ASTM D4171-03(2010)

(Specification)Standard Specification for Fuel System Icing Inhibitors

Standard Specification for Fuel System Icing Inhibitors

ABSTRACT

This specification covers additives for aviation fuels used to inhibit ice formation in aircraft fuel systems. Three types of fuel system icing inhibitors are provided as follows: type I - ethylene glycol monomethyl ether, type II - anhydrous isopropanol, and type III - diethylene glycol monomethyl ether. The relative density, color, distillation range, non-volatile matter, and odor shall be tested to meet the requirements prescribed. The water properties, heptanes miscibility, acidity, water miscibility, and flash point shall be tested to meet the requirements prescribed.

SIGNIFICANCE AND USE

A1.3.1 Fuel system icing inhibitor performance (Type III) is based upon test results using the pure inhibitor in a specific concentration range. Impurities affect inhibitor solubility in the fuel and reduce the effective concentration. Methods are therefore needed to check additive purity to ensure adequate performance in the aircraft.

SCOPE

1.1 This specification covers additives for aviation fuels (see Specifications D910 and D1655) used to inhibit ice formation in aircraft fuel systems.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

A1.1.1 This test method measures the purity of fuel system icing inhibitors (Type III). The test results are used to determine if the inhibitor meets the purity requirements listed in Table 2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D4171 – 03 (Reapproved 2010)

Standard Specification for

Fuel System Icing Inhibitors

This standard is issued under the fixed designation D4171; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1364 Test Method for Water in Volatile Solvents (Karl

Fischer Reagent Titration Method)

1.1 This specification covers additives for aviation fuels

D1476 Test Method for Heptane Miscibility of Lacquer

(see Specifications D910 and D1655) used to inhibit ice

Solvents

formation in aircraft fuel systems.

D1613 Test Method for Acidity in Volatile Solvents and

1.2 The values stated in SI units are to be regarded as

Chemical Intermediates Used in Paint, Varnish, Lacquer,

standard. No other units of measurement are included in this

and Related Products

standard.

D1655 Specification for Aviation Turbine Fuels

1.3 This standard does not purport to address all of the

D1722 Test Method for Water Miscibility of Water-Soluble

safety concerns, if any, associated with its use. It is the

Solvents

responsibility of the user of this standard to establish appro-

D3828 Test Methods for Flash Point by Small Scale Closed

priate safety and health practices and determine the applica-

Cup Tester

bility of regulatory limitations prior to use.

D4052 Test Method for Density, Relative Density, and API

2. Referenced Documents Gravity of Liquids by Digital Density Meter

D5006 Test Method for Measurement of Fuel System Icing

2.1 ASTM Standards:

Inhibitors (Ether Type) in Aviation Fuels

D56 Test Method for Flash Point by Tag Closed Cup Tester

E1 Specification for ASTM Liquid-in-Glass Thermometers

D93 Test Methods for Flash Point by Pensky-Martens

E70 Test Method for pH of Aqueous Solutions With the

Closed Cup Tester

Glass Electrode

D268 Guide for Sampling andTestingVolatile Solvents and

E203 Test Method forWater UsingVolumetric Karl Fischer

Chemical Intermediates for Use in Paint and Related

Titration

Coatings and Material

E300 Practice for Sampling Industrial Chemicals

D891 Test Methods for Specific Gravity, Apparent, of

E450 Method for Measurement of Color of Low-Colored

Liquid Industrial Chemicals

Clear Liquids Using the Hunterlab Color Difference Me-

D910 Specification for Aviation Gasolines

ter

D1078 Test Method for Distillation Range of Volatile Or-

E1064 Test Method for Water in Organic Liquids by Cou-

ganic Liquids

lometric Karl Fischer Titration

D1209 Test Method for Color of Clear Liquids (Platinum-

Cobalt Scale)

3. Classification

D1296 Test Method for Odor of Volatile Solvents and

3.1 Twotypesoffuelsystemicinginhibitorsareprovidedas

Diluents

follows:

D1353 Test Method for Nonvolatile Matter in Volatile

3.1.1 Type I—Ethylene glycol monomethyl ether is used as

Solvents for Use in Paint, Varnish, Lacquer, and Related

an anti-icing additive in both aviation gasoline and aviation

Products

turbine fuels.

NOTE 1—Ethylene glycol monomethyl ether (EGME) was previously

This specification is under the jurisdiction of ASTM Committee D02 on

included in this specification, last appearing in D4171–94. EGME is

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

considered technically satisfactory for this application, but has been

D02.J0.04 on Additives and Electrical Properties.

generally replaced by DiEGME due to availability, reduced toxicological

Current edition approved July 1, 2010. Published July 2010. Originally approved

concerns, and lack of widely available methodology to determine FSII

in 1982. Last previous edition approved in 2001 as D4171–03. DOI: 10.1520/

concentration in aviation fuels when a mixture is known to be present, or

D4171-03R10.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or when the identity of the FSII present in the fuel is not clearly known.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4171 – 03 (2010)

TABLE 2 Detailed Requirements for Fuel System Icing Inhibitors

3.2 Type II—Anhydrous isopropanol, also described as

(Type III)

99 % grade 2-Propanol or isopropyl alcohol, is used as an

Requirement

anti-icing additive in aviation gasoline. (Warning—

Property ASTM Test

DiEGME

Isopropanol (2-Propanol) is both flammable and an irritant; use

Method

(Type III)

with caution.)

Acid number, max, mg 0.09 D1613

3.3 Type III—Diethylene glycol monomethyl ether (Di-

KOH/g

EGME) is used as an anti-icing additive in both aviation

Color, platinum-cobalt, 10 D1209 or E450

gasoline and aviation turbine fuel. (Warning—Diethylene max

Purity, min, mass % 99.0 Annex A1

glycol monomethyl ether, (DiEGME). Combustible, toxic

A

pH of 25 % solution in 5.5–7.5 E70

material.)

water (25 6 2°C)

3.3.1 Test Method D5006 can be used to determine the

Relative density, 1.020– D891 (Method A or

20°/20°C 1.025 B) or D4052

concentration of DiEGME in aviation fuels.

Water, max, mass % D1364, E1064,or

E203

4. Properties

Point of manufacture 0.10

Point of use 0.8

4.1 Type II—Isopropanol anti-icing additive shall conform

Flash point, min, °C 85°C D93, D56,or

to the requirements of Table 1, as manufactured.

D3828

B

Antioxidant, mg/kg 50–150

4.2 Type III—Diethylene glycol monomethyl ether shall

A

conform to the requirements of Table 2, as manufactured. Twenty-five millilitres of the inhibitor shall be pipetted into a 100-ml volumetric

flask and filled with freshly boiled and cooled distilled water having a pH of 6.5 to

7.5. The pH value shall be measured with a pH meter calibrated in accordance with

5. Sampling

Test Method E70.

B

Acceptable antioxidants are: 2,6-ditertiary-butyl-4-methylphenol, 2,4-dimethyl-

5.1 The material shall be sampled in accordance with

6-tertiary-butyl phenol, 2,6-ditertiary-butyl phenol, and 75 % min 2,6-ditertiary-

Practice E300.

butyl phenol plus 25 % max tertiary and tritertiary butyl phenols.

6. Test Methods

6.1.1 Relative Density—Determine the relative density (that

is, specific gravity) at 20 or 25°C with respect to water by a

6.1 The properties enumerated in this specification shall be

method accurate to the third decimal place. See Section 5 of

determined in accordance with the following ASTM methods:

Test Method D268, Test Method D4052, or Method A or B of

Test Methods D891.

TABLE 1 Detailed Requirements for Isopropanol (99 % Grade)

6.1.2 Color—Test Method D1209 or E450.

(Type II) FSII

6.1.3 Distillation Range—Test Method D1078 usingASTM

ASTM Test

Property Requirement Solvents DistillationThermometers (40C with a range from 72

Method

to 126°C for isopropanol) conforming to the requirements of

Acidity, max, mg KOH/g 0.019 D1613

Specification E1.

Relative density:

6.1.4 Nonvolatile Matter—Test Method D1353.

20/20°C 0.785 to 0.787 D268

25/25°C 0.782 to 0.784 D268

6.1.5 Odor—Test Method D1296.

Color, platinum-cobalt, max 10 D1209 or E450

6.1.6 Water—Test Method D1364, E1064,or E203.

Distillation range, max, °C 1.5 (including 82.3°C) D1078

Nonvolatile matter, max, 5 D1353 6.1.7 Heptane Miscibility—Test Method D1476.

mg/100 mL

6.1.8 Acidity—Test Method D1613.

Odor characteristic, nonresidual D1296

6.1.9 Water Miscibility—Test Method D1722.

Water, max, mass % 0.2 D1364

Heptane miscibility at 20°C miscible without turbidity with D1476 6.1.10 Flash Point—Test Methods D56, D93,or D3828.

19 vol 99 % heptane

Water miscibility at 25°C miscible without turbidity when D1722

7. Keywords

diluted with 10 vol distilled

7.1 additives; aircraft fuel systems; aviation fuels; fuel

water

system icing inhibitors; ice formation

D4171 – 03 (2010)

ANNEX

(Mandatory Information)

A1. TEST METHOD FOR DETERMINING PURITY OF FUEL SYSTEM ICING INHIBITORS (TYPES I AND III)

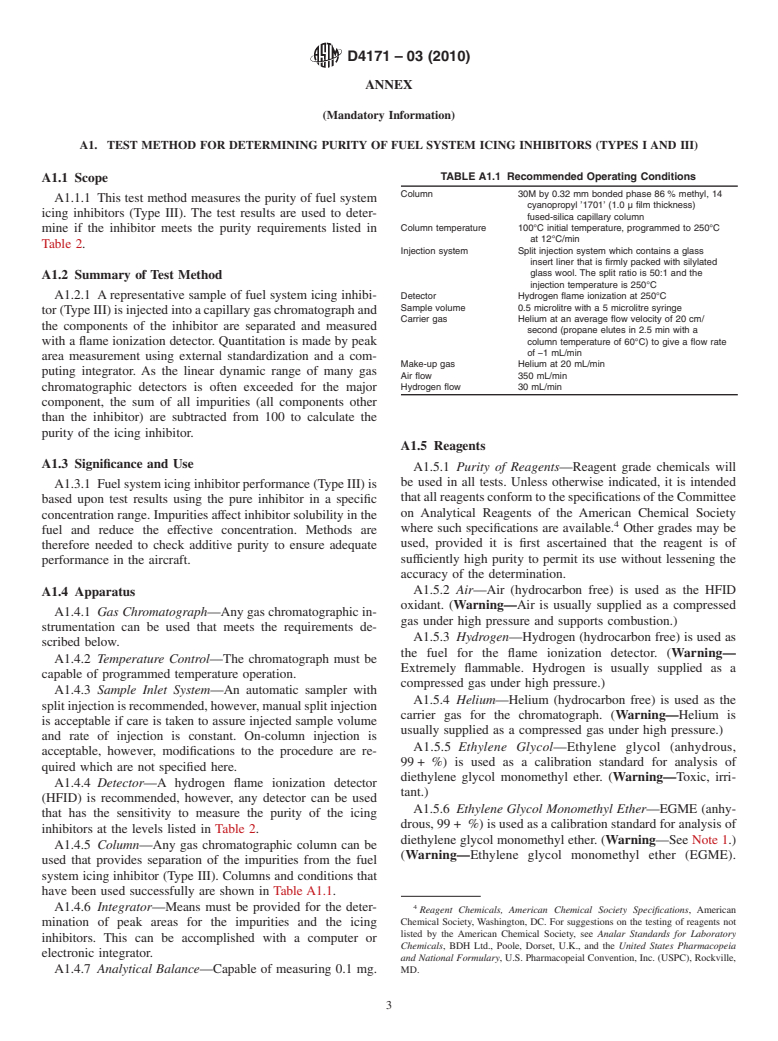

TABLE A1.1 Recommended Operating Conditions

A1.1 Scope

Column 30M by 0.32 mm bonded phase 86 % methyl, 14

A1.1.1 This test method measures the purity of fuel system

cyanopropyl ’1701’ (1.0 µ film thickness)

icing inhibitors (Type III). The test results are used to deter-

fused-silica capillary column

Column temperature 100°C initial temperature, programmed to 250°C

mine if the inhibitor meets the purity requirements listed in

at 12°C/min

Table 2.

Injection system Split injection system which contains a glass

insert liner that is firmly packed with silylated

glass wool. The split ratio is 50:1 and the

A1.2 Summary of Test Method

injection temperature is 250°C

A1.2.1 A representative sample of fuel system icing inhibi- Detector Hydrogen flame ionization at 250°C

Sample volume 0.5 microlitre witha5microlitre syringe

tor(TypeIII)isinjectedintoacapillarygaschromatographand

Carrier gas Helium at an average flow velocity of 20 cm/

the components of the inhibitor are separated and measured

second (propane elutes in 2.5 min with a

column temperature of 60°C) to give a flow rate

with a flame ionization detector. Quantitation is made by peak

of −1 mL/min

area measurement using external standardization and a com-

Make-up gas Helium at 20 mL/min

puting integrator. As the linear dynamic range of many gas

Air flow 350 mL/min

Hydrogen flow 30 mL/min

chromatographic detectors is often exceeded for the major

component, the sum of all impurities (all components other

than the inhibitor) are subtracted from 100 to calculate the

purity of the icing inhibitor.

A1.5 Reagents

A1.3 Significance and Use

A1.5.1 Purity of Reagents—Reagent grade chemicals will

be used in all tests. Unless otherwise indicated, it is intended

A1.3.1 Fuelsystemicinginhibitorperformance(TypeIII)is

thatallreagentsconformtothespecificationsoftheCommittee

based upon test results using the pure inhibitor in a specific

on Analytical Reagents of the American Chemical Society

concentration range. Impurities affect inhibitor solubility in the

where such specificat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.