ASTM C33/C33M-16

(Specification)Standard Specification for Concrete Aggregates

Standard Specification for Concrete Aggregates

ABSTRACT

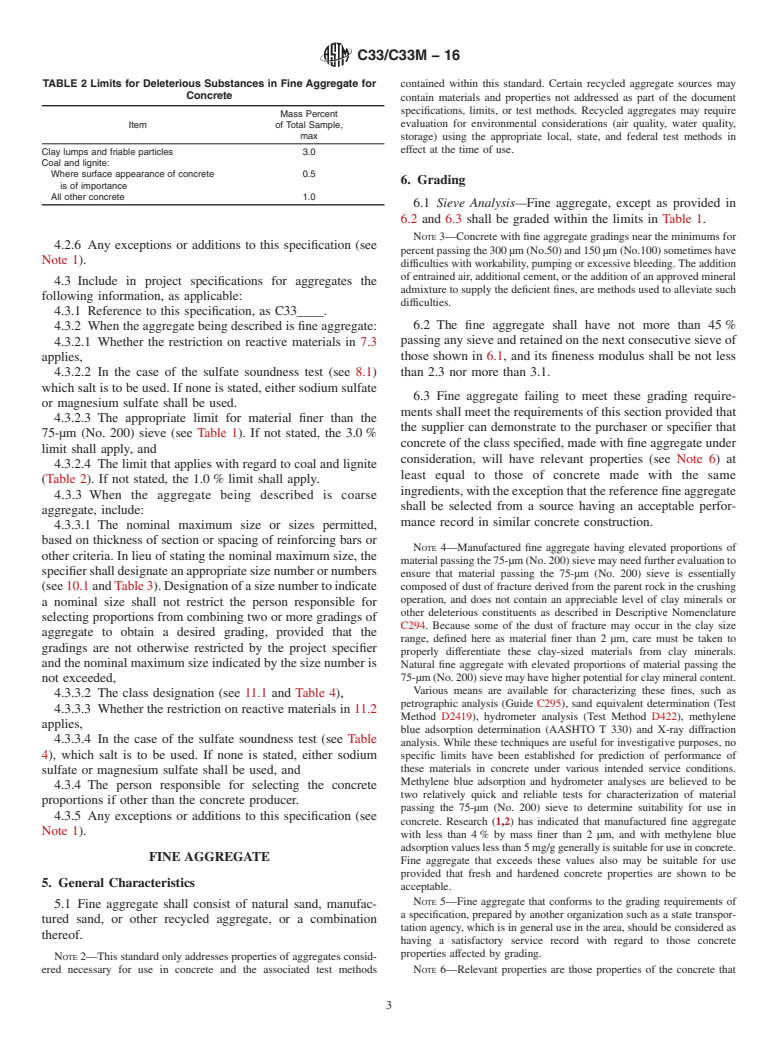

This specification defines the requirements for grading and quality of fine and coarse aggregate for use in concrete. Fine aggregate shall consist of natural sand, manufactured sand, or a combination thereof. Fine aggregate shall be free of injurious amounts of organic impurities. Fine aggregate for use in concrete that will be subject to wetting, extended exposure to humid atmosphere, or contact with moist ground shall not contain any materials that are deleteriously reactive with the alkalis in the cement in amount sufficient to cause excessive expansion of mortar or concrete. Fine aggregate subjected to five cycles of the soundness test shall have a required weighted average loss. Coarse aggregate shall consist of gravel, crushed gravel, crushed stone, air-cooled blast furnace slag, or crushed hydraulic-cement concrete, or a combination thereof. The sampling and test methods shall be done with grading and fineness modulus test, organic impurities test, effect of organic impurities on strength test, soundness test, clay lumps and friable particles test, coal and lignite test, bulk density of slag test, abrasion of coarse aggregate test, reactive aggregate test, freezing and thawing test, and chert test method.

SCOPE

1.1 This specification defines the requirements for grading and quality of fine and coarse aggregate (other than lightweight or heavyweight aggregate) for use in concrete.2

1.2 This specification is for use by a contractor, concrete supplier, or other purchaser as part of the purchase document describing the material to be furnished.

Note 1: This specification is regarded as adequate to ensure satisfactory materials for most concrete. It is recognized that, for certain work or in certain regions, it may be either more or less restrictive than needed. For example, where aesthetics are important, more restrictive limits may be considered regarding impurities that would stain the concrete surface. The specifier should ascertain that aggregates specified are or can be made available in the area of the work, with regard to grading, physical, or chemical properties, or combination thereof.

1.3 This specification is also for use in project specifications to define the quality of aggregate, the nominal maximum size of the aggregate, and other specific grading requirements. Those responsible for selecting the proportions for the concrete mixture shall have the responsibility of determining the proportions of fine and coarse aggregate and the addition of blending aggregate sizes if required or approved.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of this standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C33/C33M −16

StandardSpecification for

1

Concrete Aggregates

This standard is issued under the fixed designation C33/C33M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

3

2.1 ASTM Standards:

1.1 This specification defines the requirements for grading

C29/C29MTest Method for Bulk Density (“Unit Weight”)

andqualityoffineandcoarseaggregate(otherthanlightweight

2

and Voids in Aggregate

or heavyweight aggregate) for use in concrete.

C40Test Method for Organic Impurities in FineAggregates

1.2 This specification is for use by a contractor, concrete

for Concrete

supplier, or other purchaser as part of the purchase document

C87Test Method for Effect of Organic Impurities in Fine

describing the material to be furnished.

Aggregate on Strength of Mortar

C88Test Method for Soundness of Aggregates by Use of

NOTE 1—This specification is regarded as adequate to ensure satisfac-

Sodium Sulfate or Magnesium Sulfate

tory materials for most concrete. It is recognized that, for certain work or

C117TestMethodforMaterialsFinerthan75-µm(No.200)

incertainregions,itmaybeeithermoreorlessrestrictivethanneeded.For

Sieve in Mineral Aggregates by Washing

example, where aesthetics are important, more restrictive limits may be

consideredregardingimpuritiesthatwouldstaintheconcretesurface.The

C123Test Method for Lightweight Particles in Aggregate

specifier should ascertain that aggregates specified are or can be made

C125Terminology Relating to Concrete and Concrete Ag-

available in the area of the work, with regard to grading, physical, or

gregates

chemical properties, or combination thereof.

C131Test Method for Resistance to Degradation of Small-

1.3 Thisspecificationisalsoforuseinprojectspecifications

Size CoarseAggregate byAbrasion and Impact in the Los

to define the quality of aggregate, the nominal maximum size

Angeles Machine

of the aggregate, and other specific grading requirements.

C136Test Method for Sieve Analysis of Fine and Coarse

Thoseresponsibleforselectingtheproportionsfortheconcrete Aggregates

mixture shall have the responsibility of determining the pro- C142Test Method for Clay Lumps and Friable Particles in

portions of fine and coarse aggregate and the addition of Aggregates

C150Specification for Portland Cement

blending aggregate sizes if required or approved.

C227 Test Method for Potential Alkali Reactivity of

1.4 The values stated in either SI units or inch-pound units

Cement-Aggregate Combinations (Mortar-Bar Method)

are to be regarded separately as standard. The values stated in

C289Test Method for Potential Alkali-Silica Reactivity of

each system may not be exact equivalents; therefore, each 4

Aggregates (Chemical Method) (Withdrawn 2016)

system shall be used independently of the other. Combining

C294Descriptive Nomenclature for Constituents of Con-

values from the two systems may result in non-conformance

crete Aggregates

with the standard.

C295GuideforPetrographicExaminationofAggregatesfor

Concrete

1.5 The text of this standard references notes and footnotes

C311Test Methods for Sampling and Testing Fly Ash or

whichprovideexplanatorymaterial.Thesenotesandfootnotes

Natural Pozzolans for Use in Portland-Cement Concrete

(excluding those in tables and figures) shall not be considered

C330Specification for Lightweight Aggregates for Struc-

as requirements of this standard.

tural Concrete

C331SpecificationforLightweightAggregatesforConcrete

Masonry Units

1

This specification is under the jurisdiction of ASTM Committee C09 on

Concrete and ConcreteAggregatesand is the direct responsibility of Subcommittee

C09.20 on Normal Weight Aggregates.

3

Current edition approved Feb. 1, 2016. Published March 2016. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approvedin1921.Lastpreviouseditionapprovedin2013asC33/C33M–13.DOI: contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

10.1520/C0033_C0033M-16. Standards volume information, refer to the standard’s Document Summary page on

2

For lightweight aggregates, see Specifications C330, C331, and C332; for the ASTM website.

4

heavyweight aggregates see Specification C637 and Descriptive Nomenclature The last approved version of this historical standard is referenced on

C638. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C33/C33M−16

C332Specification for Lightweight Aggregates for Insulat- 3.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C33/C33M − 13 C33/C33M − 16

Standard Specification for

1

Concrete Aggregates

This standard is issued under the fixed designation C33/C33M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification defines the requirements for grading and quality of fine and coarse aggregate (other than lightweight or

2

heavyweight aggregate) for use in concrete.

1.2 This specification is for use by a contractor, concrete supplier, or other purchaser as part of the purchase document

describing the material to be furnished.

NOTE 1—This specification is regarded as adequate to ensure satisfactory materials for most concrete. It is recognized that, for certain work or in certain

regions, it may be either more or less restrictive than needed. For example, where aesthetics are important, more restrictive limits may be considered

regarding impurities that would stain the concrete surface. The specifier should ascertain that aggregates specified are or can be made available in the

area of the work, with regard to grading, physical, or chemical properties, or combination thereof.

1.3 This specification is also for use in project specifications to define the quality of aggregate, the nominal maximum size of

the aggregate, and other specific grading requirements. Those responsible for selecting the proportions for the concrete mixture

shall have the responsibility of determining the proportions of fine and coarse aggregate and the addition of blending aggregate

sizes if required or approved.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.5 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of this standard.

2. Referenced Documents

3

2.1 ASTM Standards:

C29/C29M Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate

C40 Test Method for Organic Impurities in Fine Aggregates for Concrete

C87 Test Method for Effect of Organic Impurities in Fine Aggregate on Strength of Mortar

C88 Test Method for Soundness of Aggregates by Use of Sodium Sulfate or Magnesium Sulfate

C117 Test Method for Materials Finer than 75-μm (No. 200) Sieve in Mineral Aggregates by Washing

C123 Test Method for Lightweight Particles in Aggregate

C125 Terminology Relating to Concrete and Concrete Aggregates

C131 Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles

Machine

C136 Test Method for Sieve Analysis of Fine and Coarse Aggregates

C142 Test Method for Clay Lumps and Friable Particles in Aggregates

C150 Specification for Portland Cement

C227 Test Method for Potential Alkali Reactivity of Cement-Aggregate Combinations (Mortar-Bar Method)

4

C289 Test Method for Potential Alkali-Silica Reactivity of Aggregates (Chemical Method) (Withdrawn 2016)

1

This specification is under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee C09.20 on

Normal Weight Aggregates.

Current edition approved Jan. 1, 2013Feb. 1, 2016. Published February 2013March 2016. Originally approved in 1921. Last previous edition approved in 20112013 as

C33/C33M – 11A.13. DOI: 10.1520/C0033_C0033M-13.10.1520/C0033_C0033M-16.

2

For lightweight aggregates, see Specifications C330, C331, and C332; for heavyweight aggregates see Specification C637 and Descriptive Nomenclature C638.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C33/

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.