ASTM D4338-97(2021)

(Test Method)Standard Test Method for Flexibility Determination of Supported Adhesive Films by Mandrel Bend

Standard Test Method for Flexibility Determination of Supported Adhesive Films by Mandrel Bend

SIGNIFICANCE AND USE

5.1 The mandrel bend test is simple and fast. It requires little investment in equipment and little operator training. The prime purpose is to determine whether a film of adhesive coated on a substrate meets flexibility requirements. The test is also useful for comparing flexibility of adhesives. It can be used to design adhesives by comparing the flexibility of various formulations to meet specific end-use parameters. The adhesive flexibility can be determined at temperatures other than ambient by conditioning the test apparatus and test specimen at the desired temperature and performing the test under those conditions.

FIG. 1 Test Mandrel (Various Diameters) for Test Frame

Note 1: Figures in parentheses are approximate.

SCOPE

1.1 This test method covers the determination of the flexibility of an adhesive film bonded to a flexible substrate. The results are useful for comparing flexibility of adhesives and not for absolute characterization of adhesives.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4338 − 97 (Reapproved 2021)

Standard Test Method for

Flexibility Determination of Supported Adhesive Films by

Mandrel Bend

This standard is issued under the fixed designation D4338; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope E171 Practice for Conditioning and Testing Flexible Barrier

Packaging

1.1 This test method covers the determination of the flex-

ibility of an adhesive film bonded to a flexible substrate. The

3. Terminology

results are useful for comparing flexibility of adhesives and not

3.1 Definitions—For terms used in this standard, refer to

for absolute characterization of adhesives.

Terminology D907.

1.2 The values stated in SI units are to be regarded as the

3.2 Definitions of Terms Specific to This Standard:

standard. The values given in parentheses are provided for

3.2.1 mandrel, n—cylindrical rod.

information purposes only.

1.3 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

4.1 Atest substrate coated with a film of adhesive, properly

responsibility of the user of this standard to establish appro-

sized and conditioned, is folded to form an inverted U-shaped

priate safety, health, and environmental practices and deter-

angle over the mandrel maintaining intimate contact with the

mine the applicability of regulatory limitations prior to use.

non-adhesive side. Using a fresh specimen for each test, the

1.4 This international standard was developed in accor-

test is repeated with progressively smaller diameter mandrels

dance with internationally recognized principles on standard-

until the adhesive fails (cracks) on bending. The flexibility

ization established in the Decision on Principles for the

value of the adhesive is the smallest diameter mandrel over

Development of International Standards, Guides and Recom-

which four out of five test specimens do not break.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

5. Significance and Use

5.1 Themandrelbendtestissimpleandfast.Itrequireslittle

2. Referenced Documents

investment in equipment and little operator training.The prime

2.1 ASTM Standards:

purpose is to determine whether a film of adhesive coated on a

D609 Practice for Preparation of Cold-Rolled Steel Panels

substrate meets flexibility requirements. The test is also useful

for Testing Paint, Varnish, Conversion Coatings, and

for comparing flexibility of adhesives. It can be used to design

Related Coating Products

adhesives by comparing the flexibility of various formulations

D907 Terminology of Adhesives

to meet specific end-use parameters. The adhesive flexibility

D3111 Practice for Flexibility Determination of Hot-Melt

can be determined at temperatures other than ambient by

Adhesives by Mandrel Bend Test

conditioning the test apparatus and test specimen at the desired

temperature and performing the test under those conditions.

This test method is under the jurisdiction of ASTM Committee D14 on

6. Apparatus

Adhesives and is the direct responsibility of Subcommittee D14.10 on Working

6.1 The test apparatus consists of a series of different

Properties.

Current edition approved April 1, 2021. Published April 2021. Originally

diameter cylindrical rods or mandrels supported at each end.

approved in 1984. Last previous edition approved in 2016 as D4338 – 97 (2016).

These should be long enough to permit placement of the flat

DOI: 10.1520/D4338-97R21.

side of a test specimen tangentially at right angles to the

This test method is intended to replace Method 1081 of Federal Test

longitudinal axis of the test mandrel. Individual requirements

Method 175A.Available from DLADocument Services, Building 4/D, 700 Robbins

Ave., Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

determine the diameter and lengths of the rods needed. For

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1 1

most tests, rods 3.2 mm ( ⁄8 in.), 6.4 mm ( ⁄4 in.), and 12.8 mm

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

( ⁄2 in.) in diameter, by 75 to 150 mm (3 to 6 in.) in length,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. made of brass or stainless steel, are satisfactory. Two simple

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4338 − 97 (2021)

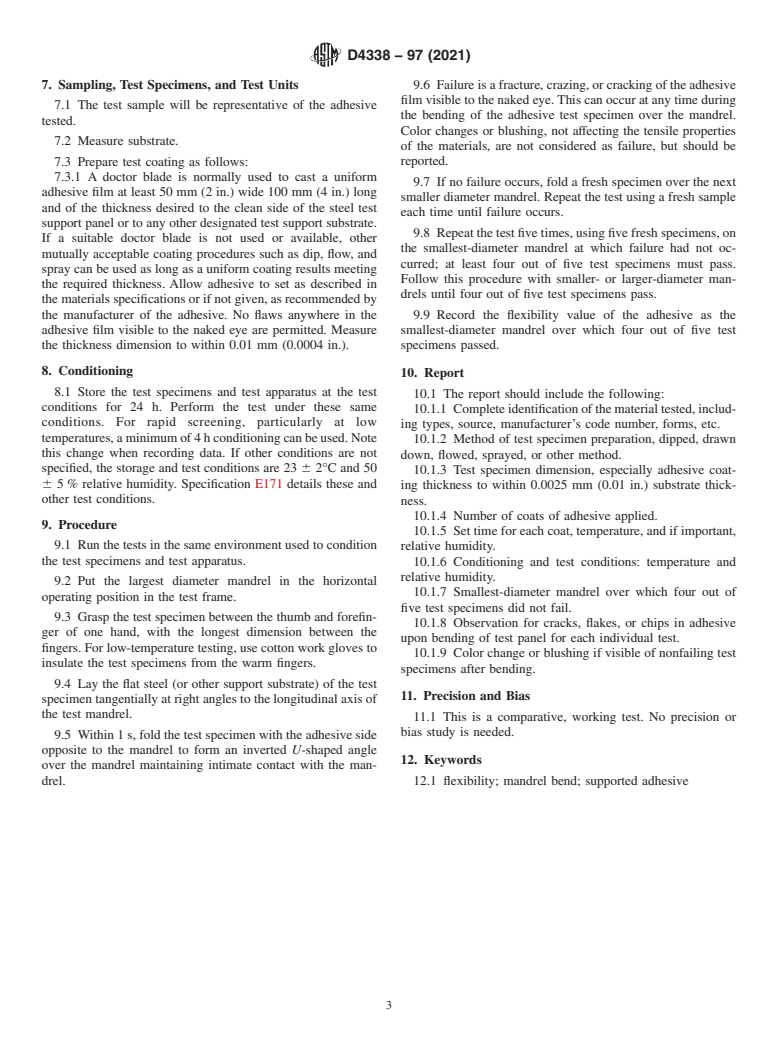

NOTE 1—Figures in parentheses are approximate.

FIG. 1 Test Mandrel (Various Diameters) for Test Frame

test frames are shown in Fig. 1, one with fixed mandrels, and the adhesive to be tested. An alternative to these steel test

the other designed to take any diameter mandrel. panels can be bonderized steel panels as available commer-

cially.

6.2 Test Support Panels, unless otherwise specified, are

6.2.2 Although steel is used in this test method, other

made of steel, not thinner than 0.25 mm (0.010 in.) nor thicker

flexible support substrates can be used, including other metals,

than 0.40 mm (0.016 in.).

plastics, and paper. Special surface preparation, for example,

6.2.1 The steel test panels are to be free of rust, corrosion,

and contamination. Prepare one face of each panel to a clean priming, corona discharge, and etching, can be defined for

surface according to Methods D609

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.