ASTM D1593-13

(Specification)Standard Specification for Nonrigid Vinyl Chloride Plastic Film and Sheeting

Standard Specification for Nonrigid Vinyl Chloride Plastic Film and Sheeting

ABSTRACT

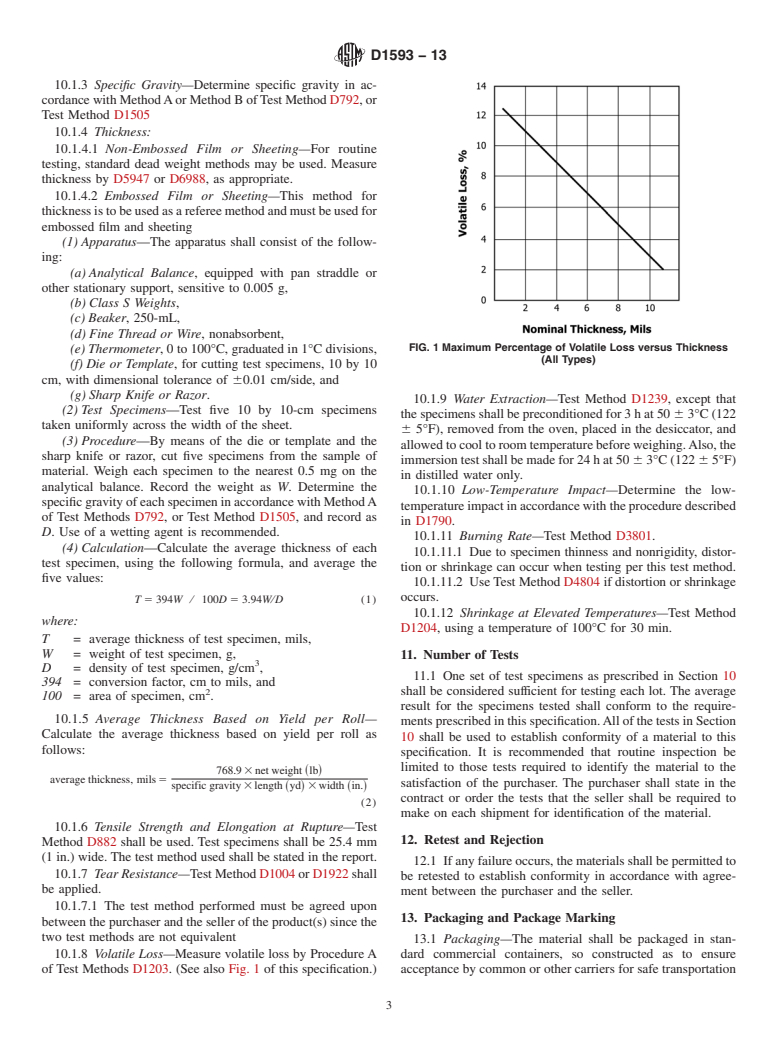

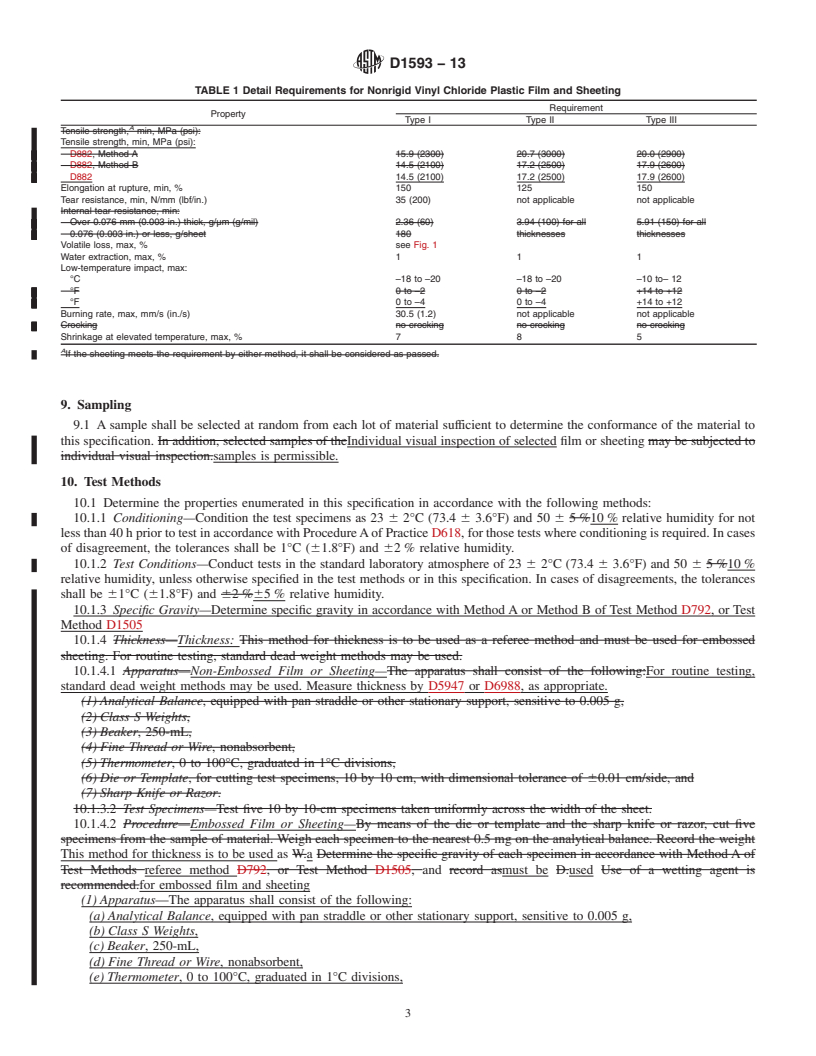

This specification covers nonrigid, unsupported vinyl chloride plastic film and sheeting in which the resin portion of the composition contains at least 90 % vinyl chloride. The remaining 10 % may include one or more monomers copolymerized with vinyl chloride, or consist of other resins mechanically blended together with poly(vinyl chloride) or copolymers thereof. The film and sheeting covered herein shall be 0.075 to 0.25 mm (3 to 10 mils) in thickness for film and greater than 0.25 mm in thickness for sheet, and shall include the stabilizers and plasticizers necessary to meet the requirements of this specification. The material may be transparent, translucent, or opaque, and may be plain, printed, embossed, or otherwise surface treated. This specification designates three general-purpose types of vinyl chloride film and sheeting - calendered, extruded, and cast. The materials shall be tested for its tensile strength and elongation at rapture, tear resistance, volatile loss, water extraction, low temperature impact, burning rate, shrinkage, and color fastness to rubbing.

SCOPE

1.1 This specification covers nonrigid, unsupported vinyl chloride plastic film and sheeting in which the resin portion of the composition contains at least 90 % vinyl chloride. The remaining 10 % can include one or more monomers copolymerized with vinyl chloride, or consist of other resins mechanically blended together with poly(vinyl chloride) or copolymers thereof.

1.2 The vinyl chloride plastic film and sheeting covered herein shall be 0.075 to 0.25 mm (3 to 10 mils) in thickness for film and greater than 0.25 mm in thickness for sheeting. The film and sheeting shall include the stabilizers and plasticizers necessary to meet the requirements of this specification. This specification covers transparent, translucent, or opaque film and sheeting that is plain, printed, embossed, or otherwise surface treated.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 10, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.Note 1—There is no known ISO equivalent to this standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1593 −13

Standard Specification for

1

Nonrigid Vinyl Chloride Plastic Film and Sheeting

This standard is issued under the fixed designation D1593; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D882 Test Method for Tensile Properties of Thin Plastic

Sheeting

1.1 This specification covers nonrigid, unsupported vinyl

D1004 Test Method for Tear Resistance (Graves Tear) of

chloride plastic film and sheeting in which the resin portion of

Plastic Film and Sheeting

the composition contains at least 90 % vinyl chloride. The

D1203 Test Methods for Volatile Loss From Plastics Using

remaining 10 % can include one or more monomers copoly-

Activated Carbon Methods

merizedwithvinylchloride,orconsistofotherresinsmechani-

D1204 Test Method for Linear Dimensional Changes of

cally blended together with poly(vinyl chloride) or copolymers

Nonrigid Thermoplastic Sheeting or Film at Elevated

thereof.

Temperature

1.2 The vinyl chloride plastic film and sheeting covered

D1239 Test Method for Resistance of Plastic Films to

herein shall be 0.075 to 0.25 mm (3 to 10 mils) in thickness for

Extraction by Chemicals

film and greater than 0.25 mm in thickness for sheeting. The

D1505 Test Method for Density of Plastics by the Density-

film and sheeting shall include the stabilizers and plasticizers

Gradient Technique

necessary to meet the requirements of this specification. This

D1790 Test Method for Brittleness Temperature of Plastic

specification covers transparent, translucent, or opaque film

Sheeting by Impact

and sheeting that is plain, printed, embossed, or otherwise

D1922 Test Method for Propagation Tear Resistance of

surface treated.

Plastic Film and Thin Sheeting by Pendulum Method

D3801 TestMethodforMeasuringtheComparativeBurning

1.3 The values stated in SI units are to be regarded as the

standard. Characteristics of Solid Plastics in a Vertical Position

D3892 Practice for Packaging/Packing of Plastics

1.4 The following safety hazards caveat pertains only to the

D4804 Test Method for Determining the Flammability Char-

test methods portion, Section 10, of this specification:This

acteristics of Nonrigid Solid Plastics

standard does not purport to address all of the safety concerns,

D5947 Test Methods for Physical Dimensions of Solid

if any, associated with its use. It is the responsibility of the user

Plastics Specimens

of this standard to establish appropriate safety and health

D6988 GuideforDeterminationofThicknessofPlasticFilm

practices and determine the applicability of regulatory limita-

Test Specimens

tions prior to use.

2.2 Military Standard:

NOTE 1—There is no known ISO equivalent to this standard.

MIL-STD-105 Sampling Procedures and Tables for Inspec-

3

tion by Attributes

2. Referenced Documents

2

3. Terminology

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

3.1 Definitions of Terms Specific to This Standard:

D792 Test Methods for Density and Specific Gravity (Rela-

3.1.1 vinyl chloride plastics—plastics based on polymers of

tive Density) of Plastics by Displacement

vinyl chloride or copolymers of vinyl chloride with other

monomers, the vinyl chloride being in greatest amount by

mass.

1

This specification is under the jurisdiction of ASTM Committee D20 on

4. Significance and Use

Plastics and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting,

and Molded Products.

4.1 This specification designates three general-purpose

Current edition approved Oct. 1, 2013. Published October 2013. Originally

types of vinyl chloride plastic film and sheeting. The tests

approved in 1958. Last previous edition approved in 2009 as D1593 - 09. DOI:

10.1520/D1593-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Standards volume information, refer to the standard’s Document Summary page on Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

the ASTM website. www.dodssp.daps.mil.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1593−13

involved are expected to provide information to identify the 7.2 Average Thickness Based on Yield per Roll—The aver-

type of material and to ensure a minimum of good workman- age thickness based on yield shall be determined in accordance

ship and quality. The test data are not nece

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1593 − 09 D1593 − 13

Standard Specification for

1

Nonrigid Vinyl Chloride Plastic Film and Sheeting

This standard is issued under the fixed designation D1593; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers nonrigid, unsupported vinyl chloride plastic film and sheeting in which the resin portion of the

composition contains at least 90 % vinyl chloride. The remaining 10 % maycan include one or more monomers copolymerized

with vinyl chloride, or consist of other resins mechanically blended together with poly(vinyl chloride) or copolymers thereof.

1.2 The vinyl chloride plastic film and sheeting covered herein shall be 0.075 to 0.25 mm (3 to 10 mils) in thickness for film

and greater than 0.25 mm in thickness for sheet.sheeting. The film and sheeting shall include the stabilizers and plasticizers

necessary to meet the requirements of this specification. The material may be This specification covers transparent, translucent, or

opaque, and may be opaque film and sheeting that is plain, printed, embossed, or otherwise surface treated.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 10, of this specification:This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent forto this specification.standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

3

D689 Test Method for Internal Tearing Resistance of Paper (Withdrawn 2009)

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

D882 Test Method for Tensile Properties of Thin Plastic Sheeting

D1004 Test Method for Tear Resistance (Graves Tear) of Plastic Film and Sheeting

D1203 Test Methods for Volatile Loss From Plastics Using Activated Carbon Methods

D1204 Test Method for Linear Dimensional Changes of Nonrigid Thermoplastic Sheeting or Film at Elevated Temperature

D1239 Test Method for Resistance of Plastic Films to Extraction by Chemicals

D1433 for Method of Rate of Burning and/or Extent and Time of Burning of Flexible Thin Plastic Sheeting Supported on a

3

45-Deg Incline (Withdrawn 1986)

D1505 Test Method for Density of Plastics by the Density-Gradient Technique

D1898D1790 Practice for Sampling of PlasticsTest Method for Brittleness Temperature of Plastic Sheeting by Impact

(Withdrawn 1998)

D1922 Test Method for Propagation Tear Resistance of Plastic Film and Thin Sheeting by Pendulum Method

D3801 Test Method for Measuring the Comparative Burning Characteristics of Solid Plastics in a Vertical Position

D3892 Practice for Packaging/Packing of Plastics

D4804 Test Method for Determining the Flammability Characteristics of Nonrigid Solid Plastics

D5947 Test Methods for Physical Dimensions of Solid Plastics Specimens

D6988 Guide for Determination of Thickness of Plastic Film Test Specimens

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and Molded

Products.

Current edition approved Feb. 1, 2009Oct. 1, 2013. Published February 2009October 2013. Originally approved in 1958. Last previous edition approved in 19992009 as

D1593 - 99D1593 - 09., which was withdrawn November 2008 and reinstated in February 2009. DOI: 10.1520/D1593-09. DOI: 10.1520/D1593-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1593 − 13

2.2 Military Standard:

3

MIL-STD-105 Sampling Procedures and Tables for Inspection by Attributes

3. Terminology

3.1 Definitions of Terms Spec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.