ASTM D4485-00

(Specification)Standard Specification for Performance of Engine Oils

Standard Specification for Performance of Engine Oils

SCOPE

1.1 This specification covers engine oils for light-duty and heavy-duty internal combustion engines used under a variety of operating conditions in automobiles, trucks, vans, buses, and off-highway farm, industrial, and construction equipment.

1.2 This specification is not intended to cover engine oil applications such as outboard motors, snowmobiles, lawn mowers, motorcycles, railroad locomotives, or ocean-going vessels.

1.3 This specification is based on engine test results that generally have been correlated with results obtained on reference oils in actual service engines operating with gasoline or diesel fuel. As it pertains to the API SL engine oil category, it is based on engine test results that generally have been correlated with results obtained on reference oils run in gasoline engine Sequence Tests that defined engine oil categories prior to 2000. It should be recognized that not all aspects of engine oil performance are evaluated by the engine tests in this specification. In addition, when assessing oil performance, it is desirable that the oil be evaluated under actual operating conditions.

1.4 This specification includes bench tests that help evaluate some aspects of engine oil performance not covered by the engine tests in this specification.

1.5 The values stated in SI units are to be regarded as the standard. The values in inch-pound units are provided for information only.

1.6 The test procedures referred to in this specification that are not yet standards are listed in Table 1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 4485 – 00

Standard Specification for

Performance of Engine Oils

This standard is issued under the fixed designation D 4485; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

INTRODUCTION

This document covers all the currently active American Petroleum Institute (API) engine oil

performancecategoriesthathavebeendefinedinaccordancewiththeASTMconsensusprocess.There

are other organizations with specifications not subject to this process, such as the International

Lubricant Standardization and Approval Committee (ILSAC), and the Association des Constructeurs

Europeans d’ Automobiles (ACEA). Their specifications are not covered in this document.

In the ASTM system, a specific API designation is assigned to each category. The system is

open-ended, that is, new designations are assigned for use with new categories as each new set of oil

performance characteristics are defined. Oil categories may be referenced by engine builders in

making lubricant recommendations, and used by lubricant suppliers and customers in identifying

products for specific applications. Where applicable, candidate oil programs are conducted in

accordance with the Chemical Manufacturers Association (CMA) Petroleum Additives Product

Approval Code of Practice.

Other service categories not shown in this document have historically been used to describe engine

oil performance (SA, SB, SC, SD, SE, SF, SG and CA, CB, CC, CD, CD-II, CE [see 3.1.2]). SA is

not included because it does not have specified engine performance requirements. SG is not included

because it was a category that could not be licensed for use in theAPI Service Symbol after December

31, 1995. The others are not included because they are based on test methods for which engine parts,

test fuel, or reference oils, or a combination thereof, are no longer available. Also, the ASTM 5-Car

andSequenceVIProceduresareobsoleteandhavebeendeletedfromthecategoryEnergyConserving

and Energy Conserving II (defined by Sequence VI). Information on excluded older categories and

obsolete test requirements can be found in SAE J183.

1. Scope engine oil performance are evaluated by the engine tests in this

specification. In addition, when assessing oil performance, it is

1.1 This specification covers engine oils for light-duty and

desirable that the oil be evaluated under actual operating

heavy-dutyinternalcombustionenginesusedunderavarietyof

conditions.

operating conditions in automobiles, trucks, vans, buses, and

1.4 Thisspecificationincludesbenchteststhathelpevaluate

off-highway farm, industrial, and construction equipment.

some aspects of engine oil performance not covered by the

1.2 This specification is not intended to cover engine oil

engine tests in this specification.

applications such as outboard motors, snowmobiles, lawn

1.5 The values stated in SI units are to be regarded as the

mowers, motorcycles, railroad locomotives, or ocean-going

standard. The values in inch-pound units are provided for

vessels.

information only.

1.3 This specification is based on engine test results that

1.6 The test procedures referred to in this specification that

generally have been correlated with results obtained on refer-

are not yet standards are listed in Table 1.

ence oils in actual service engines operating with gasoline or

diesel fuel. It should be recognized that not all aspects of

2. Referenced Documents

2.1 ASTM Standards:

D92 Test Method for Flash and Fire Points by Cleveland

This specification is under the jurisdiction of ASTM Committee D-2 on

Open Cup

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.B on Automotive Lubricants.

Current edition approved Nov. 10, 2000. Published November 2000. Originally

published as D 4485 – 85. Last previous edition D 4485 – 99b. Annual Book of ASTM Standards, Vol 05.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

D4485–00

TABLE 1 Test Procedures

D 5480 Test Method for Motor Oil Volatility by Gas Chro-

A

Test Procedure ASTM Publications matography

B

D 5533 Test Method for Evaluation of Automotive Engine

T-6 RR: D02-1219

C 4

T-7 RR: D02-1220

Oils in the Sequence IIIE Spark-Ignition Engine

D

1K RR: D02-1273

D 5800 Test Method for Evaporation Loss of Lubricating

E

1M-PC RR: D02-1320

F

Oils by the Noack Method

1N RR: D02-1321

G

Oil Aeration RR: D02-1379

D 5844 Test Method for Evaluation of Automotive Engine

H

EOFT (Modified) under development

Oils for Inhibition of Rusting (Sequence IID)

I

1P RR: D02-1441

J

D 5862 Test Method for Evaluation of Engine Oils in the

M11 RR: D02-1439

A

Two-Stroke Cycle Turbo-Supercharged 6V92TA Diesel

Research Reports are available from ASTM Headquarters. Request by Re-

search Report No. Engine

B

Multicylinder Engine Test Procedure for the Evaluation of Lubricants—Mack

D 5966 Test Method for Evaluation of Engine Oils for

T-6.

C

Roller Follower Wear in Light-Duty Diesel Engine

Multicylinder Engine Test Procedure for the Evaluation of Lubricants—Mack

T-7.

D 5967 TestMethodforEvaluationofDieselEngineOilsin

D

Caterpillar 1K Test ASTM Research Report. 6

the T8 Diesel Engine

E

Single Cylinder Piston Deposit Test CAT 1M-PC.

F

D 5968 Test Method for Evaluation of Corrosiveness of

Single Cylinder Piston Deposit Test, CAT 1N.

G 6

Navistar Engine Oil Test.

Diesel Engine Oil

H

Engine Oil Filterability Test under development by ASTM D02.06.

D 6082 Test Method for High Temperature Foaming Char-

I

Caterpillar 1P Test

J

acteristics of Lubricating Oils

Cummins M11 High Soot Test

D 6202 Test Method for Measurement of the Effects of

Automotive Engine Oils on the Fuel Economy of Passen-

D93 Test Methods for Flash Point by Pensky-Martens ger Cars and Light-Duty Trucks in the Sequence VIA

2 6

Closed Cup Tester Spark Ignition Engine

D 130 Test Method for Detection of Copper Corrosion from D 6278 Test Method for the Shear Stability of Polymer-

Petroleum Products by the Copper Strip Tarnish Test Containing Fluids Using a European Diesel Injector Ap-

D 892 Test Method for Foaming Characteristics of Lubri- paratus

cating Oils D 6335 Test Method for Determination of High Tempera-

D 2887 Test Method for Boiling Range Distribution of ture Deposits byThermo-Oxidation Engine Oil Simulation

3 6

Petroleum Fractions by Gas Chromatography Test

D 3244 Practice for Utilization of Test Data to Determine D 6417 Test Method for Estimation of Engine Oil Volalility

3 6

Conformance with Specifications by Capillary Gas Chromatography

D 4684 Test Method for Determination of Yield Stress and D 6483 Test Method For Evaluation of Diesel Engine Oils

4 6

Apparent Viscosity of Engine Oils at Low Temperature

in the T-9 Diesel Engine

D 4951 Test Method for Determination of Additive Ele- E29 Practice for Using Significant Digits in Test Data to

ments in Lubricating Oils by Inductively Coupled Plasma Determine Conformance with Specifications

4 7

Atomic Emission Spectrometry E 178 Practice for Dealing with Outlying Observations

D5119 Test Method for Evaluation of Automotive Engine 2.2 Society of Automotive Engineers Standards:

Oils in the CRC L-38 Spark-Ignition Engine SAE J183 Engine Oil Performance and Engine Service

D 5133 Test Method for Low Temperature, Low Shear Classification

Rate, Viscosity/Temperature Dependence of Lubricating SAE J300 Engine Oil Classification

Oils Using a Temperature-Scanning Technique SAE J1423 Passenger Car and Light-Duty Truck Energy-

D 5185 Test Method for the Determination of Additive Conserving Engine Oil Classification

Elements, Wear Metals, and Contaminants in Used Lubri- 2.3 American Petroleum Institute Publication:

cating Oils and Determination of Selected Elements in API 1509 Engine Oil Licensing and Certification System

Base Oils by Inductively Coupled Plasma Atomic Emis- (EOLCS)

4 10

sion Spectrometry (ICP-AES) 2.4 Government Standard:

D 5290 Test Method for Measurement of Oil Consumption, Federal Test Method Standard No. 791C, Method 3470

Piston Deposits, and Wear in a Heavy-Duty High-Speed 2.5 General Motors Corporation Engineering Standard:

Diesel Engine—NTC-400 Procedure GM9099-P Engine Oil Filterability Test (EOFT)

D 5302 Test Method for Evaluation of Automotive Engine

Oils for Inhibition of Deposit Formation and Wear in a

Annual Book of ASTM Standards, Vol 05.04.

Spark-Ignition Internal Combustion Engine Fueled with

Annual Book of ASTM Standards, Vol 14.02.

Gasoline and Operated Under Low-Temperature, Light-

Available from Society of Automotive Engineers (SAE), 400 Commonwealth

Duty Conditions

Dr., Warrendale, PA 15096.

Available from American Petroleum Institute (API), 1220 L Street NW,

Washington, DC 20005.

Available from Superintendent of Documents, U.S. Government Printing

Annual Book of ASTM Standards, Vol 05.02. Office, Washington, DC 20036.

4 11

Annual Book of ASTM Standards, Vol 05.03. Available from General Motors Corporation, CPE-Engineering Standards,

Discontinued; see 1997 Annual Book of ASTM Standards, Vol 05.03. W-3, Warren, MI 48090.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

D4485–00

2.6 Chemical Manufacturers Association Code: 4. Performance Classification

CMA Petroleum Additives Product Approval Code of

4.1 Automotive engine oils are classified in three general

Practice

arrangements, as defined in Section 3; that is, S, C, and Energy

Conserving. These arrangements are further divided into cat-

3. Terminology

egories with performance measured as follows:

3.1 Definitions:

4.1.1 SH—Oil meeting the performance requirements mea-

3.1.1 classification, n— in engine oils, the systematic ar-

sured in the following gasoline engine tests and bench tests:

rangementintocategoriesinaccordancewithdifferentlevelsof

4.1.1.1 Test Method D 5844D 5844, the Sequence IID gaso-

performance in specified engine tests.

line engine test, has been correlated with vehicles used in

3.1.2 category, n—in engine oils, a designation such as SH,

short-trip service prior to 1978, particularly with regard to

SJ,CF-4,CF,CF-2,CG-4,EnergyConserving,andsoforthfor

rusting.

a given level of performance in specified engine tests.

4.1.1.2 Test Method D 5533D 5533, the Sequence IIIE

3.1.3 automotive, adj—descriptive of equipment associated

gasoline engine test, has been correlated with vehicles used in

with self-propelled machinery, usually vehicles driven by

high-temperature service prior to 1988, particularly with

internal combustion engines.

regard to oil thickening and valve train wear.

3.1.4 engine oil, n—a liquid that reduces friction and wear

4.1.1.3 Test Method D 5302D 5480, the SequenceVE gaso-

between the moving parts within an engine, and also serves as

line engine test, has been correlated with vehicles used in

a coolant.

stop-and-go service prior to 1988, particularly with regard to

3.1.4.1 Discussion—It can contain additives to enhance

sludge and valve train wear.

certain properties. Inhibition of engine rusting, deposit forma-

4.1.1.4 Test Method D 5119D5119, the L-38 gasoline en-

tion,valvetrainwear,oiloxidation,andfoamingareexamples.

gine test, is used to measure copper-lead bearing weight loss

3.1.5 light-duty, adj— in internal combustion engine opera-

under high-temperature operating conditions.

tion, characterized by average speeds, power output, and

4.1.1.5 In addition to passing performance in the engine

internal temperatures that are generally much lower than the

tests, specific viscosity grades shall also meet bench test

potential maximums.

requirements (see Table 2), which are discussed in the follow-

3.1.6 lugging, adj—in internal combustion engine opera-

ing subsections:

tion, characterized by a combined mode of relatively low-

(a) The volatility of engine oils relates to engine oil con-

speed and high-power output.

sumption.

3.1.7 heavy duty, adj— in internal combustion engine

(b) The EOFT screens for the formation of precipitates that

operation, characterized by average speeds, power output, and

can cause oil filter plugging.

internal temperatures that are generally close to the potential

(c) Phosphorus compounds can cause glazing of automotive

maximums.

catalysts and exhaust gas oxygen sensors and, thereby, deacti-

3.1.8 light-duty engine, n— in internal combustion engine

vate them. Control of the phosphorus level in the engine oil

types, one that is designed to be normally operated at substan-

may reduce this tendency.

tially less than its peak output.

(d) The flash point can indicate if residual solvents and

3.1.8.1 Discussion—This type of engine is typically in-

low-boiling fractions remain in the finished oil.

stalled in automobiles and small trucks, vans, and buses.

(e) Foaminginengineoilcancausevalveliftercollapseand

3.1.9 heavy-duty engine, n— in internal combustion engine

a loss of lubrication due to the presence of air in the oil. The

types, one that is designed to allow operation continuous at or

foam test indicates an oil’s foaming tendency.

close to its peak output.

(f) The H and M Test indicates the compatibility of an oil

3.1.9.1 Discussion—This type of engine is typically in-

with standard test oils.

stalled in large trucks and buses as well as farm, industrial, and

(g) The L-38 Shear Stability Test indicates the ability of an

construction equipment.

oil to resist permanent viscosity loss due to shearing in an

3.2 Definitions of Terms Specific to This Standard:

engine.

3.2.1 S category, n—the group of engine oils that are

intended primarily for use in automotive gasoline engine

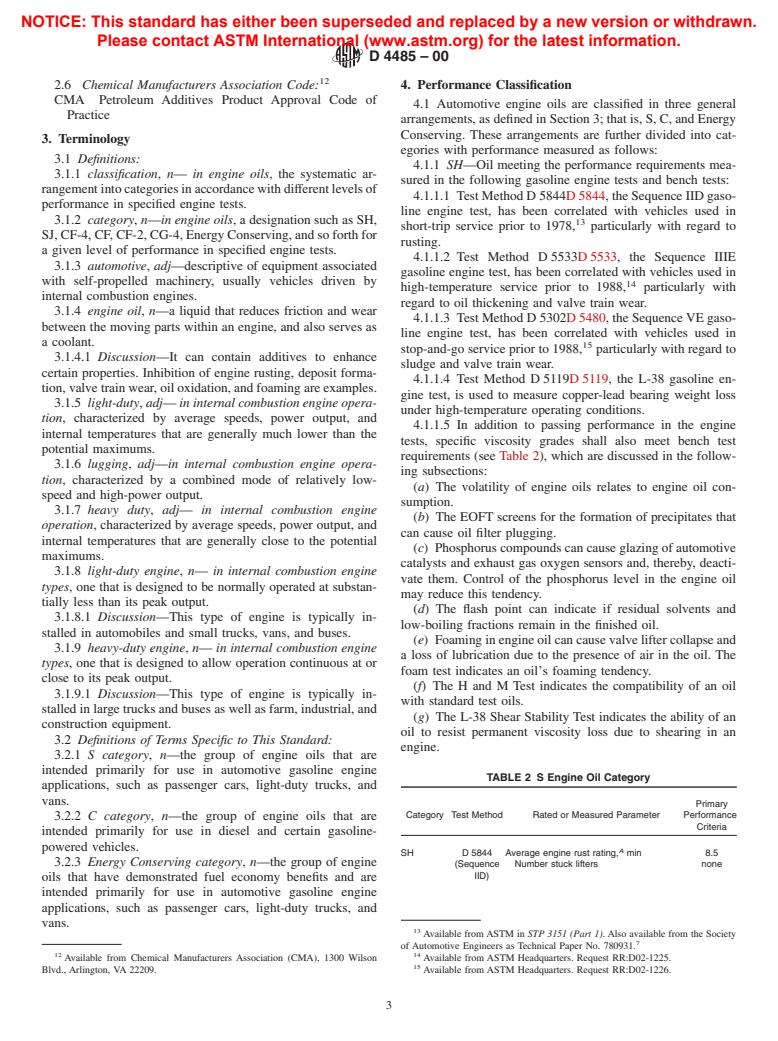

TABLE 2 S Engine Oil Category

applications, such as passenger cars, light-duty trucks, and

vans.

Primary

Category Test Method Rated or Measured Parameter Performance

3.2.2 C category, n—the group of engine oils that are

Criteria

intended primarily for use in diesel and certain gasoline-

powered vehicles.

A

SH D 5844 Average engine rust rating, min 8.5

3.2.3 Energy Conserving category, n—the group of engine

(Sequence Number stuck lifters none

IID)

oils that have demonstrated fuel economy benefits and are

intended primarily for use in automotive gasoline engine

applications, such as p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.