ASTM A865/A865M-06

(Specification)Standard Specification for Threaded Couplings, Steel, Black or Zinc-Coated (Galvanized) Welded or Seamless, for Use in Steel Pipe Joints

Standard Specification for Threaded Couplings, Steel, Black or Zinc-Coated (Galvanized) Welded or Seamless, for Use in Steel Pipe Joints

ABSTRACT

This guide covers standard specification for black or galvanized welded or seamless threaded steel couplings for use with steel pipe joints in NPS 1/8 to NPS 20 [DN 6 to DN 500] inclusive. The steel for both welded and seamless couplings shall be made by one or more of the following processes: open-hearth, electric-furnace, or basic-oxygen. Welded couplings NPS 3½ [DN 90] and under may be butt-welded. Welded couplings over NPS 3½ [DN 90] shall be electric-welded. The steel shall conform to the required chemical composition for phosphorus and sulfur.

SCOPE

1.1 This specification covers black or galvanized welded or seamless threaded steel couplings for use with steel pipe in NPS 1/8 to NPS 20 [DN 6 to DN 500] inclusive (). Couplings ordered under this specification are intended for the uses outlined in the pipe specifications referencing this specification. The dimensionless designator NPS (nominal pipe size) and DN [diameter nominal] has been substituted in this standard for such traditional terms as nominal diameter, size, and nominal size.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A865/A865M −06

StandardSpecification for

Threaded Couplings, Steel, Black or Zinc-Coated

(Galvanized) Welded or Seamless, for Use in Steel Pipe

1

Joints

This standard is issued under the fixed designationA865/A865M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2.3 API Standards:

5B Specification for Threading, Gaging, and Thread Inspec-

1.1 This specification covers black or galvanized welded or

4

tion of Casing, Tubing, and Line Pipe Threads

seamless threaded steel couplings for use with steel pipe in

4

5L Specification for Line Pipe

1

NPS ⁄8 to NPS 20 [DN 6 to DN 500] inclusive (Note 1).

Couplings ordered under this specification are intended for the

3. Ordering Information

uses outlined in the pipe specifications referencing this speci-

3.1 Orders for material under this specification should

fication.

include the following, as required, to describe the desired

NOTE 1—The dimensionless designator NPS (nominal pipe size) and material adequately:

DN [diameter nominal] has been substituted in this standard for such

3.1.1 Specification number,

traditional terms as nominal diameter, size, and nominal size.

3.1.2 Quantity (pieces),

3.1.3 Name of material (steel pipe-couplings),

1.2 The values stated in either SI units or inch-pound units

3.1.4 Method of manufacture (welded or seamless),

are to be regarded separately as standard. The values stated in

3.1.5 Finish (black or Type I or Type II) galvanized (see

each system may not be exact equivalents; therefore, each

8.1),

system shall be used independently of the other. Combining

3.1.6 Size (NPS designator [DN]),

values from the two systems may result in non-conformance

3.1.7 Standard or extra-strong classification,

with the standard.

3.1.8 Taper tapped-couplings for NPS 2 [DN 50] and

smaller, either recessed or non-recessed, if desired, and

2. Referenced Documents

3.1.9 Certification (see 11.3), if required.

2

2.1 ASTM Standards:

A700 Practices for Packaging, Marking, and Loading Meth-

4. Process

ods for Steel Products for Shipment

4.1 The steel for both welded and seamless couplings shall

B6 Specification for Zinc

be made by one or more of the following processes: open-

E376 Practice for Measuring Coating Thickness by

hearth, electric-furnace, or basic-oxygen.

Magnetic-Field or Eddy-Current (Electromagnetic) Test-

1

4.2 Welded couplings NPS 3 ⁄ [DN 90] and under may

ing Methods

be butt-welded, unless otherwise specified. Welded couplings

2.2 ANSI Standard:

1

over NPS 3 ⁄2 [DN 90] shall be electric-welded.

3

B 1.20.1 Pipe Threads

5. Chemical Composition

5.1 The steel shall conform to the chemical composition

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

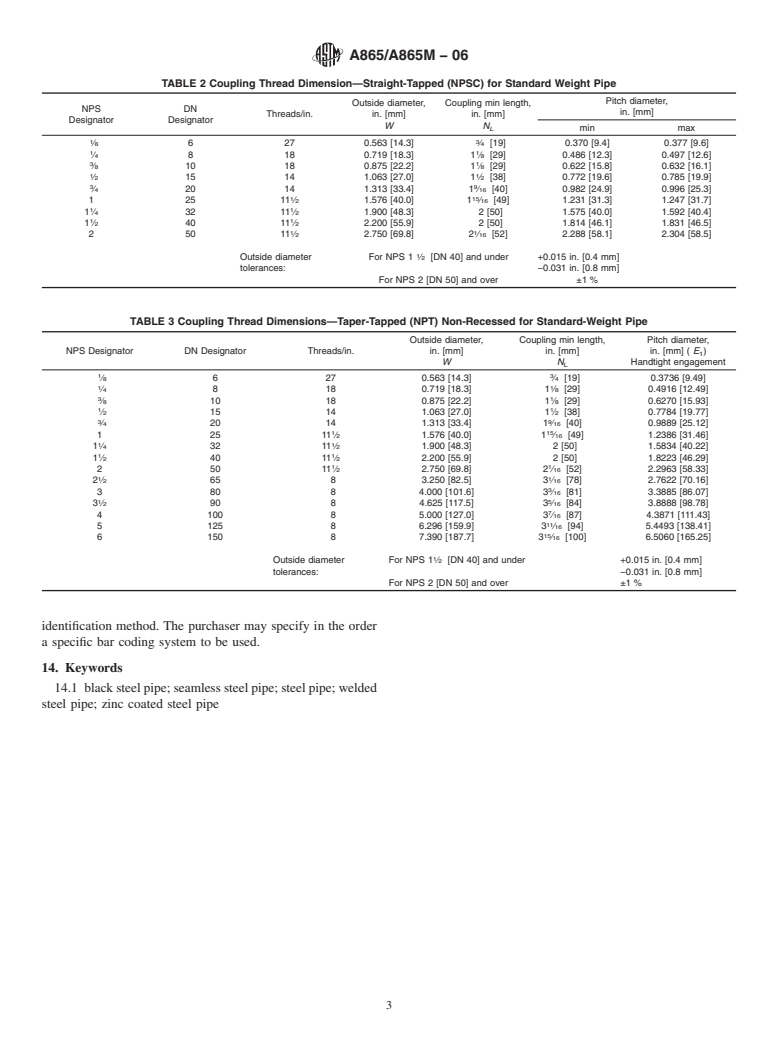

requirements as specified in Table 1.

Stainless Steel and Related Alloysand is the direct responsibility of Subcommittee

A01.09 on Carbon Steel Tubular Products.

Current edition approved July 1, 2006. Published August 2006. Originally 6. Dimensions

approved in 1986. Last previous edition approved in 2003 as A865-03. DOI:

6.1 Coupling dimensions are listed in Tables 2-4 and Figs.

10.1520/A0865_A0865M-06.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 1-3.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., Available from American Petroleum Institute (API), 1220 L. St., NW,

4th Floor, New York, NY 10036. Washington, DC 20005.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A865/A865M−06

TABLE 1 Chemical Requirements

furnished for extra-strong and double-extra strong pipe are

Composition, max % recessed. Recessed couplings (Table 4) conform toAPI Speci-

Sulfur fication 5L.

Phosphorus

10. Finish

All processes 0.14 0.35

10.1 The finished couplings shall be free of defects.

10.2 The zinc coating on galvanized couplings shall be free

7. Permissible Variations in Dimensions

of voids or excessive roughness.

1

7.1 Diameter—For couplings NPS 1 ⁄2 [DN 40] and under,

11. Inspection and Certification

1

the outside diameter at any point shall not vary more than ⁄64

1

in. [0.4 mm] over nor more than ⁄32 in. [0.8 mm] under the 11.1 The inspector representing the purchaser shall have

entry, at all times while work on the contract of the purchaser

standard specified. Fo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.