ASTM G162-23

(Practice)Standard Practice for Conducting and Evaluating Laboratory Corrosion Tests in Soils

Standard Practice for Conducting and Evaluating Laboratory Corrosion Tests in Soils

SIGNIFICANCE AND USE

4.1 This practice provides a controlled corrosive environment that has been utilized to produce relative corrosion information.

4.2 The primary application of the data from this practice is to evaluate the performance of metallic materials for use in soil environments.

4.3 This practice may not duplicate all field conditions and variables such as stray currents, microbiologically influenced corrosion, non-homogeneous conditions, pollutants in the soil, and long cell corrosion. The reproducibility of results in the practice is highly dependent on the type of specimen tested and the evaluation criteria selected as well as the control of the operating variables. In any testing program, sufficient replicates should be included to establish the variability of the results.

4.4 Structures and components may be made of several different metals; therefore, the practice may be used to evaluate galvanic corrosion effects in soils (see Guide G71).

4.5 Structures and components may be coated with sacrificial or noble metal coatings, which may be scratched or otherwise rendered discontinuous (for example, no coating on the edges of metal strips cut from a wide sheet). This test is useful to evaluate the effect of defective metallic coatings.

4.6 Structures and components may be coated or jacketed with organic materials (for example, paints and plastics), and these coatings and jackets may be rendered discontinuous. The test is useful to evaluate the effect of defective or incompletely covering coatings and jackets.

Note 1: The corrosivity of soils strongly depends on soluble salt content (related parameters are chemistry and soil resistivity, see Test Methods G57 and G187), acidity or alkalinity (measured by soil pH, see Test Method G51), Temperature, and oxygen content (loose, for example, sand, or compact, for example, clay, soils are extreme examples, see Test Method G200 – oxidation-reduction potential). The manufacturer, supplier, or user, or combination the...

SCOPE

1.1 This practice covers procedures for conducting laboratory corrosion tests in soils to evaluate the potential for corrosion attack on engineering materials in soils. The test is conducted under laboratory ambient temperature unless the effect of temperature is being evaluated. This practice does not include provisions for microbiological influenced corrosion (MIC) testing, nor its influence on results.

1.2 This practice covers specimen selection and preparation, test environments, evaluation, and reporting of test results.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G162 − 23

Standard Practice for

Conducting and Evaluating Laboratory Corrosion Tests in

1

Soils

This standard is issued under the fixed designation G162; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

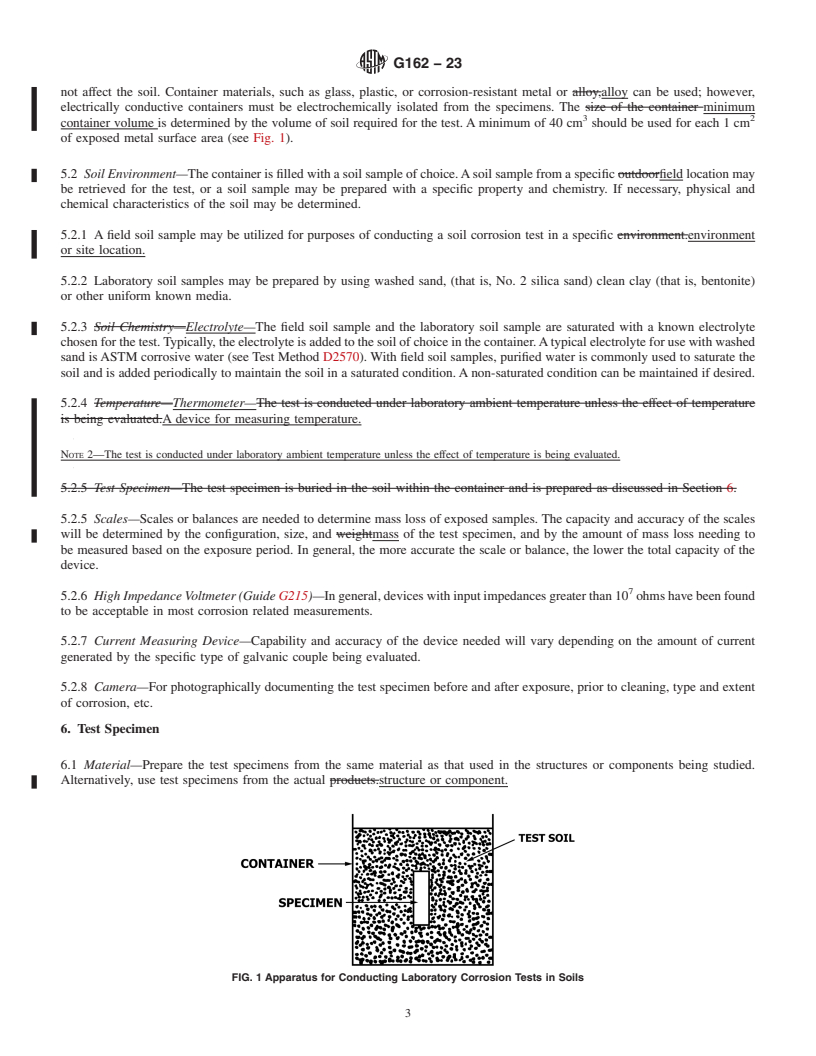

1. Scope D1654 Test Method for Evaluation of Painted or Coated

Specimens Subjected to Corrosive Environments

1.1 This practice covers procedures for conducting labora-

D2570 Test Method for Simulated Service Corrosion Testing

tory corrosion tests in soils to evaluate the potential for

of Engine Coolants

corrosion attack on engineering materials in soils. The test is

G1 Practice for Preparing, Cleaning, and Evaluating Corro-

conducted under laboratory ambient temperature unless the

sion Test Specimens

effect of temperature is being evaluated. This practice does not

G3 Practice for Conventions Applicable to Electrochemical

include provisions for microbiological influenced corrosion

Measurements in Corrosion Testing

(MIC) testing, nor its influence on results.

G4 Guide for Conducting Corrosion Tests in Field Applica-

3

1.2 This practice covers specimen selection and preparation,

tions (Withdrawn 2023)

test environments, evaluation, and reporting of test results.

G16 Guide for Applying Statistics to Analysis of Corrosion

Data

1.3 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this G31 Guide for Laboratory Immersion Corrosion Testing of

Metals

standard.

G46 Guide for Examination and Evaluation of Pitting Cor-

1.4 This standard does not purport to address all of the

rosion

safety concerns, if any, associated with its use. It is the

G51 Test Method for Measuring pH of Soil for Use in

responsibility of the user of this standard to establish appro-

Corrosion Evaluations

priate safety, health, and environmental practices and deter-

G57 Test Method for Measurement of Soil Resistivity Using

mine the applicability of regulatory limitations prior to use.

the Wenner Four-Electrode Method

1.5 This international standard was developed in accor-

G71 Guide for Conducting and Evaluating Galvanic Corro-

dance with internationally recognized principles on standard-

sion Tests in Electrolytes

ization established in the Decision on Principles for the

G102 Practice for Calculation of Corrosion Rates and Re-

Development of International Standards, Guides and Recom-

lated Information from Electrochemical Measurements

mendations issued by the World Trade Organization Technical

G187 Test Method for Measurement of Soil Resistivity

Barriers to Trade (TBT) Committee.

Using the Two-Electrode Soil Box Method

G193 Terminology and Acronyms Relating to Corrosion

2. Referenced Documents

G200 Test Method for Measurement of Oxidation-Reduction

2

2.1 ASTM Standards:

Potential (ORP) of Soil

D698 Test Methods for Laboratory Compaction Character-

G215 Guide for Electrode Potential Measurement

3

istics of Soil Using Standard Effort (12,400 ft-lbf/ft (600

3

kN-m/m ))

3. Terminology

D1193 Specification for Reagent Water

3.1 Definitions:

3.1.1 purified water, n—water that meets Specification

D1193 Type IV requirements.

1

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion

of Metals and is the direct responsibility of Subcommittee G01.10 on Corrosion in

3.2 For other definitions of terms used in this guide, refer to

Soils.

NACE/ASTM Terminology G193 (Standard Terminology and

Current edition approved Nov. 1, 2023. Published November 2023. Originally

Acronyms Relating to Corrosion).

approved in 1999. Last previous edition approved in 2018 as G162 – 18. DOI:

10.1520/G0162-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G162 − 23

4. Significance and Use

4.1 This practice provides a controlled corrosive environ-

ment that has been utilized to produce relative corrosion

information.

4.2 The primary application of the data from this practice is

to evaluate the performance of metallic materials for use in soil

environments.

4.3 This practice may not duplicate

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G162 − 18 G162 − 23

Standard Practice for

Conducting and Evaluating Laboratory Corrosion Tests in

1

Soils

This standard is issued under the fixed designation G162; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers procedures for conducting laboratory corrosion tests in soils to evaluate the corrosive potential for

corrosion attack on engineering materials. materials in soils. The test is conducted under laboratory ambient temperature unless

the effect of temperature is being evaluated. This practice does not include provisions for microbiological influenced corrosion

(MIC) testing, nor its influence on results.

1.2 This practice covers specimen selection and preparation, test environments, evaluation, and reporting of test results.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

3 3

D698 Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft (600 kN-m/m ))

D1193 Specification for Reagent Water

D1654 Test Method for Evaluation of Painted or Coated Specimens Subjected to Corrosive Environments

D2570 Test Method for Simulated Service Corrosion Testing of Engine Coolants

G1 Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens

G3 Practice for Conventions Applicable to Electrochemical Measurements in Corrosion Testing

3

G4 Guide for Conducting Corrosion Tests in Field Applications (Withdrawn 2023)

G16 Guide for Applying Statistics to Analysis of Corrosion Data

G31 Guide for Laboratory Immersion Corrosion Testing of Metals

G46 Guide for Examination and Evaluation of Pitting Corrosion

G51 Test Method for Measuring pH of Soil for Use in Corrosion Evaluations

1

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion of Metals and is the direct responsibility of Subcommittee G01.10 on Corrosion in Soils.

Current edition approved Oct. 1, 2018Nov. 1, 2023. Published November 2018November 2023. Originally approved in 1999. Last previous edition approved in 20102018

as G162 – 99 (2010).G162 – 18. DOI: 10.1520/G0162-18.10.1520/G0162-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G162 − 23

G57 Test Method for Measurement of Soil Resistivity Using the Wenner Four-Electrode Method

G71 Guide for Conducting and Evaluating Galvanic Corrosion Tests in Electrolytes

G102 Practice for Calculation of Corrosion Rates and Related Information from Electrochemical Measurements

G187 Test Method for Measurement of Soil Resistivity Using the Two-Electrode Soil Box Method

G193 Terminology and Acronyms Relating to Corrosion

G200 Test Method for Measurement of Oxidation-Reduction Potential (ORP) of Soil

G215 Guide for Electrode Potential Measurement

3. Terminology

3.1 Definitions:

3.1.1 purified water, n—water that meets Specification D1193 Type IV requirements.

3.2 For other definitions of terms used in this guide, refer to NACE/ASTM Terminology G193 (Standard Terminology and

Acronyms Relating to Corrosion).

4. Significance and Use

4.1 This practice provides a controlled corrosive environment that has been utilized to produce relative corrosion

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.