ASTM F891-00

(Specification)Standard Specification for Coextruded Poly(Vinyl Chloride) (PVC) Plastic Pipe With a Cellular Core

Standard Specification for Coextruded Poly(Vinyl Chloride) (PVC) Plastic Pipe With a Cellular Core

SCOPE

1.1 This specification covers coextruded poly(vinyl chloride) (PVC) plastic pipe with a cellular core and concentric inner and outer solid layers, and is produced using a multi-layer coextrusion die for nonpressure use in three series: an IPS Schedule 40 series; a PS series with an iron pipe size outside diameter with varying wall thickness as required for pipe stiffness of 25, 50, and 100; and a sewer and drain series.

1.2 Outside-diameter-controlled pipe may not have an inside diameter suitable for use as a fitting socket.

1.3 All series may be perforated.

1.4 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. The notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.5 The values stated in inch-pound units are to be regarded as the standard. Note 1-Specifications related to this specification are as follows: D2665, D2729, D3034, F512, F758, and F789.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 891 – 00 An American National Standard

Standard Specification for

Coextruded Poly(Vinyl Chloride) (PVC) Plastic Pipe With a

Cellular Core

This standard is issued under the fixed designation F 891; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1898 Practice for Sampling of Plastics

D 2122 Test Method for Determining Dimensions of Ther-

1.1 This specification covers coextruded poly(vinyl chlo-

moplastic Pipe and Fittings

ride) (PVC) plastic pipe with a cellular core and concentric

D 2152 Test Method for Adequacy of Fusion of Extruded

inner and outer solid layers, and is produced using a multilayer

Poly(Vinyl Chloride) (PVC) Pipe and Molded Fittings by

coextrusion die for nonpressure use in three series: an IPS

Acetone Immersion

Schedule 40 series; a PS series with an iron pipe size outside

D 2321 Practice for Underground Installation of Flexible

diameter with varying wall thickness as required for pipe

Thermoplastic Pipe for Sewers and Other Gravity-Flow

stiffness of 25, 50, and 100; and a sewer and drain series.

Applications

1.2 The function of this specification is to provide standard-

D 2412 Test Method for Determination of External Loading

ization of product-technical data and serve as a purchasing

Characteristics of Plastic Pipe by Parallel-Plate Loading

guide.

D 2444 Test Method for Impact Resistance of Thermoplas-

1.3 The text of this specification references notes, footnotes,

tic Pipe and Fittings by Means of a Tup (Falling Weight)

and appendixes which provide explanatory material. The notes

D 2564 Specification for Solvent Cements for Poly(Vinyl

and footnotes (excluding those in tables and figures) shall not

Chloride) (PVC) Plastic Piping Systems

be considered as requirements of the specification.

D 2665 Specification for Poly(Vinyl Chloride) (PVC) Plas-

NOTE 1—All the pipe series covered by this specification are permitted 4

tic Drain, Waste, and Vent Pipe and Fittings

to be perforated or belled for joining by solvent cement or belled for

D 2672 Specification for Joints for IPS PVC Pipe Using

joining by an elastomeric seal (gasket). Because this pipe is OD

Solvent Cement

controlled, the inside diameter will vary, and therefore, the pipe ID is not

D 2729 Specification for Poly(Vinyl Chloride) (PVC)

suitable for use as a socket.

Sewer Pipe and Fittings

1.4 This standard does not purport to address all of the

D 2855 Practice for Making Solvent-Cemented Joints With

safety concerns, if any, associated with its use. It is the

Poly(Vinyl Chloride) (PVC) Pipe and Fittings

responsibility of the user of this standard to establish appro-

D 3034 Specification for Type PSM Poly(Vinyl Chloride)

priate safety and health practices and determine the applica-

(PVC) Sewer Pipe and Fittings

bility of regulatory limitations prior to use.

D 3212 Specification for Joints for Drain and Sewer Plastic

1.5 The values stated in inch-pound units are to be regarded

Pipes Using Flexible Elastomeric Seals

as the standard.

D 3311 Specification for Drain, Waste, and Vent (DWV)

NOTE 2—Specifications related to this specification are as follows:

Plastic Fittings Patterns

D 2665, D 2729, D 3034, F 512, F 758, and F 789.

D 4396 Specification for Rigid Poly(Vinyl Chloride) (PVC)

and Related Plastic Compounds for Nonpressure Piping

2. Referenced Documents

Products

2.1 ASTM Standards:

F 402 Practice for Safe Handling of Solvent Cements,

D 618 Practice for Conditioning Plastics and Electrical

Primers, and Cleaners Used for Joining Thermoplastic Pipe

Insulating Materials for Testing 4

and Fittings

D 1600 Terminology for Abbreviated Terms Relating to 4

F 412 Terminology Relating to Plastic Piping Systems

Plastics

F 477 Specification for Elastomeric Seals (Gaskets) for

Joining Plastic Pipe

F 512 Specification for Smooth-Wall Poly(Vinyl Chloride)

This specification is under the jurisdiction of ASTM Committee F-17 on Plastic

(PVC) Conduit and Fittings for Underground Installation

Piping Systems and is the direct responsibility of Subcommittee F17.25 on Vinyl

Based Pipe.

Current edition approved May 10, 2000. Published August 2000. Originally

e1 3

published as F 891 – 85. Last previous edition F 891 – 98 . Discontinued; see 1997 Annual Book of ASTM Standards, Vol 08.01.

2 4

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 08.04.

Annual Book of ASTM Standards, Vol 08.03.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 891

A

TABLE 1 Minimum Wall Thickness, Pipe Stiffness, and Impact

F 545 Specification for PVC and ABS Injected Solvent

4 Strength for IPS Schedule 40 Series

Cemented Plastic Pipe Joints

Nominal Pipe Wall Thickness, Pipe Stiffness, Impact Strength,

F 656 Specification for Primers for Use in Solvent Cement

Size, in. in. lbf/in. ft·lbf

Joints of Poly(Vinyl Chloride) (PVC) Plastic Pipe and

4 1 ⁄4 0.140 600 40

Fittings

1 ⁄2 0.145 600 50

F 758 Specification for Smooth-Wall Poly(Vinyl Chloride)

2 0.154 300 80

(PVC) Plastic Underdrain Systems for Highway, Airport, 3 0.216 300 100

4 3 ⁄2 0.226 250 100

and Similar Drainage

4 0.237 200 100

F 789 Specification for Type PS-46 and Type PS-115 Poly-

5 0.258 120 100

6 0.280 120 120

(Vinyl Chloride) (PVC) Plastic Gravity Flow Sewer Pipe

8 0.322 100 120

and Fittings

10 0.365 60 120

2.2 Federal Standard:

12 0.406 50 120

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

A

The maximum wall thickness shall not be greater than 1.25 times the minimum

2.3 Military Standard: wall thickness.

MIL-STD-129 Marking for Shipment and Storage

2.4 ANSI Standards: 3.2.1 lot—a lot shall consist of all pipe of the same size

Z34.1 American National Standard for Certification-Third-

produced from one extrusion line during one designated shift.

Party Certification Program 3.2.2 IPS Schedule 40 Series—pipe produced to an iron

Z34.2 American National Standard for Certification-Self-

pipe outside diameter with a Schedule 40 wall thickness.

Certification by Producer or Supplier

3.2.3 PS Series— pipe produced to an IPS outside diameter

and having the required wall thickness to meet a designated

3. Terminology

pipe stiffness.

3.1 Definitions—Definitions are in accordance with Termi- 3.2.4 sewer and drain series—pipe produced to a sewer and

nology F 412, and abbreviations are in accordance with Ter- drain outside diameter and having a minimum wall thickness to

minology D 1600, unless otherwise specified. The abbreviation

meet a designated pipe stiffness.

for poly(vinyl chloride) plastic is PVC.

4. Classification by Application

3.1.1 cellular plastic—a plastic containing numerous cells,

4.1 Coextruded PVC plastic pipe, in an IPS Schedule 40

intentionally introduced, interconnecting or not, distributed

throughout the mass. series, is referenced in Table 1 for use in 4.1.1. A PS series with

an iron pipe outside diameter, with varying wall thickness as

3.1.2 coextruded pipe—pipe consisting of two or more

concentric layers of material bonded together in processing by required for pipe stiffness of 25, 50, and 100 is referenced in

Table 2 for use in 4.1.2, and a sewer and drain series is

any combination of temperature, pressure, grafting, crosslink-

referenced in Table 2 for use in 4.1.3 and 4.1.4.

ing, or adhesion.

4.1.1 Drain, waste, and vent pipe in IPS Schedule 40 series.

3.1.3 coextrusion—a process whereby two or more heated

4.1.2 Underground communication conduit in PS series is

or unheated plastic material streams, forced through one or

not for underground electrical power distribution usage.

more shaping orifice(s), become one continuously formed

4.1.3 Nonpressure sewer and drain pipe for underground

piece.

burial outside of the building.

3.2 Definitions of Terms Specific to This Standard:

4.1.4 Highway underdrain in sewer and drain series.

4.2 Recommendations for storage, joining, and installation

are provided in Appendix X1, Appendix X2, and Appendix X3,

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

respectively.

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Available from American National Standards Institute, 11 W. 42nd St., 13th

NOTE 3—Before installing pipe for industrial waste disposal use, the

Floor, New York, NY 10036

A

TABLE 2 Minimum Wall Thickness for PS Series or Sewer and Drain Series for Minimum Pipe Stiffness

Wall Thickness, in.

Nominal

PS Series Sewer and Drain Series

Pipe Size, in.

PS 25 PS 50 PS 100 PS 12.5 PS 25 PS 50 PS 100

2 . . . . . . 0.100 . . . . . . . . . . . .

3 . . . 0.103 0.130 . . . . . . 0.100 0.120

3 ⁄2 0.100 0.118 0.148 . . . . . . . . . . . .

4 0.106 0.133 0.167 . . . 0.100 0.124 0.156

5 0.131 0.164 0.206 . . . . . . . . . . . .

6 0.156 0.195 0.245 0.118 0.148 0.185 0.232

8 . . . . . . . . . . . . 0.198 0.248 0.310

10 . . . . . . . . . . . . . . . 0.310 0.388

12 . . . . . . . . . . . . . . . 0.369 0.462

15 . . . . . . . . . . . . . . . 0.452 0.565

18 . . . . . . . . . . . . . . . 0.548 0.691

A

The maximum wall thickness shall not be greater than 1.25 times the minimum wall thickness.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 891

approval of the cognizant building code authority must be obtained, as

If one or two fail, additional testing shall be conducted in

conditions not commonly found in normal use may be encountered.

accordance with 6.3.1.1. If all three fail, the sample does not

meet the requirement.

5. Material

6.3.1.1 Pipe Stiffness and Lower Confidence Limit—In the

5.1 Material Specification—The PVC material shall con-

event that one or two of the specimens tested in 6.3.1 fail to

form to the requirements prescribed in Specification D 4396

meet the minimum requirement, the average pipe stiffness of

with a cell class of 11432. PVC material, which has a higher

11 specimens shall meet or exceed the minimum requirement

cell class than those listed, is acceptable.

given in Table 1 for IPS Schedule 40 series pipe, and Table 2

5.2 Rework Material—The manufacturer shall use only his

for PS Series and Sewer and Drain pipe. The 99 % lower

own clean rework pipe material conforming with these cell

confidence limit (LCL) shall be within 15 % of the average

class requirements. It shall be used only in the core layer if it

value. The LCL shall be calculated using the Student’s “t”

contains any residual blowing agent. The pipe produced shall

distribution, with N-1 degrees of freedom, where N is the

meet all requirements of this specification.

number of specimens (11). The critical t value shall be used to

at least three significant digits. Alternatively, if the LCL

6. Requirements

exceeds the minimum PS requirement in the applicable table,

6.1 Workmanship—The pipe shall be homogeneous

but is not within 15 % of the average, the sample meets the

throughout and free of visible cracks, holes, foreign inclusions,

requirements of the pipe stiffness testing. The 11 specimens

or other defects. The pipe shall be as uniform as commercially

include the three tested under 6.3.1, and an additional eight

practicable in color, opacity, density, and other physical prop-

with rotation by 35°, as specified in D 2412, continuing

erties.

throughout the remaining specimens.

6.2 Dimensions and Tolerances:

The LCL based on testing eleven specimens is calculated as

6.2.1 Outside Diameter—The outside diameter and toler-

follows:

ances for the IPS Schedule 40 series, PS series, and the sewer

LCL5~avg PS!2$2.76 ~std. dev.!/=~N!%

and drain series shall meet the requirements of Table 3 when

measured in accordance with Test Method D 2122. The toler-

ances for out-of-roundness shall apply to the pipe prior to

where:

shipment. N =11

(avg PS) = [((PS )]/(11)

6.2.2 Wall Thickness—The wall thickness for the IPS

i

2 2 1/2

(std.dev.) =

Schedule 40 series shall equal or exceed the minimum dimen-

(PS 2 ~(PS! /N

F G

sions in Table 1, and for the PS series and sewer and drain

N 2 1

series it shall equal or exceed the minimum dimensions in

Table 2, when measured in accordance with Test Method

The 15 % requirement is calculated as follows:

D 2122.

~avg 2 LCL!/~avg!3 100 # 15 %

6.2.3 Length—The pipe length may be 10 or 20 ft with a

tolerance on length of + ⁄2, −0 in., unless otherwise specified.

NOTE 4—The 5 % deflection criteria is arbitrarily selected for testing

6.3 Performance Requirements:

convenience. It should not be considered as a limitation with respect to

6.3.1 Pipe Stiffness—The minimum pipe stiffness values at

in-use deflection. The engineer is responsible for establishing the accept-

5 % deflection when measure in accordance with Test Method

able deflection limit.

D 2412, shall equal or exceed the value in Table 1 for IPS

NOTE 5—The strength and load-carrying capabilities of plastic pipe are

Schedule 40 series, or the value in Table 2 or PS series and

measured and reported as pipe stiffness, which is determined in accor-

sewer and drain series. Three specimens shall be tested. If all

dance with Test Method D 2412. The term “crushing strength” is not

three meet this requirement, the sample meets this requirement. applicable to plastic piping.

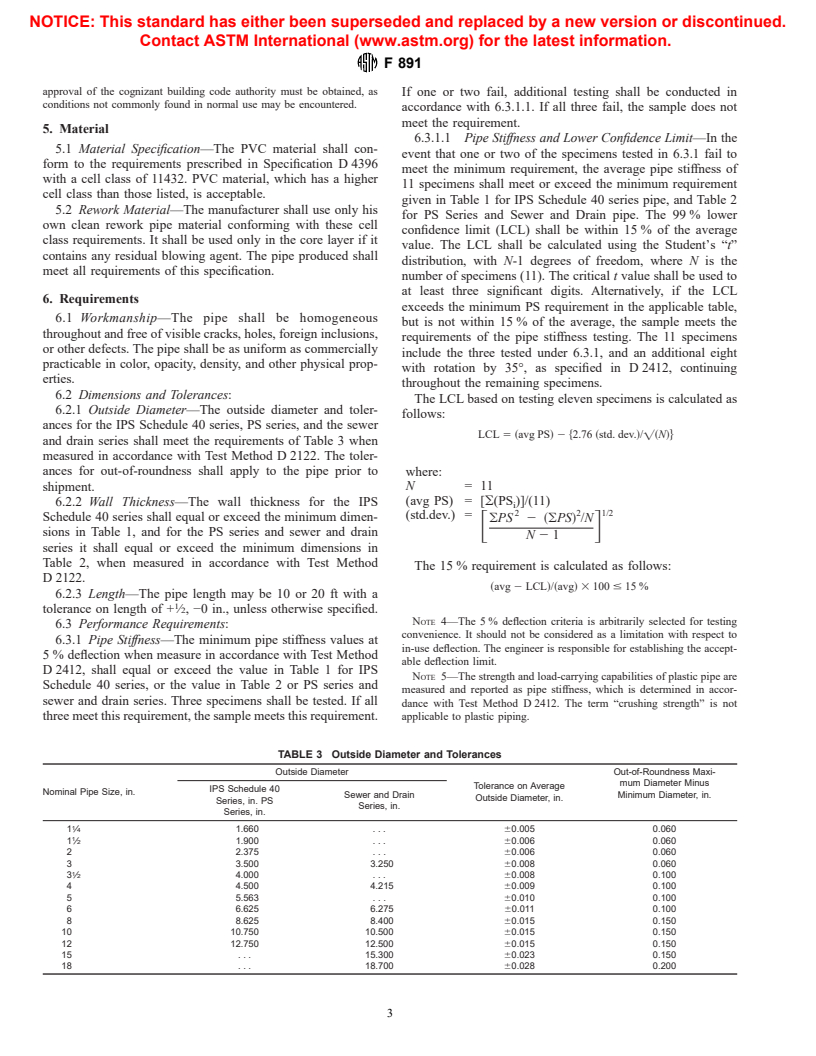

TABLE 3 Outside Diameter and Tolerances

Outside Diameter Out-of-Roundness Maxi-

mum Diameter Minus

Tolerance on Average

IPS Schedule 40

Nominal Pipe Size, in.

Sewer and Drain Minimum Diameter, in.

Outside Diameter, in.

Series, in. PS

Series, in.

Series, in.

1 ⁄4 1.660 . . . 60.005 0.060

1 ⁄2 1.900 . . . 60.006 0.060

2 2.375 . . . 60.006 0.060

3 3.500 3.250 60.008 0.060

3 ⁄2 4.000 . . . 60.008 0.100

4 4.500 4.215 60.009 0.100

5 5.563 . . . 60.010 0.100

6 6.625 6.275 60.011 0.100

8 8.625 8.400 60.015 0.150

10 10.750 10.500 60.015 0.150

12 12.750 12.500 60.015 0.150

15 . . . 15.300 60.023 0.150

18 . . . 18.700 60.028 0.200

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 891

6.3.2 Pipe Flattening—There shall be no evidence of crack- 6.4.3 Gaskets—Elastomeric seals (gaskets) shall meet the

ing, delamination, or rupture when pipe is deflected 60 % of requirements of Specification F 477.

the initial inside diameter, when tested in accordance

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.