ASTM D3349-12

(Test Method)Standard Test Method for Absorption Coefficient of Ethylene Polymer Material Pigmented with Carbon Black

Standard Test Method for Absorption Coefficient of Ethylene Polymer Material Pigmented with Carbon Black

SIGNIFICANCE AND USE

The absorption coefficient of polyolefin polymer pigmented with carbon black is useful to judge the degree and uniformity of dispersion of the pigment, and the adequacy of the quantitative level of pigment addition. These factors are used to predict the performance of the polymer material in response to prolonged exposure to ultraviolet light as evidenced by minimal changes in specific properties.

Note 1—This test method was developed to evaluate ethylene polymer materials pigmented with small particle size carbon blacks suitable for UV protection. It is not known how accurate and reproducible the test would be with larger (35 nm or greater) particle size blacks.

SCOPE

1.1 This test method measures the amount of light transmitted through a film of carbon black pigmented ethylene polymer.

1.2 After calculation of the amount of light and film thickness, an absorption coefficient is calculated.

1.3 Whenever two sets of values are presented, in different units, the values in the first set are the standard, while those in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3349 − 12

Standard Test Method for

Absorption Coefficient of Ethylene Polymer Material

1

Pigmented with Carbon Black

This standard is issued under the fixed designation D3349; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* the quantitative level of pigment addition. These factors are

used to predict the performance of the polymer material in

1.1 This test method measures the amount of light transmit-

response to prolonged exposure to ultraviolet light as evi-

ted through a film of carbon black pigmented ethylene poly-

denced by minimal changes in specific properties.

mer.

NOTE 1—This test method was developed to evaluate ethylene polymer

1.2 After calculation of the amount of light and film

materialspigmentedwithsmallparticlesizecarbonblackssuitableforUV

thickness, an absorption coefficient is calculated.

protection. It is not known how accurate and reproducible the test would

be with larger (35 nm or greater) particle size blacks.

1.3 Whenever two sets of values are presented, in different

units, the values in the first set are the standard, while those in

5. Apparatus

parentheses are for information only.

5.1 Spectrophotometer—An instrument in accordance with

1.4 This standard does not purport to address all of the

Practice E60 is required.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

NOTE 2—Consult the spectrophotometer’s operation manual or consult

the manufacturer of the instrument for the calibration procedure.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

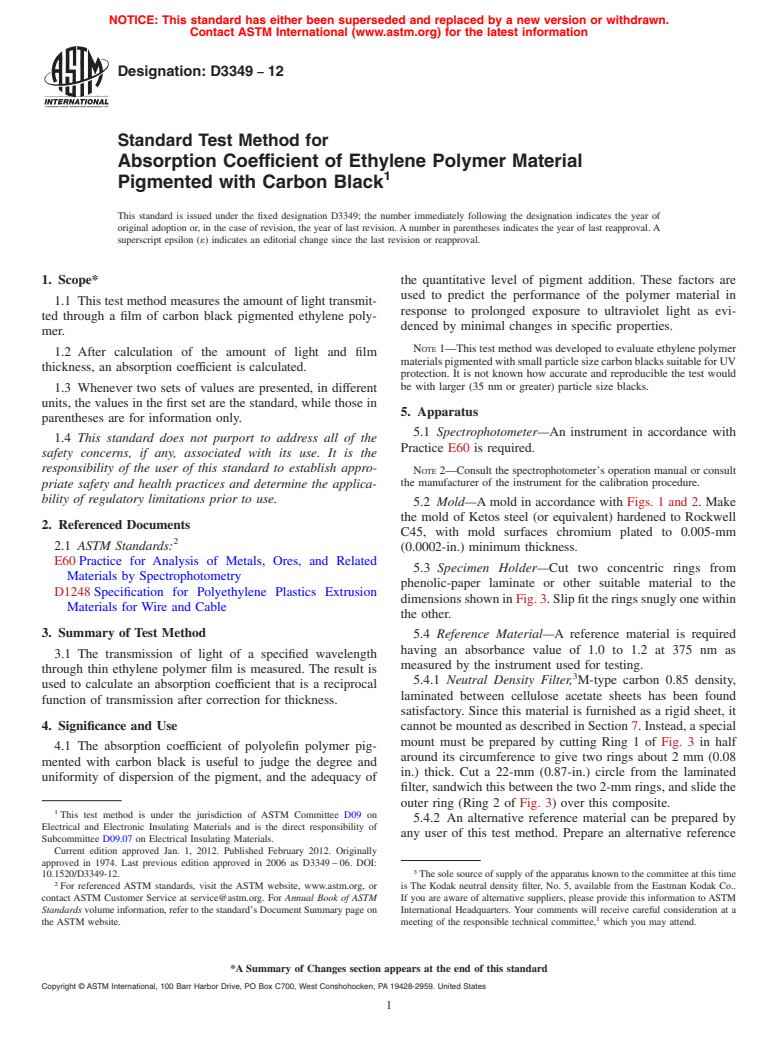

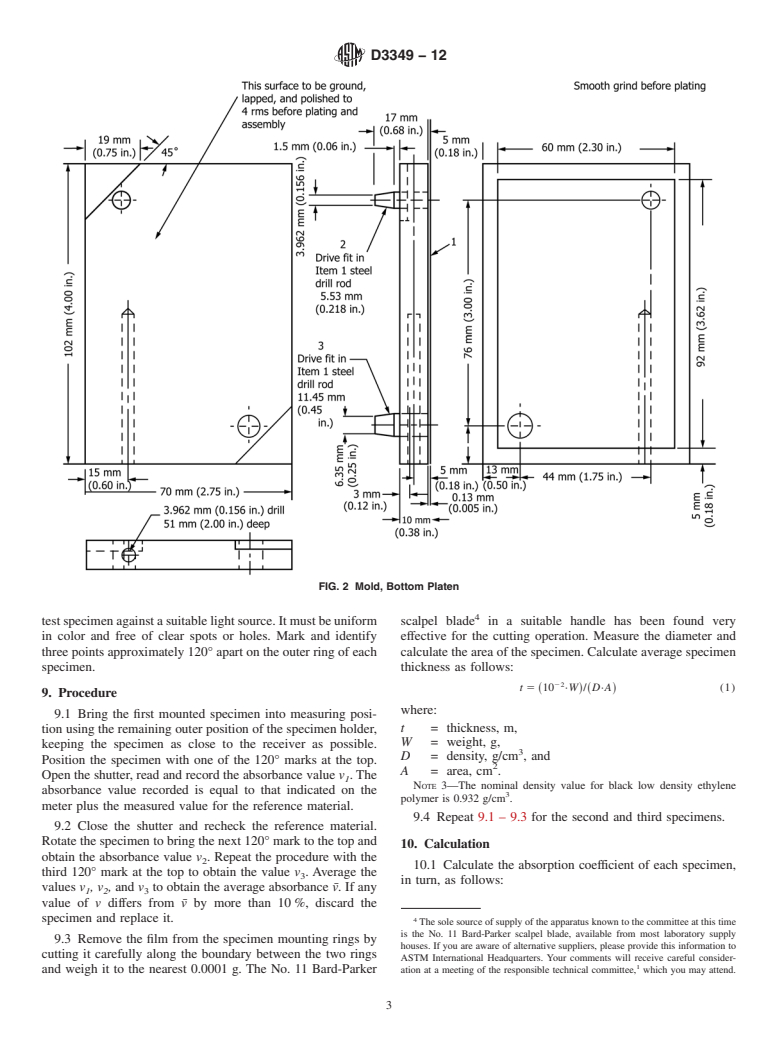

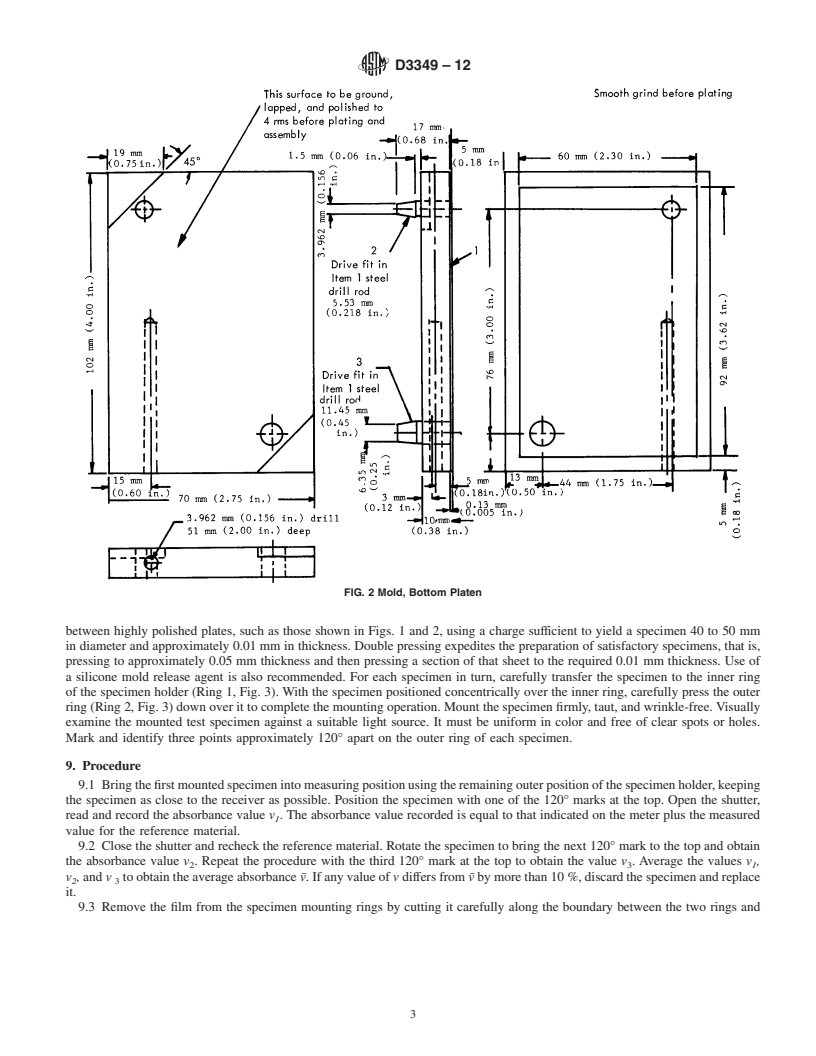

5.2 Mold—A mold in accordance with Figs. 1 and 2. Make

the mold of Ketos steel (or equivalent) hardened to Rockwell

2. Referenced Documents

C45, with mold surfaces chromium plated to 0.005-mm

2

2.1 ASTM Standards:

(0.0002-in.) minimum thickness.

E60 Practice for Analysis of Metals, Ores, and Related

5.3 Specimen Holder—Cut two concentric rings from

Materials by Spectrophotometry

phenolic-paper laminate or other suitable material to the

D1248 Specification for Polyethylene Plastics Extrusion

dimensionsshowninFig.3.Slipfittheringssnuglyonewithin

Materials for Wire and Cable

the other.

3. Summary of Test Method

5.4 Reference Material—A reference material is required

having an absorbance value of 1.0 to 1.2 at 375 nm as

3.1 The transmission of light of a specified wavelength

measured by the instrument used for testing.

through thin ethylene polymer film is measured. The result is

3

5.4.1 Neutral Density Filter, M-type carbon 0.85 density,

used to calculate an absorption coefficient that is a reciprocal

laminated between cellulose acetate sheets has been found

function of transmission after correction for thickness.

satisfactory. Since this material is furnished as a rigid sheet, it

4. Significance and Use

cannot be mounted as described in Section 7. Instead, a special

mount must be prepared by cutting Ring 1 of Fig. 3 in half

4.1 The absorption coefficient of polyolefin polymer pig-

around its circumference to give two rings about 2 mm (0.08

mented with carbon black is useful to judge the degree and

in.) thick. Cut a 22-mm (0.87-in.) circle from the laminated

uniformity of dispersion of the pigment, and the adequacy of

filter, sandwich this between the two 2-mm rings, and slide the

outer ring (Ring 2 of Fig. 3) over this composite.

1

This test method is under the jurisdiction of ASTM Committee D09 on

5.4.2 An alternative reference material can be prepared by

Electrical and Electronic Insulating Materials and is the direct responsibility of

any user of this test method. Prepare an alternative reference

Subcommittee D09.07 on Electrical Insulating Materials.

Current edition approved Jan. 1, 2012. Published February 2012. Originally

approved in 1974. Last previous edition approved in 2006 as D3349 – 06. DOI:

3

10.1520/D3349-12. The sole source of supply of the apparatus known to the committee at this time

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or is The Kodak neutral density filter, No. 5, available from the Eastman Kodak Co.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM If you are aware of alternative suppliers, please provide this information to ASTM

Standards volume information, refer to the standard’s Document Summary page on International Headquarters. Your comments will receive careful consideration at a

1

the ASTM website. meeting of the responsible technical committee, which you may attend.

*A Summary of Changes section appear

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D3349–06 Designation:D3349–12

Standard Test Method for

Absorption Coefficient of Ethylene Polymer Material

1

Pigmented with Carbon Black

This standard is issued under the fixed designation D3349; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method measures the amount of light transmitted through a film of carbon black pigmented ethylene polymer.

1.2 After calculation of the amount of light and film thickness, an absorption coefficient is calculated.

1.3 Whenever two sets of values are presented, in different units, the values in the first set are the standard, while those in

parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E60 Practice for Analysis of Metals, Ores, and Related Materials by Spectrophotometry

D1248 Specification for Polyethylene Plastics Extrusion Materials for Wire and Cable

3. Summary of Test Method

3.1 The transmission of light of a specified wavelength through thin ethylene polymer film is measured. The result is used to

calculate an absorption coefficient that is a reciprocal function of transmission after correction for thickness.

4. Significance and Use

4.1 The absorption coefficient of polyolefin polymer pigmented with carbon black is useful to judge the degree and uniformity

of dispersion of the pigment, and the adequacy of the quantitative level of pigment addition. These factors are used to predict the

performance of the polymer material in response to prolonged exposure to ultraviolet light as evidenced by minimal changes in

specific properties.

NOTE 1—This test method was developed to evaluate ethylene polymer materials pigmented with small particle size carbon blacks suitable for UV

protection. It is not known how accurate and reproducible the test would be with larger (35 nm or greater) particle size blacks.

5. Apparatus

5.1 Spectrophotometer—An instrument in accordance with Practice E60 is required.

NOTE 2—Consult the spectrophotometer’s operation manual or consult the manufacturer of the instrument for the calibration procedure.

5.2 Mold—Amold in accordance with Figs. 1 and 2. Make the mold of Ketos steel (or equivalent) hardened to Rockwell C45,

with mold surfaces chromium plated to 0.005-mm (0.0002-in.) minimum thickness.

5.3 Specimen Holder—Cut two concentric rings from phenolic-paper laminate or other suitable material to the dimensions

shown in Fig. 3. Slip fit the rings snugly one within the other.

5.4 Reference Material—A reference material is required having an absorbance value of 1.0 to 1.2 at 375 nm as measured by

the instrument used for testing.

1

This test method is under the jurisdiction of ASTM Committee D09 on Electrical and Electronic Insulating Materials and is the direct responsibility of Subcommittee

D09.18 on Solid Insulations, Non-Metallic Shieldings, and Coverings for Electrical and Telecommunications Wires and Cables.

Current edition approved AprilJan. 1, 2006.2012. Published April 2006.February 2012. Originally approved in 1974. Last previous edition approved in 19992006 as

D3349–99.D3349 – 06. DOI: 10.1520/D3349-06.10.1520/D3349-12.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3349–12

FIG. 1 Mold, Top Platen

3

5.4.1 Neutral Density Filter, M-type carbon 0.85 density, laminated between cellulose acetate sheets has been found

satisfactory. Since this material is furnished as a rigid sheet, it cannot be mounted as described in Section 7. Instead, a special

mount must be prepared by cutting Ring 1 of Fig. 3 in half around its circumference to give two rings about 2 m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.