ASTM F702-98ae1

(Specification)Standard Specification for Polysulfone Resin for Medical Applications

Standard Specification for Polysulfone Resin for Medical Applications

SCOPE

1.1 This specification covers polysulfone resin (poly(oxy-p-phenylenesulfonyl-p-phenyleneoxy-p-phenyleneisopropylidene-p-phenylene)) for medical applications (as defined in Terminology D883). This specification provides requirements and associated test methods for a form of this thermoplastic which is intended for use in manufacturing medical devices or components of medical devices.

1.2 As with any material, some characteristics may be altered by the processing techniques (such as molding, extrusion, machining, sterilization, and so forth) required for a specific application. Therefore, properties of fabricated forms of this resin should be evaluated using appropriate test methods to assure safety and efficacy.

1.3 The use of this resin in medical devices should be restricted to nonimplant applications until biocompatibility evaluations appropriate for the intended applications are successfully completed.

1.4 The biocompatibility of plastic compounds made up of polysulfone resin containing colorants, fillers, processing aids, or other additives as well as polymer blends which contain polysulfone should not be assumed on the basis of resin compatibility alone. Their biocompatibility must be established by testing the final (end-use) compositions using evaluation methods appropriate for the intended applications. Note that the types, levels, and biological effects of extractives yielded by the additives contained in a compound or blend may also have to be evaluated for some end-use applications.

1.5 All values in this standard are in SI units with the equivalent values in inch-pound units given in parentheses where applicable.

1.6 This standard does not purport to address all of the concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: F 702 – 98a

Standard Specification for

1

Polysulfone Resin for Medical Applications

This standard is issued under the fixed designation F 702; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Editorial corrections were made in Sections 1 and 2, 3.2, 8.2, and the References in May 2001.

1. Scope 2. Referenced Documents

1.1 This specification covers polysulfone resin (poly(oxy-p- 2.1 ASTM Standards:

phenylenesulfonyl-p-phenyleneoxy-p- D 149 Test Method for Dielectric Breakdown Voltage and

phenyleneisopropylidene-p-phenylene)) for medical applica- Dielectric Strength of Solid Electrical Insulating Materials

2

tions (as defined in Terminology D 883). This specification at Commercial Power Frequencies

provides requirements and associated test methods for a form D 256 Test Methods for Impact Resistance of Plastics and

3

of this thermoplastic which is intended for use in manufactur- Electrical Insulating Materials

3

ing medical devices or components of medical devices. D 570 Test Method for Water Absorption of Plastics

3

1.2 As with any material, some characteristics may be D 638 Test Method for Tensile Properties of Plastics

altered by the processing techniques (such as molding, extru- D 648 Test Method for Deflection Temperature of Plastics

3

sion, machining, sterilization, and so forth) required for a Under Flexural Load

specific application. Therefore, properties of fabricated forms D 696 Test Method for Coefficient of Linear Thermal Ex-

3

of this resin should be evaluated using appropriate test methods pansion of Plastics Between − 30°C and 30°C

3

to assure safety and efficacy. D 883 Terminology Relating to Plastics

1.3 The use of this resin in medical devices should be D 955 Test Method of Measuring Shrinkage from Mold

3

restricted to nonimplant applications until biocompatibility Dimensions of Molded Plastics

evaluations appropriate for the intended applications are suc- D 1238 Test Method for Flow Rates of Thermoplastics by

3

cessfully completed. Extrusion Plastometer

1.4 The biocompatibility of plastic compounds made up of D 1505 Test Method for Density of Plastics by the Density-

3

polysulfone resin containing colorants, fillers, processing aids, Gradient Technique

3

or other additives as well as polymer blends which contain D 1898 Practice for Sampling of Plastics

polysulfone should not be assumed on the basis of resin D 3750 Practice for Determination of Number-Average Mo-

4

compatibility alone. Their biocompatibility must be established lecular Weight of Polymers by Membrane Osmometry

5

by testing the final (end-use) compositions using evaluation F 619 Practice for Extraction of Medical Plastics

methods appropriate for the intended applications. Note that F 748 Practice for Selecting Generic Biological Test Meth-

5

the types, levels, and biological effects of extractives yielded ods for Materials and Devices

by the additives contained in a compound or blend may also 2.2 Code of Federal Regulations:

6

have to be evaluated for some end-use applications. Title 21 CFR Subpart 177.1655

1.5 All values in this standard are in SI units with the

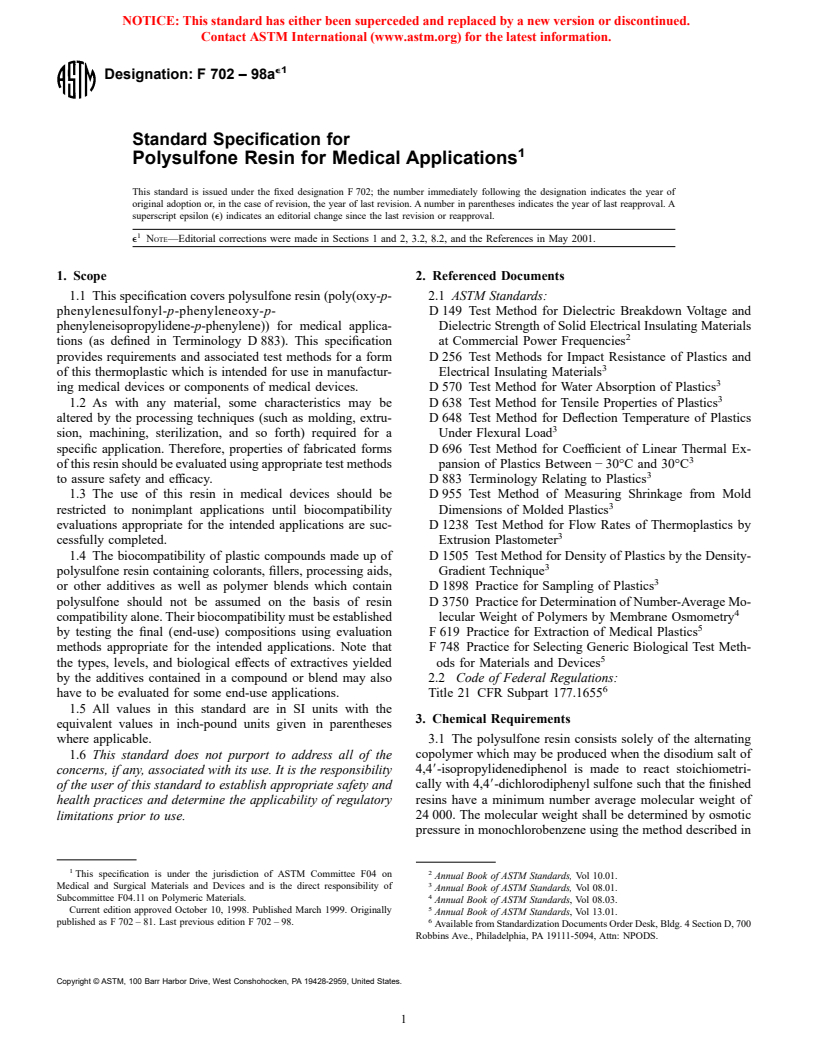

3. Chemical Requirements

equivalent values in inch-pound units given in parentheses

3.1 The polysulfone resin consists solely of the alternating

where applicable.

1.6 This standard does not purport to address all of the copolymer which may be produced when the disodium salt of

4,48-isopropylidenediphenol is made to react stoichiometri-

concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and cally with 4,48-dichlorodiphenyl sulfone such that the finished

resins have a minimum number average molecular weight of

health practices and determine the applicability of regulatory

limitations prior to use. 24 000. The molecular weight shall be determined by osmotic

pressure in monochlorobenzene using the method described in

1

2

This specification is under the jurisdiction of ASTM Committee F04 on

Annual Book of ASTM Standards, Vol 10.01.

3

Medical and Surgical Materials and Devices and is the direct responsibility of

Annual Book of ASTM Standards, Vol 08.01.

4

Subcommittee F04.11 on Polymeric Materials.

Annual Book of ASTM Standards, Vol 08.03.

5

Current edition approved October 10, 1998. Published March 1999. Originally

Annual Book of ASTM Standards, Vol 13.01.

6

published as F 702 – 81. Last previous edition F 702 – 98.

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 B

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.