ASTM B813-16

(Specification)Standard Specification for Liquid and Paste Fluxes for Soldering of Copper and Copper Alloy Tube

Standard Specification for Liquid and Paste Fluxes for Soldering of Copper and Copper Alloy Tube

ABSTRACT

This guide establishes the requirements and test methods for liquid and paste fluxes for joining by soldering of copper and copper alloy tube and fittings in plumbing, heating, air conditioning, mechanical, fire sprinkler, and other similar systems. There shall be a clear indication that in the areas of flux reaction, the sheets shall show a corrosion and residue-free surface comparable with the unwetted areas as determined by visual inspection. Samples of flux taken for the purpose of the tests listed in this specification shall be selected from the stock of the manufacturer and shall be representative of the material being evaluated. The specimen shall undergo the spreading test wherein the oven shall be equipped with a sight glass for visible control of the melting of the solder. The specimen shall then pass the aggressiveness test wherein the aggressiveness of the flux is determined by means of a resistivity test of an aqueous solution of the flux residue. The conductivity cell to be used shall be kept immersed in distilled water at ambient temperature for a given minimum number of hours before use. Resistivity tests shall be performed for both soldered and unsoldered specimen. The specimen shall then undergo corrosive test by being dipped onto ethanol.

SCOPE

1.1 This specification establishes the requirements and test methods for liquid and paste fluxes for joining by soldering of copper and copper alloy tube and fittings in plumbing, heating, air conditioning, mechanical, fire sprinkler, and other similar systems.

Note 1: This specification does not apply to fluxes intended for electronic applications.

1.2 Solder fluxes are to be tested in accordance with the requirements of this specification by an independent testing laboratory. Testing, measuring equipment, and inspection facilities shall be of sufficient accuracy and quality to comply with the requirements of this specification.

1.3 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 The following hazard caveat pertains to Sections 11 – 19. This standard does not purport to address the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B813 −16

Standard Specification for

Liquid and Paste Fluxes for Soldering of Copper and

1

Copper Alloy Tube

This standard is issued under the fixed designation B813; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

INTRODUCTION

This specification covers a series of specific requirements for liquid and paste fluxes. It also

incorporates a series of test methods that establish the procedures on how to measure these properties.

Theformatofthisspecificationinitiallydefinesthespecificationrequirementsfollowedbythespecific

test methods in the order in which they are to be performed.

2

1. Scope* 2.2 ASTM Standards:

B32 Specification for Solder Metal

1.1 This specification establishes the requirements and test

B88 Specification for Seamless Copper Water Tube

methods for liquid and paste fluxes for joining by soldering of

B88M Specification for Seamless Copper Water Tube (Met-

copper and copper alloy tube and fittings in plumbing, heating,

ric)

air conditioning, mechanical, fire sprinkler, and other similar

B152/B152M Specification for Copper Sheet, Strip, Plate,

systems.

and Rolled Bar

NOTE 1—This specification does not apply to fluxes intended for

B280 Specification for Seamless Copper Tube for Air Con-

electronic applications.

ditioning and Refrigeration Field Service

1.2 Solder fluxes are to be tested in accordance with the

B846 Terminology for Copper and Copper Alloys

requirements of this specification by an independent testing

D130 Test Method for Corrosiveness to Copper from Petro-

laboratory. Testing, measuring equipment, and inspection fa-

leum Products by Copper Strip Test

cilities shall be of sufficient accuracy and quality to comply

D1200 Test Method for Viscosity by Ford Viscosity Cup

with the requirements of this specification.

2.3 Other:

3

1.3 Units—The values stated in SI units are to be regarded

1986 Amendments to the Safe Drinking Water Act

as standard. No other units of measurement are included in this

standard.

3. General Requirements

1.4 The following hazard caveat pertains to Sections 11 –

3.1 The flux shall be suitable for joining copper tube and

19. This standard does not purport to address the safety

fittings by soldering in the size ranges shown in Table 1 of

problems, if any, associated with its use. It is the responsibility

Specifications B88 and B88M and Tables 4 and 5 of Specifi-

of the user of this standard to establish appropriate safety and

cation B280.

health practices and determine the applicability of regulatory

3.2 The flux shall remain active over the temperature range

limitations prior to use.

of the soldering operation, removing and excluding oxides

from the metal surfaces in the joint.

2. Referenced Documents

3.3 The flux shall be suitable for use with all solders listed

2.1 The following documents of the issue in effect on the

in Table 5 of Specification B32 as well as the more recently

date of materials purchase form a part of this specification to

the extent referenced herein:

1 2

This specification is under the jurisdiction of Committee B05 on Copper and For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe and contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Tube. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved May 1, 2016. Published May 2016. Originally the ASTM website.

3

approved in 1991. Last previous edition approved in 2010 as B813 – 10. DOI: Available from U.S. Government Publishing Office, 732 North Capitol Street,

10.1520/B0813-16. NW, Washington, DC 20401-0001, www.gpo.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B813−16

developed solder alloys suitable for the applications in the 7. Corrosiveness Requirements

scope of this specification.

7.1 There shall be a clear indication that in the areas of flux

3.4 The flux shall allow the solder to adequately wet and reaction, the sheets shall show a corrosion and residue-free

spread on the surfaces being soldered. surface comparable with the unwetted areas as determined by

visual inspection in accordance with Section 17.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B813 − 10 B813 − 16

Standard Specification for

Liquid and Paste Fluxes for Soldering of Copper and

1

Copper Alloy Tube

This standard is issued under the fixed designation B813; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

INTRODUCTION

This specification covers a series of specific requirements for liquid and paste fluxes. It also

incorporates a series of test methods that establish the procedures on how to measure these properties.

The format of this specification initially defines the specification requirements followed by the specific

test methods in the order in which they are to be performed.

1. Scope Scope*

1.1 This specification establishes the requirements and test methods for liquid and paste fluxes for joining by soldering of copper

and copper alloy tube and fittings in plumbing, heating, air conditioning, mechanical, fire sprinkler, and other similar systems.

NOTE 1—This specification does not apply to fluxes intended for electronic applications.

1.2 Solder fluxes are to be tested in accordance with the requirements of this specification by an independent testing laboratory.

Testing, measuring equipment, and inspection facilities shall be of sufficient accuracy and quality to comply with the requirements

of this specification.

1.3 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this

standard.

1.4 The following hazard caveat pertains to Sections 11 – 19.This standard does not purport to address the safety problems, if

any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices

and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 The following documents of the issue in effect on the date of materials purchase form a part of this specification to the extent

referenced herein:

2

2.2 ASTM Standards:

B32 Specification for Solder Metal

B88 Specification for Seamless Copper Water Tube

B88M Specification for Seamless Copper Water Tube (Metric)

B152/B152M Specification for Copper Sheet, Strip, Plate, and Rolled Bar

B280 Specification for Seamless Copper Tube for Air Conditioning and Refrigeration Field Service

B846 Terminology for Copper and Copper Alloys

D130 Test Method for Corrosiveness to Copper from Petroleum Products by Copper Strip Test

D1200 Test Method for Viscosity by Ford Viscosity Cup

1

This specification is under the jurisdiction of Committee B05 on Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.04 on Pipe and Tube.

Current edition approved April 1, 2010May 1, 2016. Published April 2010May 2016. Originally approved in 1991. Last previous edition approved in 20092010 as

B813 – 00B813 – 10. (2009). DOI: 10.1520/B0813-10.10.1520/B0813-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

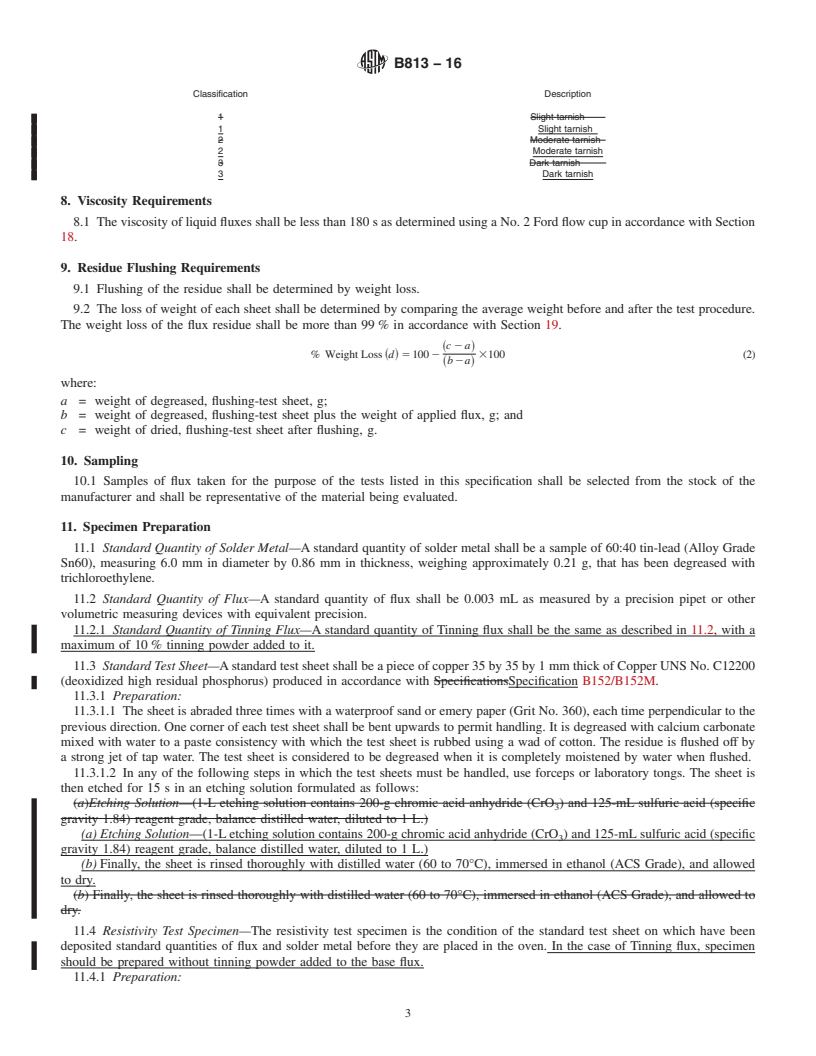

B813 − 16

2.3 Other:

3

1986 Amendments to the Safe Drinking Water Act

3. General Requirements

3.1 The flux shall be suitable for joining copper tube and fittings by soldering in the size ranges shown in Table 1 of

Specifications B88 and B88M and Tables 4 and 5 of Specification B280.

3.2 The flux shall remain active over the temperature range of the soldering operation, removing and excluding oxides from the

metal surfaces in the joint.

3.3 The flux shall be suitable for use with all solders listed in Table 5 of Specification B32 as well as the more recently

developed solder alloys suitable for the applications in the scope of this specification.

3.4 The flux shall allow the solder to adequately wet and spread on the surfaces being soldered.

3.5 The flux residue shall be water flushable after soldering as specified in accordance with Sections 7 and 9.

3.6 The flux residue shall not be corrosive or toxic after soldering po

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.