ASTM F1347-91(2006)

(Specification)Standard Specification for Manually Operated Fueling Hose Reels

Standard Specification for Manually Operated Fueling Hose Reels

ABSTRACT

This specification covers manually operated fueling hose reels for use with collapsible and noncollapsible hose. Fueling hose reels shall be of one of the following types as specified: type 1, type 2, type 3, and type 4. The hose reel shall be of a durable, rigid construction, as light in weight and compact as practicable. The reel drum may have either smoothly formed flat sides or suitable spoke ribs, so formed as not to damage the hose. Reels shall be provided with a holding brake to lock the reel in any position. The reel shall be fitted with a device for clamping the hose nozzle securely to the reel to prevent unwinding of the hose and damage to the nozzle. The reel hub discharge shall be angled to provide a smooth tangential contact of the hose with the reel drum. The reel shall have an aromatic fuels tight rotating joint between reel inlet connection and the rotating hub on the reel drum. The reel inlet connection shall be flanged, the flange being part of the rotating swivel joint. Hydrostatic tset and operating test shall be performed to meet the requirements prescribed.

SCOPE

1.1 This specification covers manually operated fueling hose reels for use with collapsible and noncollapsible hose.

1.2 The values stated in inch-pound units are to be regarded as standard. The SI units given in parentheses are for information only.

The following precautionary caveat pertains only to the test methods portion, Section 12 of this specification:This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F1347 – 91 (Reapproved 2006)

Standard Specification for

Manually Operated Fueling Hose Reels

This standard is issued under the fixed designation F1347; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2.3 Military Standard:

MIL-STD-130 Identification Marking of U.S. Military

1.1 This specification covers manually operated fueling

Property

hose reels for use with collapsible and noncollapsible hose.

1.2 The values stated in inch-pound units are to be regarded

3. Classification

as standard. The SI units given in parentheses are for informa-

3.1 Fueling hose reels shall be of one of the following types

tion only.

as specified:

1.3 The following precautionary caveat pertains only to the

3.1.1 Type 1—For 150 ft (46 m) of collapsible 2 ⁄2-in.

test methods portion, Section 12 of this specification: This

(65-mm) hose.

standard does not purport to address all of the safety concerns,

3.1.2 Type 2—For 150 ft (46 m) of noncollapsible 1 ⁄2-in.

if any, associated with its use. It is the responsibility of the user

(38-mm)hoseor100ft(30m)ofnoncollapsible2-in.(50-mm)

of this standard to establish appropriate safety and health

hose.

practices and determine the applicability of regulatory limita-

3.1.3 Type 3—For 150 ft (46 m) of noncollapsible 1 ⁄2-in.

tions prior to use.

(38-mm) hose or for 150 ft (46 m) of collapsible 2 ⁄2-in.

2. Referenced Documents (65-mm) hose.

3.1.4 Type 4—Capacity as specified by purchaser.

2.1 ASTM Standards:

B148 Specification for Aluminum-Bronze Sand Castings

4. Ordering Information

D3006 Specification for Polyethylene Plastic Pressure-

4.1 Ordersformaterialunderthisspecificationshallinclude

Sensitive Electrical Insulating Tape

the following information:

D3951 Practice for Commercial Packaging

3 4.1.1 Title, number, and year of issue of this specification,

2.2 Military Specifications:

4.1.2 Type of hose reel including hose size and type (see

MIL-S-901 Shock Test, H.I. (High-Impact); Shipboard Ma-

3.1), (length of hose for Type 4),

chinery, Equipment and Systems, Requirements for

4.1.3 Whetherright-orleft-handreelsarerequired(see6.5),

MIL-T-16366 Terminals, Electric Lug and Conductor

4.1.4 Flange inlet thickness and bolt hole dimensions (see

Splices, Crimp Style

6.7),

MIL-H-17902 Hose, End Fittings and Hose Assemblies,

4.1.5 Drawings required (see 9.1),

Synthetic Rubber, Aircraft Fuels

4.1.6 Thenumberofsamplestobeinspectedandtested(see

MIL-F-20042 Flanges, Pipe and Bulkhead, Bronze (Silver

11.2),

Brazing)

4.1.7 Certification, if required (see 15.1),

MIL-P-24441 Epoxy-Polyamide Primer

4.1.8 Test report, if required (see 15.1), and

4.1.9 Applicability of supplementary requirements.

This specification is under the jurisdiction ofASTM Committee F25 on Ships

and Marine Technology and is the direct responsibility of Subcommittee F25.07 on

5. Materials and Manufacture

General Requirements.

5.1 Exceptasotherwisespecifiedherein,thehosereelsshall

Current edition approved Dec. 1, 2006. Published January 2007. Originally

approved in 1991. Last previous edition approved in 2001 as F1347–91 (2001). be constructed of aluminum, aluminum bronze, or other

DOI: 10.1520/F1347-91R06.

suitable nonsparking materials.All fittings conveying aromatic

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

fuels through the hose reel shall be made of aluminum bronze

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in accordance with Specification B148, copper alloy UNS No.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

C95300.Topreventdeteriorationinseaatmosphere,aluminum

Available from Standardization Documents Order Desk, Building 4D, 700

parts should not contact brass or bronze; however, where such

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1347 – 91 (2006)

aluminum parts come in contact with brass or bronze, they 6.2 Reel Drum—The reel drum may have either smoothly

shall be protected by adhesive-backed insulating tape, Speci- formed flat sides or suitable spoke ribs, so formed as not to

fication D3006. All aluminum parts shall be given a coat of damage the hose. The rims of the drum shall provide a good

epoxy-polyamide primer. grip for hand rewind.

6.3 Holding Brake—Reels shall be provided with a holding

6. Construction

brake to lock the reel in any position.

6.4 Nozzle Clamp—Thereelshallbefittedwithadevicefor

6.1 Reel and Drum Assembly—The hose reel shall be of a

clamping the hose nozzle securely to the reel to prevent

durable, rigid construction, as light in weight and compact as

unwinding of the hose and damage to the nozzle.

practicable. The drum assembly (drum, reel sides, and its

6.5 Reel Hub Discharge—The reel hub discharge shall be

reinforcements)shallwithstandthehosepullwithoutdistortion

angled to provide a smooth tangential contact of the hose with

orcollapseandshallbecapableofwithstandingsomesideways

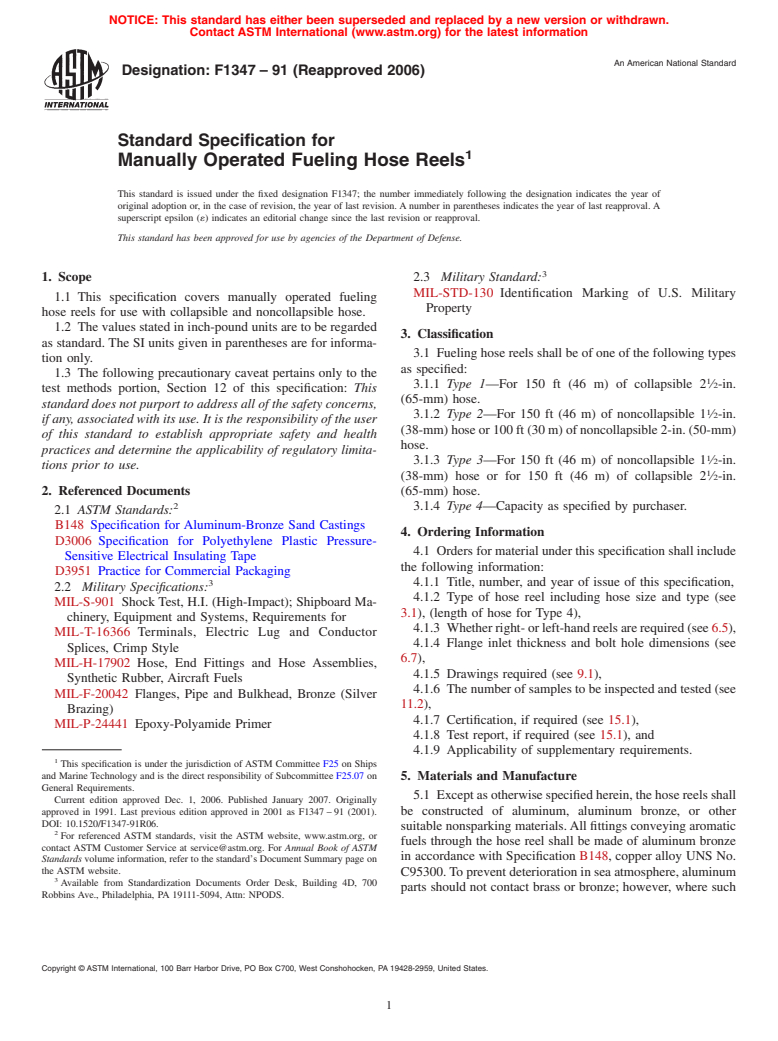

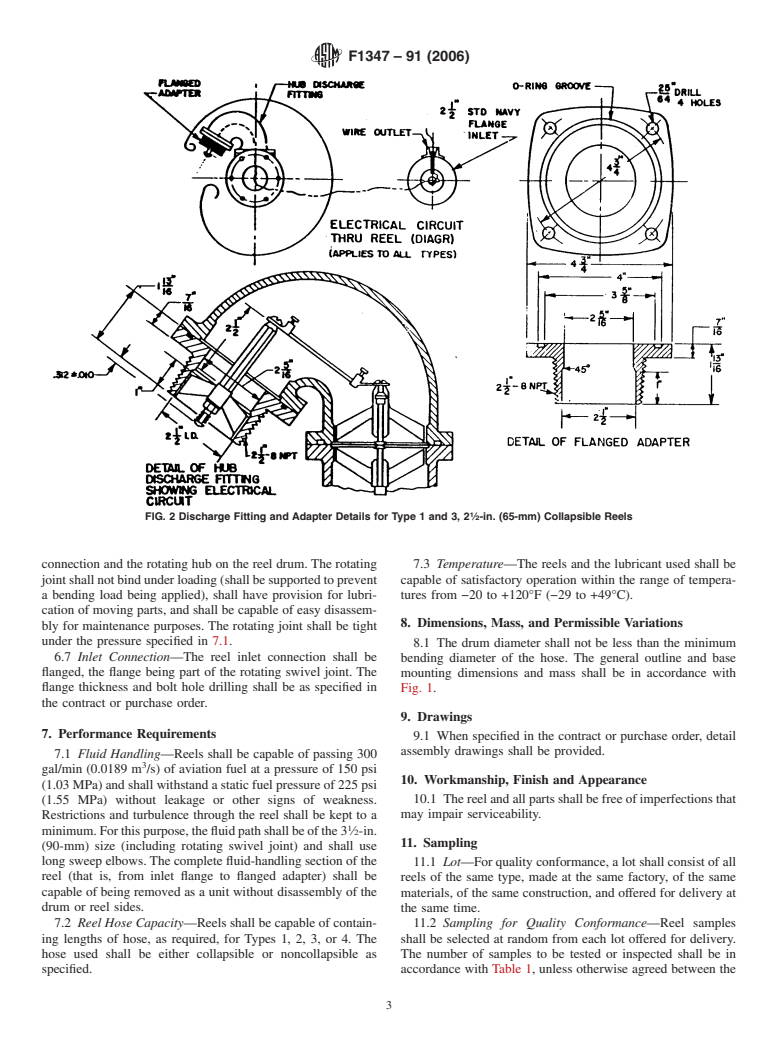

the reel drum as shown on Fig. 1 and Fig. 2, so that the hose

hose pull without undue distortions. The construction of the

will not kink at the discharge connection. The hub discharge

completed drum assembly shall be such that disassembly can

fitting and adapter shall be in accordance with Fig. 2 and Fig.

be readily accomplished with standard tools. When bolted

3 for Types 1, 2, and 3, respectively. Reels shall be right- or

down to a true flat surface, the shaft and rotating seal

left-hand operation and top or bottom wind, as specified. A

centerlines shall be in true alignment and the drum assembly

right-hand, top-wind reel is defined as one that, when looking

shall turn without binding under a rim pull not to exceed 7 lb

intotheflangedadapteronthedischargefittingwhenitisatthe

(198 kg) with the reel unpressurized. Both ends of the drum

top of the drum, has its inlet connection on the right-hand side.

shaft shall be supported on ball or roller bearings that shall

(Note that a top-wind, right-hand reel and a bottom-wind,

have provision for easy lubrication. Reels shall be designed so

left-hand reel are identical.) It shall be possible by turning the

that all bearings, and other corrodible parts, are adequately

discharge fitting around, or by other simple means, to enable

protected from the weather. Provision shall be made for

the hose to unreel from the bottom of the reel drum to either

lubrication of working parts such as bearings or other mating

sideofthereel(thatis,tomakethereeleitherrighthandorleft

surfaces, and all such parts shall be lubricated before delivery

hand) without rotating the reel drum.

with a lubricant soluble in aromatic fuels. Bearing seals shall

be such that the pressure caused by forced lubrication will not 6.6 Aromatic Fuels Tight Rotating Joint—The reel shall

bind the shaft. have an aromatic fuels tight rotating joint between reel inlet

FIG. 1 Hose Reel Dimensions

F1347 – 91 (2006)

FIG. 2 Discharge Fitting and Adapter Details for Type 1 and 3, 2 ⁄2-in. (65-mm) Collapsible Reels

connection and the rotating hub on the reel drum. The rotating 7.3 Temperature—The reels and the lubricant used shall be

jointshallnotbindunderloading(shallbesupportedtoprevent capable of satisfactory operation within the range of tempera-

a bending load being applied), shall have provision for lubri- tures from −20 to +120°F (−29 to +49°C).

cation of moving parts, and shall be capable of easy disassem-

8. Dimensions, Mass, and Permissible Variations

bly for maintenance purposes. The rotating joint shall be tight

under the pressure specified in 7.1.

8.1 The drum diameter shall not be less than the minimum

6.7 Inlet Connection—The reel inlet connection shall be bending diameter of the hose. The general outline and base

flanged, the flange being part of the rotating swivel joint. The

mounting dimensions and mass shall be in accordance with

flange thickness and bolt hole drilling shall be as specified in Fig. 1.

the contract or purchase order.

9. Drawings

7. Performance Requirements

9.1 When specified in the contract or purchase order, detail

assembly drawings shall be provided.

7.1 Fluid Handling—Reels shall be capable of passing 300

gal/min (0.0189 m /s) of aviation fuel at a pressure of 150 psi

10. Workmanship, Finish and Appearance

(1.03MPa)andshallwithstandastaticfuelpressureof225psi

10.1 Thereelandallpartsshallbefreeofimperfectionsthat

(1.55 MPa) without leakage or other signs of weakness.

may impair serviceability.

Restrictions and turbulence through the reel shall be kept to a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.