ASTM E2347-21

(Test Method)Standard Test Method for Indentation Softening Temperature by Thermomechanical Analysis

Standard Test Method for Indentation Softening Temperature by Thermomechanical Analysis

SIGNIFICANCE AND USE

5.1 Data obtained by this test method shall not be used to predict the behavior of materials at elevated temperatures except in applications in which the conditions of time, temperature, method of loading, and stress are similar to those specified in the test.

5.2 This test method is particularly suited for quality control and development work. The data are not intended for use in design or predicting endurance at elevated temperatures.

5.3 Ruggedness testing indicates that some materials, such as poly (vinyl chloride) exhibit substantially greater imprecision than that described in Section 14 for “well behaved” materials.

SCOPE

1.1 This test method is applicable to high modulus materials that soften upon heating to a modulus less than 6.0 MPa. This test method describes the determination of the temperature at which the specific modulus of either 6.65 MPa (Method A) or 33.3 MPa (Method B) (equivalent to Test Method D1525) of a test specimen is realized by indentation measurement using a thermomechanical analyzer as the test specimen is heated. This temperature is identified as the indentation softening temperature. The test may be performed over the temperature range of ambient to 300 °C.

Note 1: This test method is intended to provide results similar to those of Test Method D1525 but is performed on a thermomechanical analyzer using a smaller diameter indenting probe. Equivalence of results to those obtained by Test Method D1525 has been demonstrated on a limited number of materials. Until the user demonstrates equivalence, the results of this Test Method shall be considered to be independent and unrelated to those of Test Method D1525.

1.2 This test method is not recommended for ethyl cellulose, poly (vinyl chloride), poly (vinylidene chloride) and other materials having a large measurement imprecision (see Test Method D1525 and 5.3 and Section 14).

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2347 − 21

Standard Test Method for

Indentation Softening Temperature by Thermomechanical

1

Analysis

This standard is issued under the fixed designation E2347; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 Thistestmethodisapplicabletohighmodulusmaterials 2.1 ASTM Standards:

that soften upon heating to a modulus less than 6.0 MPa. This D1525Test Method for Vicat Softening Temperature of

test method describes the determination of the temperature at Plastics

which the specific modulus of either 6.65 MPa (MethodA) or E473Terminology Relating to Thermal Analysis and Rhe-

33.3 MPa (Method B) (equivalent to Test Method D1525)ofa ology

test specimen is realized by indentation measurement using a E1142Terminology Relating to Thermophysical Properties

thermomechanicalanalyzerasthetestspecimenisheated.This E1363Test Method forTemperature Calibration ofThermo-

temperature is identified as the indentation softening tempera- mechanical Analyzers

ture. The test may be performed over the temperature range of E2113Test Method for Length Change Calibration of Ther-

ambient to 300 °C. momechanical Analyzers

E2206Test Method for Force Calibration of Thermome-

NOTE1—Thistestmethodisintendedtoprovideresultssimilartothose

chanical Analyzers

of Test Method D1525 but is performed on a thermomechanical analyzer

using a smaller diameter indenting probe. Equivalence of results to those

obtained by Test Method D1525 has been demonstrated on a limited 3. Terminology

number of materials. Until the user demonstrates equivalence, the results

3.1 Definitions:

ofthisTestMethodshallbeconsideredtobeindependentandunrelatedto

3.1.1 Specific technical terms used in this test method are

those of Test Method D1525.

defined in Terminologies E473 and E1142 including Celsius,

1.2 This test method is not recommended for ethyl

complex modulus, modulus, strain, stress, storage modulus,

cellulose, poly (vinyl chloride), poly (vinylidene chloride) and

thermal analysis, and thermomechanical analysis.

other materials having a large measurement imprecision (see

3.1.2 penetration softening temperature, [°C],n—the tem-

Test Method D1525 and 5.3 and Section 14).

perature at which a test specimen has a modulus of either 6.65

1.3 The values stated in SI units are to be regarded as

MPa or 33.3 MPa as measured in penetration.

standard. No other units of measurement are included in this

standard.

4. Summary of Test Method

1.4 This standard does not purport to address all of the

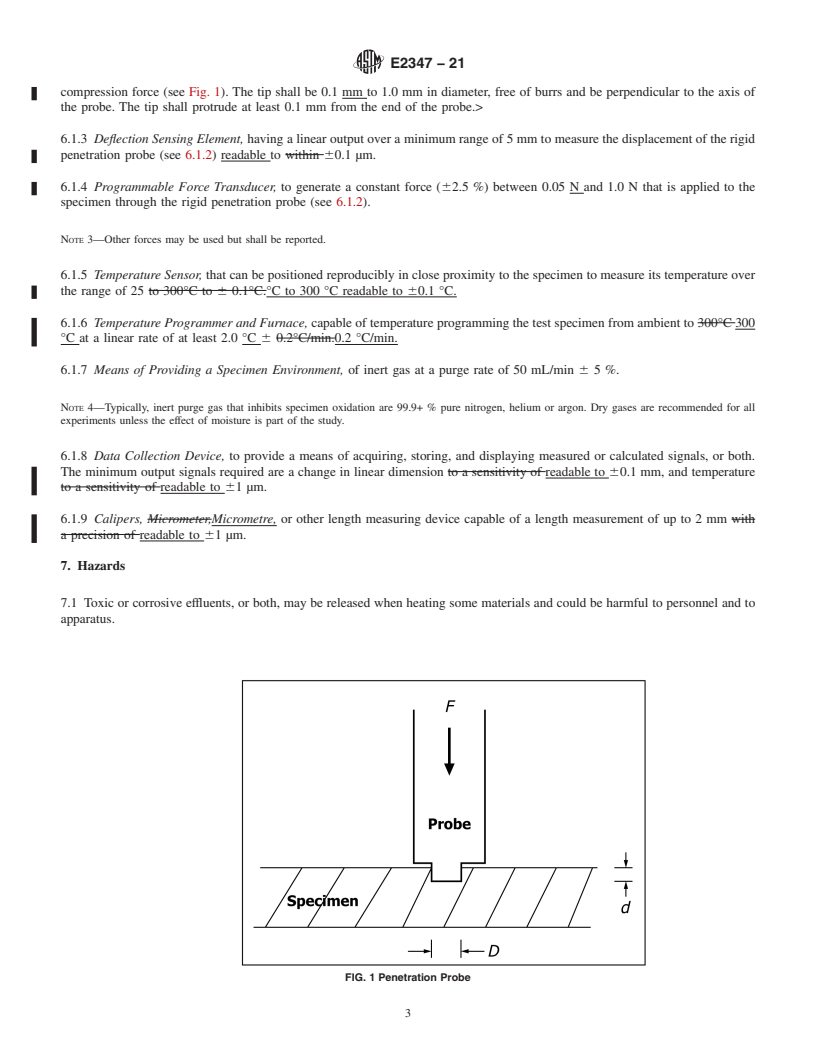

4.1 The modulus of a material may be determined by the

safety concerns, if any, associated with its use. It is the

indentation (penetration) of a circular, flat tipped probe. The

responsibility of the user of this standard to establish appro-

relationship between modulus of a material (stress divided by

priate safety, health, and environmental practices and deter-

strain) and penetration depth is given by:

mine the applicability of regulatory limitations prior to use.

E 5 3 F/ 4Dd (1)

~ !

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard- where:

ization established in the Decision on Principles for the

E = modulus, MPa,

Development of International Standards, Guides and Recom-

F = force, N,

mendations issued by the World Trade Organization Technical

D = diameter of a circular, flat tipped probe, mm, and

Barriers to Trade (TBT) Committee. d = penetration depth, mm.

2

NOTE 2—Note the identity Pa=N/m .

1

ThistestmethodisunderthejurisdictionofASTMCommitteeE37onThermal

Measurements and is the direct responsibility of Subcommittee E37.10 on

2

Fundamental, Statistical and Mechanical Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedJuly1,2021.PublishedJuly2021.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 2004. Last previous edition approved in 2016 as E2347 – 16. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

E2347-21. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2347 − 21

4.2 Somematerialssoftenuponheating.Forsuchmaterials, 6.1.2 Rigid Penetration Probe, of inert, low expansivity

-1 -1

the modulus may be determined by penetration

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2347 − 16 E2347 − 21

Standard Test Method for

Indentation Softening Temperature by Thermomechanical

1

Analysis

This standard is issued under the fixed designation E2347; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method is applicable to high modulus materials that soften upon heating to a modulus less than 6.0 MPa. This test

method describes the determination of the temperature at which the specific modulus of either 6.65 MPa (Method A) or 33.3 MPa

(Method B) (equivalent to Test Method D1525) of a test specimen is realized by indentation measurement using a

thermomechanical analyzer as the test specimen is heated. This temperature is identified as the indentation softening temperature.

The test may be performed over the temperature range of ambient to 300°C.300 °C.

NOTE 1—This test method is intended to provide results similar to those of Test Method D1525 but is performed on a thermomechanical analyzer using

a smaller diameter indenting probe. Equivalence of results to those obtained by Test Method D1525 has been demonstrated on a limited number of

materials. Until the user demonstrates equivalence, the results of this Test Method shall be considered to be independent and unrelated to those of Test

Method D1525.

1.2 This test method is not recommended for ethyl cellulose, poly (vinyl chloride), poly (vinylidene chloride) and other materials

having a large measurement imprecision (see Test Method D1525 and 5.3 and Section 14).

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 There is no ISO standard equivalent to this test method.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D1525 Test Method for Vicat Softening Temperature of Plastics

E473 Terminology Relating to Thermal Analysis and Rheology

1

This test method is under the jurisdiction of ASTM Committee E37 on Thermal Measurements and is the direct responsibility of Subcommittee E37.10 on Fundamental,

Statistical and Mechanical Properties.

Current edition approved April 1, 2016July 1, 2021. Published April 2016July 2021. Originally approved in 2004. Last previous edition approved in 20112016 as E2347

– 11.16. DOI: 10.1520/E2347-16.10.1520/E2347-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standardsstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2347 − 21

E1142 Terminology Relating to Thermophysical Properties

E1363 Test Method for Temperature Calibration of Thermomechanical Analyzers

E2113 Test Method for Length Change Calibration of Thermomechanical Analyzers

E2206 Test Method for Force Calibration of Thermomechanical Analyzers

3. Terminology

3.1 Definitions:

3.1.1 Specific technical terms used in this test method are defined in Terminologies E473 and E1142 including Celsius, complex

modulus, modulus, strain, stress, storage modulus, thermal analysis, and thermomechanical analysis.

3.1.2 penetration softening temperature, [°C],n—the temperature at which a test specimen has a modulus of either 6.65 MPa or

33.3 MPa as measured in penetration.

4. Summary of Test Method

4.1 The modulus of a material may be determined by the indentation (penetration) of a circular, flat tipped probe. The relationship

between modulus of a material (stress divided by strain) and penetration depth is given by:

E 5 3 F/~4 D d!

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.