrengthwire,whichshall

those in ASTM Standards for welded wire reinforcement.

be furnished when specifically ordered. It shall be permissible

to furnish high strength wire in place of regular wire if

2. Referenced Documents

mutually agreed to by the purchaser and supplier.

2.1 ASTM Standards:

1.2.1 A supplementary requirement (S2) of an optional

A82 Specification for Steel Wire, Plain, for Concrete Re-

nature is provided. It shall apply only when specified by the

inforcement

purchaser. In order to obtain a corrosion tested or controlled

A 185 Specification for Steel Welded Wire, Plain for Con-

magnetic permeability product, steel conforming to Supple-

crete Reinforcement

mentary Requirement S2 should be ordered.

A 262 Practices for detecting Susceptibility to Intergranular

1.3 The values stated in either inch-pound units or SI units

Attack in Austenitic Stainless Steels

are to be regarded as standard. Within the text the inch-pound

A 276 Specification for Stainless Steel Bars and Shapes

units are shown in parentheses. The values stated in each

A 314 Specification for Stainless Steel Billets and Bars for

system are not exact equivalents; therefore, each system must

Forging

be used independently of the other. Combining values may

A 342 Test Methods for Permeability of Feebly Magnetic

result in nonconformance with the specification.

Materials

1.4 The chemical composition of the steel (stainless grade)

A 370 Test Methods and Definitions for MechanicalTesting

shall be selected for suitability to the application involved by

of Steel Products

agreement between the manufacturer and the purchaser. Use

A 496 Specification for Steel Wire, Deformed, for Concrete

Specification A 276 for chemical requirements. The UNS

Reinforcement

designations are to be included with the type number and noted

A 497 Specification for Steel Welded Wire, Deformed, for

in brackets, i.e. austenitic stainless steels as Type 304

Concrete Reinforcement

[S30400], 304L [S30403], 316 [S31600], 316L [S31603],

A 700 PracticesforPackaging,MarkingandLoadingMeth-

316N [S31651], 316LN [S31653] and duplex stainless steels,

ods for Steel Products for Domestic Shipment

Types 2205 [S32205] and 329 [S32900].

A 704 SpecificationforWeldedSteelPlainBarorRodMats

NOTE 1—Only austenitic and duplex stainless steels are usually recom-

for Concrete Reinforcement

mended for use as reinforcement in concrete because of their high

A 955 Deformed and Plain Stainless Steel Bars for concrete

corrosion resistance. Austenitic stainless steels have good general corro- 2

Reinforcement (Metric)

sion resistance, strength characteristics which can be improved by cold

1 2

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Annual Book of ASTM Standards, Vol 01.04

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee Annual Book of ASTM Standards, Vol 01.03

A01.05 on Steel Reinforcement. Annual Book of ASTM Standards, Vol 03.04

Current edition approved Dec. 10, 2001. Published February 2002. Annual Book of ASTM Standards, Vol 01.05

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

A1022–01

E83 Practice for Verification and Classification of Exten- 4.1.10 Heat treatment condition.

someters 4.1.11 Supplementary requirements (if desired).

2.2 Military Standards:

NOTE 3—Atypical ordering description is as follows: For metric units:

MIL-STD-129 Marking for Shipment and Storage

10,000 square meters of welded wire for concrete reinforcement,

MIL-STD-163 Steel Mill Products Preparation for Ship-

3053305-MW653MW65, in flat sheets 2438 mm wide by 4.6 mm long

ment and Storage in secured bundles for crane or forklift truck lifts. For in-lbs units:

(100,000 square feet of welded wire for concrete reinforcement, 12312-

2.3 Federal Standard:

W103W10 in flat sheets 96 in. wide by 15 ft long) in secured bundles for

Fed. Std. No. 123 Marking for Shipments (CivilAgencies)

crane or forklift truck lifts. Testing shall be in accordance with Test

2.4 Other Standard:

Methods A 370.

ACI 318 Building Code Requirements for Structural Con-

NOTE 4—Longitudinal wires can be variably spaced. (Ex: 3053305-

crete

MW653MW65,12312-W103W10 or V3305-MD653MD65 or V312-

D103D10). See the Tables 1 and 2 for wire sizes.

3. Terminology

5. Materials

3.1 Definitions of Terms Specific to This Standard:

5.1 Stainless steel wire for welded wire reinforcement shall

3.1.1 stainless steel plain wire and welded plain wire

be cold worked, either drawn or rolled from steel rod, which is

reinforcement—as used within the scope and intent of this

rolled from properly identified heats of mold or strand cast

specification, designates a material composed of cold-worked

steel.

stainless steel wire, as cold-drawn or cold-rolled from stainless

5.2 Cold worked wire or rod used in the manufacture of

steel hot-rolled rod. The welded intersections provide the bond

stainless steel welded reinforcement shall follow the chemical

strength for shear resistance.

and physical requirements of Specification A 276.

3.1.2 stainless steel deformed wire and welded deformed

wire reinforcement—as used within the scope and intent of this

6. Manufacture

specification, designates a material composed of cold- worked

deformedstainlesssteelwireascold-drawnorcold-rolledfrom

6.1 The wire or rod shall be assembled by automatic

stainless steel hot-rolled rod. Deformations may be indented or

machines or by other suitable mechanical means which will

raised rib (protrusion) types. As with plain stainless steel

assure accurate spacing and alignment of all wires of the

welded wire, the welded intersections provide bond strength

finished welded wire reinforcement. The finished welded wire

for shear resistance and the deformations add to the bond

reinforcementshallbefurnishedinflatorbentsheetsorinrolls

strength.

as specified by the purchaser.

3.1.3 convoluted wire—when wire for welded wire rein-

6.2 Longitudinal and transverse wires shall be securely

forcement is formed into a sinusoidal wave shape, it is

connected at every intersection by a process of electrical-

commonly referred to as convoluted wire. The wire is used in

resistance welding which employs the principle of fusion

the manufacture of cages for certain applications of concrete

combined with pressure.

pipe reinforcement. Only plain wire is normally subject to

convolution.

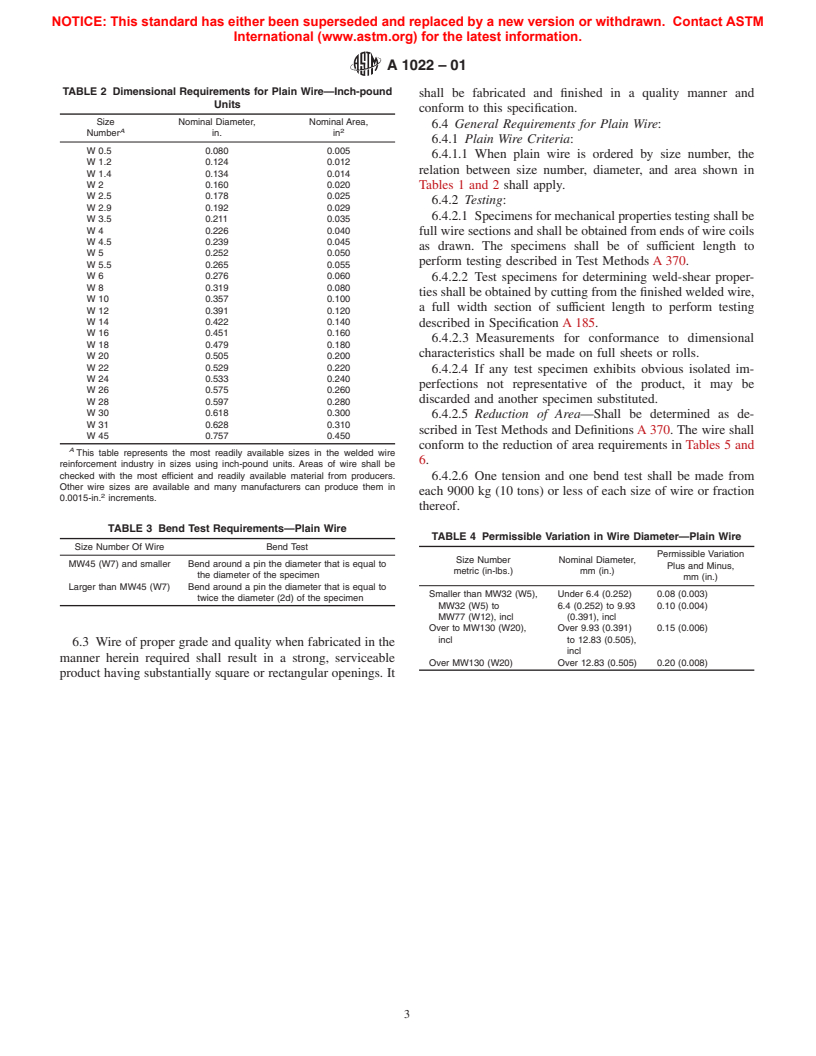

TABLE 1 Dimensional Requirements for Plain Wire—SI Units

4. Ordering Information

Size Nominal Diameter, Nominal Area,

A 2

Number mm mm

4.1 It shall be the responsibility of the purchaser to specify

MW 5 2.50 5

all requirements that are necessary for material ordered to this

MW 10 3.60 10

specification. Such requirement shall include but are not

MW 15 4.40 15

limited to the following:

MW 20 5.00 20

MW 25 5.60 25

4.1.1 Quantity–mass (weight) or square area.

MW 30 6.20 30

4.1.2 Name of material (Ex: stainless steel welded wire for

MW 35 6.70 35

concrete reinforcement).

MW 40 7.10 40

MW 45 7.60 45

4.1.3 Wire spacing and wire sizes.

MW 50 8.00 50

4.1.4 Exclusion of over-steeling or using a larger area of

MW 55 8.40 55

steel than specified.

MW 60 8.70 60

MW 65 9.10 65

4.1.5 Length and width of sheets or rolls.

MW 70 9.40 70

4.1.6 ASTM designation and year of issue.

MW 80 10.10 80

4.1.7 Application (corrosion resistance or magnetic perme- MW 90 10.70 90

MW 100 11.30 100

ability).

MW 120 12.40 120

4.1.8 Grade (strength level).

MW 130 12.90 130

4.1.9 Chemical composition (stainless steel grade). MW 200 15.95 200

MW 290 19.22 290

A

This table represents a hard metrication of the most readily available sizes in

the welded wire reinforcement industry. Table 1 shall be used in projects that are

Annual Book of ASTM Standards, Vol 03.01

designed using SI units: Table 2 shall be used on projects designed using

Available from Standardization Documents Order Desk, Bldg. 4, Section D,

inch-pound units.Areas of wire shall be checked with the most efficient and readily

700 Robbins Ave., Philadelphia, PA 19111–5094.

available material from producers. Other wire sizes are available and many

8 2

Available from ACI International, PO Box 9094, Farmington Hills, MI 48333. manufacturers can produce them in 1-mm increments.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

A1022–01

TABLE 2 Dimensional Requirements for Plain Wire—Inch-pound

shall be fabricated and finished in a quality manner and

Units

conform to this specification.

Size Nominal Diameter, Nominal Area,

6.4 General Requirements for Plain Wire:

A 2

Number in. in

6.4.1 Plain Wire Criteria:

W 0.5 0.080 0.005

6.4.1.1 When plain wire is ordered by size number, the

W 1.2 0.124 0.012

relation between size number, diameter, and area shown in

W 1.4 0.134 0.014

W 2 0.160 0.020 Tables 1 and 2 shall apply.

W 2.5 0.178 0.025

6.4.2 Testing:

W 2.9 0.192 0.029

6.4.2.1 Specimens for mechanical properties testing shall be

W 3.5 0.211 0.035

W 4 0.226 0.040

full wire sections and shall be obtained from ends of wire coils

W 4.5 0.239 0.045

as drawn. The specimens shall be of sufficient length to

W 5 0.252 0.050

perform testing described in Test Methods A 370.

W 5.5 0.265 0.055

W 6 0.276 0.060

6.4.2.2 Test specimens for determining weld-shear proper-

W 8 0.319 0.080

ties shall be obtained by cutting from the finished welded wire,

W 10 0.357 0.100

a full width section of sufficient length to perform testing

W 12 0.391 0.120

W 14 0.422 0.140

described in Specification A 185.

W 16 0.451 0.160

6.4.2.3 Measurements for conformance to dimensional

W 18 0.479 0.180

characteristics shall be made on full sheets or rolls.

W 20 0.505 0.200

W 22 0.529 0.220

6.4.2.4 If any test specimen exhibits obvious isolated im-

W 24 0.533 0.240

perfections not representative of the product, it may be

W 26 0.575 0.260

discarded and another specimen substituted.

W 28 0.597 0.280

W 30 0.618 0.300

6.4.2.5 Reduction of Area—Shall be determined as de-

W 31 0.628 0.310

scribed in Test Methods and Definitions A 370. The wire shall

W 45 0.757 0.450

conform to the reduction of area requirements in Tables 5 and

A

This table represents the most readily available sizes in the welded wire

6.

reinforcement industry in sizes using inch-pound units. Areas of wire shall be

checked with the most efficient and readily available material from producers. 6.4.2.6 One tension and one bend test shall be made from

Other wire sizes are available and many manufacturers can produce them in

each 9000 kg (10 tons) or less of each size of wire or fraction

0.0015-in. increments.

thereof.

TABLE 3 Bend Test Requirements—Plain Wire

TABLE 4 Permissible Variation in Wire Diameter—Plain Wire

Size Number Of Wire Bend Test

Permissible Variation

Size Number Nominal Diameter,

MW45 (W7) and smaller Bend around a pin the diameter that is equal to

Plus and Minus,

metric (in-lbs.) mm (in.)

the diameter of the specimen

mm (in.)

Larger than MW45 (W7) Bend around a pin the diameter that is equal to

Smaller than MW32 (W5), Under 6.4 (0.252) 0.08 (0.003)

twice the diameter (2d) of the specimen

MW32 (W5) to 6.4 (0.252) to 9.93 0.10 (0.004)

MW77 (W12), incl (0.391), incl

Over to MW130 (W20), Over 9.93 (0.391) 0.15 (0.006)

incl to 12.83 (0.505),

6.3 Wire of proper grade and quality when fabricated in the

incl

manner herein required shall result in a strong, serviceable

Over MW130 (W20) Over 12.83 (0.505) 0.20 (0.008)

product having substantially square or rectangular openings. It

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

A1022–01

TABLE 5 Tension Test Requirement—Plain Wire

6.5.1.4 The minimum average height of the center of typical

deformations based on the nominal wire diameters shown in

Tables 7 and 8 shall be as follows:

Tensile strength, min, MPa (ksi) 550 (80)

Yield strength, min, MPa (ksi) 485 (70)

Wire Sizes Minimum Average Height of Deformations,

A

Reduction of area, min. % 30

Percent of Nominal Wire Diameter

A

MD 19 (D 3) and finer 4

For material testing over 100 ksi (690 MPa) tensile strength, the reduction of

Coarser than MD 19 (D 3) through 4 ⁄2

area shall be not less than 25%.

MD 65 (D 10)

Coarser than MD 65 (D 10) 5

TABLE 6 Tension Test Requirement Plain Wire (Material for

6.5.1.5 The deformations shall be placed with respect to the

Welded Wire)

axis of the wire so that the included angle is not less than 45º;

Size MW8 (W1.2) Smaller than

and Larger Size MW8(W1.2) or if deformations are curvilinear, the angle formed by the

transverseaxisofthedeformationandthewireaxisshallbenot

Tensile strength, min, MPa (ksi) 515 (75) 485 (70)

Yield strength, min, MPa (ksi) 450 (65) 385 (56)

less

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.