ASTM D5662-06

(Test Method)Standard Test Method for Determining Automotive Gear Oil Compatability with Typical Oil Seal Elastomers

Standard Test Method for Determining Automotive Gear Oil Compatability with Typical Oil Seal Elastomers

SCOPE

1.1 This test method covers the determination of the compatibility of automotive gear oils with specific nitrile, polyacrylate, and fluoroelastomer oil seal materials.

1.2 Users of this test method should obtain Test Methods D 412, D 471, and D 2240 and become familiar with their use before proceeding with this test method.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 5662 – 06

Standard Test Method for

Determining Automotive Gear Oil Compatability with Typical

1

Oil Seal Elastomers

This standard is issued under the fixed designation D 5662; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

2

3.1 Definitions of Terms Specific to This Standard:

1.1 This test method covers the determination of the

compatibility of automotive gear oils with specific nitrile, 3.1.1 dumbbell, n—the specific cut shape (Die C) of an

polyacrylate, and fluoroelastomer oil seal materials. elastomerasexplainedinthesectionondumbbellspecimensin

1.2 Users of this test method should obtain Test Methods Test Methods D 412.

D 412, D 471, and D 2240 and become familiar with their use 3.1.2 formulation, n—the specific chemical composition

before proceeding with this test method. used in manufacturing a seal elastomer or a reference oil.

1.3 The values stated in SI units are to be regarded as the 3.1.3 percent ultimate elongation, n—the stretch length at

standard. The values given in parentheses are for information rupture of an elastomer dumbbell oil-aged by running this

only. procedure minus the rupture stretch length of an untested

1.4 This standard does not purport to address all of the dumbbell, all divided by rupture stretch length of the untested

safety concerns, if any, associated with its use. It is the dumbbell and then multiplied by 100.

responsibility of the user of this standard to establish appro- 3.1.4 percent volume change, n—the change in volume of a

priate safety and health practices and determine the applica- test specimen as explained in the procedure for change in

bility of regulatory limitations prior to use. volume in Test Method D 471.

2. Referenced Documents 4. Summary of Test Method

3

2.1 ASTM Standards: 4.1 Non-referenceoilsaretestedusingamodifiedversionof

D 412 Test Methods for Vulcanized Rubber and Thermo- Test Method D 471 on specific elastomer compounds. Mea-

plastic Elastomers—Tension sured quantities are percent ultimate elongation changes (fur-

D 471 Test Method for Rubber Property—Effect of Liquids ther referred to as just percent elongation changes), durometer

D 2240 Test Method for Rubber Property—Durometer Type A hardness changes, and percent volume changes. Ref-

Hardness erenceoilsarerunconcurrentlyinthesameoilbathtomeasure

D 5704 Test Method for Evaluation of the Thermal and consistency from one test to another.

Oxidative Stability of Lubricating Oils Used for Manual 4.2 The duration of these tests is 240 h. Table 1 shows the

Transmissions and Final Drive Axles types of seal materials and their associated test reference oils

D 5760 Specification for Performance of Manual Transmis- and temperatures. The reference oils are available from the

4

sion Gear Lubricants ASTM Test Monitoring Center (TMC). The seal materials are

5

E29 Practice for Using Significant Digits in Test Data to available through a Central Parts Distributor (CPD).

Determine Conformance with Specifications

5. Significance and Use

5.1 There are several major causes of automotive lubricant-

1 related seal failures. This test method addresses only those

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee failures caused by excessive elastomer hardening, elongation

D02.B0 on Automotive Lubricants.

loss, and volume swell and attempts to determine the likeli-

Current edition approved May 1, 2006. Published May 2006. Originally

hood that an oil might cause premature sealing system failures

approved in 1995. Last previous edition approved in 1999 as D 5662–99.

2

in field use. This test method may be used as a requirement of

Until the next revision of this test method, the ASTM Test Monitoring Center

will update changes in this test method by means of Information Letters; these can

a performance specification, such as Specification D 5760.

be obtained from theASTMTest Monitoring Center, 6555 PennAve., Pittsburgh, Pa

15206–4489. Attention: Administrator. This edition incorporates revisions in all

Information Letters through No. 05–1.

3 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or ReferenceoilsareavailablefromtheASTMTestMonitoringCenter,6555Penn

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Ave., Pittsburgh, PA 15206-4489.

5

Standards volume information, refer to the standard’s Document Summary page on The Central Parts Distributor for this procedure isTest Engineering Inc., 12758

the ASTM website. Ci

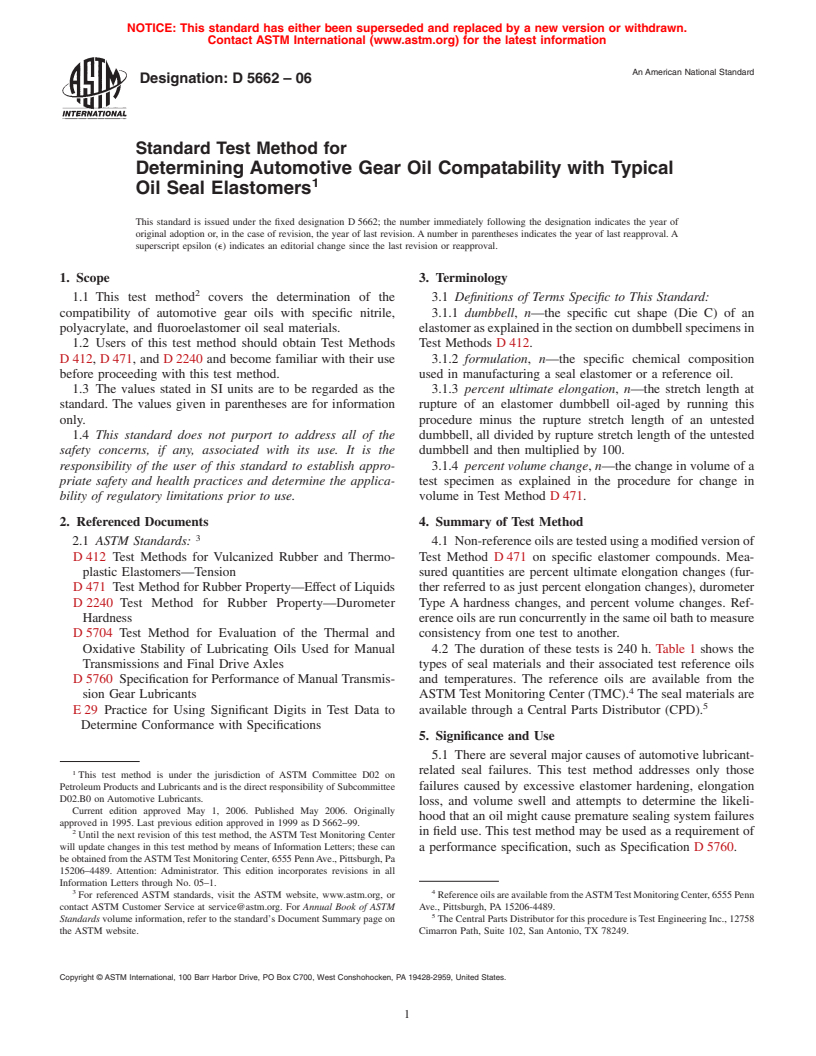

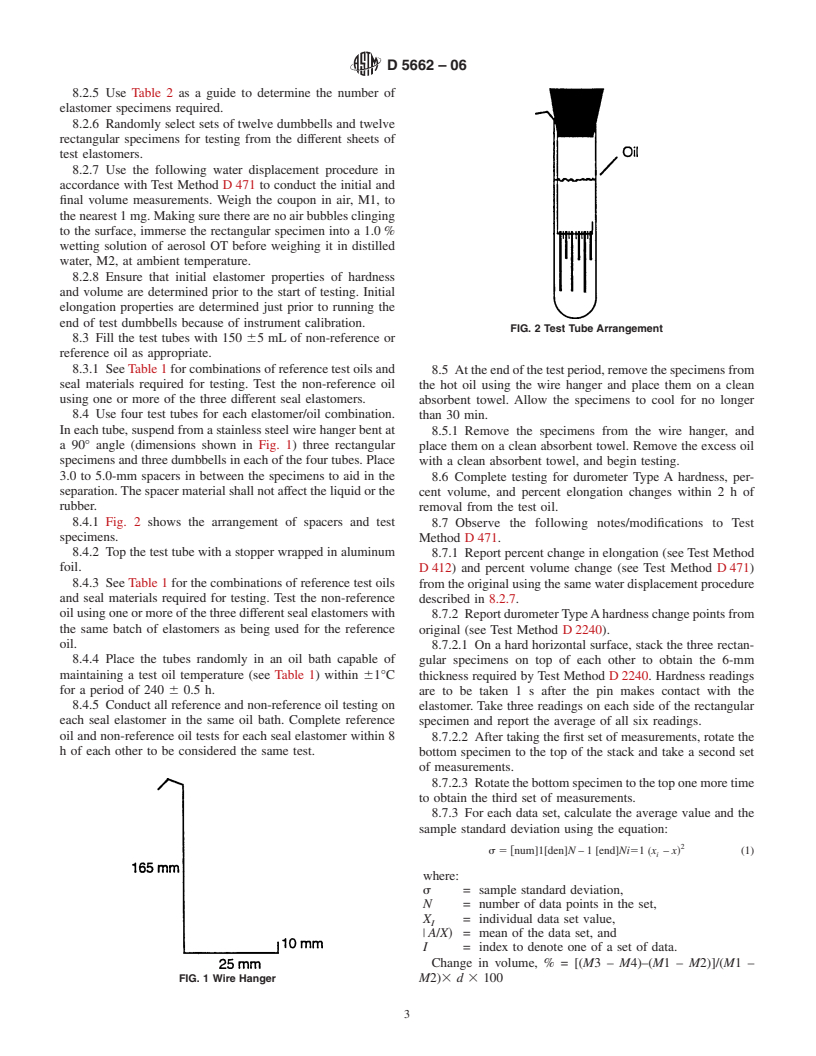

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.