ASTM F2565-13

(Guide)Standard Guide for Extensively Irradiation-Crosslinked Ultra-High Molecular Weight Polyethylene Fabricated Forms for Surgical Implant Applications

Standard Guide for Extensively Irradiation-Crosslinked Ultra-High Molecular Weight Polyethylene Fabricated Forms for Surgical Implant Applications

ABSTRACT

This guide covers extensively irradiation-crosslinked ultra-high molecular weight polyethylene (UHMWPE) fabricated forms for surgical implant applications. Only gamma and electron beam irradiated extensively crosslinked materials are covered by this guide. Chemical composition and physical properties of extensively crosslinked UHMWPE fabricated form shall conform to the requirements of this guide which include ultimate tensile strength, yield strength, elongation, Izod impact strength, ultimate load, fatigue crack propagation, compressive modulus, percent crystallinity, melting temperature, residual free radicals, swell ratio, oxidation index, and t-vinylene content. Biocompatibility of the material shall also be considered when new applications of the material, or modification to the material or physical forms of the materials are being contemplated.

SCOPE

1.1 This guide covers extensively crosslinked ultra-high molecular weight polyethylene (UHMWPE) materials (fabricated forms) that are produced starting with virgin resin powders and consolidated forms meeting all the requirements of Test Method F648.

1.2 This guide does not cover fabricated forms of ultra-high molecular weight polyethylene which have received only gas plasma, ethylene oxide, or less than 40 kGy ionizing radiation treatments, that is, materials treated only by historical sterilization methods.

1.3 This guide pertains only to UHMWPE materials extensively crosslinked by gamma and electron beam sources of ionizing radiation.

1.4 The specific relationships between these mechanical properties and the in vivo performance of a fabricated form have not been determined. While trends are apparent, specific property-polymer structure and polymer-design relationships are not well understood. These mechanical tests are frequently used to evaluate the reproducibility of a fabrication procedure and are applicable for comparative studies of different materials.

1.5 The following precautionary caveat pertains only to the test method portion, Section 5, of this guide. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2565 − 13

Standard Guide for

Extensively Irradiation-Crosslinked Ultra-High Molecular

Weight Polyethylene Fabricated Forms for Surgical Implant

1

Applications

This standard is issued under the fixed designation F2565; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This guide covers extensively crosslinked ultra-high

D638 Test Method for Tensile Properties of Plastics

molecular weight polyethylene (UHMWPE) materials (fabri-

D695 Test Method for Compressive Properties of Rigid

cated forms) that are produced starting with virgin resin

Plastics

powders and consolidated forms meeting all the requirements

3

D1898 Practice for Sampling of Plastics (Withdrawn 1998)

of Test Method F648.

D2765 Test Methods for Determination of Gel Content and

1.2 This guide does not cover fabricated forms of ultra-high

Swell Ratio of Crosslinked Ethylene Plastics

molecular weight polyethylene which have received only gas

E647 Test Method for Measurement of Fatigue Crack

plasma, ethylene oxide, or less than 40 kGy ionizing radiation

Growth Rates

treatments, that is, materials treated only by historical steril-

F619 Practice for Extraction of Medical Plastics

ization methods.

F648 Specification for Ultra-High-Molecular-Weight Poly-

1.3 This guide pertains only to UHMWPE materials exten-

ethylene Powder and Fabricated Form for Surgical Im-

sively crosslinked by gamma and electron beam sources of

plants

ionizing radiation.

F748 PracticeforSelectingGenericBiologicalTestMethods

for Materials and Devices

1.4 The specific relationships between these mechanical

F749 Practice for Evaluating Material Extracts by Intracuta-

properties and the in vivo performance of a fabricated form

neous Injection in the Rabbit

have not been determined. While trends are apparent, specific

F756 Practice for Assessment of Hemolytic Properties of

property-polymer structure and polymer-design relationships

Materials

are not well understood. These mechanical tests are frequently

F763 Practice for Short-Term Screening of Implant Materi-

used to evaluate the reproducibility of a fabrication procedure

als

and are applicable for comparative studies of different materi-

F813 Practice for Direct Contact Cell Culture Evaluation of

als.

Materials for Medical Devices

1.5 The following precautionary caveat pertains only to the

F895 TestMethodforAgarDiffusionCellCultureScreening

test method portion, Section 5, of this guide. This standard

for Cytotoxicity

does not purport to address all of the safety concerns, if any,

F981 Practice for Assessment of Compatibility of Biomate-

associated with its use. It is the responsibility of the user of this

rials for Surgical Implants with Respect to Effect of

standard to establish appropriate safety and health practices

Materials on Muscle and Bone

and determine the applicability of regulatory limitations prior

F2003 Practice for Accelerated Aging of Ultra-High Mo-

to use.

lecular Weight Polyethylene after Gamma Irradiation in

Air

1 2

This guide is under the jurisdiction of ASTM Committee F04 on Medical and For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Surgical Materials and Devices and is the direct responsibility of Subcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

F04.11 on Polymeric Materials. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved July 15, 2013. Published August 2013. Originally the ASTM website.

3

approved in 2006. Last previous edition approved in 2006 as F2565-06. DOI: The last approved version of this historical standard is referenced on

10.1520/F2565-13. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2565 − 13

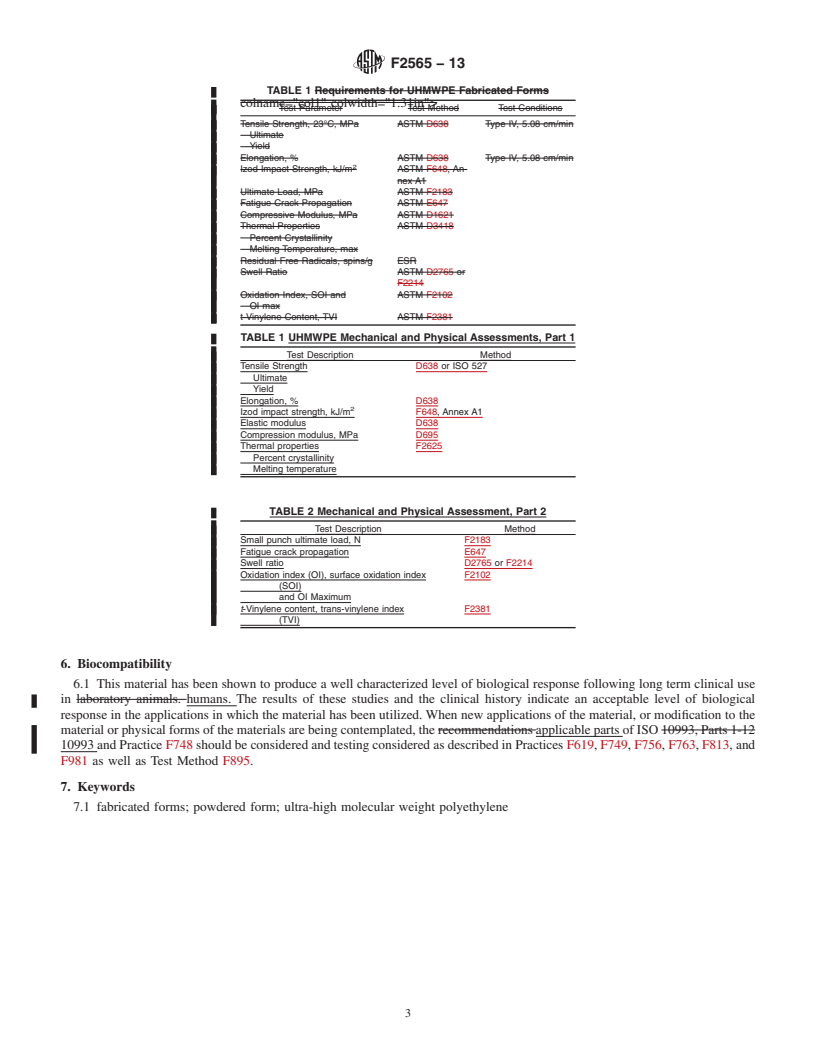

TABLE 1 UHMWPE Mechanical and Physical Assessments, Part 1

F2102 Guide for Evaluating the Extent of Oxidation in

Ultra-High-Molecular-Weight Polyethylene Fabricated Test Description Method

Tensile Strength D638 or ISO 527

Forms Intended for Surgical Implants

Ultimate

F2183 Test Method for Small Punch Testing of Ultra-High

Yield

MolecularWeight Polyethylene Used in Surgical Implants Elongation, % D638

2

Izod impact strength, kJ/m F648, Annex A1

F2214 Test Method forIn Situ Determination of Network

Elastic modulus D638

Parameters of Crosslinked Ultra High Molecular Weight

Compression modulus, MPa D695

Thermal properties F2625

Polyethylene (UHMWPE)

Percent crystallinity

F2381 Test

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2565 − 06 F2565 − 13

Standard Guide for

Extensively Irradiation-Crosslinked Ultra-High Molecular

Weight Polyethylene Fabricated Forms for Surgical Implant

1

Applications

This standard is issued under the fixed designation F2565; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide covers extensively crosslinked ultra-high molecular weight polyethylene (UHMWPE) materials (fabricated

forms) that are produced starting with virgin resin powders and consolidated forms meeting all the requirements of Test Method

F648.

1.2 This guide does not cover fabricated forms of ultra-high molecular weight polyethylene which have received only gas

plasma, ethylene oxide, or less than 40 kGy ionizing radiation treatments, that is, materials treated only by historical sterilization

methods.

1.3 This guide pertains only to UHMWPE materials extensively crosslinked by gamma and electron beam sources of ionizing

radiation.

1.4 The specific relationships between these mechanical properties and the in vivo performance of a fabricated form have not

been determined. While trends are apparent, specific property-polymer structure and polymer-design relationships are not well

understood. These mechanical tests are frequently used to evaluate the reproducibility of a fabrication procedure and are applicable

for comparative studies of different materials.

1.5 The following precautionary caveat pertains only to the test method portion, Section 5, of this guide. This standard does

not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard

to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D638 Test Method for Tensile Properties of Plastics

D1621D695 Test Method for Compressive Properties of Rigid Cellular Plastics

3

D1898 Practice for Sampling of Plastics (Withdrawn 1998)

D2765 Test Methods for Determination of Gel Content and Swell Ratio of Crosslinked Ethylene Plastics

D3418 Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential

Scanning Calorimetry

E647 Test Method for Measurement of Fatigue Crack Growth Rates

F619 Practice for Extraction of Medical Plastics

F648 Specification for Ultra-High-Molecular-Weight Polyethylene Powder and Fabricated Form for Surgical Implants

F748 Practice for Selecting Generic Biological Test Methods for Materials and Devices

F749 Practice for Evaluating Material Extracts by Intracutaneous Injection in the Rabbit

F756 Practice for Assessment of Hemolytic Properties of Materials

F763 Practice for Short-Term Screening of Implant Materials

F813 Practice for Direct Contact Cell Culture Evaluation of Materials for Medical Devices

1

This guide is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee F04.11

on Polymeric Materials.

Current edition approved July 1, 2006July 15, 2013. Published July 2006August 2013. Originally approved in 2006. Last previous edition approved in 2006 as F2565-06.

DOI: 10.1520/F2565-06.10.1520/F2565-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2565 − 13

F895 Test Method for Agar Diffusion Cell Culture Screening for Cytotoxicity

F981 Practice for Assessment of Compatibility of Biomaterials for Surgical Implants with Respect to Effect of Materials on

Muscle and Bone

F2003 Practice for Accelerated Aging of Ultra-High Molecular Weight Polyethylene after Gamma Irradiation in Air

F2102 Guide for Evaluating the Extent of Oxidation in Ultra-High-Molecular-Weight Polyethylene Fabricated Forms Intended

for Surgical Implants

F2183 Test Method for Small Punch Testing of Ultra-High Molecular We

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.