ASTM C877M-02

(Specification)Standard Specification for External Sealing Bands for Concrete Pipe, Manholes, and Precast Box Sections (Metric)

Standard Specification for External Sealing Bands for Concrete Pipe, Manholes, and Precast Box Sections (Metric)

SCOPE

1.1 This specification covers external sealing bands to be used in conjunction with concrete pipe as defined in Terminology C 822 and conforming to Specifications C 14M, C 76M, C 412M, C 478M, C 506M, C 507M, C 655M, C 985M, C 1417M, and C 1433M.

1.1.1 Type I, Rubber and Mastic Bands.

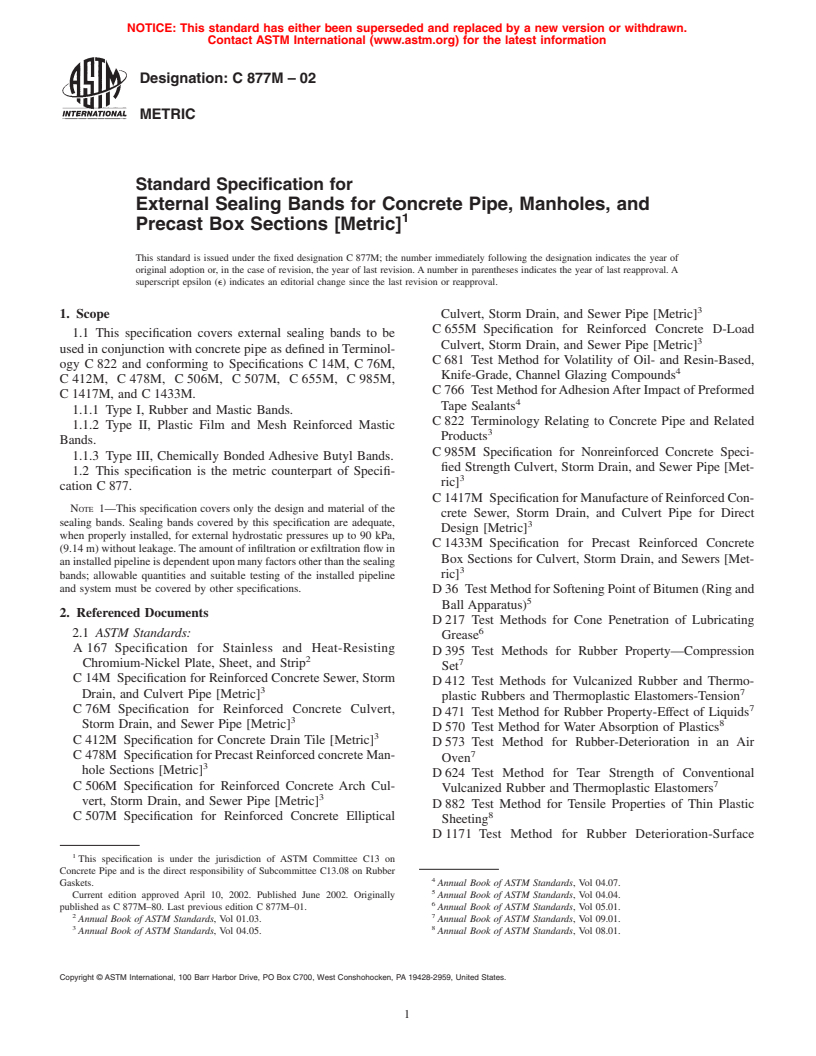

1.1.2 Type II, Plastic Film and Mesh Reinforced Mastic Bands.

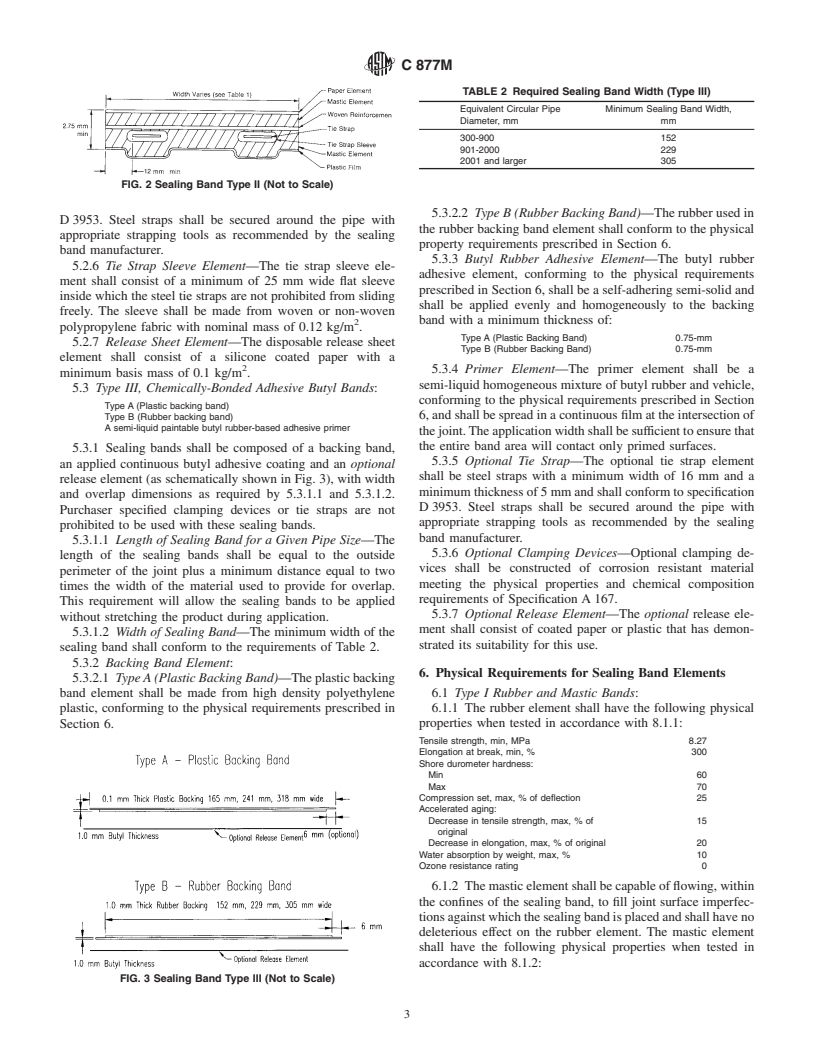

1.1.3 Type III, Chemically Bonded Adhesive Butyl Bands.

1.2 This specification is the metric counterpart of Specification C 877.

Note 1—This specification covers only the design and material of the sealing bands. Sealing bands covered by this specification are adequate, when properly installed, for external hydrostatic pressures up to 90 kPa, (9.14 m) without leakage. The amount of infiltration or exfiltration flow in an installed pipeline is dependent upon many factors other than the sealing bands; allowable quantities and suitable testing of the installed pipeline and system must be covered by other specifications.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 877M – 02

METRIC

Standard Specification for

External Sealing Bands for Concrete Pipe, Manholes, and

1

Precast Box Sections [Metric]

This standard is issued under the fixed designation C 877M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

3

1. Scope Culvert, Storm Drain, and Sewer Pipe [Metric]

C 655M Specification for Reinforced Concrete D-Load

1.1 This specification covers external sealing bands to be

3

Culvert, Storm Drain, and Sewer Pipe [Metric]

used in conjunction with concrete pipe as defined in Terminol-

C 681 Test Method for Volatility of Oil- and Resin-Based,

ogy C 822 and conforming to Specifications C 14M, C 76M,

4

Knife-Grade, Channel Glazing Compounds

C 412M, C 478M, C 506M, C 507M, C 655M, C 985M,

C 766 Test Method forAdhesionAfter Impact of Preformed

C 1417M, and C 1433M.

4

Tape Sealants

1.1.1 Type I, Rubber and Mastic Bands.

C 822 Terminology Relating to Concrete Pipe and Related

1.1.2 Type II, Plastic Film and Mesh Reinforced Mastic

3

Products

Bands.

C 985M Specification for Nonreinforced Concrete Speci-

1.1.3 Type III, Chemically Bonded Adhesive Butyl Bands.

fied Strength Culvert, Storm Drain, and Sewer Pipe [Met-

1.2 This specification is the metric counterpart of Specifi-

3

ric]

cation C 877.

C 1417M SpecificationforManufactureofReinforcedCon-

NOTE 1—This specification covers only the design and material of the

crete Sewer, Storm Drain, and Culvert Pipe for Direct

sealing bands. Sealing bands covered by this specification are adequate,

3

Design [Metric]

when properly installed, for external hydrostatic pressures up to 90 kPa,

C 1433M Specification for Precast Reinforced Concrete

(9.14 m) without leakage.The amount of infiltration or exfiltration flow in

Box Sections for Culvert, Storm Drain, and Sewers [Met-

aninstalledpipelineisdependentuponmanyfactorsotherthanthesealing

3

ric]

bands; allowable quantities and suitable testing of the installed pipeline

and system must be covered by other specifications.

D 36 TestMethodforSofteningPointofBitumen(Ringand

5

Ball Apparatus)

2. Referenced Documents

D 217 Test Methods for Cone Penetration of Lubricating

6

2.1 ASTM Standards:

Grease

A 167 Specification for Stainless and Heat-Resisting

D 395 Test Methods for Rubber Property—Compression

2

7

Chromium-Nickel Plate, Sheet, and Strip

Set

C 14M Specification for Reinforced Concrete Sewer, Storm

D 412 Test Methods for Vulcanized Rubber and Thermo-

3

7

Drain, and Culvert Pipe [Metric]

plastic Rubbers and Thermoplastic Elastomers-Tension

7

C 76M Specification for Reinforced Concrete Culvert,

D 471 Test Method for Rubber Property-Effect of Liquids

3

8

Storm Drain, and Sewer Pipe [Metric]

D 570 Test Method for Water Absorption of Plastics

3

C 412M Specification for Concrete Drain Tile [Metric]

D 573 Test Method for Rubber-Deterioration in an Air

7

C 478M SpecificationforPrecastReinforcedconcreteMan-

Oven

3

hole Sections [Metric]

D 624 Test Method for Tear Strength of Conventional

7

C 506M Specification for Reinforced Concrete Arch Cul-

Vulcanized Rubber and Thermoplastic Elastomers

3

vert, Storm Drain, and Sewer Pipe [Metric]

D 882 Test Method for Tensile Properties of Thin Plastic

8

C 507M Specification for Reinforced Concrete Elliptical

Sheeting

D 1171 Test Method for Rubber Deterioration-Surface

1

This specification is under the jurisdiction of ASTM Committee C13 on

Concrete Pipe and is the direct responsibility of Subcommittee C13.08 on Rubber

4

Gaskets. Annual Book of ASTM Standards, Vol 04.07.

5

Current edition approved April 10, 2002. Published June 2002. Originally Annual Book of ASTM Standards, Vol 04.04.

6

published as C 877M–80. Last previous edition C 877M–01. Annual Book of ASTM Standards, Vol 05.01.

2 7

Annual Book of ASTM Standards, Vol 01.03. Annual Book of ASTM Standards, Vol 09.01.

3 8

Annual Book of ASTM Standards, Vol 04.05. Annual Book of ASTM Standards, Vol 08.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C 877M

Ozone Cracking Outdoors or Chamber (Triangular Speci- 5.1.1.2 Width of Sealing Band—The width of the sealing

7

mens) band shall conform to the requirements of Table 1.

D 1278 Test Methods for Rubber from Natural Sources—

5.1.2 Rubber Element—The rubber element shall be ex-

7

Chemical Analysis

truded or molded from a high-grade rubber compound and

D 1682 Test Methods for Breaking Load and Elongation of

shall be cured in such a manner that any cross section will be

9

Textile Fabrics

dense, homogeneous, and free of porosity, blisters, pitting, an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.