ASTM E2824-18

(Test Method)Standard Test Method for Determination of Beryllium in Copper-Beryllium Alloys by Phosphate Gravimetric Method

Standard Test Method for Determination of Beryllium in Copper-Beryllium Alloys by Phosphate Gravimetric Method

SIGNIFICANCE AND USE

5.1 This test method is primarily intended to test such materials for compliance with compositional specifications. It is assumed that all who use these test methods will be trained analysts capable of performing common laboratory procedures skillfully and safely. It is expected that work will be performed in a properly equipped laboratory.

SCOPE

1.1 This test method describes the determination of beryllium in copper-beryllium alloys in percentages from 0.1 % to 3.0 % by the phosphate gravimetric method.

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 9.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2824 − 18

Standard Test Method for

Determination of Beryllium in Copper-Beryllium Alloys by

1

Phosphate Gravimetric Method

This standard is issued under the fixed designation E2824; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Methods for Chemical Analysis of Metals (Withdrawn

3

1998)

1.1 This test method describes the determination of beryl-

E255 Practice for Sampling Copper and Copper Alloys for

lium in copper-beryllium alloys in percentages from 0.1 % to

the Determination of Chemical Composition

3.0 % by the phosphate gravimetric method.

E1601 Practice for Conducting an Interlaboratory Study to

1.2 Units—The values stated in SI units are to be regarded

Evaluate the Performance of an Analytical Method

as standard. No other units of measurement are included in this

standard. 3. Terminology

3.1 For definitions of terms used in this method, refer to

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the Terminology E135.

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 4.1 Beryllium is precipitated as the phosphate, which is

Specific hazard statements are given in Section 9.

filtered, ignited, and weighed as beryllium pyrophosphate.

Interfering elements, if present, may be complexed with

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard- (ethylenedinitrilo) tetraacetate solution.

ization established in the Decision on Principles for the

5. Significance and Use

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

5.1 This test method is primarily intended to test such

Barriers to Trade (TBT) Committee.

materials for compliance with compositional specifications. It

is assumed that all who use these test methods will be trained

2. Referenced Documents

analysts capable of performing common laboratory procedures

2 skillfully and safely. It is expected that work will be performed

2.1 ASTM Standards:

in a properly equipped laboratory.

E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

6. Interferences

E50 Practices for Apparatus, Reagents, and Safety Consid-

6.1 The elements ordinarily present in beryllium-copper

erations for Chemical Analysis of Metals, Ores, and

alloys do not interfere.

Related Materials

E135 Terminology Relating to Analytical Chemistry for

7. Apparatus

Metals, Ores, and Related Materials

7.1 Electrodes for Electroanalysis—Recommended station-

E173 Practice for Conducting Interlaboratory Studies of

ary type platinum electrodes are described in 7.1.1 and 7.1.2.

The surface of the platinum electrode should be smooth, clean,

and bright to promote uniform deposition and good adherence.

1

This test method is under the jurisdiction of ASTM Committee E01 on

Deviations from the exact size and shape are allowable. In

Analytical Chemistry for Metals, Ores, and Related Materials and is the direct

instances where it is desirable to decrease the time of

responsibility of Subcommittee E01.05 on Cu, Pb, Zn, Cd, Sn, Be, Precious Metals,

their Alloys, and Related Metals.

deposition, a generally available rotating type of electrode may

Current edition approved April 15, 2018. Published June 2018. Originally

be employed. Cleaning of the electrode by sandblasting is not

approved in 2011. Last previous edition approved in 2011 as E2824–11. DOI:

recommended.

10.1520/E2824-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2824 − 18

7.1.1 Cathodes—Platinum cathodes may be either open or Beryllium-containing residues (especially ignited oxide)

closed cylinders formed from sheets that are plain or should be carefully disposed.

perforated, or from gauze. Gauze cathodes are recommended;

preferably from 50-mesh gauze woven from approximately 10. Sampling

0.21 mm diameter wire. The top and bottom of gauze cathodes

10.1 Sampling shall conform

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2824 − 11 E2824 − 18

Standard Test Method for

Determination of Beryllium in Copper-Beryllium Alloys by

1

Phosphate Gravimetric Method

This standard is issued under the fixed designation E2824; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method describes the determination of beryllium in copper-beryllium alloys in percentages from 0.1 % to 3.0 %

by the phosphate gravimetric method.

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this

standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 9.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E50 Practices for Apparatus, Reagents, and Safety Considerations for Chemical Analysis of Metals, Ores, and Related Materials

E135 Terminology Relating to Analytical Chemistry for Metals, Ores, and Related Materials

3

E173 Practice for Conducting Interlaboratory Studies of Methods for Chemical Analysis of Metals (Withdrawn 1998)

E255 Practice for Sampling Copper and Copper Alloys for the Determination of Chemical Composition

E1601 Practice for Conducting an Interlaboratory Study to Evaluate the Performance of an Analytical Method

3. Terminology

3.1 For definitions of terms used in this method, refer to Terminology E135.

4. Summary of Test Method

4.1 Beryllium is precipitated as the phosphate, which is filtered, ignited, and weighed as beryllium pyrophosphate. Interfering

elements, if present, may be complexed with (ethylenedinitrilo) tetraacetate solution.

5. Significance and Use

5.1 This test method for the chemical analysis of metals and alloys is primarily intended to test such materials for compliance

with compositional specifications. It is assumed that all who use these test methods will be trained analysts capable of performing

common laboratory procedures skillfully and safely. It is expected that work will be performed in a properly equipped laboratory.

6. Interferences

6.1 The elements ordinarily present in beryllium-copper alloys do not interfere.

1

This test method is under the jurisdiction of ASTM Committee E01 on Analytical Chemistry for Metals, Ores, and Related Materials and is the direct responsibility of

Subcommittee E01.05 on Cu, Pb, Zn, Cd, Sn, Be, Precious Metals, their Alloys, and Related Metals.

Current edition approved May 1, 2011April 15, 2018. Published July 2011June 2018. Originally approved in 2011. Last previous edition approved in 2011 as E2824–11.

DOI: 10.1520/E2824-11.10.1520/E2824-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2824 − 18

7. Apparatus

7.1 Electrodes for Electroanalysis—Recommended stationary type platinum electrodes are described in 7.1.1 and 7.1.2. The

surface of the platinum electrode should be smooth, clean, and bright to promote uniform deposition and good adherence.

Deviations from the exact size and shape are allowable. In instances where it is desirable to decrease the time of deposition and

agitation of the electrolyte is permissible, deposition, a generally available rotating type of electrode may be employed. Cleaning

of the electrode by sandblasting

...

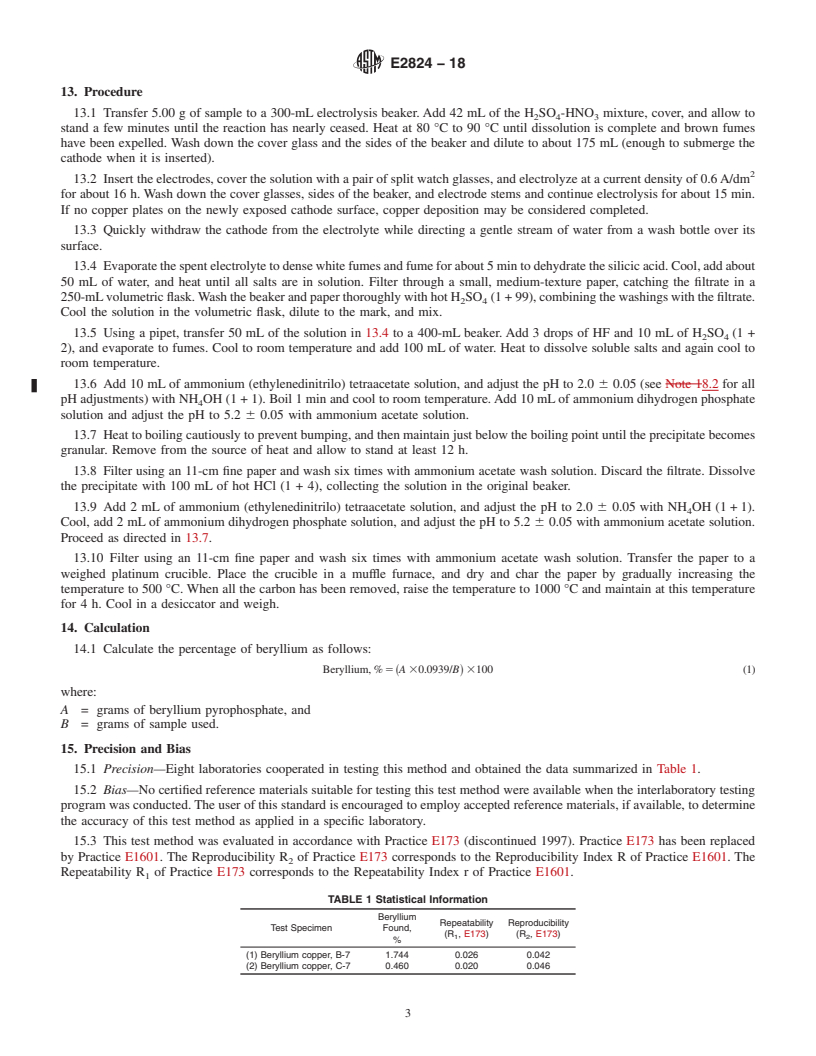

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.