ASTM A932/A932M-01(2006)

(Test Method)Standard Test Method for Alternating-Current Magnetic Properties of Amorphous Materials at Power Frequencies Using Wattmeter-Ammeter-Voltmeter Method with Sheet Specimens

Standard Test Method for Alternating-Current Magnetic Properties of Amorphous Materials at Power Frequencies Using Wattmeter-Ammeter-Voltmeter Method with Sheet Specimens

SIGNIFICANCE AND USE

This test method provides a satisfactory means of determining various ac magnetic properties of amorphous magnetic materials. It was developed to supplement the testing of toroidal and Epstein specimens. For testing toroidal specimens of amorphous materials, refer to Test Method A 912/A 912M.

The procedures described herein are suitable for use by manufacturers and users of amorphous magnetic materials for materials specification acceptance and manufacturing control.

Note 2—This test method has been principally applied to the magnetic testing of thermally, magnetically annealed, and flattened amorphous strip at 50 and 60 Hz. Specific core loss at 13 or 14 kG [1.3 or 1.4T], specific exciting power at 13 or 14 kG [1.3 or 1.4T], and the flux density, B, at 1 Oe [79.6 A/m] are the recommended parameters for evaluating power grade amorphous materials.

SCOPE

1.1 This test method covers tests for various magnetic properties of flat-cast amorphous magnetic materials at power frequencies (50 and 60 Hz) using sheet-type specimens in a yoke-type test fixture. It provides for testing using either single- or multiple-layer specimens.

Note 1—This test method has been applied only at frequencies of 50 and 60 Hz, but with proper instrumentation and application of the principles of testing and calibration embodied in the test method, it is believed to be adaptable to testing at frequencies ranging from 25 to 400 Hz.

1.2 This test method provides a test for specific core loss, specific exciting power and ac peak permeability at moderate and high flux densities, but is restricted to very soft magnetic materials with dc coercivities of 0.07 Oe [5.57 A/m] or less.

1.3 The test method also provides procedures for calculating ac peak permeability from measured peak values of total exciting currents at magnetic field strengths up to about 2 Oe [159 A/m].

1.4 Explanation of symbols and abbreviated definitions appear in the text of this test method. The official symbols and definitions are listed in Terminology A 340.

1.5 This test method shall be used in conjunction with Practice A 34/A 34M.

1.6 The values stated in either customary (cgs-emu and inch-pound) or SI units are to be regarded separately as standard. Within this standard, SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation: A932/A932M − 01 (Reapproved 2006)

Standard Test Method for

Alternating-Current Magnetic Properties of Amorphous

Materials at Power Frequencies Using Wattmeter-Ammeter-

Voltmeter Method with Sheet Specimens

This standard is issued under the fixed designationA932/A932M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 This test method covers tests for various magnetic

bility of regulatory limitations prior to use.

properties of flat-cast amorphous magnetic materials at power

frequencies (50 and 60 Hz) using sheet-type specimens in a

2. Referenced Documents

yoke-type test fixture. It provides for testing using either

2.1 ASTM Standards:

single- or multiple-layer specimens.

A34/A34MPractice for Sampling and Procurement Testing

NOTE 1—This test method has been applied only at frequencies of 50

of Magnetic Materials

and 60 Hz, but with proper instrumentation and application of the

A340Terminology of Symbols and Definitions Relating to

principles of testing and calibration embodied in the test method, it is

Magnetic Testing

believed to be adaptable to testing at frequencies ranging from 25 to

A343/A343MTest Method for Alternating-Current Mag-

400Hz.

netic Properties of Materials at Power Frequencies Using

1.2 This test method provides a test for specific core loss,

Wattmeter-Ammeter-Voltmeter Method and 25-cm Ep-

specific exciting power and ac peak permeability at moderate

stein Test Frame

and high flux densities, but is restricted to very soft magnetic

A876Specification for Flat-Rolled, Grain-Oriented, Silicon-

materials with dc coercivities of 0.07 Oe [5.57 A/m] or less.

Iron, Electrical Steel, Fully Processed Types

1.3 Thetestmethodalsoprovidesproceduresforcalculating

A901Specification for Amorphous Magnetic Core Alloys,

ac peak permeability from measured peak values of total

Semi-Processed Types

exciting currents at magnetic field strengths up to about 2 Oe

A912/A912MTest Method for Alternating-Current Mag-

[159 A/m].

netic Properties of Amorphous Materials at Power Fre-

quencies Using Wattmeter-Ammeter-Voltmeter Method

1.4 Explanation of symbols and abbreviated definitions

with Toroidal Specimens

appear in the text of this test method.The official symbols and

definitions are listed in Terminology A340.

3. Terminology

1.5 This test method shall be used in conjunction with

3.1 The definitions of terms, symbols, and conversion fac-

Practice A34/A34M.

tors relating to magnetic testing, used in this test method, are

1.6 The values stated in either customary (cgs-emu and found in Terminology A340.

inch-pound) or SI units are to be regarded separately as

3.2 Definitions of Terms Specific to This Standard:

standard. Within this standard, SI units are shown in brackets.

3.2.1 sheet specimen—a rectangular specimen comprised of

Thevaluesstatedineachsystemmaynotbeexactequivalents;

a single piece of material or parallel multiple strips of material

therefore,eachsystemshallbeusedindependentlyoftheother.

arranged in a single layer.

Combiningvaluesfromthetwosystemsmayresultinnoncon-

3.2.2 specimen stack—test specimens (as in 3.2.1) arranged

formance with this standard.

in a stack two or more layers high.

1.7 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

4.1 This test method provides a satisfactory means of

determining various ac magnetic properties of amorphous

This test method is under the jurisdiction of ASTM Committee A06 on

MagneticPropertiesandisthedirectresponsibilityofSubcommitteeA06.01onTest

Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2006. Published May 2006. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1995. Last previous edition approved in 2001 as A932/A932M −01. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/A0932_A0932M-01R06. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A932/A932M − 01 (2006)

magneticmaterials.Itwasdevelopedtosupplementthetesting 5.2 Some amorphous magnetic materials are highly magne-

of toroidal and Epstein specimens. For testing toroidal speci- tostrictive. This is an additional potential source of error

mens of amorphous materials, refer to Test Method A912/ because even a small amount of surface loading, twisting, or

A912M. flattening will cause a noticeable change in the measured

values.

4.2 The procedures described herein are suitable for use by

manufacturers and users of amorphous magnetic materials for

6. Basic Test Circuit

materials specification acceptance and manufacturing control.

6.1 Fig. 1 provides a schematic circuit diagram for the test

NOTE 2—This test method has been principally applied to the magnetic

method.Apowersourceofpreciselycontrollableacsinusoidal

testingofthermally,magneticallyannealed,andflattenedamorphousstrip

voltage is used to energize the primary circuit. To minimize

at 50 and 60 Hz. Specific core loss at 13 or 14 kG [1.3 or 1.4T], specific

exciting power at 13 or 14 kG [1.3 or 1.4T], and the flux density, B,at1 flux-waveform distortion, current ratings of the power source

Oe [79.6 A/m] are the recommended parameters for evaluating power

and of the wiring and switches in the primary circuit shall be

grade amorphous materials.

such as to provide very low impedance relative to the imped-

ance arising from the test fixture and test specimen. Ratings of

5. Interferences

switches and wiring in the secondary circuit also shall be such

5.1 Because amorphous magnetic strip is commonly less

astocausenegligiblevoltagedropbetweentheterminalsofthe

than 0.0015 in. [0.04 mm] thick, surface roughness tends to

secondary test winding and the terminals of the measuring

have a large effect on the cross-sectional area and the cross

instruments.

sectioninsomeareascanbelessthanthecomputedaverage.In

suchcases,thetestresultsusingasingle-stripspecimencanbe

7. Apparatus

substantially different from that measured with a stack of

7.1 The test circuit shall incorporate as many of the follow-

several strips. One approach to minimize the error caused by

ing components as are required to perform the desired mea-

surface roughness is to use several strips in a stack to average

surements.

out the variations. The penalty for stacking is that the active

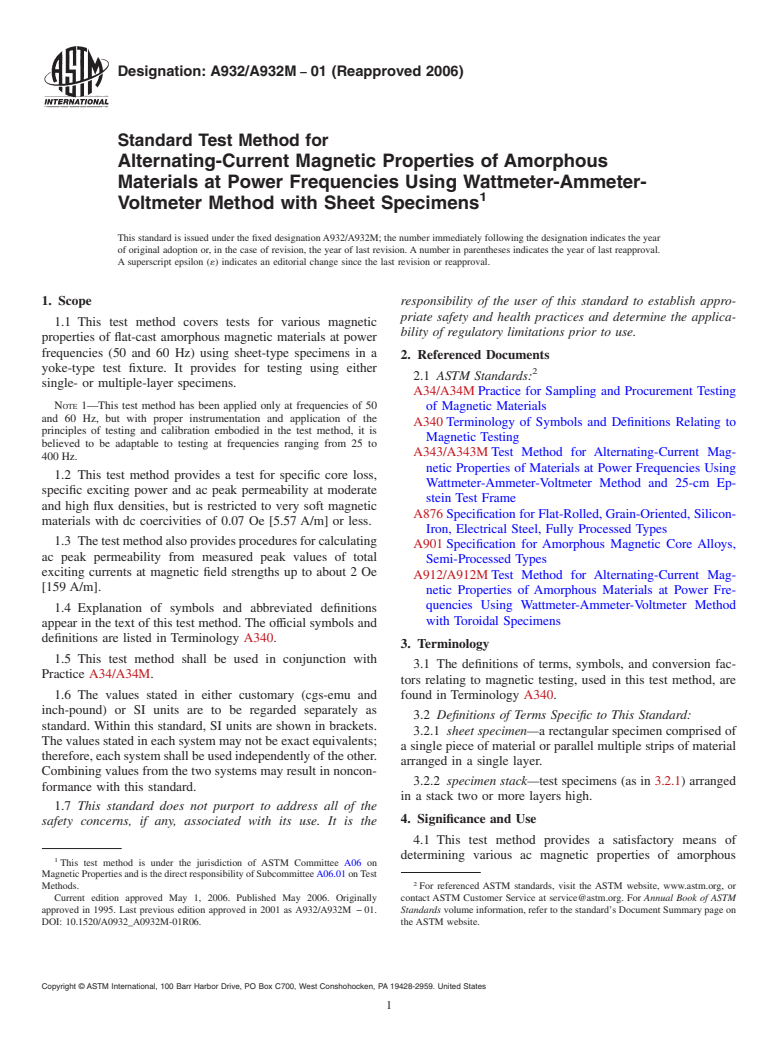

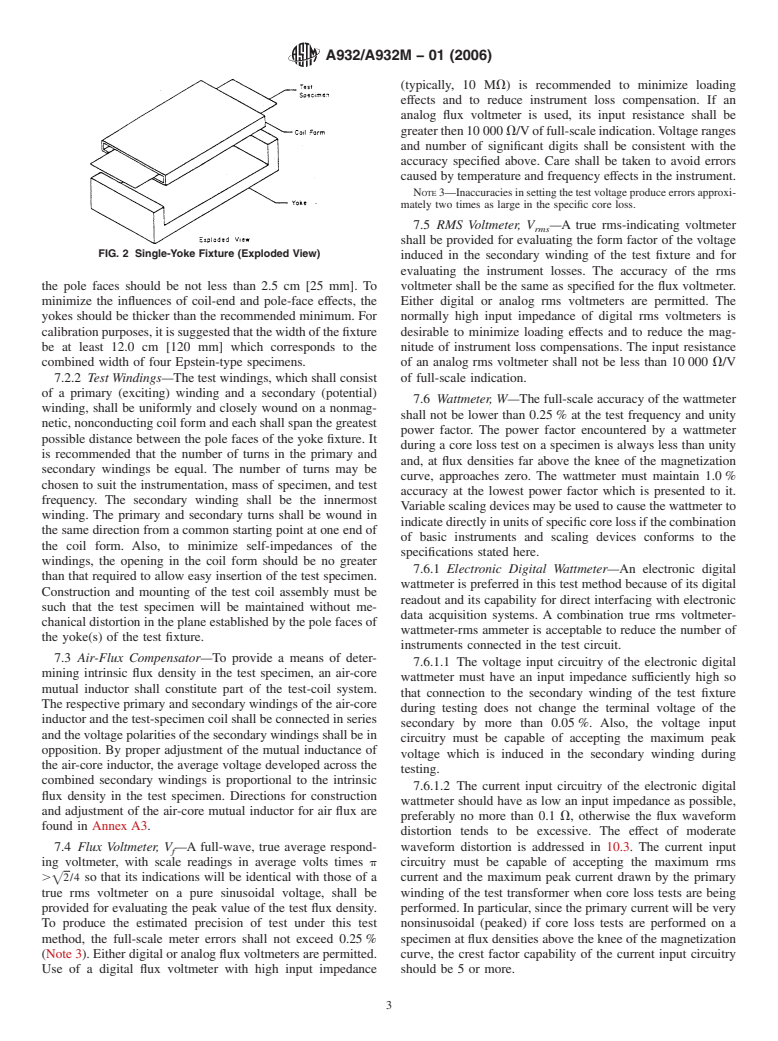

magnetic path length of the specimen stack becomes poorly 7.2 Yoke Test Fixture—Fig.2showsalinedrawingofayoke

defined. The variation of the active length increases with each fixture. Directions concerning the design, construction, and

additional strip in the stack. Moreover, the active length for calibration of the fixture are given in 7.2.1, 7.2.2, Annex A1,

stacked strips tends to vary from sample to sample. As the Annex A2, and Annex A3.

stack height increases, the error as a result of cross-sectional 7.2.1 Yoke Structure—Various dimensions and fabrication

variations diminishes but that as a result of length variations procedures in construction are permissible. Since the recom-

increases with the overall optimum at about four to six layers. mended calibration procedure requires correlation with the

The accuracy for stacked strips is never as good as for a single 25-cm Epstein test, the minimum inside dimension between

layer of smooth strip. pole faces must be at least 22 cm [220 mm]. The thickness of

FIG. 1 Basic Block Circuit Diagram of the Wattmeter Method

A932/A932M − 01 (2006)

(typically, 10 MV) is recommended to minimize loading

effects and to reduce instrument loss compensation. If an

analog flux voltmeter is used, its input resistance shall be

greaterthen10000 V/Voffull-scaleindication.Voltageranges

and number of significant digits shall be consistent with the

accuracy specified above. Care shall be taken to avoid errors

caused by temperature and frequency effects in the instrument.

NOTE3—Inaccuraciesinsettingthetestvoltageproduceerrorsapproxi-

mately two times as large in the specific core loss.

7.5 RMS Voltmeter, V —A true rms-indicating voltmeter

rms

shall be provided for evaluating the form factor of the voltage

FIG. 2 Single-Yoke Fixture (Exploded View)

induced in the secondary winding of the test fixture and for

evaluating the instrument losses. The accuracy of the rms

the pole faces should be not less than 2.5 cm [25 mm]. To voltmeter shall be the same as specified for the flux voltmeter.

minimize the influences of coil-end and pole-face effects, the Either digital or analog rms voltmeters are permitted. The

yokes should be thicker than the recommended minimum. For normally high input impedance of digital rms voltmeters is

calibrationpurposes,itissuggestedthatthewidthofthefixture desirable to minimize loading effects and to reduce the mag-

be at least 12.0 cm [120 mm] which corresponds to the nitude of instrument loss compensations. The input resistance

combined width of four Epstein-type specimens. of an analog rms voltmeter shall not be less than 10000 V/V

7.2.2 Test Windings—The test windings, which shall consist of full-scale indication.

of a primary (exciting) winding and a secondary (potential)

7.6 Wattmeter, W—The full-scale accuracy of the wattmeter

winding, shall be uniformly and closely wound on a nonmag-

shall not be lower than 0.25% at the test frequency and unity

netic,nonconductingcoilformandeachshallspanthegreatest

power factor. The power factor encountered by a wattmeter

possible distance between the pole faces of the yoke fixture. It

during a core loss test on a specimen is always less than unity

is recommended that the number of turns in the primary and

and, at flux densities far above the knee of the magnetization

secondary windings be equal. The number of turns may be

curve, approaches zero. The wattmeter must maintain 1.0%

chosen to suit the instrumentation, mass of specimen, and test

accuracy at the lowest power factor which is presented to it.

frequency. The secondary winding shall be the innermost

Variablescalingdevicesmaybeusedtocausethewattmeterto

winding. The primary and secondary turns shall be wound in

indicatedirectlyinunitsofspecificcorelossifthecombination

the same direction from a common starting point at one end of

of basic instruments and scaling devices conforms to the

the coil form. Also, to minimize self-impedances of the

specifications stated here.

windings, the opening in the coil form should be no greater

7.6.1 Electronic Digital Wattmeter—An electronic digital

than that required to allow easy insertion of the test specimen.

wattmeter is preferred in this test method because of its digital

Construction and mounting of the test coil assembly must be

readout and its capability for direct interfacing with electronic

such that the test specimen will be maintained without me-

data acquisition systems. A combination true rms voltmeter-

chanicaldistortionintheplaneestablishedbythepolefacesof

wattmeter-rms ammeter is acceptable to reduce the number of

the yoke(s) of the test fixture.

instruments connected in the test circuit.

7.3 Air-Flux Compensator—To provide a means of deter-

7.6.1.1 The voltage input circuitry of the electronic digital

mining intrinsic flux density in the test specimen, an air-core

wattmeter must have an input impedance sufficiently high so

mutual inductor shall constitute part of the test-coil system.

that connection to the secondary winding of the test fixture

The respective primary and secondary windings of the air-core

during testing does not change the terminal voltage of the

inductorandthetest-specimencoilshallbeconnectedinseries

secondary by more than 0.05%. Also, the voltage input

andthevoltagepolaritiesofthesecondarywindingsshallbein

circuitry must be capable of accepting the maximum peak

opposition. By proper adjustment of the mutual inductance of

voltage which is induced in the secondary winding during

the air-core inductor, the average voltage developed across the

testing.

combined secondary windings is proportional to the intrinsic

7.6.1.2 The current input circuitry of the electronic digital

flux density in the test specimen. Directions for construction

wattmeter should have as low an input impedance as possible,

and adjustment of the air-core mutual inductor for air flux are

preferably no more than 0.1 V, otherwise the flux waveform

found in Annex A3.

distortion tends to be excessive. The effect of moderate

7.4 Flux Voltmeter, V—A full-wave, true average respond- waveform distortion is addressed in 10.3. The current input

f

ing voltmeter, with scale readings in average volts times p circuitry must be capable of accepting the maximum rms

. 2/4 so that its indications will be identical with those of a current and the maximum peak current drawn by the primary

=

true rms voltmeter on a pure sinusoidal voltage, shall be winding of the test transformer when core loss tests are being

provided for evaluating the peak value of the test flux density. performed. In particular, since the primary current will be very

To produce the estimated precision of test under this test nonsinusoidal (peaked) if core loss tests are performed on a

method, the full-scale meter errors shall not exceed 0.25% specimen at flux densities above the knee of the magnetization

(Note3).Eitherdigitaloranalogfluxvoltmetersarepermitted. curve, the crest factor capability of the current input circuitry

Use of a digital flux voltmeter with high input impedance should be 5 or more.

A932/A932M − 01 (2006)

7.6.2 Electrodynamometer Wattmeter—Areflecting-typeas- adequate current-carrying capacity and is accurate to at least

tatic electrodynamometer wattmeter is permitted as an alterna- 0.1%. It shall have negligible variation with temperature and

tive to an electronic wattmeter. frequency under the conditions applicable to this test method.

7.6.2.1 The sensitivity of the electrodynamometer wattme- If desired, the value of the resistor may be such that the

ter must be such that the connection of the potential circuit of peak-reading voltmeter indicates directly in terms of peak

the wattmeter, during testing, to the secondary winding of the magnetic field strength, provided that the resistor conforms to

test fixture does not change the terminal voltage of the the limitations stated above.

secondary by more than 0.05%. Also, the resistance of the

7.9 Power Supply—Asourceofsinusoidaltestpoweroflow

potential circuit of the wattmeter must be suffic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.