ASTM A523-96

(Specification)Standard Specification for Plain End Seamless and Electric-Resistance-Welded Steel Pipe for High-Pressure Pipe-Type Cable Circuits

Standard Specification for Plain End Seamless and Electric-Resistance-Welded Steel Pipe for High-Pressure Pipe-Type Cable Circuits

SCOPE

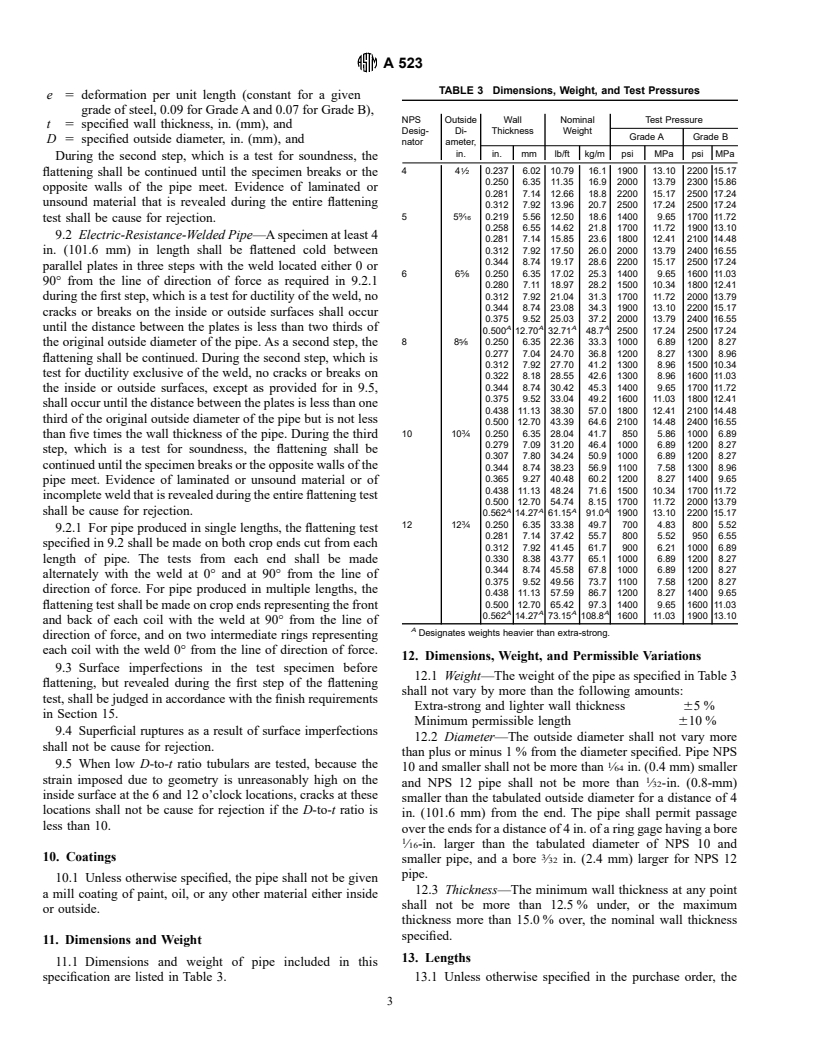

1.1 This specification covers seamless and electric-resistance-welded steel pipe used as conduit for the installation of high-pressure pipe-type electrical cables in NPS 4 to NPS 12, inclusive, with nominal (average) wall thicknesses 0.219 to 0.562 in., depending on size. Pipe having other dimensions (Note 2) may be furnished, provided such pipe complies with all other requirements of this specification.

Note 1—The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as "nominal diameter," "size," and "nominal size."

Note 2—A comprehensive listing of standardized pipe dimensions is contained in ANSI B36.10.

1.2 Pipe ordered under this specification is suitable for welding and for forming operations involving flaring, belling, and bending.

1.3 Pipe for this purpose shall be furnished in Grade A or Grade B as specified in the purchase order. Grade A is more suitable for forming operations involving bending, flaring, or belling and this grade is normally preferred. This provision is not intended to prohibit the cold bending, flaring, or belling of Grade B pipe.

1.4 The values stated in inch-pound units are to be regarded as the standard.

1.5 The following hazard caveat applies to the test method portion, Section 20, of this specification: This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: A 523 – 96 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Plain End Seamless and Electric-Resistance-Welded Steel

1

Pipe for High-Pressure Pipe-Type Cable Circuits

This standard is issued under the fixed designation A 523; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope A 370 Test Methods and Definitions for Mechanical Testing

2

of Steel Products

1.1 This specification covers seamless and electric-

A 751 Test Methods, Practices, and Terminology for

resistance-welded steel pipe used as conduit for the installation

2

Chemical Analysis of Steel Products

of high-pressure pipe-type electrical cables in NPS 4 to NPS

E 59 Method of Sampling Steel and Iron for Determination

12, inclusive, with nominal (average) wall thicknesses 0.219 to

3

of Chemical Composition

0.562 in., depending on size. Pipe having other dimensions

2.2 ANSI Standard:

(Note 2) may be furnished, provided such pipe complies with

4

B36.10 Welded and Seamless Wrought Steel Pipe

all other requirements of this specification.

3. Ordering Information

NOTE 1—The dimensionless designator NPS (nominal pipe size) has

been substituted in this standard for such traditional terms as “nominal

3.1 Orders for material under this specification should

diameter,” “size,” and “nominal size.”

include the following, as required, to describe the desired

material adequately:

NOTE 2—A comprehensive listing of standardized pipe dimensions is

3.1.1 Quantity (feet or number of lengths),

contained in ANSI B36.10.

3.1.2 Name of material (steel pipe),

1.2 Pipe ordered under this specification is suitable for

3.1.3 Method of manufacture (seamless or electric-

welding and for forming operations involving flaring, belling,

resistance-welded),

and bending.

3.1.4 Grade (Table 1),

1.3 Pipe for this purpose shall be furnished in Grade A or

3.1.5 Size (outside diameter and nominal wall thickness or

Grade B as specified in the purchase order. Grade A is more

weight per foot),

suitable for forming operations involving bending, flaring, or

3.1.6 Length when other than specified in Section 13,

belling and this grade is normally preferred. This provision is

3.1.7 End finish (Section 16),

not intended to prohibit the cold bending, flaring, or belling of

3.1.8 Skelp for tension tests, if permitted 20.2,

Grade B pipe.

3.1.9 When mill applied coating is required (Section 10),

1.4 The values stated in inch-pound units are to be regarded

and

as the standard.

3.1.10 ASTM specification number.

1.5 The following hazard caveat applies to the test method

portion, Section 20, of this specification: This standard does 4. Process

not purport to address all of the safety problems, if any,

4.1 The steel shall be made by one or more of the following

associated with its use. It is the responsibility of the user of this

processes: open-hearth, basic-oxygen, or electric-furnace.

standard to establish appropriate safety and health practices

4.2 Steel may be cast in ingots or may be strand cast. When

and determine the applicability of regulatory limitations prior

steels of different grades are sequentially strand cast, identifi-

to use.

cation of the resultant transition material is required. The

producer shall remove the transition material by any estab-

2. Referenced Documents

lished procedure that positively separates the grades.

2.1 ASTM Standards:

5. Chemical Composition

5.1 The steel shall conform to the requirements as to

1

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

chemical composition prescribed in Table 2 and the chemical

Stainless Steel, and Related Alloys, and is the direct responsibility of Subcommittee

analysis shall be in accordance with Test Methods, Practices,

A01.09 on Steel Pipe.

Current edition approved Oct. 10, 1996. Published November 1997. Originally

published as A 523 – 64. Last previous edition A 523 – 93.

2

This specification was initiated by the IEEE Insulated Conductors Committee in Annual Book of ASTM Standards, Vol 01.03.

3

recognition of the need for a specification embodying the special requirements of Annual Book of ASTM Standards, Vol 03.05.

4

pipe for high-voltage electrical circuits. It was prepared for acceptance as an ASTM Available from American National Standards Institute, 11 West 42nd St., 13th

specification by a task group of Subcommittee A01.09 of ASTM Committee A-1. Floor, New York, NY 10036.

1

---------------------- Page: 1 ----------------------

A 52

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.