ASTM B479-06

(Specification)Standard Specification for Annealed Aluminum and Aluminum-Alloy Foil for Flexible Barrier, Food Contact, and Other Applications (Withdrawn 2015)

Standard Specification for Annealed Aluminum and Aluminum-Alloy Foil for Flexible Barrier, Food Contact, and Other Applications (Withdrawn 2015)

ABSTRACT

This specification covers annealed aluminum and aluminum-alloy foil used in packaging, which includes food handling and processing applications, requiring flexible barrier materials, and other general applications. The foil may also be as supplied or laminated to other materials, such as paper or plastic films. Chemical composition shall be in conformity with provisions herein, and shall be determined through suitable chemical and spectrochemical methods. Tensile breaking load limits shall be as agreed, and shall be tested twice with test methods for tension testing of metallic foil using two samples from different rolls of foil.

SCOPE

1.1 This specification covers annealed aluminum and aluminum-alloy foil containing 98.00 % minimum aluminum and in thicknesses 0.00025 in. (0.0064 mm) to, but not including, 0.006 in. (0.15 mm). Alloys (see Note 0) covered by this specification include, but are not limited to 1100, 1145, 1235, 8011, 8079, and 8111, which conform to the requirements of and . Unless otherwise specified by the purchaser, the alloy to be supplied shall be left to the discretion of the producer.

1.2 The foil is for use in packaging, which includes food handling and processing applications, requiring flexible barrier materials, and other general applications. The foil may be used as supplied or laminated to other materials, such as paper or plastic films.

1.3 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see .

1.4 The values stated in inch-pound units are to be regarded as the standard. The SI values in parentheses are for information only.

The following precautionary caveat pertains only to the test method portion of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.Note 0

Throughout this specification, use of the term alloyin the general sense includes aluminum as well as aluminum alloy.Note 2

If the alloy is specified by the purchaser, its designation shall be in accordance with ANSI H35.1. The equivalent Unified Numbering System alloy designations are those shown in preceded by A9, for example, A91100 for aluminum 1100 in accordance with Practice E 527.

WITHDRAWN RATIONALE

This specification covers annealed aluminum and aluminum-alloy foil containing 98.00 % minimum aluminum and in thicknesses 0.00025 in. (0.0064 mm) to, but not including, 0.006 in. (0.15 mm).

Formerly under the jurisdiction of Committee B07 on Light Metals and Alloys, this specification was withdrawn in January 2015 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B479 −06

StandardSpecification for

Annealed Aluminum and Aluminum-Alloy Foil for Flexible

1

Barrier, Food Contact, and Other Applications

This standard is issued under the fixed designation B479; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2.1 The following documents of the date of issue in effect

1.1 This specification covers annealed aluminum and

on date of material procurement form a part of this specifica-

aluminum-alloy foil containing 98.00 % minimum aluminum

tion to the extent referenced herein.

and in thicknesses 0.00025 in. (0.0064 mm) to, but not

2

including, 0.006 in. (0.15 mm).Alloys (see Note 1) covered by

2.2 ASTM Standards:

this specification include, but are not limited to 1100, 1145,

B926 Method for Pinhole Determination in Aluminum and

1235, 8011, 8079, and 8111, which conform to the require-

Aluminum Alloy Plain Foil by Means of a Light Table

ments of 6.1 and Table 1. Unless otherwise specified by the

E29 Practice for Using Significant Digits in Test Data to

purchaser, the alloy to be supplied shall be left to the discretion

Determine Conformance with Specifications

of the producer.

E34 Test Methods for Chemical Analysis of Aluminum and

Aluminum-Base Alloys

1.2 The foil is for use in packaging, which includes food

E55 Practice for Sampling Wrought Nonferrous Metals and

handling and processing applications, requiring flexible barrier

Alloys for Determination of Chemical Composition

materials, and other general applications. The foil may be used

E96/E96M Test Methods for Water Vapor Transmission of

as supplied or laminated to other materials, such as paper or

Materials

plastic films.

E252 Test Method for Thickness of Foil, Thin Sheet, and

1.3 For acceptance criteria for inclusion of new aluminum Film by Mass Measurement

and aluminum alloys in this specification, see Annex A1. E345 Test Methods of Tension Testing of Metallic Foil

E607 Test Method for Atomic Emission Spectrometric

1.4 The values stated in inch-pound units are to be regarded

Analysis Aluminum Alloys by the Point to Plane Tech-

as the standard. The SI values in parentheses are for informa-

3

nique Nitrogen Atmosphere (Withdrawn 2011)

tion only.

E716 Practices for Sampling and Sample Preparation of

1.5 The following precautionary caveat pertains only to the Aluminum and Aluminum Alloys for Determination of

test method portion of this specification: This standard does Chemical Composition by Spectrochemical Analysis

E1251 Test Method for Analysis of Aluminum and Alumi-

not purport to address all of the safety concerns, if any,

associated with its use. It is the responsibility of the user of this num Alloys by Spark Atomic Emission Spectrometry

standard to establish appropriate safety and health practices 2.3 American National Standard:

and determine the applicability of regulatory limitations prior

H35.1 Alloy and Temper Designation Systems for Wrought

4

to use. Aluminum

Z1.4 Sampling Procedures and Tables for Inspection by

NOTE 1—Throughout this specification, use of the term alloy in the

4

Attributes

general sense includes aluminum as well as aluminum alloy.

NOTE 2—If the alloy is specified by the purchaser, its designation shall

3. Terminology

be in accordance with ANSI H35.1. The equivalent Unified Numbering

System alloy designations are those shown in 1.1 preceded by A9, for

3.1 Definitions:

example, A91100 for aluminum 1100 in accordance with Practice E527.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This specification is under the jurisdiction of ASTM Committee B07 on Light Standards volume information, refer to the standard’s Document Summary page on

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on the ASTM website.

3

Aluminum Alloy Wrought Products. The last approved version of this historical standard is referenced on

Current edition approved May 1, 2006. Published May 2006. Originally www.astm.org.

4

approved in 1969. Last previous edition approved in 2000 as B479–00. DOI: Available from American National Standards Institute, 11 W. 42nd St., 13th

10.1520/B0479-06. Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B479−06

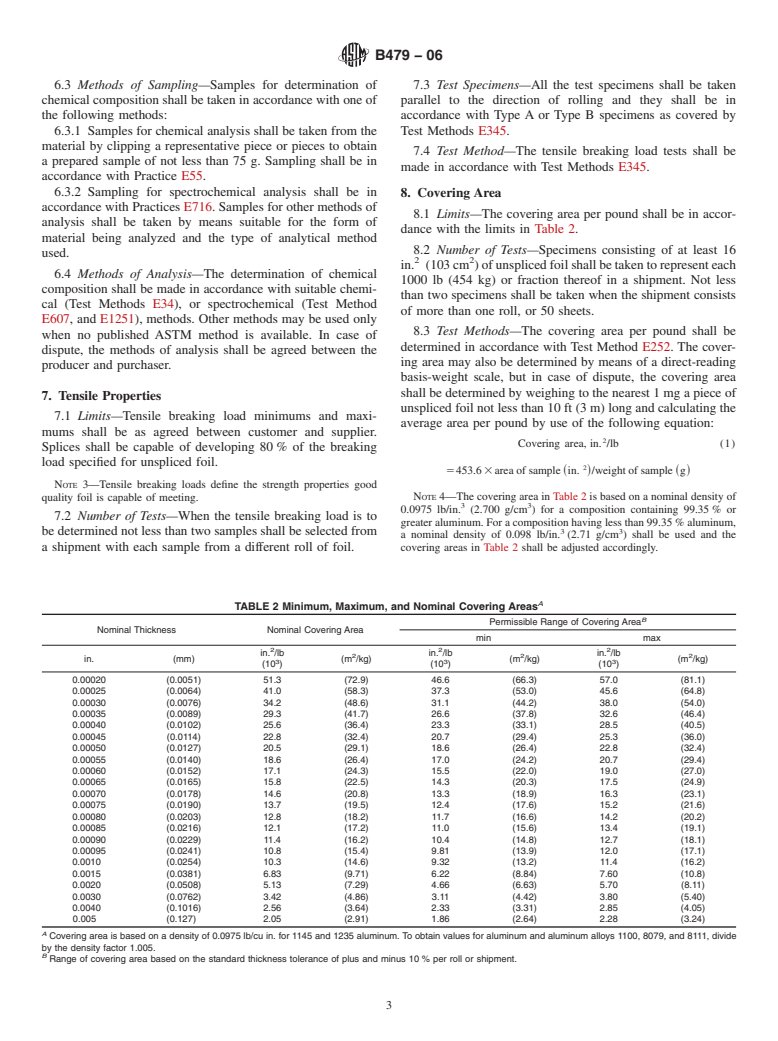

A,B,C

TABLE 1 Chemical Composition Limits

4.1.3 Nominal thickness and (a) sheet size, or (b) maximum

Si + Fe 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.