ASTM D1092-11

(Test Method)Standard Test Method for Measuring Apparent Viscosity of Lubricating Greases

Standard Test Method for Measuring Apparent Viscosity of Lubricating Greases

SIGNIFICANCE AND USE

Apparent viscosity versus shear rate information can be useful in predicting pressure drops in grease distribution systems under steady-state flow conditions at constant temperature.

SCOPE

1.1 This test method covers measurement, in poises, of the apparent viscosity of lubricating greases in the temperature range from −54 to 38°C (−65 to 100°F). Measurements are limited to the range from 25 to 100 000 P at 0.1 s−1 and 1 to 100 P at 15 000 s−1.

Note 1—At very low temperatures the shear rate range may be reduced because of the great force required to force grease through the smaller capillaries. Precision has not been established below 10 s−1.

1.2 This standard uses inch-pound units as well as SI (acceptable metric) units. The values stated first are to be regarded as standard. The values given in parentheses are for information only. The capillary dimensions in SI units in Fig. A1.1 and Fig. A1.2 are standard.

1.3 WARNINGMercury has been designated by many regulatory agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s websitehttp://www.epa.gov/mercury/faq.htmfor additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1092 − 11

StandardTest Method for

1

Measuring Apparent Viscosity of Lubricating Greases

This standard is issued under the fixed designation D1092; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This test method covers measurement, in poises, of the

apparent viscosity of lubricating greases in the temperature

2. Referenced Documents

2

range from −54 to 38°C (−65 to 100°F). Measurements are

2.1 ASTM Standards:

−1

limitedtotherangefrom25to100000Pat0.1s and1to100

D88Test Method for Saybolt Viscosity

−1

P at 15000 s .

D217Test Methods for Cone Penetration of Lubricating

Grease

NOTE1—Atverylowtemperaturestheshearraterangemaybereduced

D3244Practice for Utilization of Test Data to Determine

because of the great force required to force grease through the smaller

−1

capillaries. Precision has not been established below 10 s .

Conformance with Specifications

1.2 This standard uses inch-pound units as well as SI

3. Terminology

(acceptable metric) units. The values stated first are to be

3.1 Definitions:

regarded as standard. The values given in parentheses are for

3.1.1 apparent viscosity, n—of a lubricating grease is the

information only. The capillary dimensions in SI units in Fig.

ratio of shear stress to shear rate calculated from Poiseuille’s

A1.1 and Fig. A1.2 are standard.

equation, and is measured in poises (see 10.1).

1.3 WARNING—Mercury has been designated by many

3.1.2 capillary, n—For the purpose of this method, a capil-

regulatory agencies as a hazardous material that can cause

lary is any right cylindrical tube having a length to diameter

central nervous system, kidney and liver damage. Mercury, or

ratio of 40 to 1.

its vapor, may be hazardous to health and corrosive to

3.1.3 shear rate, n—the rate at which a series of adjacent

materials.Cautionshouldbetakenwhenhandlingmercuryand

layers of grease move with respect to each other; proportional

mercury containing products. See the applicable product Ma-

to the linear velocity of flow divided by the capillary radius,

terial Safety Data Sheet (MSDS) for details and EPA’s

and is thus expressed as reciprocal seconds.

website—http://www.epa.gov/mercury/faq.htm—for addi-

tional information. Users should be aware that selling mercury

4. Summary of Test Method

and/or mercury containing products into your state or country

4.1 The sample is forced through a capillary by means of a

may be prohibited by law.

floating piston actuated by the hydraulic system. From the

predeterminedflowrateandtheforcedevelopedinthesystem,

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the the apparent viscosity is calculated by means of Poiseuille’s

responsibility of the user of this standard to establish appro- equation.Aseriesofeightcapillariesandtwopumpspeedsare

used to determine the apparent viscosity at sixteen shear rates.

Theresultsareexpressedasalog-logplotofapparentviscosity

versus shear rate.

1

This test method is under the jurisdiction of ASTM Committee D02 on

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee

2

D02.G0.02 on Consistency and Related Rheological Tests. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2011. Published September 2011. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1950. Last previous edition approved in 2005 as D1092–05. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D1092-11. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1092 − 11

FIG. 1 Schematic Drawing of Apparatus

5. Significance and Use

5.1 Apparent viscosity versus shear rate information can be

useful in predicting pressure drops in grease distribution

systems under steady-state flow conditions at constant tem-

perature.

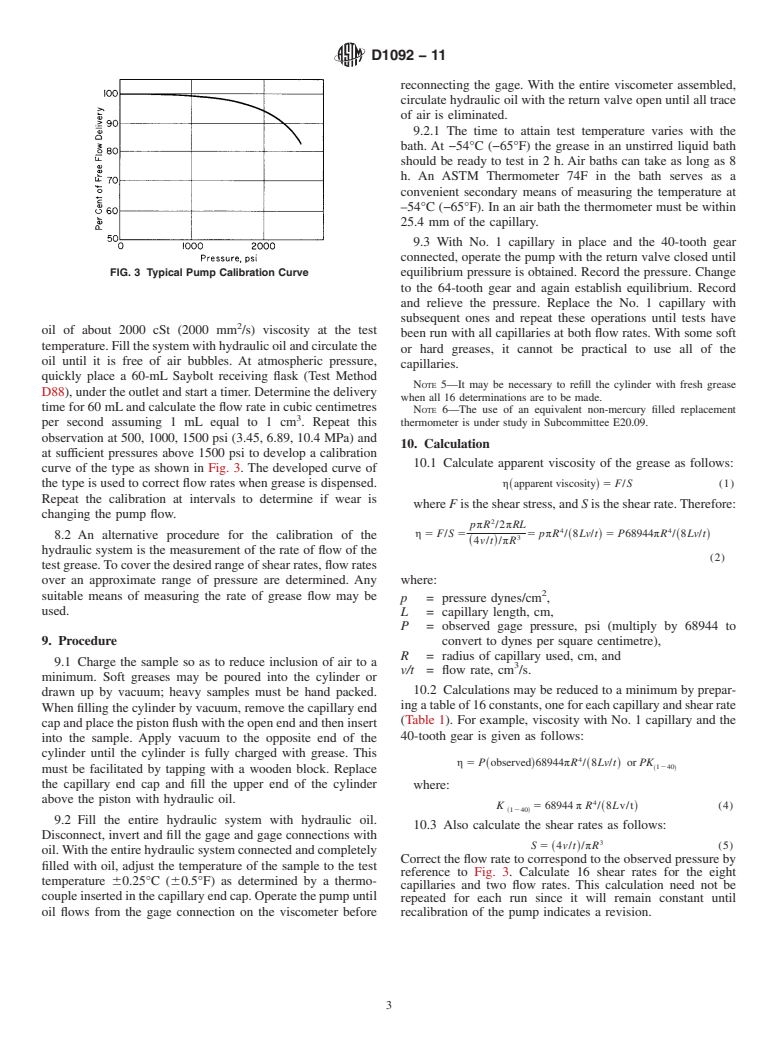

6. Apparatus

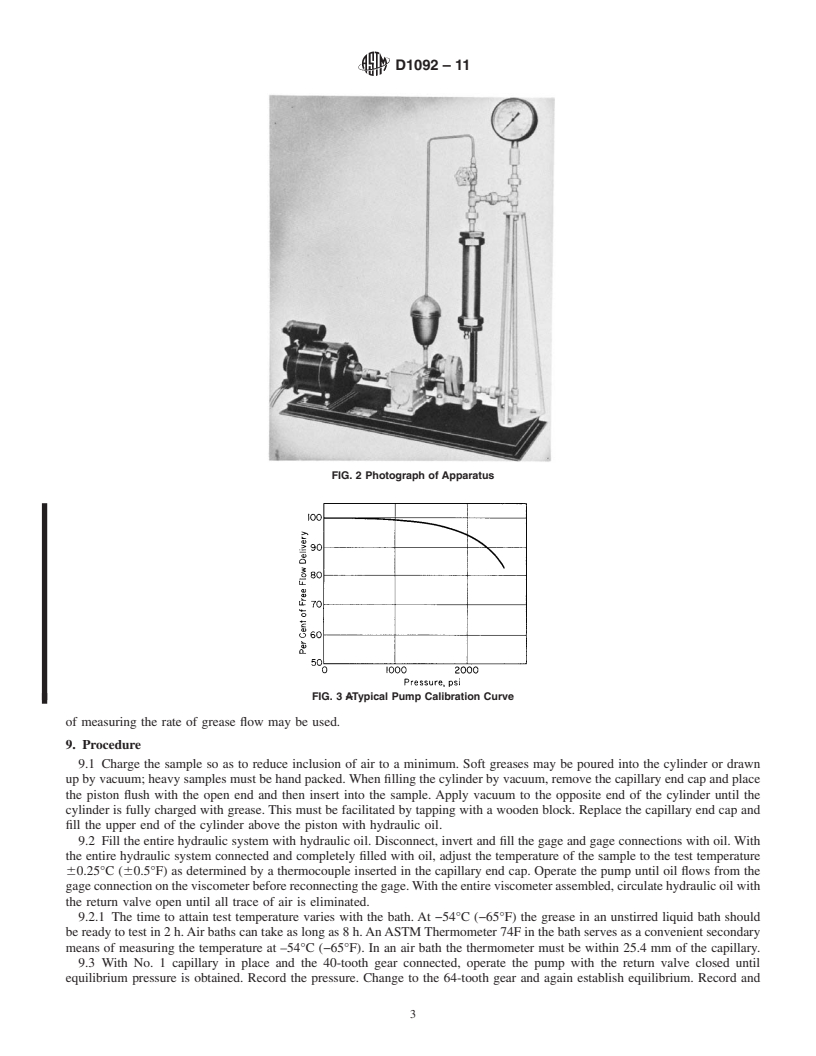

6.1 The assembled pressure viscometer consists of four

major divisions, the power system, the hydraulic system, the

grease system (described in the annex and shown in Fig. 1),

andabathofoptionaldesign.Fig.2isaphotographofthefirst

three divisions as commonly used at room temperature. This

form of the apparatus can be used with a cylindrical insulated

tank178mm(7in.)india

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D1092–05 Designation:D1092–11

Standard Test Method for

1

Measuring Apparent Viscosity of Lubricating Greases

This standard is issued under the fixed designation D1092; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method covers measurement, in poises, of the apparent viscosity of lubricating greases in the temperature range

−1

from −54 to 38°C (−65 to 100°F). Measurements are limited to the range from 25 to 100000 Pat 0.1 s and 1 to 100 Pat 15000

−1

s .

NOTE 1—At very low temperatures the shear rate range may be reduced because of the great force required to force grease through the smaller

−1

capillaries. Precision has not been established below 10 s .

1.2 This standard uses inch-pound units as well as SI (acceptable metric) units. The values stated first are to be regarded as

standard.Thevaluesgiveninparenthesesareforinformationonly.ThecapillarydimensionsinSIunitsinFig.A1.1andFig.A1.2

are standard.

1.3

1.3 WARNING—Mercury has been designated by many regulatory agencies as a hazardous material that can cause central

nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution

should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet

(MSDS) for details and EPA’s website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware

that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D88 Test Method for Saybolt Viscosity

D217 Test Methods for Cone Penetration of Lubricating Grease

D3244 Practice for Utilization of Test Data to Determine Conformance with Specifications

3. Terminology

3.1 Definitions:

3.1.1 apparent viscosity, n—ofalubricatinggreaseistheratioofshearstresstoshearratecalculatedfromPoiseuille’sequation,

and is measured in poises (see 10.1).

3.1.2 capillary, n—For the purpose of this method, a capillary is any right cylindrical tube having a length to diameter ratio of

40 to 1.

3.1.3 shear rate, n—the rate at which a series of adjacent layers of grease move with respect to each other; proportional to the

linear velocity of flow divided by the capillary radius, and is thus expressed as reciprocal seconds.

4. Summary of Test Method

4.1 The sample is forced through a capillary by means of a floating piston actuated by the hydraulic system. From the

predetermined flow rate and the force developed in the system, the apparent viscosity is calculated by means of Poiseuille’s

equation.Aseriesofeightcapillariesandtwopumpspeedsareusedtodeterminetheapparentviscosityatsixteenshearrates.The

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.G0.02

on Lubricating Grease. Consistency and Related Rheological Tests.

Current edition approved Nov.Sept. 1, 2005.2011. Published November 2005.September 2011. Originally approved in 1950. Last previous edition approved in 19992005

as D1092–99.D1092–05. DOI: 10.1520/D1092-05.10.1520/D1092-11.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1092–11

results are expressed as a log-log plot of apparent viscosity versus shear rate.

5. Significance and Use

5.1 Apparent viscosity versus shear rate information can be useful in predicting pressure drops in grease distribution systems

under steady-state flow conditions at constant temperature.

6. Apparatus

6.1 The assembled pressure viscometer consists of f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.