ASTM D5399-09

(Test Method)Standard Test Method for Boiling Point Distribution of Hydrocarbon Solvents by Gas Chromatography

Standard Test Method for Boiling Point Distribution of Hydrocarbon Solvents by Gas Chromatography

SIGNIFICANCE AND USE

The gas chromatographic determination of the boiling point distribution of hydrocarbon solvents can be used as an alternative to conventional distillation methods for control of solvents quality during manufacture, and specification testing.

Boiling point distribution data can be used to monitor the presence of product contaminants and compositional variation during the manufacture of hydrocarbon solvents.

Boiling point distribution data obtained by this test method are not equivalent to those obtained by Test Methods D86, D850, D1078, D2887, D2892, and D3710.

SCOPE

1.1 This test method covers the determination of the boiling point distribution of hydrocarbon solvents by capillary gas chromatography. This test method is limited to samples having a minimum initial boiling point of 37°C (99°F), a maximum final boiling point of 285°C (545°F), and a boiling range of 5 to 150°C (9 to 270°F) as measured by this test method.

1.2 For purposes of determining conformance of an observed or calculated value using this test method to relevant specifications, test result(s) shall be rounded off “to the nearest unit” in the last right-hand digit used in expressing the specification limit, in accordance with the rounding-off method of Practice E29.

1.3 The values stated in SI units are standard. The values given in parentheses are for information purposes only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5399 − 09

Standard Test Method for

Boiling Point Distribution of Hydrocarbon Solvents by Gas

1

Chromatography

This standard is issued under the fixed designation D5399; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D2892 Test Method for Distillation of Crude Petroleum

(15-Theoretical Plate Column)

1.1 This test method covers the determination of the boiling

D3710 Test Method for Boiling Range Distribution of Gaso-

point distribution of hydrocarbon solvents by capillary gas

line and Gasoline Fractions by Gas Chromatography

chromatography. This test method is limited to samples having

3

(Withdrawn 2014)

a minimum initial boiling point of 37°C (99°F), a maximum

E29 Practice for Using Significant Digits in Test Data to

final boiling point of 285°C (545°F), and a boiling range of 5

Determine Conformance with Specifications

to 150°C (9 to 270°F) as measured by this test method.

E691 Practice for Conducting an Interlaboratory Study to

1.2 For purposes of determining conformance of an ob-

Determine the Precision of a Test Method

served or calculated value using this test method to relevant

specifications, test result(s) shall be rounded off “to the nearest

3. Terminology

unit” in the last right-hand digit used in expressing the

3.1 Definitions:

specification limit, in accordance with the rounding-off method

3.1.1 initial boiling point (IBP), n—the point at which a

of Practice E29.

cumulativeareacountequalto0.5 %ofthetotalareaunderthe

1.3 The values stated in SI units are standard. The values

chromatogram is obtained.

given in parentheses are for information purposes only.

3.1.2 final boiling point (FBP), n—the point at which a

1.4 This standard does not purport to address all of the

cumulative area count equal to 99.5 % of the total area under

safety concerns, if any, associated with its use. It is the

the chromatogram is obtained.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 4. Summary of Test Method

bility of regulatory limitations prior to use.

4.1 The sample is introduced into a capillary gas chromato-

graphic column that separates hydrocarbons in the order of

2. Referenced Documents

increasing boiling point. The column temperature is raised at a

2

2.1 ASTM Standards:

reproducible rate and the area under the chromatogram is

D86 Test Method for Distillation of Petroleum Products at recorded throughout the run. Boiling points are assigned from

Atmospheric Pressure

a calibration curve obtained under the same conditions by

D850 Test Method for Distillation of Industrial Aromatic running a known mixture of hydrocarbons covering the boiling

Hydrocarbons and Related Materials

range expected in the sample. From these data, the boiling

D1078 Test Method for Distillation Range of Volatile Or- point distribution of the sample is obtained.

ganic Liquids

5. Significance and Use

D2887 Test Method for Boiling Range Distribution of Pe-

troleum Fractions by Gas Chromatography

5.1 The gas chromatographic determination of the boiling

point distribution of hydrocarbon solvents can be used as an

alternative to conventional distillation methods for control of

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

solvents quality during manufacture, and specification testing.

and Related Coatings, Materials, andApplications and is the direct responsibility of

5.2 Boiling point distribution data can be used to monitor

Subcommittee D01.35 on Solvents, Plasticizers, and Chemical Intermediates.

Current edition approved Dec. 1, 2009. Published December 2009. Originally

the presence of product contaminants and compositional varia-

approved in 1993. Last previous edition approved in 2009 as D5399 – 04 (2009).

tion during the manufacture of hydrocarbon solvents.

DOI: 10.1520/D5399-09.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

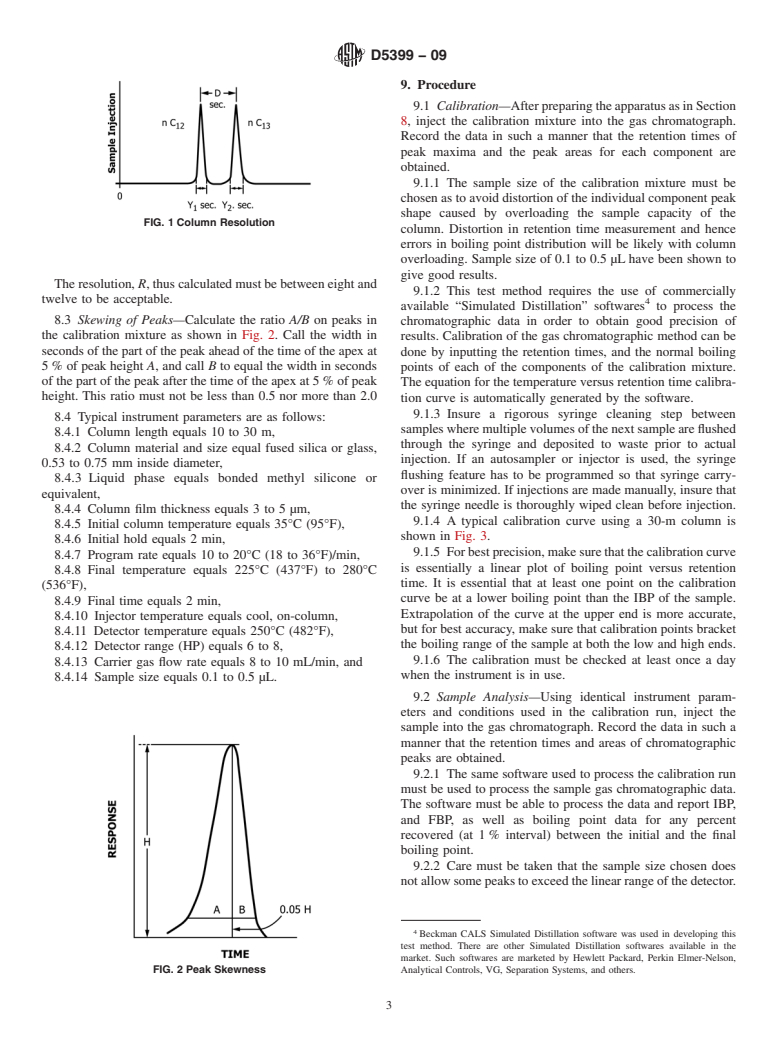

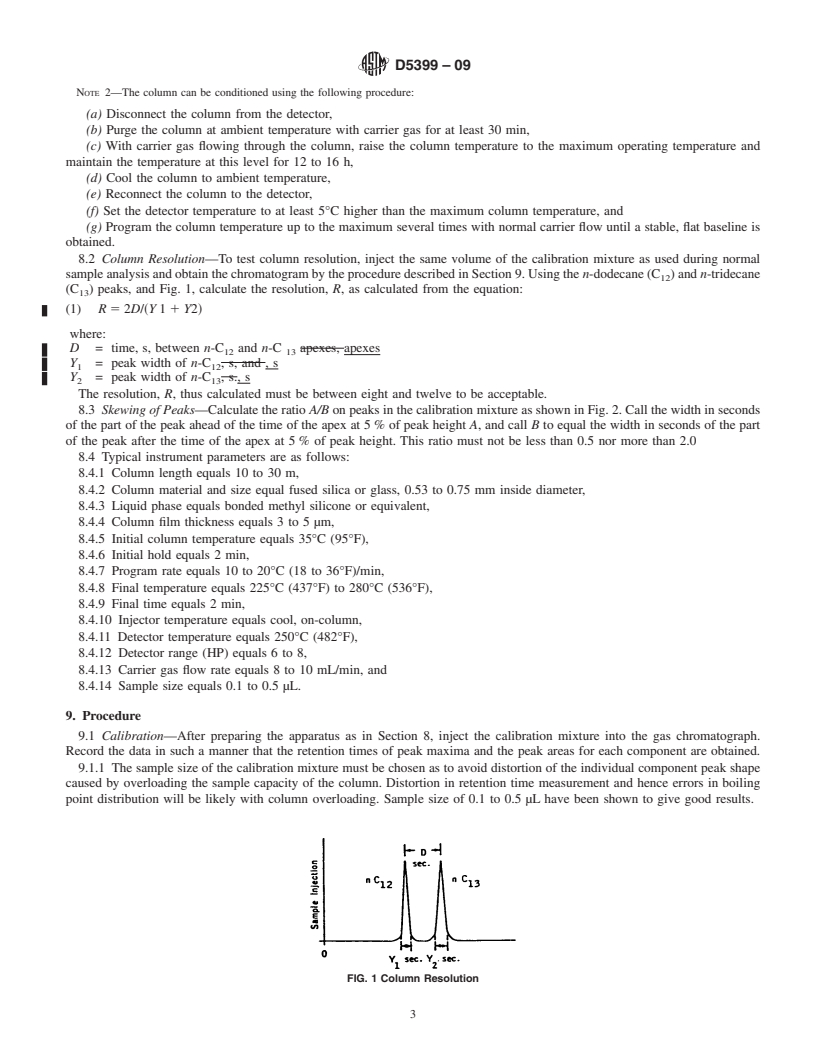

D5399 − 09

TABLE 1 Calibration Mixture

5.3 Boiling point distribution data obtained by this test

method are not equivalent to those obtained by Test Methods Peak Number

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5399–04(Reapproved2009) Designation:D5399–09

Standard Test Method for

Boiling Point Distribution of Hydrocarbon Solvents by Gas

1

Chromatography

This standard is issued under the fixed designation D5399; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of the boiling point distribution of hydrocarbon solvents by capillary gas

chromatography. This test method is limited to samples having a minimum initial boiling point of 37°C (99°F), a maximum final

boiling point of 285°C (545°F), and a boiling range of 5 to 150°C (9 to 270°F) as measured by this test method.

1.2 For purposes of determining conformance of an observed or calculated value using this test method to relevant

specifications, test result(s) shall be rounded off “to the nearest unit” in the last right-hand digit used in expressing the specification

limit, in accordance with the rounding-off method of Practice E29.

1.3 The values stated in SI units are standard. The values given in parentheses are for information purposes only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D86 Test Method for Distillation of Petroleum Products at Atmospheric Pressure

D850 Test Method for Distillation of Industrial Aromatic Hydrocarbons and Related Materials

D1078 Test Method for Distillation Range of Volatile Organic Liquids

D2887 Test Method for Boiling Range Distribution of Petroleum Fractions by Gas Chromatography

D2892 Test Method for Distillation of Crude Petroleum (15-Theoretical Plate Column)

D3710 Test Method for Boiling Range Distribution of Gasoline and Gasoline Fractions by Gas Chromatography

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions:

3.1.1 initial boiling point (IBP), n—the point at which a cumulative area count equal to 0.5 % of the total area under the

chromatogram is obtained.

3.1.2 final boiling point (FBP), n—the point at which a cumulative area count equal to 99.5 % of the total area under the

chromatogram is obtained.

4. Summary of Test Method

4.1 Thesampleisintroducedintoacapillarygaschromatographiccolumnthatseparateshydrocarbonsintheorderofincreasing

boiling point.The column temperature is raised at a reproducible rate and the area under the chromatogram is recorded throughout

the run. Boiling points are assigned from a calibration curve obtained under the same conditions by running a known mixture of

hydrocarbons covering the boiling range expected in the sample. From these data, the boiling point distribution of the sample is

obtained.

5. Significance and Use

5.1 The gas chromatographic determination of the boiling point distribution of hydrocarbon solvents can be used as an

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.35 on Solvents, Plasticizers, and Chemical Intermediates.

Current edition approved JuneDec. 1, 2009. Published JuneDecember 2009. Originally approved in 1993. Last previous edition approved in 20042009 as

D5399 – 04 (2009). DOI: 10.1520/D5399-04R09.10.1520/D5399-09.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5399–09

alternative to conventional distillation methods for control of solvents quality during manufacture, and specification testing.

5.2 Boiling point distribution data can be used to monitor the presence of product contaminants and compositional va

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.