ASTM D4049-99(2004)

(Test Method)Standard Test Method for Determining the Resistance of Lubricating Grease to Water Spray

Standard Test Method for Determining the Resistance of Lubricating Grease to Water Spray

SCOPE

1.1 This test method evaluates the ability of a grease to adhere to a metal surface, when subjected to a water spray under prescribed laboratory conditions.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

An American National Standard

Designation:D4049–99 (Reapproved 2004)

Standard Test Method for

Determining the Resistance of Lubricating Grease to Water

1

Spray

This standard is issued under the fixed designation D 4049; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 oil separation, n—the appearance of a liquid fraction

2

from an otherwise homogeneous lubricating composition.

1.1 Thistestmethod coverstheabilityofagreasetoadhere

D 1742

to a metal surface when subjected to a water spray under

3.1.3 thickener, n—in lubricating grease, a substance com-

prescribed laboratory conditions.

posed of finely divided particles dispersed in a liquid lubricant

1.2 The values stated in SI units are to be regarded as the

to form the product’s structure.

standard. The values given in parentheses are for information

3.1.3.1 Discussion—The thickeners can be fibers (such as

only.

various metallic soaps) or plates or spheres (such as certain

1.3 This standard does not purport to address all of the

non-soapthickeners),whichareinsolubleor,atmost,onlyvery

safety concerns, if any, associated with its use. It is the

slightly soluble in the liquid lubricant. The general require-

responsibility of the user of this standard to establish appro-

ments are that the solid particles be extremely small, uniformly

priate safety and health practices and determine the applica-

dispersed, and capable of forming a relatively stable, gel-like

bility of regulatory limitations prior to use.

structure with the liquid lubricant. D 217

2. Referenced Documents

4. Summary of Test Method

3

2.1 ASTM Standards:

4.1 The grease to be tested is coated on a stainless steel

D 217 Test Methods for Cone Penetration of Lubricating

panel and sprayed with water at the specified test temperature

Grease

and pressure. The amount of grease remaining on the panel

D 235 Specification for Mineral Spirits (Petroleum Spirits)

after 5 min 6 15 s is a measure of the resistance of the grease

(Hydrocarbon Dry Cleaning Solvent)

to water spray.

D 1742 Test Method for Oil Separation from Lubricating

Grease During Storage

5. Significance and Use

E 691 Practice for Conducting an Interlaboratory Study to

5.1 This test method is used to evaluate the ability of a

Determine the Precision of a Test Method

grease to adhere to a metal surface when subjected to direct

3. Terminology water spray. The results obtained from the use of this test

methodsuggestcorrelationinoperationsinvolvingdirectwater

3.1 Definitions:

spray impingement such as steel mill roll neck bearing ser-

3.1.1 lubricating grease, n—a semi-fluid to solid product of

4

vice. This test method is used for quality control and purchase

a thickener in a liquid lubricant.

specifications.

3.1.1.1 Discussion—Thedispersionofthethickenerformsa

two-phase system and immobilizes the liquid by surface

5

6. Apparatus

tension and other physical forces. Other ingredients are com-

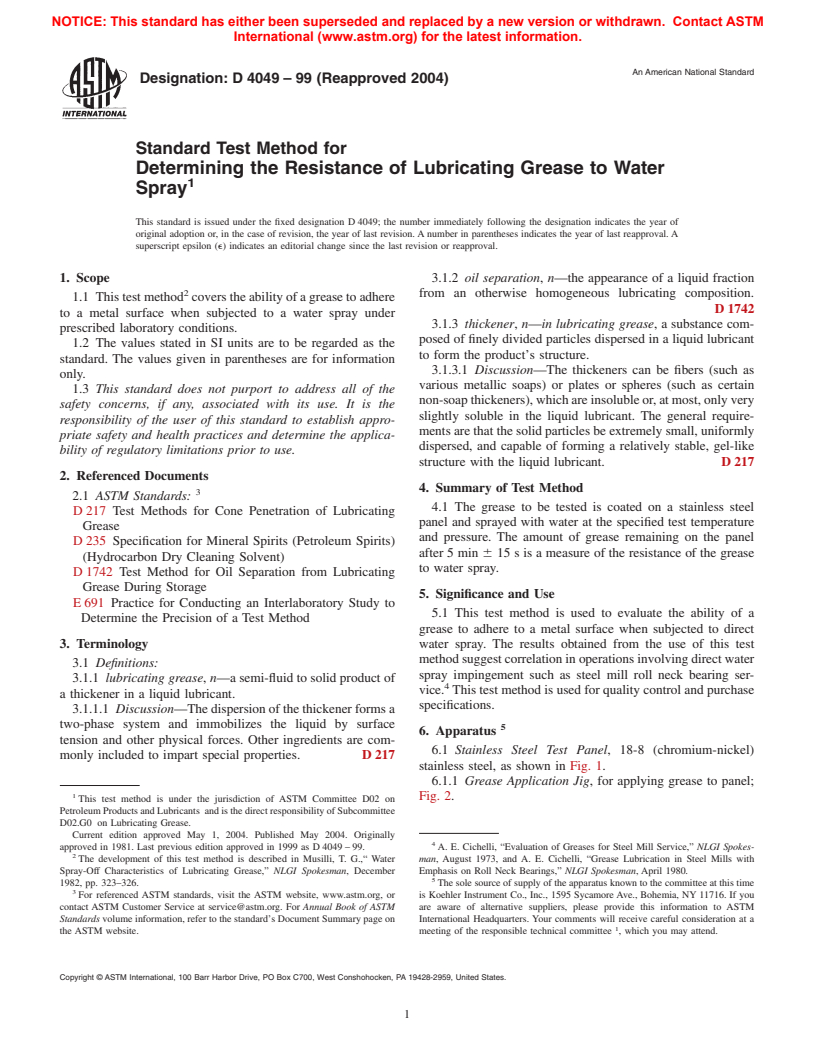

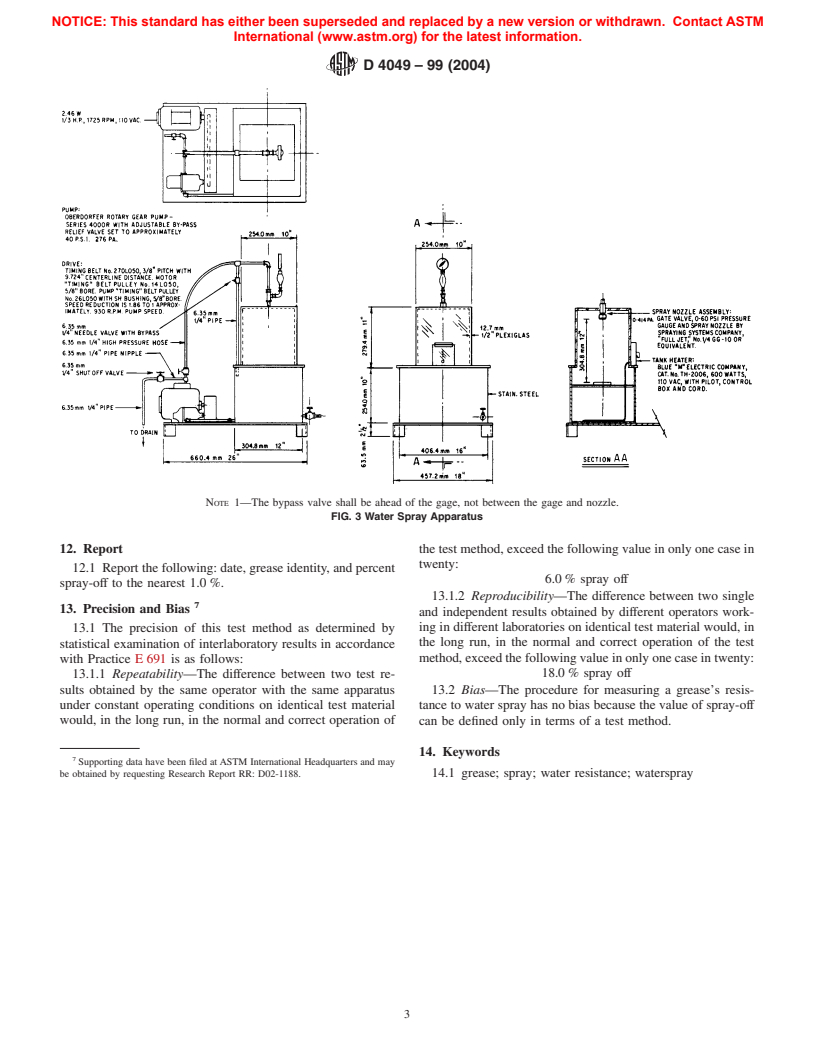

6.1 Stainless Steel Test Panel, 18-8 (chromium-nickel)

monly included to impart special properties. D 217

stainless steel, as shown in Fig. 1.

6.1.1 Grease Application Jig, for applying grease to panel;

1

Fig. 2.

This test method is under the jurisdiction of ASTM Committee D02 on

PetroleumProductsandLubricants andisthedirectresponsibilityofSubcommittee

D02.G0 on Lubricating Grease.

Current edition approved May 1, 2004. Published May 2004. Originally

4

approved in 1981. Last previous edition approved in 1999 as D 4049 – 99. A. E. Cichelli, “Evaluation of Greases for Steel Mill Service,” NLGI Spokes-

2

The development of this test method is described in Musilli, T. G.,“ Water man, August 1973, and A. E. Cichelli, “Grease Lubrication in Steel Mills with

Spray-Off Characteristics of Lubricating Grease,” NLGI Spokesman, December Emphasis on Roll Neck Bearings,” NLGI Spokesman, April 1980.

5

1982, pp. 323–326. The sole source of supply of the apparatus known to the committee at this time

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or is Koehler Instrument Co., Inc., 1595 Sycamore Ave., Bohemia, NY 11716. If you

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM are aware of alternative suppliers, please provide this information to ASTM

Standards volume information, refer to the standard’s Document Summary page on International Headquarters. Your comments will receive careful consideration at a

1

the ASTM website. meeting of the responsible technical committee , which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.