ASTM E1363-03

(Test Method)Standard Test Method for Temperature Calibration of Thermomechanical Analyzers

Standard Test Method for Temperature Calibration of Thermomechanical Analyzers

SIGNIFICANCE AND USE

Thermomechanical analyzers are employed in their various modes of operation (penetration, expansion, flexure, etc.) to characterize a wide range of materials. In most cases, the value to be assigned in thermomechanical measurements is the temperature of the transition (or event) under study. Therefore, the temperature axis (abscissa) of all TMA thermal curves must be accurately calibrated either by direct reading of a thermocouple or by adjusting the programmer temperature to match the actual temperature over the temperature range of interest.

SCOPE

1.1 This test method describes the temperature calibration of thermomechanical analyzers from -50 to 1100°C. (See Note 2.)

1.2 Computer or electronic based instruments, techniques, or data treatment equivalent to this test method may be used. Note 2Users of this test method are advised that all such instruments or techniques may not be equivalent. It is the responsibility of the user of this test method to determine the necessary equivalency prior to use.

1.3 SI units are the standard.

1.4 This standard is similar to ISO 11359-1 but addresses a larger temperature range and utilizes additional calibration materials.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 7 and Note 10.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1363–03

Standard Test Method for

1

Temperature Calibration of Thermomechanical Analyzers

This standard is issued under the fixed designation E1363; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

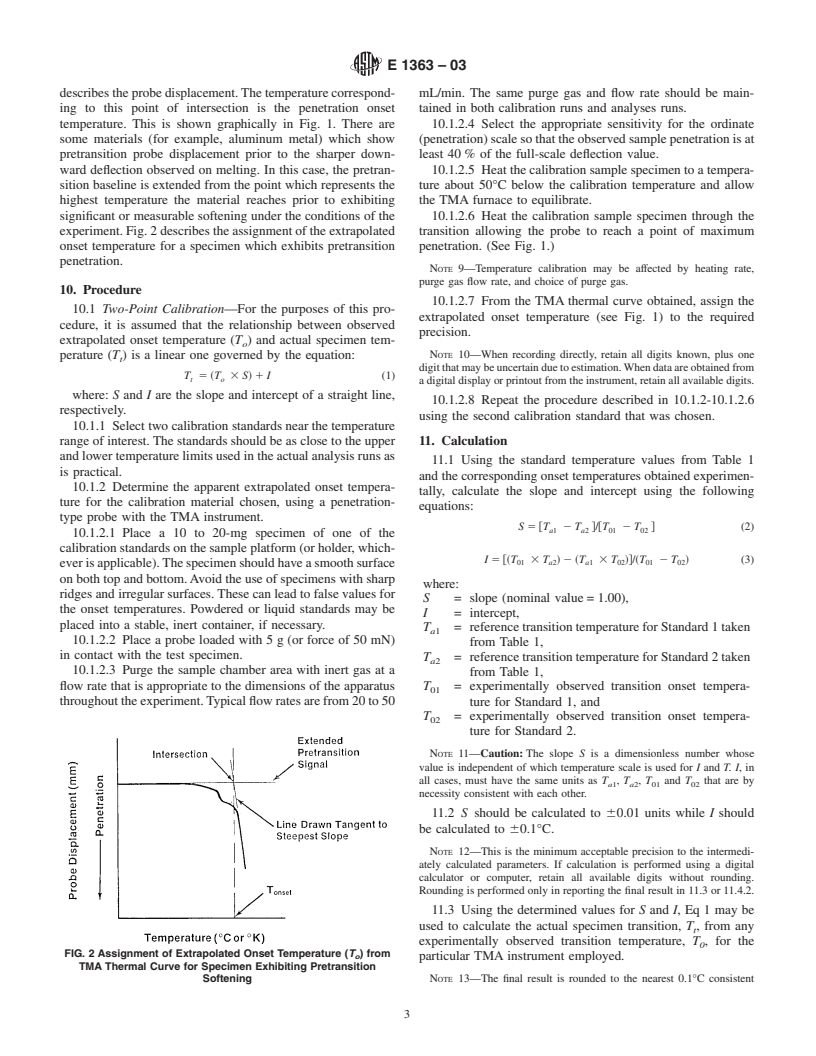

1. Scope melting temperature for known melting standards. This is

accomplished through the use of a thermomechanical analyzer

1.1 This test method describes the temperature calibration

with a penetration probe to obtain the onset temperatures for

of thermomechanical analyzers from−50 to 1100°C. (See

twomeltingpointstandards.Analternate,one-pointmethodof

Note 2.)

temperature calibration, is also given for use over very narrow

1.2 Computer or electronic based instruments, techniques,

temperature ranges. (See Note 3.)

or data treatment equivalent to this test method may be used.

NOTE 2—Thistestmethodmaybeusedforcalibratingthermomechani-

NOTE 1—Usersofthistestmethodareadvisedthatallsuchinstruments

cal analyzers at temperatures outside this range of temperature. However,

or techniques may not be equivalent. It is the responsibility of the user of

the accuracy of the calibration will be no better than that of the

this test method to determine the necessary equivalency prior to use.

temperature standards used.

1.3 SI units are the standard.

NOTE 3—Itispossibletodevelopamoreelaboratemethodoftempera-

1.4 This standard is similar to ISO 11359–1 but addresses a

ture calibration using multiple (more than two) fusion standards and

quadratic regression analysis. Since most modern instruments are capable

larger temperature range and utilizes additional calibration

of heating rates which are essentially linear in the region of use, the

materials.

procedure given here is limited to a two-point calibration.

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 Thermomechanical analyzers are employed in their

priate safety and health practices and determine the applica-

various modes of operation (penetration, expansion, flexure,

bility of regulatory limitations prior to use. Specific precau-

etc.) to characterize a wide range of materials. In most cases,

tionary statements are given in Section 7 and Note 10.

thevaluetobeassignedinthermomechanicalmeasurementsis

the temperature of the transition (or event) under study.

2. Referenced Documents

Therefore, the temperature axis (abscissa) of all TMAthermal

2.1 ASTM Standards:

curvesmustbeaccuratelycalibratedeitherbydirectreadingof

2

E473 Terminology Relating to Thermal Analysis

athermocoupleorbyadjustingtheprogrammertemperatureto

2.2

match the actual temperature over the temperature range of

11359–1 Thermomechanical Analysis (TMA)-Part 1: Gen-

interest.

3

eral Principles

6. Apparatus

3. Terminology

6.1 Thermomechanical Analyzer (TMA), The essential in-

3.1 Definitions:

strumentation required to provide the minimum thermome-

3.1.1 The terminology relating to thermal analysis appear-

chanical analytical or thermodilatometric capability for this

ing in E473 shall be considered applicable to this document.

method includes:

6.1.1 A Rigid Specimen Holder or Platform, of inert, low

4. Summary of Test Method

-1 -1

expansivitymaterial(<1µmm K )tocenterthespecimenin

4.1 Anequationisdevelopedforthelinearcorrelationofthe

the furnace and to fix the specimen to mechanical ground.

experimentally observed program temperature and the actual

6.1.2 A Rigid (expansion compression, flexure, tensile, etc)

-1 -1

Probe, of inert, low expansivity material (< 1 µm m K ) that

1

ThistestmethodisunderthejurisdictionofASTMCommitteeE37onThermal

contacts with the specimen with an applied compressive or

Measurements and is the direct responsibility of Subcommittee E37.01 on Test

tensileforce.Forthistestmethodtheuseofapenetrationprobe

Methods and Recommended Practices.

is recommended.

Current edition approved March 10, 2003. Published April 2003. Originally

approved in 1990. Last previous edition approved in 1997 as E1363–97.

2

Annual Book of ASTM Standards, Vol 14.02.

3

Available from American National Standards Institute, 11 W. 42nd St., 13th

Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1363–03

A

TABLE 1 Recommended Melting Temperature Standards

6.1.3 A Sensing Element—linear over a minimum range of

2 mm to measure the displacement of the rigid probe to 6 50 Melting Temperature

B

Calibration Materi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.