ASTM B152/B152M-09

(Specification)Standard Specification for Copper Sheet, Strip, Plate, and Rolled Bar

Standard Specification for Copper Sheet, Strip, Plate, and Rolled Bar

ABSTRACT

This standard covers the requirements for copper sheet, strip, plate, and rolled bar produced from copper with the following UNS Nos.; C10100, C10200, C10300, C10400, C10500, C10700, C10800, C10910, C11000, C11300, C11400, C11600, C12000, C12200, C12300, C14200, C14420, and C14530. Chemical composition shall conform to the chemical requirements pertaining to the materials UNS No. Tempering of materials shall be done by hot-rolling, cold rolling, and annealing. Copper material shall meet the maximum limit of electrical resistivity as indicated. The material shall undergo tensile strength, Rockwell hardness, and plate item tests to conform with the mechanical proptery requirement of the specification. The material shall also be capable of passing microscopical examination and embrittlement test, but not required by the specification.

SCOPE

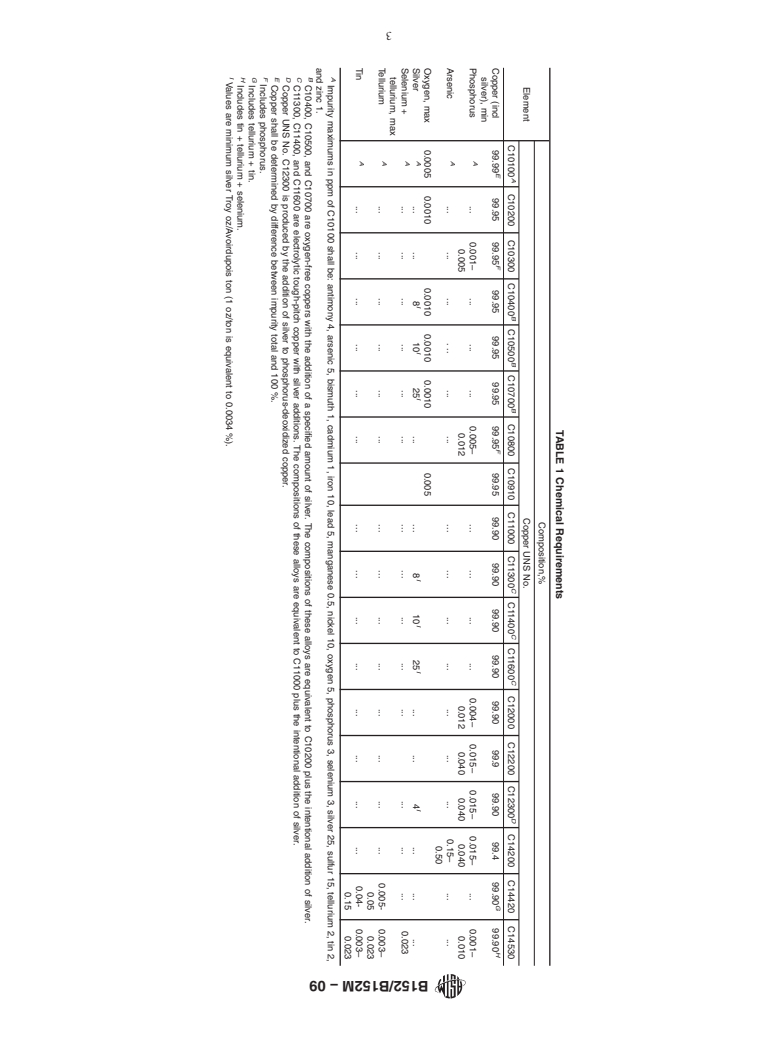

1.1 This specification establishes the requirements for copper sheet, strip, plate, and rolled bar produced from the following coppers.

Copper

UNS No.APrevious

Designation

Type of Copper C10100B OFEOxygen-free electronic C10200B OF Oxygen-free without residual

deoxidants C10300 ...Oxygen-free extra low phosphorus C10400, C10500, C10700 OFS Oxygen-free, silver bearing C10800 ...Oxygen-free low phosphorus C10910 ...Low oxygen C11000B,C ETP,

TPC Electrolytic tough pitchC, Tough pitchC C11300, C11400, C11600B STP Silver bearing tough pitch C12000 DLPPhosphorized, low residual phos-

phorus C12200B DHP Phosphorized, high residual phos-

phorus C12300 DPSPhosphorized, silver bearing C14200 DPAPhosphorus deoxidized, arsenical C14420 ...Tin bearing tellurium copper C14530 ...Tin tellurium bearing copper _______________

A Except Copper UNS Nos. C10910 (low oxygen), C14200 (phosphorus deoxidized, arsenical), C14420 (tin bearing tellurium), and C14530 (tin tellurium bearing) these types of copper are classified in Classification B224.

B SAE Specification CA101 conforms to Copper UNS No. C10100; SAE Specification CA102 conforms to the requirements for Copper UNS No. C10200; SAE Specification CA110 conforms to the requirements for Copper UNS No. C11000; SAE Specifications CA113, CA114, and CA116 conform to the requirements for Copper UNS Nos. C11300, C11400, and C11600; SAE Specification CA120 conforms to Copper UNS No. C12000; and SAE Specification CA122 conforms to the requirements for Copper UNS No. C12200.

C Unless specified in the contract or purchase order the supplier is permitted to provide ETP copper or TP copper.

Note 1—Each of the coppers listed has unique properties that can make it suitable for specific applications. The purchaser should consult with the supplier to determine which copper would be best suited for the intended application.

Note 2—This specification is not intended to establish requirements for material rolled to ounce-weight thicknesses. Such material is defined in Specification B370.

Plates for locomotive fireboxes are defined in Specification B11.

Flat copper products with finished (rolled or drawn) edges (flat wire and strip) are defined in Specification B272.

1.1.1 When a specific copper is not identified in the contract or purchase order, the supplier may furnish product from any of the listed coppers.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 The following safety hazards caveat only pertains to the test method portion, Section 13 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B152/B152M −09 Usedin USDOE-NE standards

Standard Specification for

1

Copper Sheet, Strip, Plate, and Rolled Bar

This standard is issued under the fixed designation B152/B152M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

NOTE2—Thisspecificationisnotintendedtoestablishrequirementsfor

1. Scope*

material rolled to ounce-weight thicknesses. Such material is defined in

2

1.1 This specification establishes the requirements for cop-

Specification B370.

per sheet, strip, plate, and rolled bar produced from the Plates for locomotive fireboxes are defined in Specification B11.

Flatcopperproductswithfinished(rolledordrawn)edges(flatwireand

following coppers.

strip) are defined in Specification B272.

Previous

Copper

Designation

1.1.1 When a specific copper is not identified in the contract

A

UNS No. Type of Copper

orpurchaseorder,thesuppliermayfurnishproductfromanyof

B

the listed coppers.

C10100 OFE Oxygen-free electronic

B

C10200 OF Oxygen-free without residual

1.2 The values stated in either SI units or inch-pound units

deoxidants

are to be regarded separately as standard. The values stated in

C10300 . Oxygen-free extra low phosphorus

C10400, C10500, C10700 OFS Oxygen-free, silver bearing

each system may not be exact equivalents; therefore, each

C10800 . Oxygen-free low phosphorus

system shall be used independently of the other. Combining

C10910 . Low oxygen

B,C C

values from the two systems may result in non-conformance

C11000 ETP, Electrolytic tough pitch , Tough

C

C

pitch

TP

with the standard.

B

C11300, C11400, C11600 STP Silver bearing tough pitch

C12000 DLP Phosphorized, low residual phos- 1.3 The following safety hazards caveat only pertains to the

phorus

test method portion, Section 13 of this specification:This

B

C12200 DHP Phosphorized, high residual phos-

standard does not purport to address all of the safety concerns,

phorus

C12300 DPS Phosphorized, silver bearing if any, associated with its use. It is the responsibility of the user

C14200 DPA Phosphorus deoxidized, arsenical

of this standard to establish appropriate safety and health

C14420 . Tin bearing tellurium copper

practices and determine the applicability of regulatory limita-

C14530 . Tin tellurium bearing copper

_______________ tions prior to use.

A

Except Copper UNS Nos. C10910 (low oxygen), C14200 (phosphorus

2. Referenced Documents

deoxidized, arsenical), C14420 (tin bearing tellurium), and C14530 (tin tellurium

bearing) these types of copper are classified in Classification B224.

3

B

2.1 ASTM Standards:

SAE Specification CA101 conforms to Copper UNS No. C10100; SAE Specifi-

cation CA102 conforms to the requirements for Copper UNS No. C10200; SAE

B11 Specification for Copper Plates for Locomotive Fire-

4

Specification CA110 conforms to the requirements for Copper UNS No. C11000;

boxes (Withdrawn 1980)

SAE Specifications CA113, CA114, and CA116 conform to the requirements for

B170 Specification for Oxygen-Free Electrolytic Copper—

Copper UNS Nos. C11300, C11400, and C11600; SAE Specification CA120

conforms to Copper UNS No. C12000; and SAE Specification CA122 conforms to

Refinery Shapes

the requirements for Copper UNS No. C12200.

B193 Test Method for Resistivity of Electrical Conductor

C

Unless specified in the contract or purchase order the supplier is permitted to

Materials

provide ETP copper or TP copper.

B216 Specification for Tough-Pitch Fire-Refined Copper—

NOTE1—Eachofthecopperslistedhasuniquepropertiesthatcanmake

Refinery Shapes

it suitable for specific applications. The purchaser should consult with the

B224 Classification of Coppers

supplier to determine which copper would be best suited for the intended

application. B248 Specification for General Requirements for Wrought

Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled

Bar

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

andCopperAlloysandisthedirectresponsibilityofSubcommitteeB05.01onPlate,

3

Sheet, and Strip. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2009. Published November 2009. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

´1

approved in 1942. Last previous edition approved in 2006 as B152/B152M – 06a . Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/B0152_B0152M-09. the ASTM website.

2

4

For ASME Boiler and Pressure Vessel Code applications see related Specifi- The last approved version of this historical standard is referenced

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Used in USDOE-NE standards

´1

Designation:B152/B152M–06a Designation: B152/B152M – 09

Standard Specification for

1

Copper Sheet, Strip, Plate, and Rolled Bar

This standard is issued under the fixed designation B152/B152M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

´ NOTE—Table 4 was editorially corrected in February 2008.

1. Scope*

2

1.1 This specification establishes the requirements for copper sheet, strip, plate, and rolled bar produced from the following

coppers.

Previous

Copper

Designa-

A

UNS No. Type of Copper

tion

B

C10100 OFE Oxygen-free electronic

B

C10200 OF Oxygen-free without residual

deoxidants

C10300 . Oxygen-free extra low phosphorus

C10400, C10500, C10700 OFS Oxygen-free, silver bearing

C10800 . Oxygen-free low phosphorus

C10910 . Low oxygen

B

C11000 ETP Electrolytic tough pitch

B,C C

C11000 ETP, Electrolytic tough pitch , Tough

C C

TP pitch

B

C11300, C11400, C11600 STP Silver bearing tough pitch

C12000 DLP Phosphorized, low residual phos-

phorus

B

C12200 DHP Phosphorized, high residual phos-

phorus

C12300 DPS Phosphorized, silver bearing

C14200 DPA Phosphorus deoxidized, arsenical

C14420 . Tin bearing tellurium copper

C14530 . Tin tellurium bearing copper

_______________

A

Except Copper UNS Nos. C10910 (low oxygen), C14200 (phosphorus deoxidized, arsenical), C14420 (tin bearing tellurium), and C14530 (tin tellurium bearing) these

types of copper are classified in Classification B224.

B

SAE Specification CA101 conforms to Copper UNS No. C10100; SAE Specification CA102 conforms to the requirements for Copper UNS No. C10200; SAE

Specification CA110 conforms to the requirements for Copper UNS No. C11000; SAE Specifications CA113, CA114, and CA116 conform to the requirements for Copper

UNS Nos. C11300, C11400, and C11600; SAE Specification CA120 conforms to Copper UNS No. C12000; and SAE Specification CA122 conforms to the requirements

for Copper UNS No. C12200.

C

Unless specified in the contract or purchase order the supplier is permitted to provide ETP copper or TP copper.

NOTE 1—Each of the coppers listed has unique properties that can make it suitable for specific applications. The purchaser should consult with the

supplier to determine which copper would be best suited for the intended application.

NOTE 2—This specification is not intended to establish requirements for material rolled to ounce-weight thicknesses. Such material is defined in

Specification B370.

Plates for locomotive fireboxes are defined in Specification B11.

Flat copper products with finished (rolled or drawn) edges (flat wire and strip) are defined in Specification B272.

1.1.1 When a specific copper is not identified in the contract or purchase order, the supplier may furnish product from any of

the listed coppers.

1.2 The values stated in inch-pound either SI units or SIinch-pound units are to be regarded separately as standard. The values

stated in each system aremay not be exact equivalents; therefore, each system shall be used independently of the other. Combining

values from the two systems may result in non-conformance with the specification. standard.

1

This specification is under the jurisdiction of ASTM Committee B05 on Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.01 on Plate,

Sheet, and Strip.

Current edition approved Oct. 1, 2006.2009. Published October 2006.November 2009. Originally approved in 1942. Last previous edition approved in 2006 as

´1

B152/B152M – 06a . DOI: 10.1520/B0152_B0152M-06AE01.10.1520/B0152_B0152M-09.

2

For ASME Boiler and Pressure Vessel Code applications see related Specification SB-152 in Section 11 of that Code.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B152/B152M – 09

1.3 The following safety hazards caveat only pertains to the test method portion, Section 13 of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.