ASTM C1585-04

(Test Method)Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes

Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes

SCOPE

1.1 This test method is used to determine the rate of absorption (sorptivity) of water by hydraulic cement concrete by measuring the increase in the mass of a specimen resulting from absorption of water as a function of time when only one surface of the specimen is exposed to water. The exposed surface of the specimen is immersed in water and water ingress of unsaturated concrete dominated by capillary suction during initial contact with water.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1585–04

Standard Test Method for

Measurement of Rate of Absorption of Water by Hydraulic-

Cement Concretes

This standard is issued under the fixed designation C 1585; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method is used to determine the rate of 3.1 For definitions of terms used in this standard, refer to

absorption (sorptivity) of water by hydraulic cement concrete Terminology C 125.

by measuring the increase in the mass of a specimen resulting

4. Significance and Use

from absorption of water as a function of time when only one

surface of the specimen is exposed to water. The exposed 4.1 The performance of concrete subjected to many aggres-

sive environments is a function, to a large extent, of the

surfaceofthespecimenisimmersedinwaterandwateringress

of unsaturated concrete dominated by capillary suction during penetrability of the pore system. In unsaturated concrete, the

rate of ingress of water or other liquids is largely controlled by

initial contact with water.

1.2 The values stated in SI units are to be regarded as the absorption due to capillary rise. This test method is based on

that developed by Hall who called the phenomenon “water

standard.

1.3 This standard does not purport to address all of the sorptivity.”

4.2 The water absorption of a concrete surface depends on

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- many factors including: (a) concrete mixture proportions; (b)

the presence of chemical admixtures and supplementary ce-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. mentitious materials; (c) the composition and physical charac-

teristics of the cementitious component and of the aggregates;

2. Referenced Documents

(d) the entrained air content; (e) the type and duration of

2.1 ASTM Standards: curing; (f) the degree of hydration or age; (g) the presence of

C 31/C 31M Practice for Making and Curing Concrete Test microcracks; (h) the presence of surface treatments such as

Specimens in the Field sealers or form oil; and (i) placement method including

C 42/C 42M Test Method for Obtaining and Testing Drilled consolidation and finishing. Water absorption is also strongly

Cores and Sawed Beams of Concrete affectedbythemoistureconditionoftheconcreteatthetimeof

C 125 Terminology Relating to Concrete and Concrete testing.

Aggregates 4.3 This method is intended to determine the susceptibility

C 192/C 192M Practice for Making and Curing Concrete of an unsaturated concrete to the penetration of water. In

Test Specimens in the Laboratory general, the rate of absorption of concrete at the surface differs

C 642 Test Method for Density, Absorption, and Voids in from the rate of absorption of a sample taken from the interior.

Hardened Concrete The exterior surface is often subjected to less than intended

C 1005 Specification for Reference Masses and Devices for curing and is exposed to the most potentially adverse condi-

Determining Mass and Volume for Use in the Physical tions. This test method is used to measure the water absorption

Testing of Hydraulic Cements rate of both the concrete surface and interior concrete. By

drilling a core and cutting it transversely at selected depths, the

absorption can be evaluated at different distances from the

This test method is under the jurisdiction of ASTM Committee C09 on

exposed surface. The core is drilled vertically or horizontally.

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

4.4 This test method differs from Test Method C 642 in

C09.66 on Resistance to Fluid Penetration.

which the specimens are oven dried, immersed completely in

Current edition approved Feb. 1, 2004. Published March 2004.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Hall, C., “Water Sorptivity of Mortars and Concretes:AReview,” Magazine of

the ASTM website. Concrete Research, Vol. 41, No. 147, June 1989, pp. 51-61.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1585–04

water at 21°C, and then boiled under water for 5 h. In this test 7. Test Specimens

method, only one surface is exposed to water at room tempera-

7.1 The standard test specimen is a 100 6 6 mm diameter

ture while the other surfaces are sealed simulating water

disc,withalengthof50 63mm.Specimensareobtainedfrom

absorption in a member that is in contact with water on one

either molded cylinders according to Practices C 31/C 31M or

side only. Test Method C 642, on the other hand, is used to

C 192/C 192M or drilled cores according to Test Method

estimate the maximum amount of water that can be absorbed

C 42/C 42M. The cross sectional area of a specimen shall not

by a dry specimen and therefore provides a measure of the

varymorethan1 %fromthetoptothebottomofthespecimen.

total, water permeable pore space.

When cores are taken, they should be marked (see Note 1) so

that the surface to be tested relative to the original location in

5. Apparatus

the structure is clearly indicated.

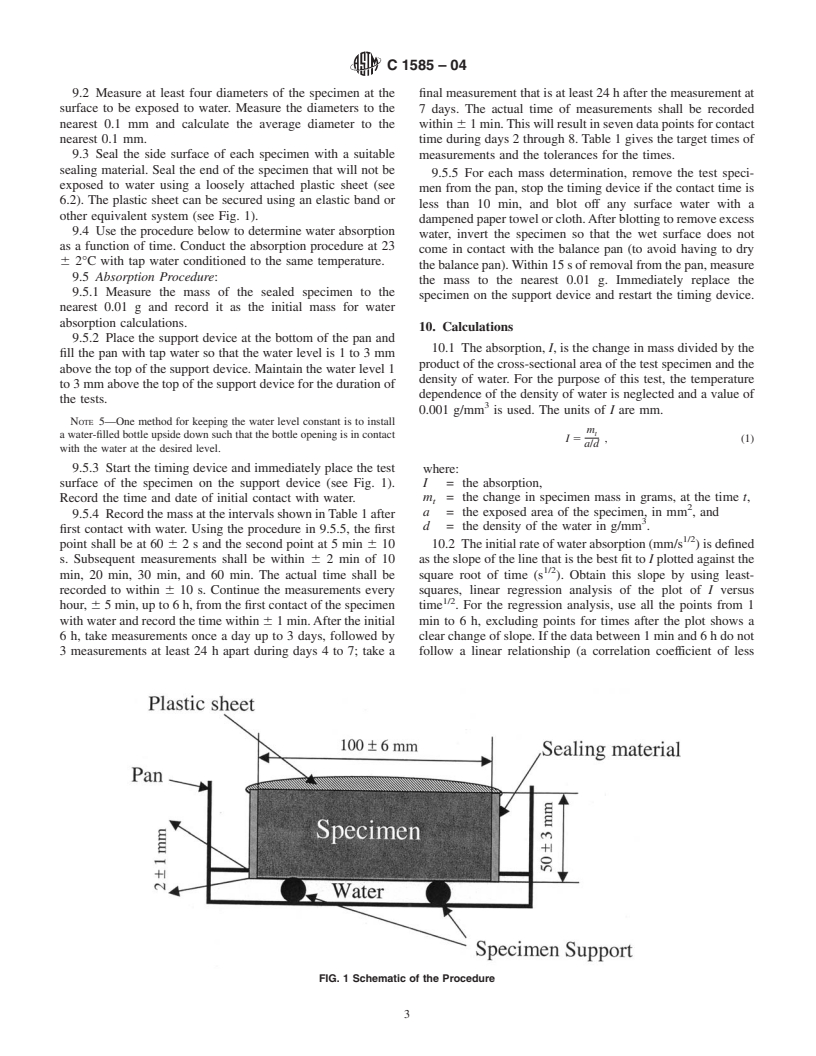

5.1 Pan, a watertight polyethylene or other corrosion-

NOTE 1—The surface to be exposed during testing shall not be marked

resistant pan large enough to accommodate the test specimens orotherwisedisturbedinsuchamannerasmaymodifytheabsorptionrate

of the specimen.

with the surfaces to be tested exposed to water.

7.2 The average test results on at least 2 specimens (Note 2)

5.2 Support Device, rods, pins, or other devices, which are

shall constitute the test result. The test surfaces shall be at the

made of materials resistant to corrosion by water or alkaline

same distance from the original exposed surface of the con-

solutions, and which allow free access of water to the exposed

crete.

surface of the specimen during testing. Alternatively, the

specimens can be supported on several layers of blotting paper

NOTE 2—Concrete is not a homogeneous material. Also, an exterior

or filter papers with a total thickness of at least 1 mm.

surface of a concrete specimen seldom has the same porosity as the

interior concrete. Therefore, replicate measurements are taken on speci-

5.3 Top-pan Balance, complying with Specification C 1005

mens from the same depth to reduce the scatter of the data.

and with sufficient capacity for the test specimens and accurate

to at least 6 0.01 g.

8. Sample Conditioning

5.4 Timing Device, stop watch or other suitable timing

8.1 Place test specimens in the environmental chamber at a

device accurate to 61s.

temperature of 50 6 2°C and RH of 80 6 3 % for 3 days.

5.5 Paper Towel or Cloth, for wiping excess water from Alternatively, place test specimens in a dessicator inside an

specimen surfaces. oven at a temperature of 50 6 2°C for 3 days. If the dessicator

is used, control the relative humidity in the dessicator with a

5.6 Water-Cooled Saw, with diamond impregnated blade to

saturated solution of potassium bromide (see 5.7), but do not

cut test specimens from larger samples.

allow test specimens to contact the solution.

5.7 Environmental Chamber, a chamber allowing for air

circulation and able to maintain a temperature of 50 6 2°C and

NOTE 3—To control the RH using the potassium bromide solution, the

solution should be placed in the bottom of the dessicator, to ensure the

a relative humidity at 80 6 3 %.Alternatively, an oven able to

largest surface of evaporation possible.

maintain a temperature of 50 6 2°C and a dessicator large

enough to contain the specimens to be tested is permitted. The 8.2 After the 3 days, place each specimen inside a sealable

relative humidity (RH) is controlled in the dessicator at 80 6 container (as defined in 5.8). Use a separate container for each

0.5 % by a saturated solution of potassium bromide. The specimen. Precautions must be taken to allow free flow of air

solubility of potassium bromide is 80.2 g/100 g of water at around the specimen by ensuring minimal contact of the

50°C. The solution shall be maintained at the saturation point specimen with the walls of the container.

for the duration of the test. The presence of visible crystals in 8.3 Store the container at 23 6 2°C for at least 15 days

before the start of the absorption procedure.

the solution provides acceptable evidence of saturation.

5.8 Polyethylene Storage Containers, with sealable lids,

NOTE 4—Storage in the sealed container for at least 15 days results in

largeenoughtocontainatleastonetestspecimenbutnotlarger equilibrationofthemoisturedistributionwithinthetestspecimensandhas

been found to provide internal relative humidities of 50 to 70 %. This is

than 5 times the specimen volume.

similar to the relative humidities found near the surface in some field

5.9 Caliper, to measure the specimen dimensions to the

5,6

structures.

nearest 0.1 mm.

9. Procedure

6. Reagents and Materials

9.1 Remove the specimen from the storage container and

recordthemassoftheconditionedspecimentothenearest0.01

6.1 Potassium Bromide, Reagent Grade, required if the

g before sealing of side surfaces.

oven and dessicator system described in 5.7 is used.

6.2 Sealing Material, strips of low permeability adhesive

Bentz D. P., Ehlen M. A., Ferraris C. F., and Winpigler J. A., “Service Life

sheets, epoxy paint, vinyl electrician’s tape, duct tape, or

PredictionBasedonSorptivityforHighwayConcreteExposedtoSulfateAttackand

aluminium t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.