ASTM C357-07(2015)

(Test Method)Standard Test Method for Bulk Density of Granular Refractory Materials

Standard Test Method for Bulk Density of Granular Refractory Materials

SIGNIFICANCE AND USE

3.1 Granular refractory materials may be either refractory grain raw materials that are used in the manufacture of finished refractory products, or bulk granular refractory materials that are sold, with or without some degree of processing, to refractory consumers for various uses. In either case, characterizing the properties of a granular refractory material is essential in evaluating its quality or consistency of quality and in determining suitability for end use. One of the important properties is bulk density because of its relationship to end product quality, usage, and performance.

3.2 The refractories producer can use this test method as one of the quality-control tests for his manufactured or mined refractory grain raw materials or for evaluating potential refractory grain raw materials.

3.3 For the refractories consumer, the principal use of this test method is in the evaluation of the quality or the consistency of quality of the granular material in purchased refractory mixes or in bulk granular refractory materials used by the consumer.

3.4 This is a primary test method, and thus is suitable for use in specifications, quality control, and research and development. It can also serve as a referee test method in purchasing contracts or agreements and as a base for development of more rapid, secondary test methods for use in quality control on manufactured refractory raw materials.

3.5 Fundamental assumptions inherent in this test method are that the sample is representative of the material in general, the particle size of the sample is within the range specified by the test method, the material is not readily hydratable, and the size and quantity of pores in the material permits removal of surface water without drainage from the pores themselves. Deviation from any of these assumptions negates the usefulness of the test results.

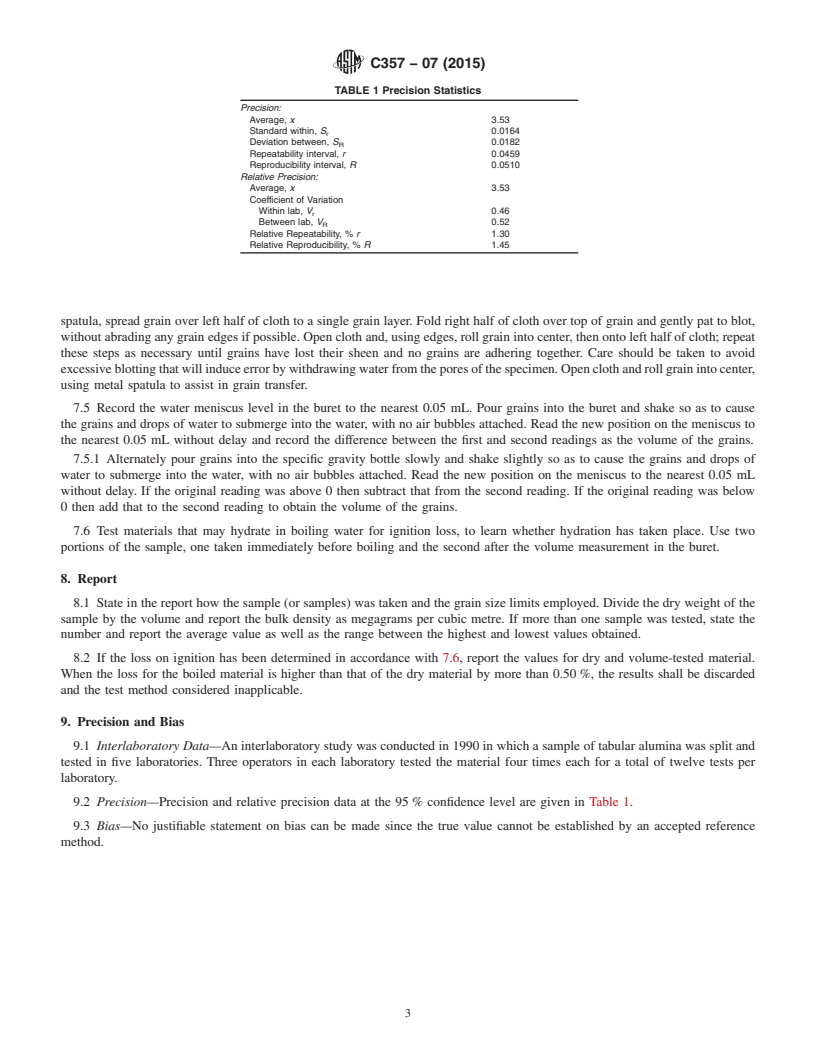

3.6 In interpreting the results of this test method, it must be recognized that the specific gravity of the materia...

SCOPE

1.1 This test method covers a procedure for determining the bulk density of granular refractory materials, commercial products which usually have particles that are retained on a 0.265-in. (6.7-mm) or coarser sieve.

Note 1: This test method is not suitable for materials that hydrate in boiling water.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.2.1 Exceptions—In Sections 4, 7, and 8, the apparatus used is only available in SI units.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C357 − 07 (Reapproved 2015)

Standard Test Method for

1

Bulk Density of Granular Refractory Materials

This standard is issued under the fixed designation C357; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope properties is bulk density because of its relationship to end

product quality, usage, and performance.

1.1 This test method covers a procedure for determining the

bulk density of granular refractory materials, commercial

3.2 Therefractoriesproducercanusethistestmethodasone

products which usually have particles that are retained on a

of the quality-control tests for his manufactured or mined

0.265-in. (6.7-mm) or coarser sieve.

refractory grain raw materials or for evaluating potential

refractory grain raw materials.

NOTE 1—This test method is not suitable for materials that hydrate in

boiling water.

3.3 For the refractories consumer, the principal use of this

1.2 Units—The values stated in inch-pound units are to be

testmethodisintheevaluationofthequalityortheconsistency

regarded as standard. The values given in parentheses are of quality of the granular material in purchased refractory

mathematical conversions to SI units that are provided for

mixes or in bulk granular refractory materials used by the

information only and are not considered standard. consumer.

1.2.1 Exceptions—In Sections 4, 7, and 8, the apparatus

3.4 Thisisaprimarytestmethod,andthusissuitableforuse

used is only available in SI units.

in specifications, quality control, and research and develop-

1.3 This standard does not purport to address all of the

ment. It can also serve as a referee test method in purchasing

safety concerns, if any, associated with its use. It is the

contracts or agreements and as a base for development of more

responsibility of the user of this standard to establish appro-

rapid, secondary test methods for use in quality control on

priate safety and health practices and determine the applica-

manufactured refractory raw materials.

bility of regulatory limitations prior to use.

3.5 Fundamental assumptions inherent in this test method

are that the sample is representative of the material in general,

2. Referenced Documents

the particle size of the sample is within the range specified by

2

2.1 ASTM Standards:

the test method, the material is not readily hydratable, and the

E11 Specification for Woven Wire Test Sieve Cloth and Test

size and quantity of pores in the material permits removal of

Sieves

surface water without drainage from the pores themselves.

Deviation from any of these assumptions negates the useful-

3. Significance and Use

ness of the test results.

3.1 Granular refractory materials may be either refractory

3.6 In interpreting the results of this test method, it must be

grain raw materials that are used in the manufacture of finished

recognized that the specific gravity of the material as well as

refractory products, or bulk granular refractory materials that

the porosity affects the value obtained for bulk density. Thus,

are sold, with or without some degree of processing, to

comparisons of results should only be made between like

refractory consumers for various uses. In either case, charac-

materials or with full recognition of inherent differences

terizing the properties of a granular refractory material is

between the materials being compared.

essential in evaluating its quality or consistency of quality and

in determining suitability for end use. One of the important

4. Apparatus

4.1 Laboratory Jaw Crusher or Rolls , for crushing samples

1

This test method is under the jurisdiction of the ASTM Committee C08 on

to pass a 0.265-in. (6.7-mm) sieve.

Refractories and is the direct responsibility of Subcommittee C08.03 on Physical

Properties.

4.2 Standard Sieves, 0.265-in. and No. 8 (2.36-mm) with

Current edition approved March 1, 2015. Published April 2015. Originally

Pan and Cover (Note 2)—The sieves shall conform to Speci-

approved in 1955. Last previous edition approved in 2009 as C357–07 (2009)ε1.

DOI: 10.1520/C0357-07R15. fication E11.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.2.1 The coarser sieve may be the No. 4 (4.75 mm) and the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

finer sieve may be the No. 6 (3.35 mm) or No. 12 (1.70 mm),

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. if tests indicate that the range in particle size is not critical.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: C357 − 07 (Reapproved 2009) C357 − 07 (Reapproved 2015)

Standard Test Method for

1

Bulk Density of Granular Refractory Materials

This standard is issued under the fixed designation C357; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Units usage was updated in April 2009.

1. Scope

1.1 This test method covers a procedure for determining the bulk density of granular refractory materials, commercial products

which usually have particles that are retained on a 0.265-in. (6.7-mm) or coarser sieve.

NOTE 1—This test method is not suitable for materials that hydrate in boiling water.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are

mathematical conversions to SI units that are provided for information only and are not considered standard.

1.2.1 Exceptions—In Sections 4, 7, and 8, the apparatus used is only available in SI units.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

3. Significance and Use

3.1 Granular refractory materials may be either refractory grain raw materials that are used in the manufacture of finished

refractory products, or bulk granular refractory materials that are sold, with or without some degree of processing, to refractory

consumers for various uses. In either case, characterizing the properties of a granular refractory material is essential in evaluating

its quality or consistency of quality and in determining suitability for end use. One of the important properties is bulk density

because of its relationship to end product quality, usage, and performance.

3.2 The refractories producer can use this test method as one of the quality-control tests for his manufactured or mined

refractory grain raw materials or for evaluating potential refractory grain raw materials.

3.3 For the refractories consumer, the principal use of this test method is in the evaluation of the quality or the consistency of

quality of the granular material in purchased refractory mixes or in bulk granular refractory materials used by the consumer.

3.4 This is a primary test method, and thus is suitable for use in specifications, quality control, and research and development.

It can also serve as a referee test method in purchasing contracts or agreements and as a base for development of more rapid,

secondary test methods for use in quality control on manufactured refractory raw materials.

3.5 Fundamental assumptions inherent in this test method are that the sample is representative of the material in general, the

particle size of the sample is within the range specified by the test method, the material is not readily hydratable, and the size and

quantity of pores in the material permits removal of surface water without drainage from the pores themselves. Deviation from any

of these assumptions negates the usefulness of the test results.

3.6 In interpreting the results of this test method, it must be recognized that the specific gravity of the material as well as the

porosity affects the value obtained for bulk density. Thus, comparisons of results should only be made between like materials or

with full recognition of inherent differences between the materials being compared.

1

This test method is under the jurisdiction of the ASTM Committee C08 on Refractories and is the direct responsibility of Subcommittee C08.03 on Physical Properties.

Current edition approved March 1, 2009March 1, 2015. Published April 2009April 2015. Originally approved in 1955. Last previous edition approved in 20072009 as

C357–07. –07 (2009)ε1. DOI: 10.1520/C0357-07R09E01.10.1520/C0357-07R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.