ASTM B479-00

(Specification)Standard Specification for Annealed Aluminum and Aluminum-Alloy Foil for Flexible Barrier, Food Contact, and Other Applications

Standard Specification for Annealed Aluminum and Aluminum-Alloy Foil for Flexible Barrier, Food Contact, and Other Applications

SCOPE

1.1 This specification covers annealed aluminum and aluminum-alloy foil containing 98.00% minimum aluminum and in thicknesses 0.00025 in. (0.0064 mm) through 0.0015 in. (0.038 mm). Alloys (see Note 1) covered by this specification include, but are not limited to 1100, 1145, 1235, 8079 and 8111, which conform to the requirements of 6.1 and Table 1. Unless otherwise specified by the purchaser, the alloy to be supplied shall be left to the discretion of the producer.

1.2 The foil is for use in packaging or other applications requiring flexible barrier materials, and may be used as supplied or it may be subsequently coated or laminated to other materials such as paper or plastics.

1.3 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A1.

1.4 The values stated in inch-pound units are to be regarded as the standard. The SI values in parentheses are for information only.

1.5 The following precautionary caveat pertains only to the test method portion of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1-Throughout this specification, use of the term alloy in the general sense includes aluminum as well as aluminum alloy. Note 2-If the alloy is specified by the purchaser, its designation shall be in accordance with ANSI H35.1. The equivalent Unified Numbering System alloy designations are those shown in Section 1.1 preceded by A9, for example, A91100 for aluminum 1100 in accordance with Practice E527.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 479 – 00

Standard Specification for

Annealed Aluminum and Aluminum-Alloy Foil for Flexible

Barrier, Food Contact, and Other Applications

This standard is issued under the fixed designation B 479; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification covers annealed aluminum and 2.1 The following documents of the date of issue in effect

aluminum-alloy foil containing 98.00 % minimum aluminum on date of material procurement form a part of this specifica-

and in thicknesses 0.00025 in. (0.0064 mm) to, but not tion to the extent referenced herein.

including, 0.006 in. (0.15 mm).Alloys (see Note 1) covered by 2.2 ASTM Standards:

this specification include, but are not limited to 1100, 1145, B 660 Practices for Packaging/Packing of Aluminum and

1235, 8079, and 8111, which conform to the requirements of Magnesium Products

6.1 and Table 1. Unless otherwise specified by the purchaser, E 29 Practice for Using Significant Digits in Test Data to

the alloy to be supplied shall be left to the discretion of the Determine Conformance with Specifications

producer. E 34 Test Methods for ChemicalAnalysis ofAluminum and

1.2 The foil is for use in packaging, which includes food Aluminum Base Alloys

handling and processing applications, requiring flexible barrier E 55 PracticeforSamplingWroughtNonferrousMetalsand

materials, and other general applications. The foil may be used Alloys for Determination of Chemical Compo sition

as supplied or laminated to other materials, such as paper or E 96 Test Methods for Water Vapor Transmission of Mate-

plastic films. rials

1.3 For acceptance criteria for inclusion of new aluminum E 227 Test Method for Optical Emission Spectrometric

and aluminum alloys in this specification, see Annex A1. Analysis of Aluminum and Aluminum Alloys by the

1.4 The values stated in inch-pound units are to be regarded Point-to-Plane Technique

as the standard. The SI values in parentheses are for informa- E 252 Test Method for Thickness of Thin Foil and Film by

tion only. Weighing

1.5 The following precautionary caveat pertains only to the E 345 Test Methods of Tension Testing of Metallic Foil

test method portion of this specification: This standard does E 607 Test Method for Optical Emission Spectrometric

not purport to address all of the safety concerns, if any, Analysis of Aluminum and Aluminum Alloys by the

associated with its use. It is the responsibility of the user of this Point-to-Plane Technique, Nitrogen Atmosphere

standard to establish appropriate safety and health practices E 716 Practices for Sampling of Aluminum and Aluminum

and determine the applicability of regulatory limitations prior Alloys for Spectrochemical Analysis

to use. E 1251 Test Method for Optical Emission Spectrometric

Analysis ofAluminum andAluminumAlloys by theArgon

NOTE 1—Throughout this specification, use of the term alloy in the

Atmosphere, Point-to-Plane, Unipolar Self-Initiating Ca-

general sense includes aluminum as well as aluminum alloy.

pacitor Discharge

NOTE 2—If the alloy is specified by the purchaser, its designation shall

2.3 American National Standard:

be in accordance with ANSI H35.1. The equivalent Unified Numbering

System alloy designations are those shown in Section 1.1 preceded byA9,

for example, A91100 for aluminum 1100 in accordance with Practice

E 527.

Annual Book of ASTM Standards, Vol 02.02.

1 3

This specification is under the jurisdiction of ASTM Committee B07 on Light Annual Book of ASTM Standards, Vol 14.02.

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on Annual Book of ASTM Standards, Vol 03.05.

Aluminum Alloy Wrought Products. Annual Book of ASTM Standards, Vol 03.06.

Current edition approved May 10, 2000. Published August 2000. Originally Annual Book of ASTM Standards, Vol 04.06.

published as B 479–69T. Last previous edition B 479–97. Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 479

A,B,C

TABLE 1 Chemical Composition Limits

4. Ordering Information

Si + Fe 1.8 Ti 0.08

4.1 Orders for material to this specification shall include the

D E,F

Cu 0.20 Others—each 0.05

D following information:

Mn 0.10 Others—total 0.15

G

Mg 0.05 Al, min. 98.00

4.1.1 This specification designation (which includes the

Zn 0.10

number, the year, and the revision letter, if applicable),

A

Limits are in percent maximum unless otherwise noted.

4.1.2 Quantity in pieces or lbs (kg),

B

Analysis shall be made for the elements for which limits are shown in this table.

4.1.3 Nominal thickness and (a) sheet size, or (b) maximum

C

For purposes of determining conformance to these limits, an observed value

or a calculated value obtained from analysis shall be rounded to the nearest unit roll diameter, nominal roll width, and core size (Section 9),

in the last right-hand place or figures used in expressing the specified limit, in

4.1.4 Surface condition (see 3.1.2 and 3.1.3),

accordance with the rounding method of Practice E 29.

D 4.1.5 Type of splice (for rolls only), (see 10.2),

Others includes all unlisted metallic elements. The producer may analyze

samples for trace elements not specified in the specification. However, such 4.2 Additionally, orders for material to this specification

analysis is not required and may not cover all metallic Others elements. Should

shall include the following information when required by the

any analysis by the producer or the purchaser establish that an Others element

purchaser:

exceeds the limit of Each or that the aggregate of several Others elements

exceeds the limit of Total, the material shall be considered non-conforming.

4.2.1 Whether supply of a specific alloy is required (see

E

For food applications, lead, arsenic, and cadmium shall be less than 0.01 %

1.1),

each. For purposes of determining conformance to the limits of these three

4.2.2 Whether inspection or witness of inspection and tests

elements, an observed value or a calculated value obtained from analysis shall be

considered significant, in accordance with the absolute method of Practice E 29.

by the purchaser’s representative is required prior to shipment

F

Food packaging, in accordance with CONEG Model Legislation, shall have a

(see 11.1),

maximum total of less than 100 ppm for the combined total of lead, mercury,

tb

4.2.3 Whether the intended use involves food processing,

cadmium, and hexavalent-chrome (Pb, Hg, Cd, and Cr ).

G

The aluminum content shall be calculated by subtracting from 100.00 % the

food packaging, or food preservation (see 6.1 and 15.2), and if

sum of all metallic elements present in amounts of 0.010 % or more each, rounded

so, what government regulations are applicable.

to the nearest 0.01 % prior to determining the sum.

4.2.4 Whether certification is required (Section 13).

4.2.5 Whether Mullen test is required (see Section 11).

4.2.6 Whether special statistical methods are to be used for

H35.1 Alloy and Temper Designation Systems for Wrought

visualanddimensionalinspection.Ifso,thesemethodsshallbe

Aluminum

listed.

Z1.4 Sampling Procedures and Tables for Inspection by

Attributes

5. Responsibility for Quality Assurance

5.1 Responsibility for Inspection and Tests—Unless other-

3. Terminology

wise specified in the contract or purchase order, the producer is

3.1 Definitions:

responsible for the performance of all inspection and test

3.1.1 foil—a rolled product rectangular in cross section of

requirements specified herein. Except as otherwise specified in

thickness less than 0.006 in. (0.15 mm).

the contract or order, the producer may use his own or any

3.1.2 matte one-side foil (MIS)—foil with a diffuse reflect-

other suitable facilities for the performance of the inspection

ingfinish(matte)ononesideandabrightspecularfinishonthe

and test requirements specified herein, unless disapproved by

other side.

the purchaser at the time the order is placed. The purchaser

3.1.3 bright two-sides foil (B2S)—foil having a uniform

shall have the right to perform any of the inspections and tests

bright specular finish on both sides.

set forth in this specification where such inspections are

3.1.4 dry annealed, A—having a test dryness 100/0,

deemed necessary to assure that the material conforms to

free from residual rolling oil as determined by the water

prescribed requirements.

test.

3.1.5 dry annealed, B—having a test dryness 90/10, having

6. Chemical Composition

a slight film of residual rolling oil as determined by the

6.1 Limits—The foil shall conform to the chemical compo-

water-alcohol test.

sition limits in Table 1. For applications involving food

3.1.6 dry annealed, C—having a test dryness 80/20, having

packaging, handling, or preservation the absolute amounts of

a slight film of residual rolling oil as determined by the

lead, arsenic, and cadmium shall be less than 0.01 % each (see

water-alcohol test.

footnote E of Table 1). The producer shall determine conform-

3.1.7 slick annealed—having a uniform film of residual

ance by analyzing samples taken when the ingots are poured,

rolling or applied oil as determined by the drop of water test.

or when continuous sheet or plate is cast, or by analyzing

3.2 Definitions of Terms Specific to This Standard:

samples taken from the finished or semifinished product. If the

3.2.1 capable of—The term capable of as used in this

producer has determined the chemical composition during the

specification means that the test need not be performed by the

course of manufacture, he shall not be required to sample and

producer of the material. However, should subsequent testing

analyze the finished product.

by the purchaser establish that the material does not meet these

NOTE 3—It is standard practice in the United States aluminum industry

requirements, the material shall be subject to rejection.

to determine conformance to the chemical composition limits prior to

further processing of ingots or continuously cast plate or sheet into

wrought products. Due to the continuous nature of the process, it is not

practicaltokeepaspecificingotanalysisidentifiedwithaspecificquantity

Available from American National Standards Institute, 11 W. 42nd St., 13th

Floor, New York, NY 10036. of finished material.

B 479

quality foil is capable of meeting.

6.2 Number of Samples—The number of samples taken for

determination of chemical composition shall be as follows:

7.2 Number of Tests—When the tensile breaking load is to

6.2.1 When samples are taken at the time the ingots are

be determined not less than two samples shall be selected from

poured, at least one sample shall be taken for each group of

a shipment with each sample from a different roll of foil.

ingots poured simultaneously from the same source of molten

7.3 Test Specimens—All the test specimens shall be taken

metal.

parallel to the direction of rolling and they shall be in

6.2.2 When samples are taken at the time a coil is cast, at

accordance with Type A or Type B specimens as covered by

leastonesampleshallbetakenforeachcoilcastfromthesame

Test Methods E 345.

source of molten metal.

7.4 Test Method—The tensile breaking load tests shall be

6.2.3 When samples are taken from the finished or semifin-

made in accordance with Test Methods E 345.

ished product, a sample shall be taken to represent each 4000

lb (1814 kg), or fraction thereof, in the shipment. 8. Covering Area

6.3 Methods of Sampling—Samples for determination of

8.1 Limits—The covering area per pound shall be in accor-

chemical composition shall be taken in accordance with one of

dance with the limits in Table 3.

the following methods:

8.2 Number of Tests—Specimens consisting of at least 16

6.3.1 Samples for chemical analysis shall be taken from the 2 2

in. (103cm )ofunsplicedfoilshallbetakentorepresenteach

material by clipping a representative piece or pieces to obtain

1000 lb (454 kg) or fraction thereof in a shipment. Not less

a prepared sample of not less than 75 g. Sampling shall be in

than two specimens shall be taken when the shipment consists

accordance with Practice E 55.

of more than one roll, or 50 sheets.

6.3.2 Sampling for spectrochemical analysis shall be in

8.3 Test Methods—The covering area per pound shall be

accordancewithPracticesE 716.Samplesforothermethodsof

determined in accordance with Test Method E 252. The cov-

analysis shall be taken by means suitable for the form of

eringareamayalsobedeterminedbymeansofadirect-reading

material being analyzed and the type of analytical method

basis-weight scale, but in case of dispute, the covering area

used.

shall be determined by weighing to the nearest 1 mg a piece of

6.4 Methods of Analysis—The determination of chemical

unspliced foil not less than 10 ft (3 m) long and calculating the

composition shall be made in accordance with suitable chemi-

average area per pound by use of the following equation:

cal (Test Methods E 34), or spectrochemical (Test Method

Covering area, in. /lb (1)

E 227, E 607, and E 1251), methods. Other methods may be

used only when no published ASTM method is available. In

5 453.6 3 area of sample ~in. !/weight of sample ~g!

case of dispute, the methods of analysis shall be agreed

between the producer and purchaser.

NOTE 5—The covering area in Table 3 is based on a nominal density of

3 3

0.0975 lb/in. (2.700 g/cm ) for a composition containing 99.35 % or

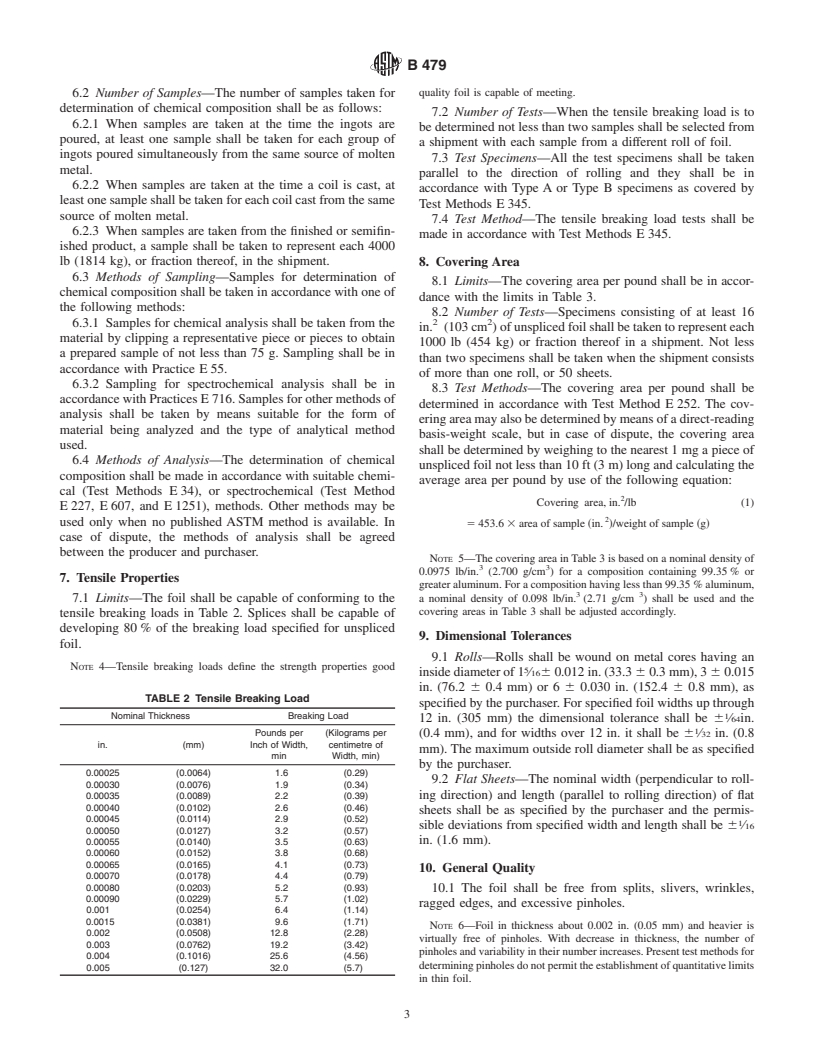

7. Tensile Properties

greater aluminum. For a composition having less than 99.35 % aluminum,

3 3

7.1 Limits—The foil shall be capable of conforming to the a nominal density of 0.098 lb/in. (2.71 g/cm ) shall be used and the

covering areas in Table 3 shall be adjusted accordingly.

tensile breaking loads in Table 2. Splices shall be capable of

developing 80 % of the breaking load specified for unspliced

9. Dimensional Tolerances

foil.

9.1 Rolls—Rolls shall be wound on metal cores having an

NOTE 4—Tensile breaking loads define the strength properties good

insidediameterof1 ⁄1660.012in.(33.3 60.3mm),3 60.015

in. (76.2 6 0.4 mm) or 6 6 0.030 in. (152.4 6 0.8 mm), as

TABLE 2 Tensile Breaking Load

specified by the purchaser. For specified foil widths up through

Nominal Thickness Breaking Load

12 in. (305 mm) the dimensional tolerance shall be 6 ⁄64in.

Pounds per (Kilograms per

(0.4 mm), and for widths over 12 in. it shall be 6 ⁄32 in. (0.8

in. (mm) Inch of Width, centimetre of

mm). The maximum outside roll diameter shall be as specified

min Width, min)

by the purch

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.