ASTM F1661-96

(Test Method)Standard Test Method for Determining the Contact Bounce Time of a Membrane Switch

Standard Test Method for Determining the Contact Bounce Time of a Membrane Switch

SCOPE

1.1 This test method covers the determination of the contact bounce time of a membrane switch.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1661 – 96

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Determining the Contact Bounce Time of a Membrane

1

Switch

This standard is issued under the fixed designation F 1661; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the contact

bounce time of a membrane switch.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 2240 Test Method for Rubber Property—Durometer

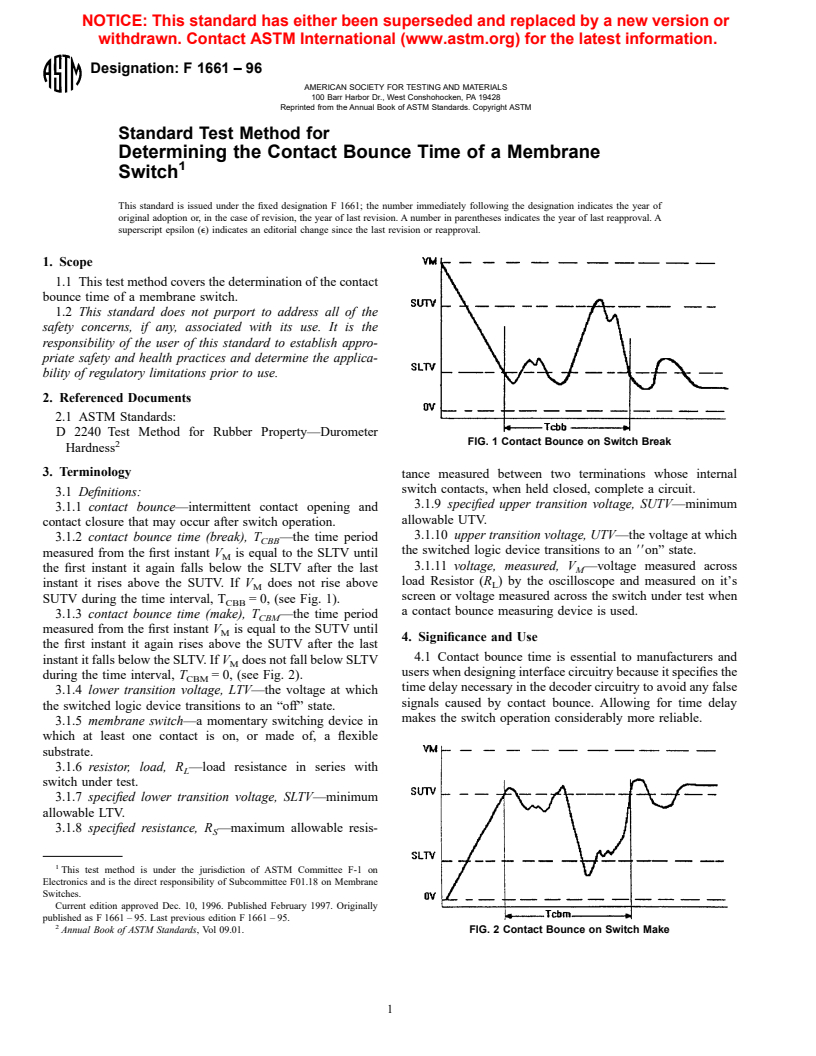

FIG. 1 Contact Bounce on Switch Break

2

Hardness

3. Terminology

tance measured between two terminations whose internal

switch contacts, when held closed, complete a circuit.

3.1 Definitions:

3.1.9 specified upper transition voltage, SUTV—minimum

3.1.1 contact bounce—intermittent contact opening and

allowable UTV.

contact closure that may occur after switch operation.

3.1.10 upper transition voltage, UTV—the voltage at which

3.1.2 contact bounce time (break), T —the time period

CBB

the switched logic device transitions to an 88on” state.

measured from the first instant V is equal to the SLTV until

M

3.1.11 voltage, measured, V —voltage measured across

the first instant it again falls below the SLTV after the last M

load Resistor (R ) by the oscilloscope and measured on it’s

instant it rises above the SUTV. If V does not rise above L

M

screen or voltage measured across the switch under test when

SUTV during the time interval, T = 0, (see Fig. 1).

CBB

a contact bounce measuring device is used.

3.1.3 contact bounce time (make), T —the time period

CBM

measured from the first instant V is equal to the SUTV until

M

4. Significance and Use

the first instant it again rises above the SUTV after the last

4.1 Contact bounce time is essential to manufacturers and

instant it falls below the SLTV. If V does not fall below SLTV

M

users when designing interface circuitry because it specifies the

during the time interval, T = 0, (see Fig. 2).

CBM

time delay necessary in the decoder circuitry to avoid any false

3.1.4 lower transition voltage, LTV—the voltage at which

signals caused by contact bounce. Allowing for time delay

the switched logic device transitions to an “off” state.

makes the switch operation considerably more reliable.

3.1.5 membrane switch—a momentary switching device in

which at least one contact is on, or made of, a flexible

substrate.

3.1.6 resistor, load, R —load resistance in series with

L

switch under test.

3.1.7 specified lower transition voltage, SLTV—minimum

allowable LTV.

3.1.8 specified resistance, R —maximum allowable resis-

S

1

This test method is under the jurisdiction of ASTM Committee F-1 on

Electronics and is the direct responsibility of Subcommittee F01.18 on Membrane

Switches.

Current edition approved Dec. 10, 1996. Published February 1997. Originally

published as F 1661 – 95. Last previous edition F 1661 – 95.

2

Annual Book of ASTM Standards, Vol 09.01. FIG. 2 Contact Bounce on Switch Make

1

---------------------- Page: 1 ----------------------

F 1661

5. Interference

5.1 The following parameters may affect the results of this

test:

5.1.1 If a human finger is used in place of a mechanical

probe the results are more varied and larger sample sizes

should be used, and

5.1.2 Mechanical probe materials (hardness) and speed will

affect results.

6. Apparatus

6.1 Test Probe, built to either of the configuration shown in

Fig. 3 and Fig. 4 are acceptable but must be made of an inert

FIG. 4 Test Probe Option

elastomeric material with a hardness number equivalent to

A/45 6 5 as measured in accordance with Test Method

D 2240. Test probes that do not meet the above criteria must be

fully specified and recorded.

6.2 Test Surface—flat, smooth, unyielding, and larger than

switch under test.

6.3 Oscilloscope, with recording capabilities and power

supply, or suitable contact bounce time measuring instrument.

6.4 Device, which will consistently move probe into and FIG. 5 Test Setup Option

away from the switch at a controlled speed. Also capable of

applying a specified force.

8.1.1 Secure switch on test surface.

CONTACT BOUNCE TIME MEASURING

8.1.2 Connect switch terminals as shown in Fig. 6 so that:

INSTRUMENT METHOD

R 5 10 to 100 times R (1)

L S

7. Procedure

8.1.3 Adj

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.