ASTM D6807-02(2009)

(Test Method)Standard Test Method for Operating Performance of Continuous Electrodeionization Systems on Reverse Osmosis Permeates from2 to 100 S/cm

Standard Test Method for Operating Performance of Continuous Electrodeionization Systems on Reverse Osmosis Permeates from2 to 100 S/cm

SIGNIFICANCE AND USE

CEDI devices can be used to produce deionized water from feeds of pretreated water. This test method permits the measurement of key performance capabilities of CEDI devices using a standard set of conditions. The data obtained can be analyzed to provide information on whether changes may have occurred in operating characteristics of the device independently of any variability in feed water characteristics or operating conditions. Under specific circumstances, the method may also provide sufficient information for plant design.

SCOPE

1.1 This test method covers the determination of the operating characteristics of continuous electrodeionization (CEDI) devices, indicative of deionization performance when a device is applied to production of highly deionized water from the product water of a reverse osmosis system. This test method is a procedure applicable to feed waters containing carbonic acid and/or dissolved silica and other solutes, with a conductivity range of approximately 2 to 100 microsiemens-cm-1.

1.2 This test method covers the determination of operating characteristics under standard test conditions of CEDI devices where the electrically active transfer media therein is predominantly regenerated.

1.3 The test method is not necessarily indicative of:

1.3.1 Long term performance on feed waters containing foulants and/or sparingly soluble solutes;

1.3.2 Performance on feeds of brackish water, sea water, or other high salinity feeds;

1.3.3 Performance on synthetic industrial feed solutions, pharmaceuticals, or process solutions of foods and beverages; or,

1.3.4 Performance on feed waters less than 2 μS/cm, particularly performance relating to organic solutes, colloidal or particulate matter, or biological or microbial matter.

1.4 The test method, subject to the limitations described, can be applied as either an aid to predict expected deionization performance for a given feed water quality, or as a method to determine whether performance of a given device has changed over some period of time. It is ultimately, however, the user's responsibility to ensure the validity of the test method for their specific applications.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6807 − 02 (Reapproved 2009)

Standard Test Method for

Operating Performance of Continuous Electrodeionization

Systems on Reverse Osmosis Permeates from

2 to 100 µS/cm

This standard is issued under the fixed designation D6807; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 This standard may involve hazardous materials,

operations, and equipment. This standard does not purport to

1.1 This test method covers the determination of the oper-

address all of the safety concerns, if any, associated with its

ating characteristics of continuous electrodeionization (CEDI)

use. It is the responsibility of the user of this standard to

devices, indicative of deionization performance when a device

establish appropriate safety and health practices and deter-

is applied to production of highly deionized water from the

mine the applicability of regulatory limitations prior to use.

product water of a reverse osmosis system. This test method is

a procedure applicable to feed waters containing carbonic acid

2. Referenced Documents

and/or dissolved silica and other solutes, with a conductivity

-1

2.1 ASTM Standards:

range of approximately 2 to 100 microsiemens-cm .

D513 Test Methods for Total and Dissolved Carbon Dioxide

1.2 This test method covers the determination of operating

in Water

characteristics under standard test conditions of CEDI devices

D859 Test Method for Silica in Water

where the electrically active transfer media therein is predomi-

D1125 Test Methods for Electrical Conductivity and Resis-

nantly regenerated.

tivity of Water

1.3 The test method is not necessarily indicative of:

D1129 Terminology Relating to Water

1.3.1 Long term performance on feed waters containing

D1293 Test Methods for pH of Water

foulants and/or sparingly soluble solutes;

D2777 Practice for Determination of Precision and Bias of

1.3.2 Performance on feeds of brackish water, sea water, or

Applicable Test Methods of Committee D19 on Water

other high salinity feeds;

D4194 Test Methods for Operating Characteristics of Re-

1.3.3 Performance on synthetic industrial feed solutions,

verse Osmosis and Nanofiltration Devices

pharmaceuticals, or process solutions of foods and beverages;

or,

3. Terminology

1.3.4 Performance on feed waters less than 2 µS/cm, par-

3.1 Definitions—For definitions of general terms used in

ticularly performance relating to organic solutes, colloidal or

these test methods, refer to Terminology D1129.

particulate matter, or biological or microbial matter.

3.2 For descriptions of terms relating to reverse osmosis,

1.4 The test method, subject to the limitations described,

refer to Test Methods D4194.

can be applied as either an aid to predict expected deionization

3.3 Definitions of Terms Specific to This Standard:

performance for a given feed water quality, or as a method to

3.3.1 cell—an independently fed chamber formed by two

determine whether performance of a given device has changed

adjacent ion exchange membranes, or by a membrane and an

over some period of time. It is ultimately, however, the user’s

adjacent electrode.

responsibility to ensure the validity of the test method for their

specific applications.

3.3.2 continuous electrodeionization (CEDI) device—a de-

vice that removes ionized and ionizable species from liquids

1.5 The values stated in SI units are to be regarded as

using electrically active media and using an electrical potential

standard. No other units of measurement are included in this

to influence ion transport, where the ionic transport properties

standard.

of the active media are a primary sizing parameter. CEDI

This test method is under the jurisdiction of ASTM Committee D19 on Water

and is the direct responsibility of Subcommittee D19.08 on Membranes and Ion

Exchange Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2009. Published June 2009. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2002. Last previous edition approved in 2002 as D6807 – 02. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D6807-02R09. the ASTM website.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

D6807 − 02 (2009)

devices typically comprise semi-permeable ion exchange high temperature and overflow protection. The tank also

membranes and permanently charged ion exchange media. incorporates a drain valve. During operation of the apparatus,

Examples include continuous deionization, electrodiaresis, and the drain valve may be used in combination with a valve

packed-bed or filled-cell electrodialysis. controlling the rate of feed water to the apparatus to aid in

control of solute concentrations, water level, and temperature

3.3.3 current effıciency—the ratio, expressed in percent, of

within the tank. The tank supplies water to a recirculation

the net transfer of ionized and ionizable solutes per unit cell

pump designed to feed water to the CEDI device at a flow rate

within a CEDI device, expressed in chemical equivalents

and pressure consistent with the ratings of the CEDI device.A

transferred per unit time, to the number of coulombs trans-

recirculation line with shut off valve from the pump discharge

ferred from an external DC power source to each electrode

to the tank may be incorporated as required for proper pump

pair, expressed in faradays per unit time. Calculation of current

operation.

efficiency is described in 9.2.

6.1.3 Adjustment of feed water solute concentration is not

4. Summary of Test Method

required.AdjustfeedwaterpHasrequiredbythemanufacturer

4.1 This test method is used to determine performance of the CEDI device. Feed water to the CEDI device must be

monitored for solute concentrations, pH (Test Method D1293),

capabilities of CEDI devices with regard to extent of ion

removal, pressure/flow relationships and electrical power con- and temperature. Solute concentration may be monitored via

sumption at standard or nominal operating conditions, electri- electrical conductivity or resistivity (Test Method D1125)in

cal current characteristics, and the relative ability of the device combination with silica (Test Method D513) and carbon

to remove ionized and ionizable species when fed reverse dioxide (Test Method D859) concentration measurement, or

osmosis permeate water. On this type of feed, there is consid- alternately may be monitored for individual ionic species and

erable water splitting and ion-exchange resin regeneration, dissolved carbon dioxide and silica, depending on the feed

causing certain species to become ionized within the device, water supplied to the tank and the solutes of interest.

either by the electromotive force or a localized pH shift. The

6.1.4 Feed water provided to the CEDI device should be

method is applicable to both new and used devices.

plumbedasspecifiedbythesupplier,withappropriateflowand

pressure controls, internal recirculations, drains, interlocks,

4.2 Pressurelossdataisobtained.Thisinformationprovides

safety controls, and other features as required. Pressure at the

information relating to possible particulate plugging, fouling,

inlet and outlet and flow rates of each the streams of interest

or internal damage of the device. Deionization performance,

must be monitored (for example, deionized water stream,

extent of silica and dissolved carbon dioxide removal, concen-

concentrate stream, and electrode feed stream).

trating stream pH, and applied voltage are determined at a

predetermined level of electrical current transfer. The ohmic

6.1.5 The CEDI device should be powered as specified by

(electrical) resistance is determined. This information in com-

the supplier, with equipment and wiring to provide appropriate

bination with concentrating stream pH provides basic design

supply DC voltage and amperage, controls, interlocks,

and performance information.

grounding, and safety features. Supply voltage and supply

amperage to the CEDI device should be monitored at positions

5. Significance and Use

within the device or device assembly as specified by the

5.1 CEDI devices can be used to produce deionized water supplier.

from feeds of pretreated water. This test method permits the

6.1.6 Streams leaving the CEDI device may be returned to

measurement of key performance capabilities of CEDI devices

thetankviareturnlines.Alternately,oneormoreofthestreams

using a standard set of conditions. The data obtained can be

may be sent either completely or partially to drain via

analyzed to provide information on whether changes may have

appropriate valving if such operation provides easier control of

occurred in operating characteristics of the device indepen-

desiredfeedwaterconditions.Theoutletdeionizationstreamis

dently of any variability in feed water characteristics or

monitored for the same solutes as for the feed water.The outlet

operatingconditions.Underspecificcircumstances,themethod

concentrating stream is also monitored for the same solutes as

may also provide sufficient information for plant design.

for the feed water. Control of temperature is not required. For

CEDI devices with internal recirculation and “feed and bleed”

6. Apparatus

features, solute concentrations must be measured at locations

6.1 Description:

that are indicative of conditions within the CEDI module prior

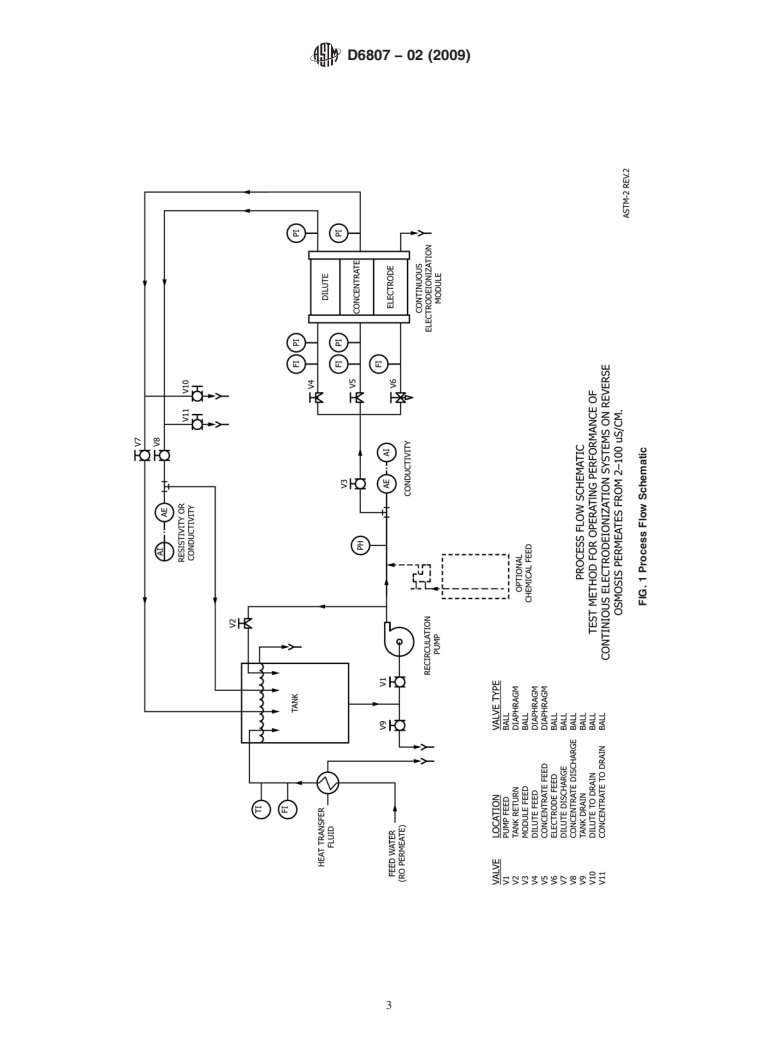

6.1.1 The test apparatus is schematically represented in Fig.

to mixing of recirculation flows.

1. Feed water to the apparatus may be passed through a heat

6.1.7 Feed water to the tank of the test apparatus shall be

exchanger and/or other accessories to modify and/or control

prepared using reverse osmosis apparatus. The pretreatment

feed water temperature as desired. Alternately, data obtained

requirements for the RO are optional depending on the

from the operation of the apparatus may be normalized for

application, but should, at minimum, conform to the manufac-

temperature if normalization factors are known.

turer’s specifications for the particular system.

6.1.2 Feed water to the apparatus enters a holding tank

6.2 Installation:

(open or vented) of volume sufficient to maintain good control

of water level and solute concentrations. The tank is 6.2.1 Materials of construction shall be as specified by the

unpressurized, ported to be capable of occasional cleanings or supplier of the CEDI device and in conformance to standard

sanitizations, and incorporates needed safety features such as engineering practice.

D6807 − 02 (2009)

FIG. 1 Process Flow Schematic

D6807 − 02 (2009)

6.2.2 Controls and monitors should be calibrated and main- voltage should be controlled so as to avoid exceeding suppli-

tained according with suppliers requirements and standard er’s recommended operating parameters and to speed the

engineering practice. attainment of steady state conditions.

8.2.3 Continue to operate until steady state is achieved,

7. Reagents

including applied voltage, concentrate stream electrical

7.1 Specific chemical reagents are not required for this test conductivity, deionization performance, silica and carbon di-

method. However, chemical modification such as pH

oxide concentrations at the deionizing and concentrating

adjustment, addition of trace solutes, and the addition of stream outlets, and deionizing and concentrating stream flows

dissolved carbon dioxide may be applicable under certain

and inlet and outlet pressures. Since electroregeneration of the

circumstances. Unless otherwise indicated, it is intended that active media can be a gradual process, it will typically take 4

all reagents shall conform to the specifications of the Commit-

to8hto reach steady state. Pressures should be expected to

tee onAnalytical Reagents of theAmerican Chemical Society,

change as the internal media electroregenerates. Do not exceed

where such specifications are available. Other grades may be

supplier’s specifications for pressure differentials.

used, provided it is first ascertained that the reagent is of

8.2.4 MeasureandrecordDCvoltage,DCamperage,device

sufficiently high purity to permit its use without lessening the

feed water temperature, deionizing stream inlet and outlet

accuracy of the determination.

conductivity or resistivity, and deionizing stream flow rate.

Also, measure and record feed pH, feed and deionizing stream

8. Procedure

and concentrating stream outlet silica and carbon dioxide

8.1 Start Up:

concentrations. Attachment A is a sample test data sheet.

8.1.1 Ensure that the tank and reagent feed reservoirs are

NOTE 1—In RO permeates, dissolved CO often comprises the majority

sufficiently full, with adequate feed water rate to accommodate

of ionized and ionizable material present, and the CO concentration can

any losses of water caused by the positioning of the various

varygreatlydependinguponthepHoftheROfeedwater.Sinceitmaynot

drain valves. Control valves to the CEDI device should be

be practical to control the CO concentration feeding the CEDI device, it

closed and the device should be unpowered.

is very important that the feed CO be measured when this test is

performed.

8.1.2 Turn on the recirculation pump and then slowly open

the feed water throttling valves and various valves and recir-

8.3 Pressure Drop Measurements—Once steady state is

culation devices on the CEDI device until the device is

achieved, as described in 8.2, measure and record pressures of

operating at nominal or supplier recommended flow condi-

the various inlet and outlet streams of the device. If necessary,

tions. Modify throttling valves to adjust inlet and outlet

normalize pressure differentials for temperature and compare

pressures of the various device streams in accordance with

to supplier’s specifications.

supplier recommendations.

8.4 Shut Down Procedure—The CEDI system should be

8.1.3 Operate the system with no DC power applied for a

shut down in accordance with the manufacturer’s recommen-

sufficient time to ensure adequate removal of any residual air

dations. If no specific recommendations are given the follow-

from the piping and device. During this time, flows, pressures,

ing procedure should be suitable. Turn off applied DC voltage.

feedsoluteconcentrations,andtemperature,shouldbeadjusted

For shutdown periods longer than 2 weeks, it is recommended

until a desirable steady state device feed water condition has

that the ac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.