ASTM D5662-99

(Test Method)Standard Test Method for Determining Automotive Gear Oil Compatability with Typical Oil Seal Elastomers

Standard Test Method for Determining Automotive Gear Oil Compatability with Typical Oil Seal Elastomers

SCOPE

1.1 This laboratory test method is used to determine the compatibility of automotive gear oils with specific nitrile, polyacrylate, and fluoroelastomer oil seal materials.

1.2 Users of this test method should obtain Test Methods D 412, D 471, and D 2240 and become familiar with their use before proceeding with this test method.

1.3 The values stated in either SI units or inch pound units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 5662 – 99

Standard Test Method for

Determining Automotive Gear Oil Compatability with Typical

Oil Seal Elastomers

This standard is issued under the fixed designation D 5662; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 Thislaboratorytestmethod coversthedeterminationof 3.1 Definitions of Terms Specific to This Standard:

the compatibility of automotive gear oils with specific nitrile, 3.1.1 dumbbell, n—the specific cut shape (Die C) of an

polyacrylate, and fluoroelastomer oil seal materials. elastomer as explained in Section 13 of Test Methods D 412.

1.2 Users of this test method should obtain Test Methods 3.1.2 formulation, n—the specific chemical composition

D 412, D 471, and D 2240 and become familiar with their use used in manufacturing a seal elastomer or a reference oil.

before proceeding with this test method. 3.1.3 percent ultimate elongation, n—the stretch length at

1.3 The values stated in either SI units or inch pound units rupture of an elastomer dumbbell oil-aged by running this

are to be regarded separately as standard. The values stated in procedure minus the rupture stretch length of an untested

each system are not exact equivalents; therefore, each system dumbbell, all divided by rupture stretch length of the untested

shall be used independently of the other. dumbbell and then multiplied by 100.

1.4 This standard does not purport to address all of the 3.1.4 percent volume change, n—the change in volume of a

safety concerns, if any, associated with its use. It is the testspecimenasexplainedinSection10ofTestMethodD 471.

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 4.1 Non-referenceoilsaretestedusingamodifiedversionof

Test Method D 471 on specific elastomer compounds. Mea-

2. Referenced Documents

sured quantities are percent ultimate elongation changes (fur-

2.1 ASTM Standards: ther referred to as just percent elongation changes), durometer

D 412 Test Methods for Vulcanized Rubber and Thermo- Type A hardness changes, and percent volume changes. Ref-

plastic Rubbers and Thermoplastic Elastomers—Tension erenceoilsarerunconcurrentlyinthesameoilbathtomeasure

D 471 Test Method for Rubber Property—Effect of Liq- consistency from one test to another.

uids 4.2 The duration of these tests is 240 h. Table 1 shows the

D 2240 Test Method for Rubber Property—Durometer types of seal materials and their associated test reference oils

Hardness and temperatures. The reference oils are available from the

D 5704 Test Method for Evaluation of the Thermal and ASTM Test Monitoring Center (TMC). The seal materials are

Oxidative Stability of Lubricating Oils Used for Manual available through a Central Parts Distributor (CPD).

Transmissions and Final Drive Axles

5. Significance and Use

D 5760 Specification for Performance of Manual Transmis-

sion Gear Lubricants 5.1 There are several major causes of automotive lubricant-

related seal failures. This test method addresses only those

failures caused by excessive elastomer hardening, elongation

This test method is under the jurisdiction of ASTM Committee D-2 on

loss, and volume swell and attempts to determine the likeli-

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

hood that an oil might cause premature sealing system failures

D02.B0.03 on Gear Lubricants.

in field use. This test method may be used as a requirement of

Current edition approved June 10, 1999. Published August 1999.

Originally published as D 5662 – 95. Last previous edition D 5662 – 98.

a performance specification, such as Specification D 5760.

Until the next revision of this test method, the ASTM Test Monitoring Center

will update changes in this test method by means of Information Letters; these can

be obtained from theASTMTest Monitoring Center, 6555 PennAve., Pittsburgh, Pa

15206–4489. Attention: Administrator. This edition incorporates revisions in all ReferenceoilsareavailablefromtheASTMTestMonitoringCenter,6555Penn

Information Letters through No. 98–1. Ave., Pittsburgh, PA 15206-4489.

3 6

Annual Book of ASTM Standards, Vol 09.01. The Central Parts Distributor for this procedure isTest Engineering Inc., 12758

Annual Book of ASTM Standards, Vol 05.03. Cimarron Path, Suite 102, San Antonio, TX 78249.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5662–99

TABLE 1 Seal Materials, Reference Oils, and Test Temperatures

7.2.1 Information and location of the current CPD is also

Test available from the TMC.

Seal Material Reference Oils

Temperature

7.3 Specificreferencesealelastomersusedareanitrile(NI),

Nitrile No. 161, No. 162 100°C

a polyacrylate (PA), and a fluoroelastomer (FL). Notation of

Polyacrylate No. 160, No. 161 150°C

the numbering system is established by the TMC as follows:

Fluoroelastomer No. 160, No. 161 150°C

[Type] Y – X

where:

5.2 Another major cause of seal failure is the formation of Type = NI, PA, FL,

Y = specific formulation of the elastomer type, and

carbon, varnish, and sludge-like deposits on the seal lip. The

X = batch number of the particular formulation.

deposit-forming characteristics of automotive gear oils are

7.4 The shelf life for the seal elastomers is two years from

evaluated in Test Method D 5704. That procedure is intended

the date the batch was cured. Invalidate any test with a seal

in part to evaluate the potential for oils to cause premature seal

cure date older than two years.

failure in field service.

7.4.1 Storetheelastomersinacool,dark,anddryplace.The

6. Apparatus preferred method of storage is a refrigerator maintained at 38

to 42°F (3 to 6°C).

6.1 Specific test equipment as outlined in Test Methods

7.5 The shelf life of reference oils is typically five years

D 412, D 471, and D 2240 is required.

unless the TMC, through their analysis, specifies otherwise.

6.1.1 Hardness Durometer—See Test Method D 2240.

7.6 Wetting solution of Aerosol OT—0.1 % sodium diocytl

6.1.1.1 Calibration—Calibrate the hardness durometer an-

sulfosuccinate, made by a 1.0 % dilution of a 10 % solution

nually. Use an outside source, with standards traceable to

with reagent water.

National Institute for Standards Technology (NIST) for annual

calibration. Perform checks with internal standards weekly.

8. Procedure

Checks with internal standards shall be within 6 3 points.

8.1 The testing laboratory shall conduct reference oil tests

Calibrate internal standards annually, using an outside source,

with standards traceable to NIST. concurrently with the non-reference oil in the same oil bath.

Reference oils shall perform within a specific range prescribed

6.1.2 Tension Testing Machine—See Test Method D 412.

Set the testing machine rate of grip separation for the percent and evaluated by TMC for validity and updated as needed.

8.2 Prior to cutting specimens and prior to performing

elongation change determinations at 8.5 6 0.8 mm/s.

6.1.2.1 Calibration—Calibrate the tension testing machine elongation tests for initial properties, allow 3 h for the

elastomer to warm to 23+ 2°C, as required by Test Method

annually. Annual calibration shall be performed by the manu-

facturer, using NIST traceable standards. D 412. Referring to the procedure in Test Method D 412, use

Die C to cut a set of twelve dumbbell specimens out of the

6.1.3 Glass Tubes,havinganoutsidediameterof38mmand

an overall length of 300 mm. The tube is fitted loosely with an elastomer sheets as required for each reference and non-

reference oil tested.

aluminum foil-covered stopper.

6.1.4 Balance—Use any commercially available balance 8.2.1 Cut the dumbbells parallel to the grain using the same

unaltered dies for the entire lot. When cutting dumbbells, only

capable of weighing samples to the nearest 1.0 mg.

6.1.4.1 Calibration—Calibrate the balance annually. Use an cutonethicknessatatimetoavoidanydimensionalvariations.

8.2.2 Cut all elastomer specimens, including those used for

outside source, with standards traceable to NIST for annual

calibration. Perform checks with internal standards monthly, measuring initial properties, from the same elastomer batch.

Use these dumbbells for measuring the percent elongation

using NIST traceable weights. The difference between the

changes.

weights and balance shall be < 0.5 mg. Calibrate internal

standards annually, using an outside source, with standards 8.2.3 Next, cut twelve 25 by 50 by 2.0 6 0.1-mm (1 by 2 by

0.08 6 0.005-in.) rectangular specimens for the percent vol-

traceable to NIST.

ume change and hardness testing.

7. Reagents and Materials

8.2.4 Finally, cut twelve more NI, PA, and FLdumbbells for

the purpose of determining initial elongation properties.

7.1 Specific reference test oils are maintained and distrib-

uted by the TMC. The oils used are labeled No. 160, No. 161,

and No. 162, or current equivalent. To receive the test oils and

TABLE 2 Elastomer Specimens Required

seal materials, individual laboratories shall commit to furnish-

Nitrile Polyacrylate Fluoroelastomer

ing the TMC with reference data developed using these

Purpose

Dumb- Speci- Dumb- Speci- Dumb- Speci-

reference materials.TheTMC is also responsible for managing

bells mens bells mens bells mens

a system that ensures the performance and formulation con-

Oil No. 160 0 0 12 12 12 12

cerning these reference oils.

Oil No. 161 12 12 12 12 12 12

7.2 The CPD is responsible for maintaining the numbering

Oil No. 162 12 12 0 0 0 0

and tracking system for the seal elastomer batches used. Non-reference 12 each 12 each 12 each 12 each 12 each 12 each

Initial Properties 12 0 12 0 12 0

Certain specific information concerning these reference mate-

Totals for a Single 48 36 48 36 48 36

rials is available only to the CPD. This information is used to

Non-reference

ensure batch-to-batch consistency.

D5662–99

8.2.5 Use Table 2 as a guide to determine the number of

elastomer specimens required.

8.2.6 Randomly select sets of twelve dumbbells and twelve

rectangular specimens for testing from the different sheets of

test elastomers.

8.2.7 Use the following water displacement procedure in

accordance with Test Method D 471 to conduct the initial and

final volume measurements. Weigh the coupon in air, M1, to

the nearest 1 mg. Making sure there are no air bubbles clinging

to the surface, immerse the rectangular specimen into a 1.0 %

wetting solution of aerosol OT before weighing it in distilled

water, M2, at ambient temperature.

8.2.8 Ensure that initial elastomer properties of hardness

and volume are determined prior to the start of testing. Initial

elongation properties are determined just prior to running the

end of test dumbbells because of instrument calibration.

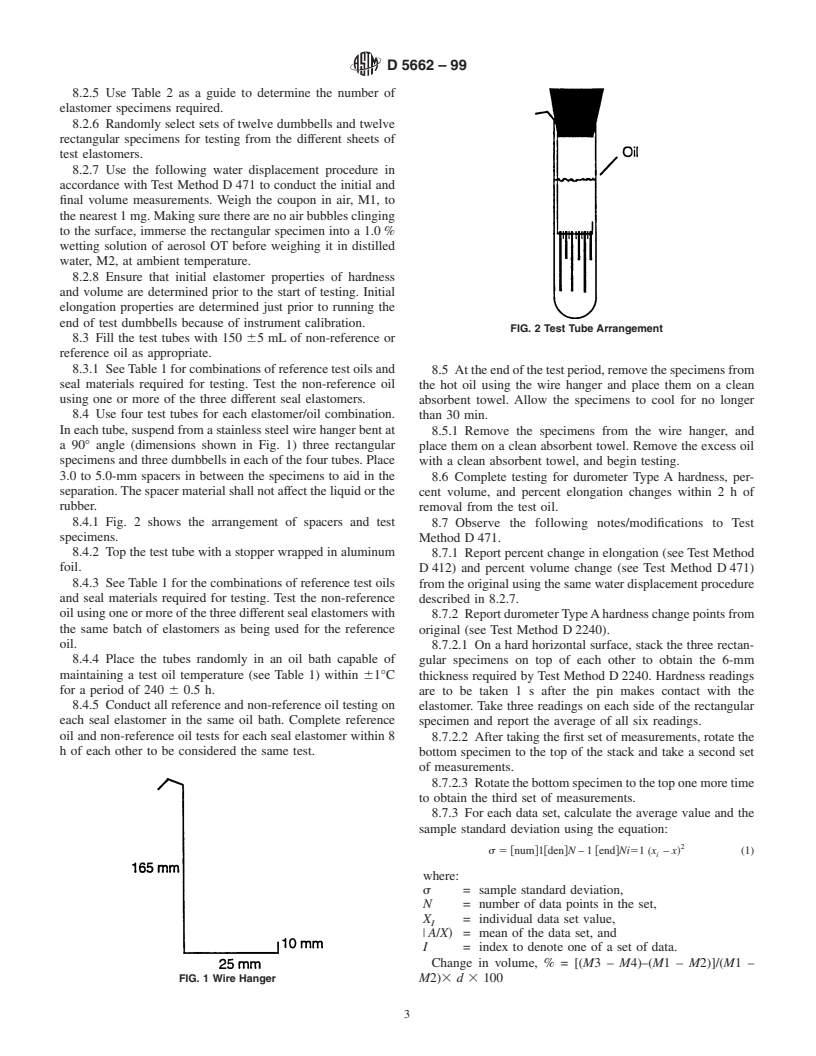

FIG. 2 Test Tube Arrangement

8.3 Fill the test tubes with 150 65 mL of non-reference or

reference oil as appropriate.

8.3.1 SeeTable 1 for combinations of reference test oils and

8.5 Attheendofthetestperiod,removethespecimensfrom

seal materials required for testing. Test the non-reference oil

the hot oil using the wire hanger and place them on a clean

using one or more of the three different seal elastomers.

absorbent towel. Allow the specimens to cool for no longer

8.4 Use four test tubes for each elastomer/oil combination.

than 30 min.

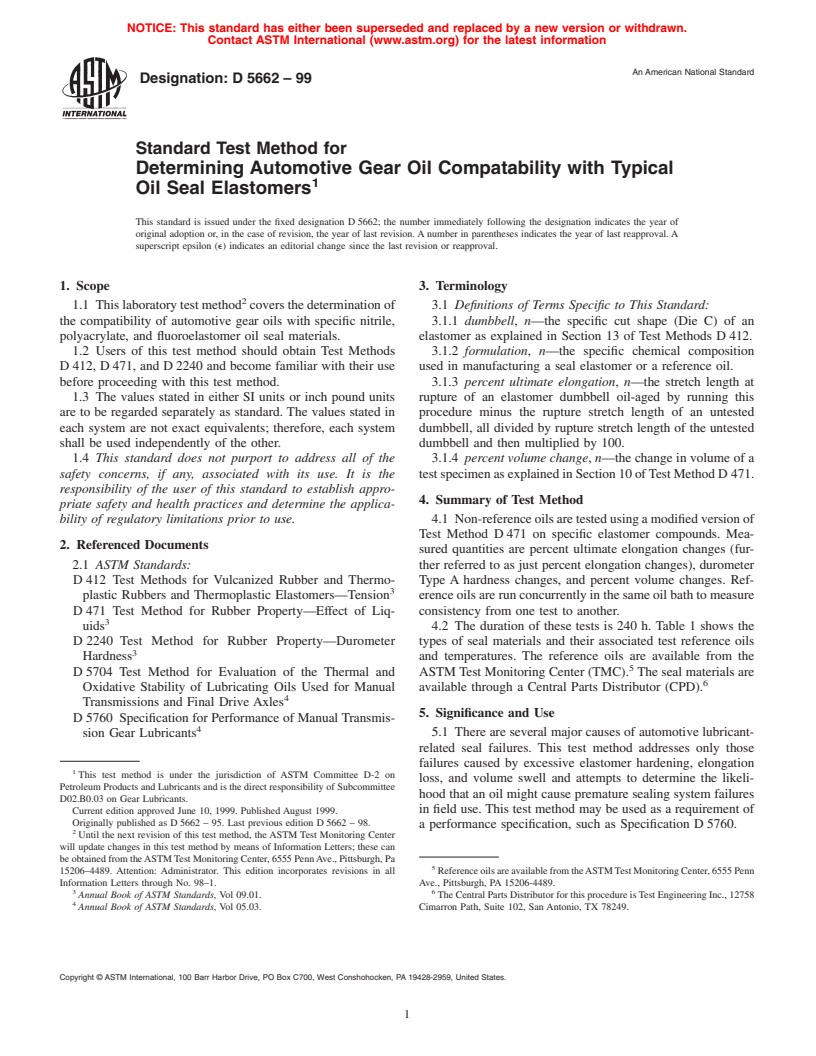

In each tube, suspend from a stainless steel wire hanger bent at

8.5.1 Remove the specimens from the wire hanger, and

a 90° angle (dimensions shown in Fig. 1) three rectangular

place them on a clean absorbent towel. Remove the excess oil

specimens and three dumbbells in each of the four tubes. Place

with a clean absorbent towel, and begin testing.

3.0 to 5.0-mm spacers in between the specimens to aid in the

8.6 Complete testing for durometer Type A hardness, per-

separation.The spacer material shall not affect the liquid or the cent volume, and percent elongation changes within2hof

rubber.

removal from the test oil.

8.4.1 Fig. 2 shows the arrangement of spacers and test 8.7 Observe the following notes/modifications to Test

specimens.

Method D 471.

8.4.2 Top the test tube with a stopper wrapped in aluminum 8.7.1 Report percent change in elongation (see Test Method

foil.

D 412) and percent volume change (see Test Method D 471)

8.4.3 See Table 1 for the combinations of reference test oils from the original using the same water displacement procedure

and seal materials required for testing. Test the non-reference

described in 8.2.7.

oilusingoneormoreofthethreedifferentsealelastomerswith

8.7.2 ReportdurometerTypeAhardnesschangepointsfrom

the same batch of elastomers as being used for the reference

original (see Test Method D 2240).

oil.

8.7.2.1 On a hard horizontal surface, stack the three rectan-

8.4.4 Place the tubes randomly in an oil bath capable of

gular specimens on top of each other to obtain the 6-mm

maintaining a test oil temperature (see Table 1) within 61°C

thickness required by Test Method D 2240. Hardness readings

for a period of 240 6 0.5 h.

are to be taken 1 s after the pin makes contact with the

8.4.5 Conduct all reference and non-reference oil testing on

elastomer. Take three readings on each side of the rectangular

each seal elastomer in the same oil bath. Complete reference

specimen and report the average of all six readings.

oil and non-reference oil tests for each seal elastomer within 8

8.7.2.2 After taking the first set of measurements, rotate the

h of each other to be considered the same test.

bottom specimen to the top of the stack and take a second set

of measurements.

8.7.2.3 Rotatethebottomspecimentothetoponemoretime

to obtain the third set of measurements.

8.7.3 For each data set, calculate the average value and the

sample standard deviation using the equation:

s5@num#1@den#N–1 @end#Ni51 ~x – x! (1)

i

where:

s = sample standard deviation,

N = number of data points in the set,

X = individual data set value,

I

?A/X! = mean of the data set, and

I = index to denote one of a set of data.

Change in volume,%=[(M3– M4)–(M1– M2)]/(M1–

FIG. 1 Wire Hanger M2)3 d 3 100

D5662–99

9.1.4 End of test date,

where:

9.1.5 Elastomer batch date and code,

M1 = the original weight in air,

9.1.6 Oil bath identification, and

M2 = the original weight in water,

M3 = the end of test weight in air, 9.2 Report to the TMC the information identified in 9.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.