ASTM C203-05a(2012)

(Test Method)Standard Test Methods for Breaking Load and Flexural Properties of Block-Type Thermal Insulation

Standard Test Methods for Breaking Load and Flexural Properties of Block-Type Thermal Insulation

SIGNIFICANCE AND USE

These test methods are to be used to determine the resistance of some types of preformed block insulation when transverse loads are normally applied to the surface. Values are measured at the maximum load or breaking point under specified conditions or specimen size, span between supports, and rate of load application. The equations used are based on the assumption that the materials are uniform and presume that the stress-strain characteristics below the elastic limit are linearly elastic. These assumptions are not strictly applicable to thermal insulations of certain types in which crushing occurs before failure is obtained in transverse bending; however, depending upon the accuracy required, these procedures are capable of providing acceptable results.

Test Method I is especially useful when testing only for the modulus of rupture or the breaking load. This information is useful for quality control inspection and qualification for specification purposes.

Test Method II is useful in determining the elastic modulus in bending as well as the flexural strength. Flexural properties determined by these test methods are also useful for quality control and specification purposes.

The basic differences between the two test methods is in the location of the maximum bending moment, maximum axial fiber (flexural or tensile) stresses, and the resolved stress state in terms of shear stress and tensile/compression stress. The maximum axial fiber stresses occur on a line under the loading fitting in Test Method I and over the area between the loading fittings in Test Method II. Test Method I has a high shear stress component in the direction of loading, perpendicular to the axial fiber stress. Sufficient resolved shear stress is capable of producing failure by a shear mode rather than a simple tension/flexural failure. There is no comparable shear component in the central region between the loading fittings in Test Method II. Test Method II simulates a uniformly loaded b...

SCOPE

1.1 These test methods cover the determination of the breaking load and calculated flexural strength of a rectangular cross section of a preformed block-type thermal insulation tested as a simple beam. It is also applicable to cellular plastics. Two test methods are described as follows:

1.1.1 Test Method I—A loading system utilizing center loading on a simply supported beam, supported at both ends.

1.1.2 Test Method II—A loading system utilizing two symmetric load points equally spaced from their adjacent support points at each end with a distance between load points of one half of the support span.

1.2 Either test method is capable of being used with the four procedures that follow:

1.2.1 Procedure A— Designed principally for materials that break at comparatively small deflections.

1.2.2 Procedure B— Designed particularly for those materials that undergo large deflections during testing.

1.2.3 Procedure C— Designed for measuring at a constant stress rate, using a CRL (constant rate of loading) machine. Used for breaking load measurements only.

1.2.4 Procedure D— Designed for measurements at a constant crosshead speed, using either a CRT (constant rate of traverse) or CRE (constant rate of extension) machine. Used for breaking load measurements using a fixed crosshead speed machine.

1.3 Comparative tests are capable of being run according to either method or procedure, provided that the method or procedure is found satisfactory for the material being tested.

1.4 These test methods are purposely general in order to accommodate the widely varying industry practices. It is important that the user consult the appropriate materials specification for any specific detailed requirements regarding these test methods.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.6 This standard does not purport to address all of...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C203 − 05a (Reapproved 2012)

Standard Test Methods for

Breaking Load and Flexural Properties of Block-Type

Thermal Insulation

This standard is issued under the fixed designation C203; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.5 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are provided for

1.1 These test methods cover the determination of the

information only.

breaking load and calculated flexural strength of a rectangular

1.6 This standard does not purport to address all of the

cross section of a preformed block-type thermal insulation

safety concerns, if any, associated with its use. It is the

testedasasimplebeam.Itisalsoapplicabletocellularplastics.

responsibility of the user of this standard to establish appro-

Two test methods are described as follows:

priate safety and health practices and determine the applica-

1.1.1 Test Method I—A loading system utilizing center

bility of regulatory limitations prior to use. For specific

loading on a simply supported beam, supported at both ends.

precautionary statements, see Section 11

1.1.2 Test Method II—A loading system utilizing two sym-

metric load points equally spaced from their adjacent support

2. Referenced Documents

points at each end with a distance between load points of one

half of the support span.

2.1 ASTM Standards:

C133 Test Methods for Cold Crushing Strength and Modu-

1.2 Either test method is capable of being used with the four

lus of Rupture of Refractories

procedures that follow:

C168 Terminology Relating to Thermal Insulation

1.2.1 Procedure A—Designed principally for materials that

C390 Practice for Sampling and Acceptance of Thermal

break at comparatively small deflections.

Insulation Lots

1.2.2 Procedure B—Designed particularly for those materi-

C870 Practice for Conditioning of Thermal Insulating Ma-

als that undergo large deflections during testing.

terials

1.2.3 Procedure C—Designed for measuring at a constant

D76 Specification for Tensile Testing Machines for Textiles

stress rate, using a CRL (constant rate of loading) machine.

E4 Practices for Force Verification of Testing Machines

Used for breaking load measurements only.

1.2.4 Procedure D—Designed for measurements at a con-

3. Terminology

stant crosshead speed, using either a CRT (constant rate of

traverse) or CRE (constant rate of extension) machine. Used

3.1 Terminology C168 shall be considered applied to the

for breaking load measurements using a fixed crosshead speed

terms used in this method.

machine.

4. Summary of Test Methods

1.3 Comparative tests are capable of being run according to

either method or procedure, provided that the method or

4.1 A bar of rectangular cross section is tested in flexure as

procedure is found satisfactory for the material being tested.

a beam as follows:

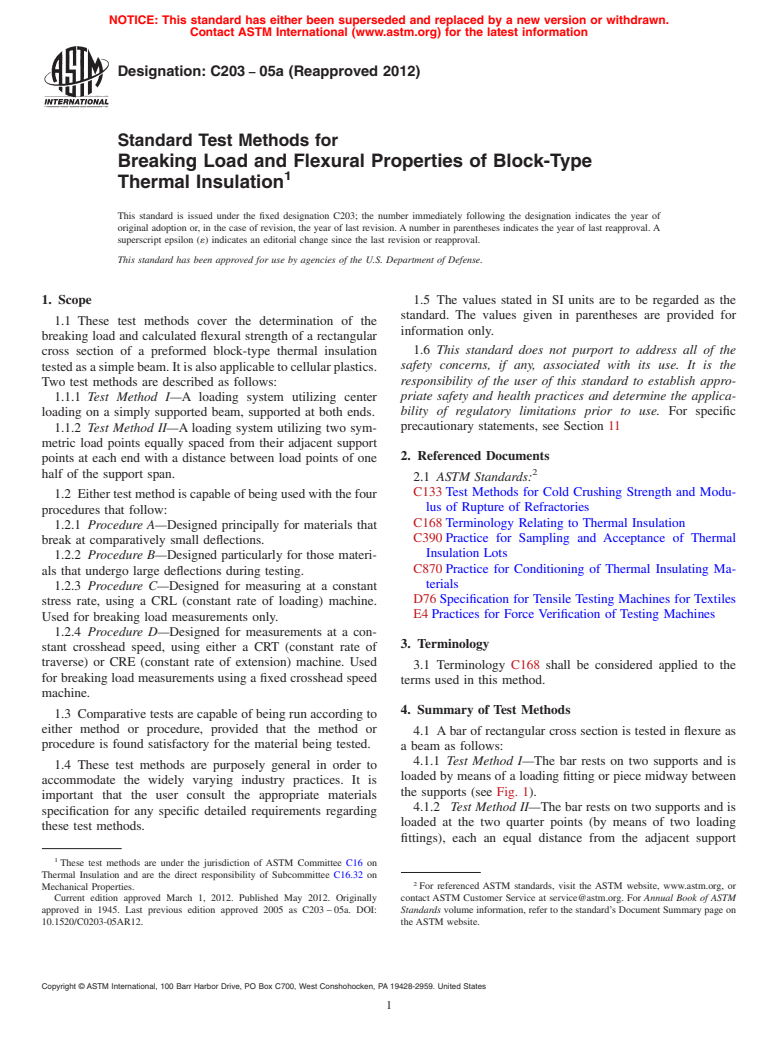

4.1.1 Test Method I—The bar rests on two supports and is

1.4 These test methods are purposely general in order to

loaded by means of a loading fitting or piece midway between

accommodate the widely varying industry practices. It is

the supports (see Fig. 1).

important that the user consult the appropriate materials

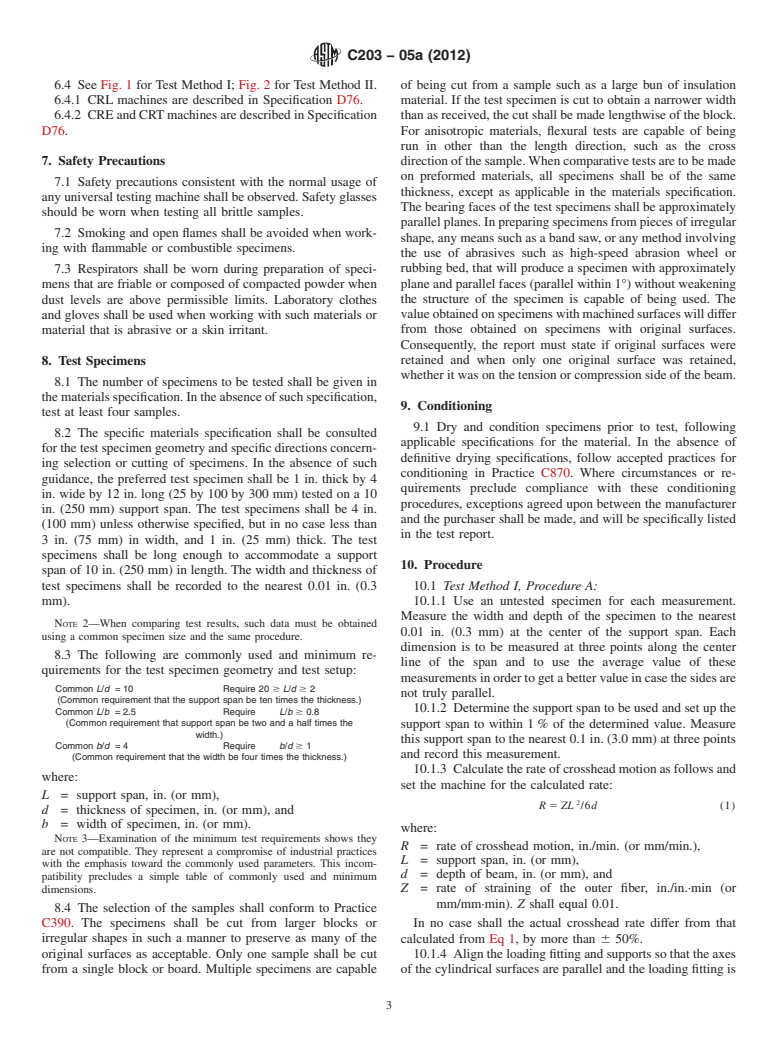

4.1.2 Test Method II—The bar rests on two supports and is

specification for any specific detailed requirements regarding

loaded at the two quarter points (by means of two loading

these test methods.

fittings), each an equal distance from the adjacent support

These test methods are under the jurisdiction of ASTM Committee C16 on

Thermal Insulation and are the direct responsibility of Subcommittee C16.32 on

Mechanical Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 1, 2012. Published May 2012. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1945. Last previous edition approved 2005 as C203 – 05a. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C0203-05AR12. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C203 − 05a (2012)

depending upon the accuracy required, these procedures are

capable of providing acceptable results.

5.2 Test Method I is especially useful when testing only for

the modulus of rupture or the breaking load. This information

is useful for quality control inspection and qualification for

specification purposes.

5.3 Test Method II is useful in determining the elastic

FIG. 1 Loading System for Test Method I

modulus in bending as well as the flexural strength. Flexural

properties determined by these test methods are also useful for

quality control and specification purposes.

point. The distance between the loading fittings is one half of

the support span (see Fig. 2).

5.4 The basic differences between the two test methods is in

thelocationofthemaximumbendingmoment,maximumaxial

4.2 The specimen is deflected until rupture occurs, unless

fiber (flexural or tensile) stresses, and the resolved stress state

the materials specification indicates termination at a particular

in terms of shear stress and tensile/compression stress. The

maximum strain level.

maximum axial fiber stresses occur on a line under the loading

NOTE 1—One criteria used is to limit the strain to 5 %. If failure does

fitting in Test Method I and over the area between the loading

not occur at 5 % strain, the strain rate is increased and the test repeated on

fittings inTest Method II.Test Method I has a high shear stress

a new specimen.

component in the direction of loading, perpendicular to the

4.3 Procedures A and B allow for testing at two different

axial fiber stress. Sufficient resolved shear stress is capable of

strain rates. Procedure C specifies a stress rate. Procedure D

producing failure by a shear mode rather than a simple

specifies a rate of extension or traverse.

tension/flexural failure. There is no comparable shear compo-

4.3.1 Procedure A specifies a strain rate of 0.01 in./in.

nent in the central region between the loading fittings in Test

(mm/mm)thatisusefulfortestinginsulationsthatareverystiff

Method II. Test Method II simulates a uniformly loaded beam

or break at quite low deflections.

in terms of equivalent stresses at the center of the specimen.

4.3.2 Procedure B specifies a strain rate of 0.1 in./in.

5.5 Flexural properties are capable of varing with specimen

(mm/mm) which is useful for testing insulations that are

span-to-thickness ratio, temperature, atmospheric conditions,

relatively flexible or break at higher deflections.

and the difference in rate of straining specified in ProceduresA

4.3.3 Procedure C specifies a stress rate of 550 psi (3.79

and B. In comparing results it is important that all parameters

MPa)/min except as applicable in the materials specification.

be equivalent. Increases in the strain rate typically result in

4.3.4 Procedure D specifies a CRE machine with a fixed

increased strengths and in the elastic modulus.

crosshead speed, or a CRT machine with a movable load

clamp, such as the Scott tester. Because the strain rate is a

6. Apparatus

function of specimen geometry, this procedure does not give a

6.1 TestingMachine—Aproperly calibrated testing machine

constant strain rate for specimens of different thicknesses

that is capable of being operated at either constant load rates or

tested on the same loading fixture.

constant rates of crosshead motion over the range indicated,

5. Significance and Use and in which the error in the load-measuring system shall not

exceed 61 % of maximum load expected to be measured. The

5.1 These test methods are to be used to determine the

load-indicating mechanism shall be essentially free of inertial

resistance of some types of preformed block insulation when

lag. The accuracy and calibration of the testing machine shall

transverse loads are normally applied to the surface.Values are

be verified in accordance with Practice E4. If stiffness or

measured at the maximum load or breaking point under

deflection measurements are to be made, then the machine

specified conditions or specimen size, span between supports,

shall be equipped with a deflection-type measuring device.The

and rate of load application. The equations used are based on

stiffness of the testing machine shall be such that the total

the assumption that the materials are uniform and presume that

elastic deformation of the system does not exceed 1 % of the

the stress-strain characteristics below the elastic limit are

total deflection of the test specimen during test, or appropriate

linearlyelastic.Theseassumptionsarenotstrictlyapplicableto

corrections shall be made.

thermal insulations of certain types in which crushing occurs

before failure is obtained in transverse bending; however, 6.2 Bearing Edges—The loading fittings and supports shall

have cylindrical surfaces. In order to avoid excessive

indentation,orfailureduetostressconcentrationdirectlyunder

the loading fitting or fittings, the diameter of these bearing

1 1

edgesshallbe1 ⁄4 6 ⁄4in.(32 66mm).Thebearingcylinders

shall be straight and parallel to each other, and they shall be

self-aligning to maintain full contact with the specimen

throughout the test. They shall have a length at least equal to

the width of the specimen.

6.3 Bearing cylindrical supports are described inTest Meth-

FIG. 2 Loading System for Test Method II ods C133.

C203 − 05a (2012)

6.4 See Fig. 1 for Test Method I; Fig. 2 for Test Method II. of being cut from a sample such as a large bun of insulation

6.4.1 CRL machines are described in Specification D76. material. If the test specimen is cut to obtain a narrower width

6.4.2 CREandCRTmachines are described in Specification than as received, the cut shall be made lengthwise of the block.

D76. For anisotropic materials, flexural tests are capable of being

run in other than the length direction, such as the cross

7. Safety Precautions directionofthesample.Whencomparativetestsaretobemade

on preformed materials, all specimens shall be of the same

7.1 Safety precautions consistent with the normal usage of

thickness, except as applicable in the materials specification.

any universal testing machine shall be observed. Safety glasses

The bearing faces of the test specimens shall be approximately

should be worn when testing all brittle samples.

parallelplanes.Inpreparingspecimensfrompiecesofirregular

7.2 Smoking and open flames shall be avoided when work-

shape, any means such as a band saw, or any method involving

ing with flammable or combustible specimens.

the use of abrasives such as high-speed abrasion wheel or

rubbing bed, that will produce a specimen with approximately

7.3 Respirators shall be worn during preparation of speci-

mens that are friable or composed of compacted powder when plane and parallel faces (parallel within 1°) without weakening

the structure of the specimen is capable of being used. The

dust levels are above permissible limits. Laboratory clothes

valueobtainedonspecimenswithmachinedsurfaceswilldiffer

and gloves shall be used when working with such materials or

from those obtained on specimens with original surfaces.

material that is abrasive or a skin irritant.

Consequently, the report must state if original surfaces were

retained and when only one original surface was retained,

8. Test Specimens

whether it was on the tension or compression side of the beam.

8.1 The number of specimens to be tested shall be given in

thematerialsspecification.Intheabsenceofsuchspecification,

9. Conditioning

test at least four samples.

9.1 Dry and condition specimens prior to test, following

8.2 The specific materials specification shall be consulted

applicable specifications for the material. In the absence of

for the test specimen geometry and specific directions concern-

definitive drying specifications, follow accepted practices for

ing selection or cutting of specimens. In the absence of such

conditioning in Practice C870. Where circumstances or re-

guidance, the preferred test specimen shall be 1 in. thick by 4

quirements preclude compliance with these conditioning

in. wide by 12 in. long (25 by 100 by 300 mm) tested on a 10

procedures, exceptions agreed upon between the manufacturer

in. (250 mm) support span. The test specimens shall be 4 in.

and the purchaser shall be made, and will be specifically listed

(100 mm) unless otherwise specified, but in no case less than

in the test report.

3 in. (75 mm) in width, and 1 in. (25 mm) thick. The test

specimens shall be long enough to accommodate a support

10. Procedure

span of 10 in. (250 mm) in length. The width and thickness of

test specimens shall be recorded to the nearest 0.01 in. (0.3 10.1 Test Method I, Procedure A:

mm). 10.1.1 Use an untested specimen for each measurement.

Measure the width and depth of the specimen to the nearest

NOTE 2—When comparing test results, such data must be obtained

0.01 in. (0.3 mm) at the center of the support span. Each

using a common specimen size and the same procedure.

dimension is to be measured at three points along the center

8.3 The following are commonly used and minimum re-

line of the span and to use the average value of these

quirements for the test specimen geometry and test setup:

measurementsinordertogetabettervalueincasethesidesare

Common L/d = 10 Require 20$ L/d$ 2

not truly parallel.

(Common requirement that the support span be ten times the thickness.)

10.1.2 Determine the support span to be used and set up the

Common L/b = 2.5 Require L/b$ 0.8

(Common requirement that support span be two and a half times the

support span to within 1 % of the determined value. Measure

width.)

this support span to the nearest 0.1 in. (3.0 mm) at three points

Common b/d = 4 Require b/d$ 1

and record this measurement.

(Common requirement that the width be four times the thickness.)

10.1.3 Calculatetherateofcrossheadmotionasfollowsand

where:

set the machine for the calculated rate:

L = support span, in. (or mm),

R 5 ZL /6d (1)

d = thickness of specimen, in. (or mm), and

b = width of specimen, in. (or mm).

where:

NOTE 3—Examination of the minimum test requirements shows they

R = rate of crosshead motion, in./min. (or mm/min.),

are not compatible. They represent a compromise of industrial practices

L = support span, in. (or mm),

with the emphasis toward the commonly used parameters. This incom-

d = depth of beam, in. (or mm), and

patibility precludes

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.