ASTM D3433-99(2020)

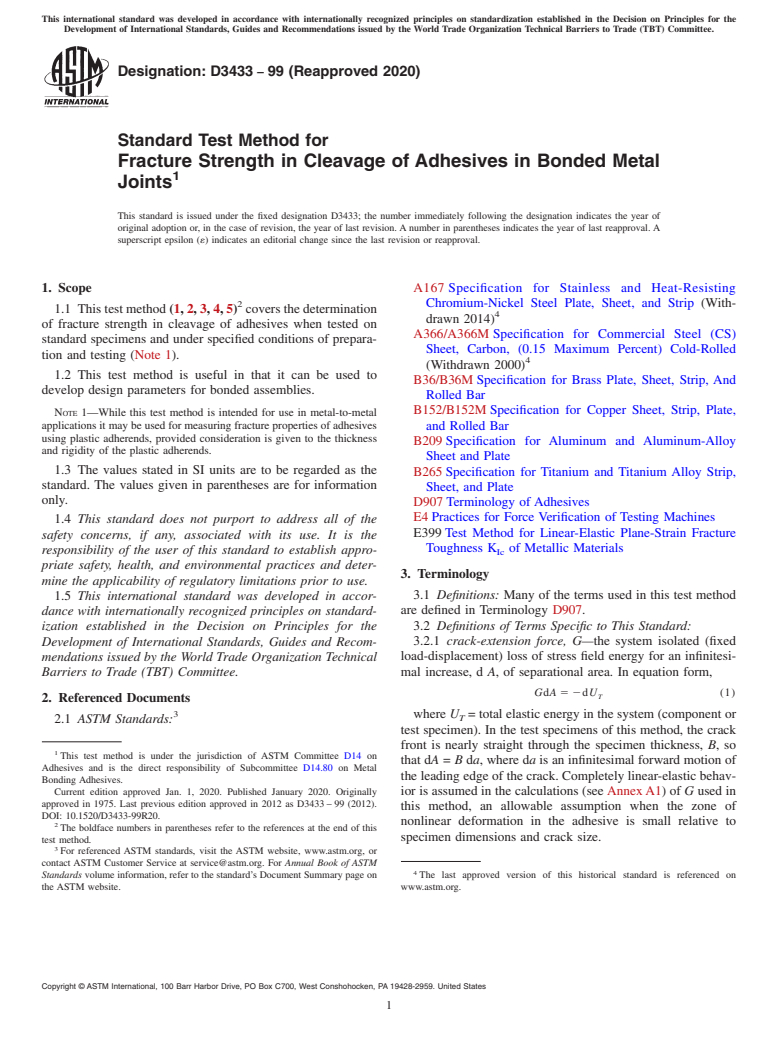

(Test Method)Standard Test Method for Fracture Strength in Cleavage of Adhesives in Bonded Metal Joints

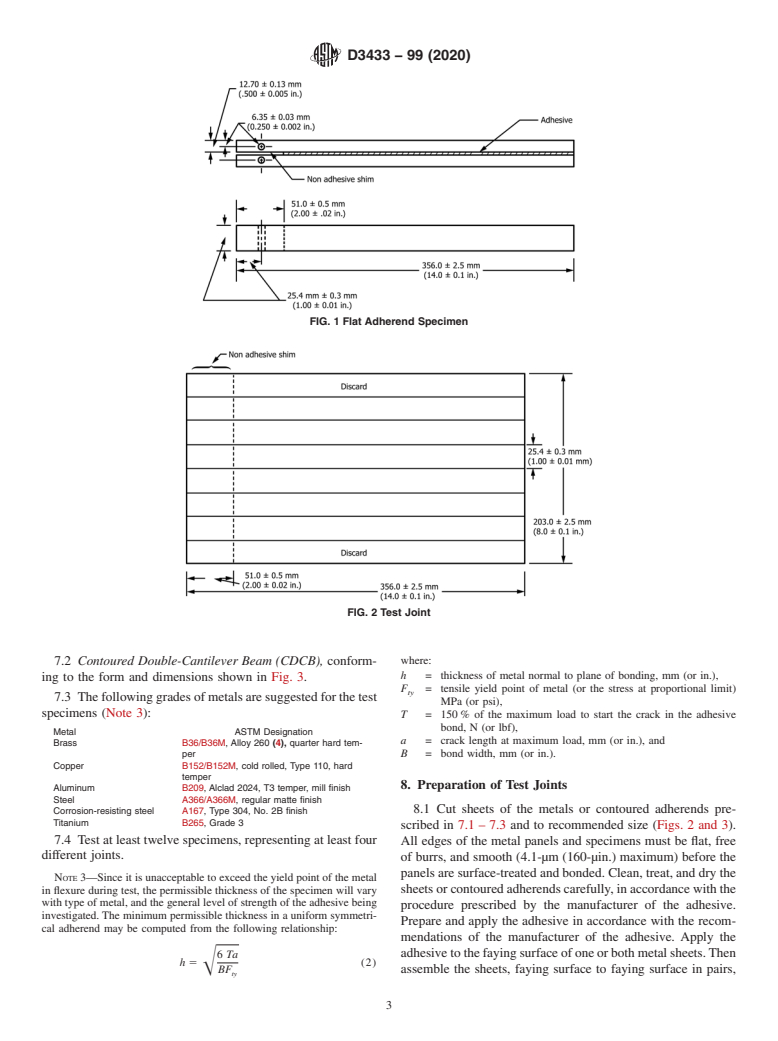

Standard Test Method for Fracture Strength in Cleavage of Adhesives in Bonded Metal Joints

SIGNIFICANCE AND USE

Note 2: Crack growth in adhesive bond specimens can proceed in two ways: (1) by a slow-stable extension where the crack velocity is dictated by the crosshead rate or (2) by a run-arrest extension where the stationary crack abruptly jumps ahead outrunning the crosshead-predicted rate. The first type of crack extension is denoted flat; the second type peaked because of the appearance of the autographic record. The flat behavior is characteristic of adhesives or test temperatures, or both, for these adhesives where there is no difference between initiation, G1c, and arrest, G1a. For example, the rubber modified film adhesives tested above −17.8°C (0°F) all exhibit flat autographic records. Peaked curves are exhibited for all modified materials tested below −73°C (−100°F) and in general for unmodified epoxies.

It should be noted that both peaked and flat behaviors are determined from a crack-length-independent specimen. For other specimens or structures where G increases with a at constant load the onset of crack growth would result in rapid complete fracturing whatever the adhesive characteristics.

5.1 The property G1c (and G1a if relevant) determined by this test method characterizes the resistance of a material to slow-stable or run-arrest fracturing in a neutral environment in the presence of a sharp crack under severe tensile constraint, such that the state of stress near the crack front approaches tritensile plane strain, and the crack-tip plastic region is small compared with the crack size and specimen dimensions in the constraint direction. It has not been proven that tough adhesive systems fully meet this criteria. Therefore, data developed using equations based on this assumption may not represent plane-strain fracture values. Comparison of fracture toughness between adhesive systems widely different in brittleness or toughness should take this into consideration. In general, systems of similar type toughness (6, 7, 8, 9, 10) can be compared as can t...

SCOPE

1.1 This test method (1, 2, 3, 4, 5)2 covers the determination of fracture strength in cleavage of adhesives when tested on standard specimens and under specified conditions of preparation and testing (Note 1).

1.2 This test method is useful in that it can be used to develop design parameters for bonded assemblies.

Note 1: While this test method is intended for use in metal-to-metal applications it may be used for measuring fracture properties of adhesives using plastic adherends, provided consideration is given to the thickness and rigidity of the plastic adherends.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3433 − 99 (Reapproved 2020)

Standard Test Method for

Fracture Strength in Cleavage of Adhesives in Bonded Metal

1

Joints

This standard is issued under the fixed designation D3433; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A167 Specification for Stainless and Heat-Resisting

2 Chromium-Nickel Steel Plate, Sheet, and Strip (With-

1.1 Thistestmethod (1, 2, 3, 4, 5) coversthedetermination

4

drawn 2014)

of fracture strength in cleavage of adhesives when tested on

A366/A366M Specification for Commercial Steel (CS)

standard specimens and under specified conditions of prepara-

Sheet, Carbon, (0.15 Maximum Percent) Cold-Rolled

tion and testing (Note 1).

4

(Withdrawn 2000)

1.2 This test method is useful in that it can be used to

B36/B36MSpecification for Brass Plate, Sheet, Strip, And

develop design parameters for bonded assemblies.

Rolled Bar

B152/B152MSpecification for Copper Sheet, Strip, Plate,

NOTE 1—While this test method is intended for use in metal-to-metal

applications it may be used for measuring fracture properties of adhesives and Rolled Bar

using plastic adherends, provided consideration is given to the thickness

B209 Specification for Aluminum and Aluminum-Alloy

and rigidity of the plastic adherends.

Sheet and Plate

1.3 The values stated in SI units are to be regarded as the

B265Specification for Titanium and Titanium Alloy Strip,

standard. The values given in parentheses are for information

Sheet, and Plate

only.

D907Terminology of Adhesives

E4Practices for Force Verification of Testing Machines

1.4 This standard does not purport to address all of the

E399Test Method for Linear-Elastic Plane-Strain Fracture

safety concerns, if any, associated with its use. It is the

Toughness K of Metallic Materials

responsibility of the user of this standard to establish appro- Ic

priate safety, health, and environmental practices and deter-

3. Terminology

mine the applicability of regulatory limitations prior to use.

3.1 Definitions: Many of the terms used in this test method

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard- are defined in Terminology D907.

3.2 Definitions of Terms Specific to This Standard:

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- 3.2.1 crack-extension force, G—the system isolated (fixed

load-displacement) loss of stress field energy for an infinitesi-

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. mal increase, d A, of separational area. In equation form,

GdA52dU (1)

T

2. Referenced Documents

3

where U =total elastic energy in the system (component or

T

2.1 ASTM Standards:

test specimen). In the test specimens of this method, the crack

front is nearly straight through the specimen thickness, B,so

1

This test method is under the jurisdiction of ASTM Committee D14 on

that dA=B da, where da is an infinitesimal forward motion of

Adhesives and is the direct responsibility of Subcommittee D14.80 on Metal

the leading edge of the crack. Completely linear-elastic behav-

Bonding Adhesives.

Current edition approved Jan. 1, 2020. Published January 2020. Originally ior is assumed in the calculations (see AnnexA1)of G used in

approved in 1975. Last previous edition approved in 2012 as D3433–99 (2012).

this method, an allowable assumption when the zone of

DOI: 10.1520/D3433-99R20.

nonlinear deformation in the adhesive is small relative to

2

The boldface numbers in parentheses refer to the references at the end of this

specimen dimensions and crack size.

test method.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3433 − 99 (2020)

3.2.1.1 When the shear stress on the plane of crack and plane-strain fracture values. Comparison of fracture toughness

forward to its leading edge is zero, the stress state is termed between adhesive systems widely different in brittleness or

“opening mode.” The symbol for

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.