ASTM D5764-97a

(Test Method)Standard Test Method for Evaluating Dowel-Bearing Strength of Wood and Wood-Base Products

Standard Test Method for Evaluating Dowel-Bearing Strength of Wood and Wood-Base Products

SCOPE

1.1 This test method provides the basic procedure for evaluating dowel-bearing strength of wood and wood-base products. The bearing test results are used to determine the static load resistance and deformation characteristics of connections in wood and wood-base products resulting from the application of a load transmitted by a fastener inserted into a predrilled hole, or driven without drilling. Methods are given for preparing specimens with predrilled holes larger than the fastener diameter and specimens with holes produced by inserting fasteners in holes smaller than the fastener diameter. The methods apply to fasteners such as dowels, bolts, nails, spikes, drift pins, screws, lag screws, and staples.

1.2 This test method also provides the basis for determining the compression behavior of wood products beneath a laterally loaded fastener where the thickness of the product and the diameter of the fastener are such that minimal bending of the fastener occurs during testing.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5764 – 97a

Standard Test Method for

Evaluating Dowel-Bearing Strength of Wood and Wood-

Based Products

This standard is issued under the fixed designation D 5764; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 4 Practices for Force Verification of Testing Machines

1.1 This test method provides the basic procedure for

3. Terminology

evaluating dowel-bearing strength of wood and wood-based

3.1 Definitions:

products. The bearing test results are used to determine the

3.1.1 dowel-bearing behavior—the load-deformation be-

static load resistance and deformation characteristics of con-

havior of wood or wood-base products laterally loaded by a

nections in wood and wood-base products resulting from the

fastener where the fastener does not bend during loading.

application of a load transmitted by a fastener inserted into a

3.1.2 dowel-bearing strength—yield load obtained from the

predrilled hole, or driven without drilling. Methods are given

load-deformation curve of a dowel-bearing test divided by the

for preparing specimens with predrilled holes larger than the

dowel diameter and specimen thickness.

fastener diameter and specimens with holes produced by

inserting fasteners in holes smaller than the fastener diameter.

4. Summary of Test Method

The methods apply to fasteners such as dowels, bolts, nails,

4.1 Specimens consisting of a single rectangular parallele-

spikes, drift pins, screws, lag screws, and staples.

piped member with a fastener hole perpendicular to the faces of

1.2 This test method also provides the basis for determining

the member are evaluated for the resistance to embedding the

the compression behavior of wood products beneath a laterally

fastener into the fastener hole, so as not to bend the fastener.

loaded fastener where the thickness of the product and the

Tests are conducted on a testing machine at a uniform

diameter of the fastener are such that minimal bending of the

deformation rate, while loads and deformation are measured at

fastener occurs during testing.

various intervals. Supplementary physical properties of the

1.3 This standard does not purport to address all of the

wood or wood-base member are also determined.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and determine the applica-

5.1 The localized crushing behavior of wood or wood-base

bility of regulatory limitations prior to use.

products beneath a fastener where the fastener does not bend

provides a material property that is used in theoretical models

2. Referenced Documents

for connections where crushing or fastener bending, or both,

2.1 ASTM Standards:

occur. These theoretical models are used to establish design

D 143 Methods for Testing Small Clear Specimens of

values for wood and wood-base connections. The tests are

Timber

appropriate when studying the effects of such variables as

D 2395 Test Methods for Specific Gravity of Wood and

fastener diameter, fastener hole size, moisture content, specific

Wood-Based Materials

gravity, and grain direction on the dowel-bearing strength.

D 2915 Practice for Evaluating Allowable Properties for

Grades of Structural Lumber

6. Apparatus

D 4442 Test Methods for Direct Moisture Content Measure-

6.1 Testing Machine—Any suitable testing machine capable

ment of Wood and Wood-Base Materials

of operation at a constant rate of motion of its movable head

and having an accuracy of 61 % when calibrated in accor-

dance with Practices E 4.

This test method is under the jurisdiction of ASTM Committee D-7 on Wood

and is the direct responsibility of Subcommittee D07.05 on Wood Assemblies.

Current edition approved Oct. 10, 1997. Published March 1998. Originally

published as D 5764 – 95. Last previous edition D 5764 – 97.

2 3

Annual Book of ASTM Standards, Vol 04.10. Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5764 – 97a

NOTE 2—For driven dowels in species that tend to split, larger than

6.2 Deformation Gage—A deformation-measuring device,

minimum dimensions are recommended to prevent splitting during

with a least reading of 0.001 in. (0.025 mm) for measuring the

specimen preparation and testing.

movement of the fastener into the wood or wood-base speci-

8.2.2.1 For specimens that tend to split before the comple-

men.

tion of the test, a full hole test configuration is allowed in Fig.

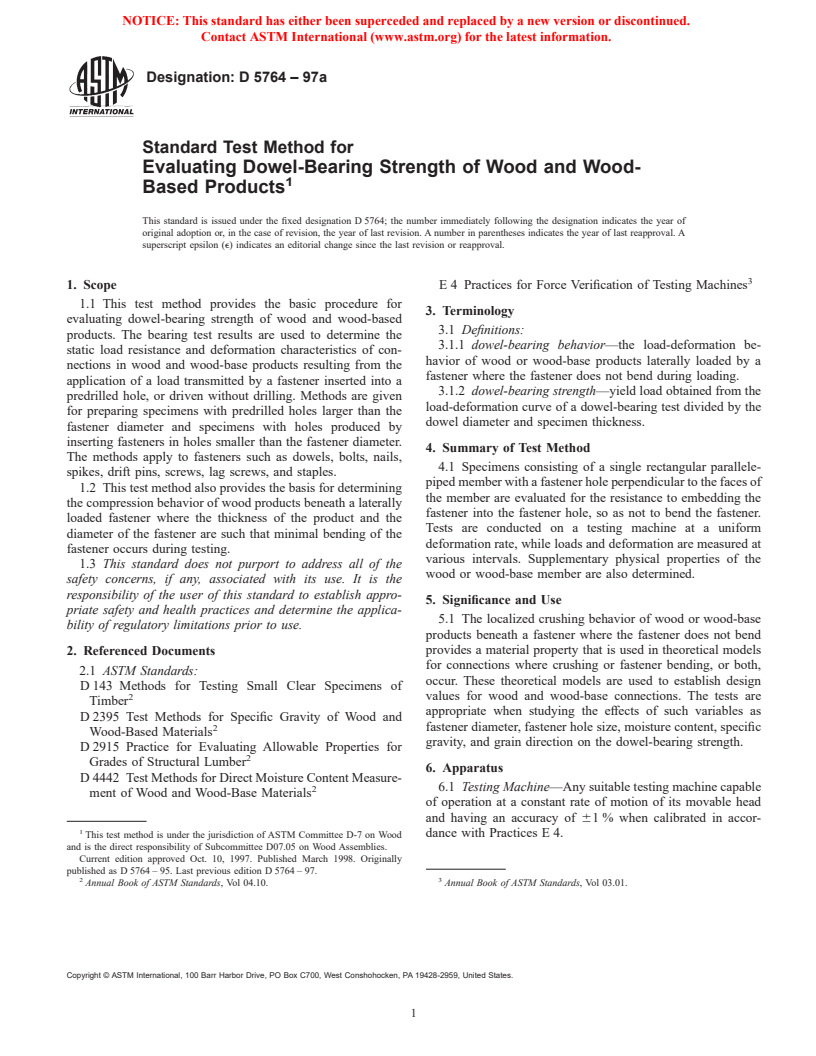

7. Sampling 2. Minimum dimensions shall be made large enough so

splitting does not occur during fabrication and not less than as

7.1 Sampling shall provide for selection of representative

follows (see Fig. 3):

test specimens which are appropriate to the objectives of the

Thickness $ the smaller of 1 ⁄2 in. (38 mm) or 2 dowel diameters

testing program.

Width $ the larger of 2 in. (50 mm) or 4 dowel diameters

7.2 Sample size shall be estimated using procedures in

Length:

Practice D 2915.

Loaded End $ the larger of 2 in. (50 mm) or 4 dowel diameters

Unloaded End $ the larger of 1 in. (50 mm) or 2 dowel diameters

NOTE 1—The precision required, the manner of sampling, and the

number of tests will depend upon the specific test objectives. General 8.2.3 For wood-base panel products, the minimum thickness

experience indicates that the coefficient of variation from embedment tests

shall be the thickness of the panel. Minimum width and length

ranges from 15 to 30 %.

shall be the same as for solid wood.

8. Specimens

8.1 Wood members shall be selected, and the dowel posi-

tioned in such a way that the results are not affected by knots,

cross grain, or other natural or manufacturing characteristics,

unless the objective of the study is to determine the effect of

such variables. Frequently, this will necessitate selecting mem-

bers which are essentially clear and straight grained. For

wood-based products, specimens shall be selected with regard

to manufactured characteristics.

8.2 Specimen Dimensions:

8.2.1 Specimens shall consist of a rectangular parallele-

piped member with half a dowel hole across one face (see Fig.

1).

8.2.2 For solid wood and wood composites, minimum

dimensions shall be made large enough so splitting does not

occur during fabrication and not less than as follows (see Fig.

1):

Thickness $ the smaller of 1 ⁄2 in. (38 mm), or 2 dowel diameters

Width $ the larger of 2 in. (50 mm) or 4 dowel diameters

Length $ the larger of 2 in. (50 mm) or 4 dowel diameters

NOTE 1—Half of the fastener hole is produced by drilling oversized

hole or by the method shown in Fig. 4.

FIG. 1 Specimen Configuration FIG. 2 Schematic of Testing Setup—Full Hole

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5764 – 97a

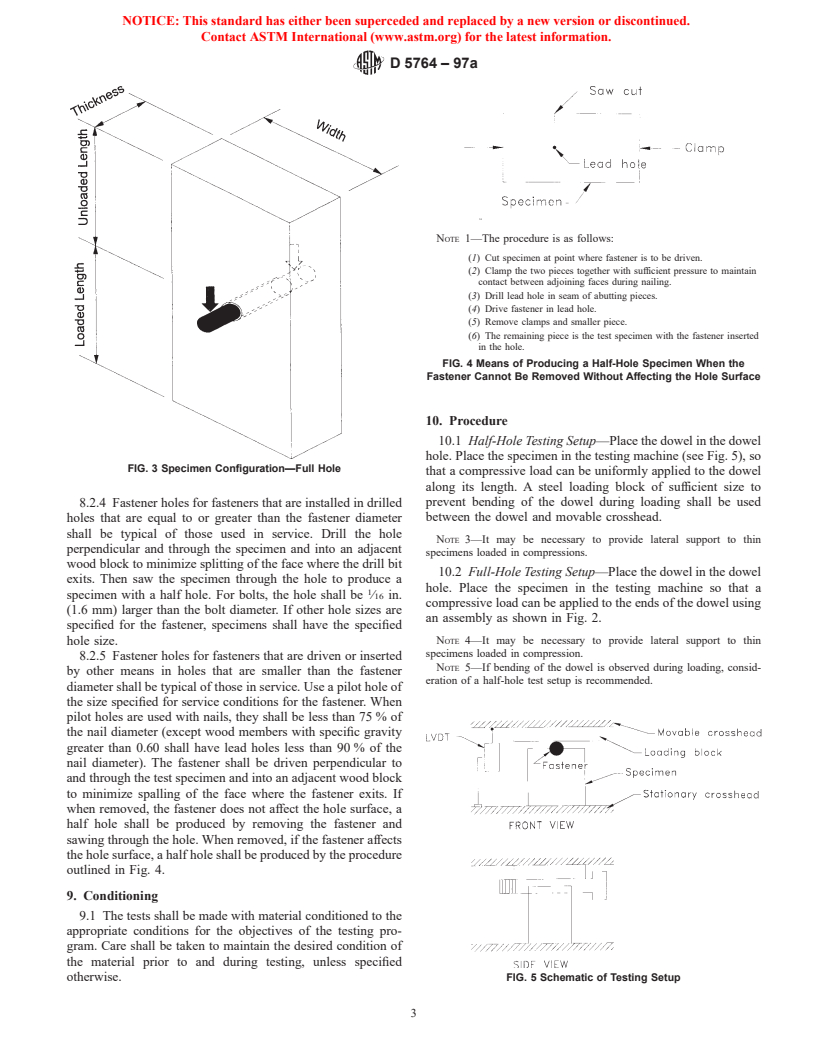

NOTE 1—The procedure is as follows:

(1) Cut specimen at point where fastener is to be driven.

(2) Clamp the two pieces together with sufficient pressure to maintain

contact between adjoining faces during nailing.

(3) Drill lead hole in seam of abutting pieces.

(4) Drive fastener in lead hole.

(5) Remove clamps and smaller piece.

(6) The remaining piece is the test specimen with the fastener inserted

in the hole.

FIG. 4 Means of Producing a Half-Hole Specimen When the

Fastener Cannot Be Removed Without Affecting the Hole Surface

10. Procedure

10.1 Half-Hole Testing Setup—Place the dowel in the dowel

hole.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.