ASTM D8041/D8041M-16

(Test Method)Standard Test Method for Whole Boot Breathability (MVTR)

Standard Test Method for Whole Boot Breathability (MVTR)

SIGNIFICANCE AND USE

4.1 The materials and construction methods used in the manufacture of footwear play a significant role in the “breathability” of the footwear. This test method provides a means to measure moisture vapor permeability, expressed as MVTR, which is one aspect of comfort of the footwear.

SCOPE

1.1 The whole boot breathability test method is designed to indicate the Moisture Vapor Transmission Rate (MVTR) through the boot upper by means of a difference in temperature and moisture vapor concentration between the interior of the boot and the exterior environment. This method is intended for a size 10 R U.S. (Regular width) boot that is at least 6 in. [15.2 cm] tall above the insole

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system is to be used independently of the other, without combining values in any way. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8041/D8041M − 16

Standard Test Method for

1

Whole Boot Breathability (MVTR)

This standard is issued under the fixed designation D8041/D8041M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.1.6 heel, n—the part of the boot which supports the back

part of the foot.

1.1 The whole boot breathability test method is designed to

2.1.7 insert, n—removable foot bed which is shaped or

indicate the Moisture Vapor Transmission Rate (MVTR)

molded to match the approximate contour of the bottom

throughthebootupperbymeansofadifferenceintemperature

surface of the foot.

and moisture vapor concentration between the interior of the

boot and the exterior environment.This method is intended for

2.1.8 plug, n—a circular or oval shaped (non metallic) boot

asize10RU.S.(Regularwidth)bootthatisatleast6in.[15.2

plug that holds the (copper foot form) water heating assembly

cm] tall above the insole

and seals the top of the water holding bootie insert and upper

at the water interface. The plug must be made from material

1.2 The values stated in either inch-pound units or SI units

that is impervious to both liquid water and water vapor.

are to be regarded separately as standard. Within the text, the

SI units are shown in brackets. The values stated in each

2.1.9 sole or outsole, n—the bottom layer of the footwear,

system are not exact equivalents; therefore, each system is to

including the heel, in contact with the ground forming the

be used independently of the other, without combining values

walking surface.

inanyway.Combiningvaluesfromthetwosystemsmayresult

2.1.10 upper, n—the entire part of the footwear located

in non-conformance with the standard.

above the sole. Includes external leather and synthetic materi-

1.3 This standard does not purport to address all of the

als as well as internal linings.

safety concerns, if any, associated with its use. It is the

2.1.11 water holding bootie insert (WHBI), n—a thin,

responsibility of the user of this standard to establish appro-

flexible, waterproof, breathable bootie meeting the require-

priate safety and health practices and determine the applica-

ments of 6.3.

bility of regulatory limitations prior to use.

3. Summary of Test Method

2. Terminology

3.1 A test sample boot fitted with a water holding bootie

2.1 Definitions:

insert (WHBI) is filled with preheated water and weighed.The

2.1.1 boot, n—footwear in which the upper reaches above

wateriskeptataconstanttemperaturefor6handthentheboot

the ankle.

(with water) is reweighed. The loss in weight is used to

2.1.2 eyelet, n—textile, metal or plastic reinforcements

calculate the Moisture Vapor Transmission Rate (MVTR) of

around the holes which carry the lace.

the footwear, otherwise known as breathability.

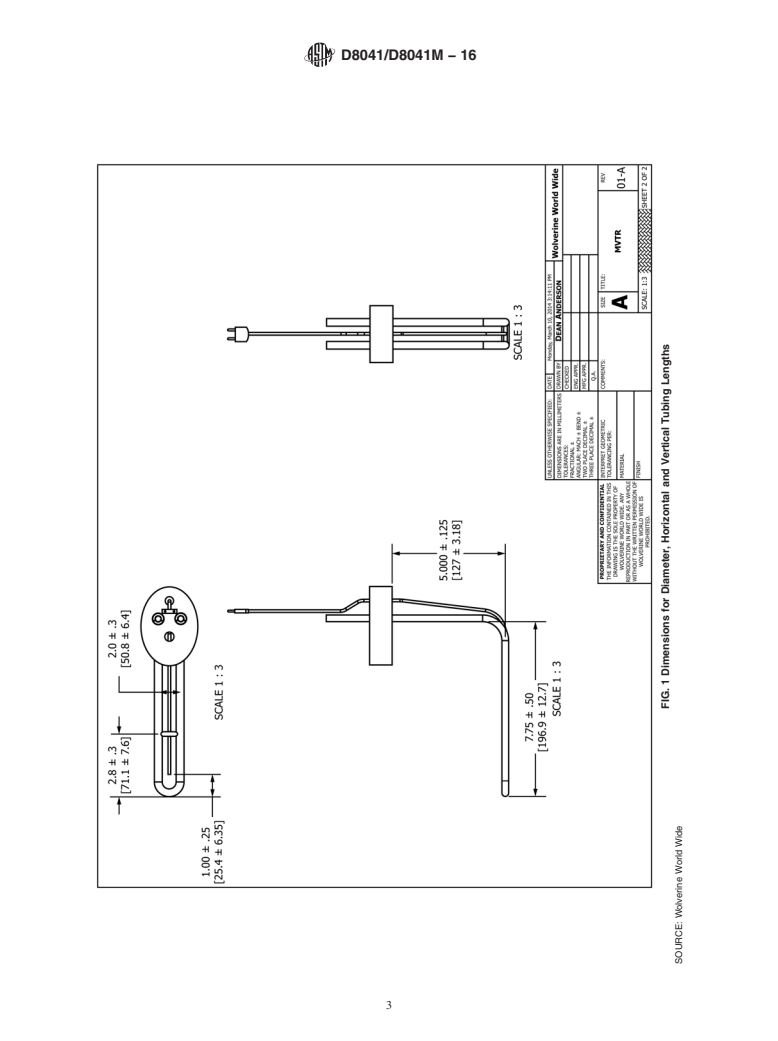

2.1.3 foot form assembly, n—relating to this test method,the

foot form consists of boot plug with copper tubing in a shape

4. Significance and Use

of a foot.

4.1 The materials and construction methods used in the

2.1.4 footwear, n—wearing apparel for feet (such as shoes,

manufacture of footwear play a significant role in the “breath-

boots, slippers).

ability” of the footwear. This test method provides a means to

measure moisture vapor permeability, expressed as MVTR,

2.1.5 gusset, n—the part of the vamp that extends over the

which is one aspect of comfort of the footwear.

instep of the foot between the eyestays and allows expansions

of the opening at the top of the footwear.

5. Interferences

2.1.5.1 Discussion—For slip-on footwear this may include

anelasticgussetthatallowsexpansionattheopeningatthetop

5.1 Temperature, humidity or air movement fluctuations.

of the footwear.

6. Apparatus

1

This test method is under the jurisdiction ofASTM Committee D31 on Leather

6.1 The external test environment control system shall be

and is the direct responsibility of Subcommittee D31.03 on Footwear.

capable of maintaining 73 6 2 °F [23.0 6 1.0 °C] and 50 6 2

Current edition approved Sept. 1, 2016. Published November 2016. DOI:

10.1520/D8041_D8041M-16. % relative humidity throughout the test duration.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8041/D8041M − 16

6.2 Theweightscaleshallbecapableofdeterminingweight 6.11 The wind speed shall be 250 6 30 ft/min [1.3 60.15

of boot, plus foot form assembly and WHBI filled with water m/s] at the heel

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D8041/D8041M − 16

Standard Test Method for

1

Whole Boot Breathability (MVTR)

This standard is issued under the fixed designation D8041/D8041M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.1.6 heel, n—the part of the boot which supports the back

part of the foot.

1.1 The whole boot breathability test method is designed to

2.1.7 insert, n—removable foot bed which is shaped or

indicate the Moisture Vapor Transmission Rate (MVTR)

molded to match the approximate contour of the bottom

through the boot upper by means of a difference in temperature

surface of the foot.

and moisture vapor concentration between the interior of the

boot and the exterior environment. This method is intended for

2.1.8 plug, n—a circular or oval shaped (non metallic) boot

a size 10 R U.S. (Regular width) boot that is at least 6 in. [15.2

plug that holds the (copper foot form) water heating assembly

cm] tall above the insole

and seals the top of the water holding bootie insert and upper

at the water interface. The plug must be made from material

1.2 The values stated in either inch-pound units or SI units

that is impervious to both liquid water and water vapor.

are to be regarded separately as standard. Within the text, the

SI units are shown in brackets. The values stated in each

2.1.9 sole or outsole, n—the bottom layer of the footwear,

system are not exact equivalents; therefore, each system is to

including the heel, in contact with the ground forming the

be used independently of the other, without combining values

walking surface.

in any way. Combining values from the two systems may result

2.1.10 upper, n—the entire part of the footwear located

in non-conformance with the standard.

above the sole. Includes external leather and synthetic materi-

1.3 This standard does not purport to address all of the

als as well as internal linings.

safety concerns, if any, associated with its use. It is the

2.1.11 water holding bootie insert (WHBI), n—a thin,

responsibility of the user of this standard to establish appro-

flexible, waterproof, breathable bootie meeting the require-

priate safety and health practices and determine the applica-

ments of 6.3.

bility of regulatory limitations prior to use.

3. Summary of Test Method

2. Terminology

3.1 A test sample boot fitted with a water holding bootie

2.1 Definitions:

insert (WHBI) is filled with preheated water and weighed. The

2.1.1 boot, n—footwear in which the upper reaches above

water is kept at a constant temperature for 6 h and then the boot

the ankle.

(with water) is reweighed. The loss in weight is used to

2.1.2 eyelet, n—textile, metal or plastic reinforcements

calculate the Moisture Vapor Transmission Rate (MVTR) of

around the holes which carry the lace.

the footwear, otherwise known as breathability.

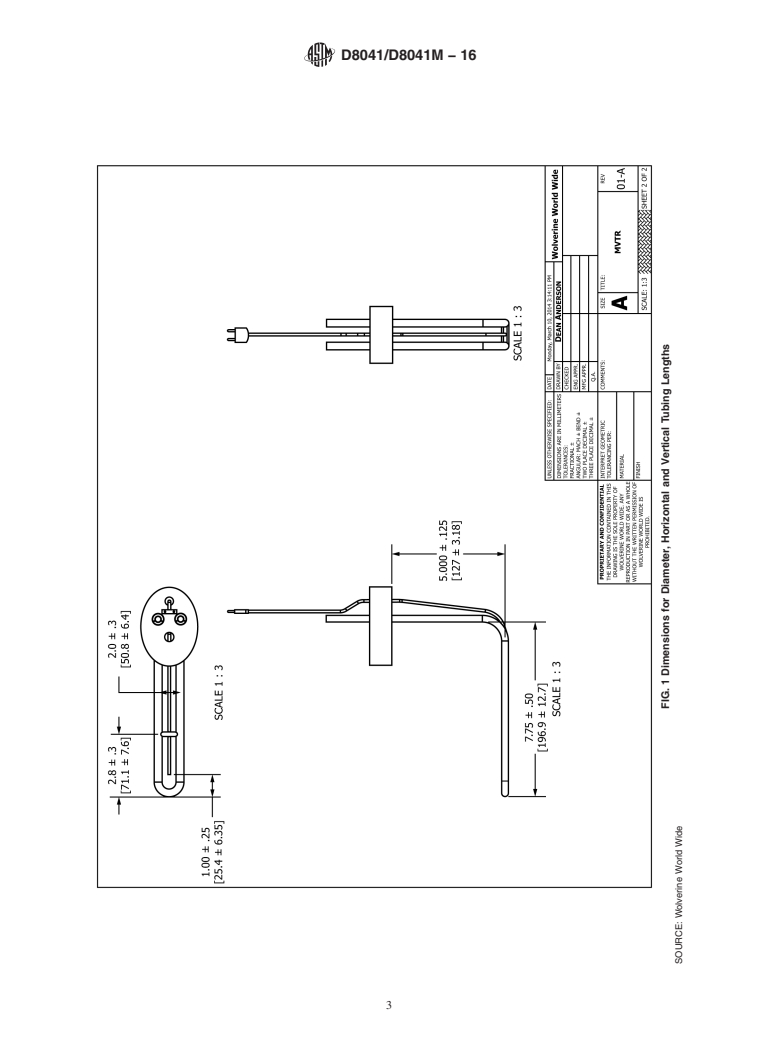

2.1.3 foot form assembly, n—relating to this test method, the

foot form consists of boot plug with copper tubing in a shape

4. Significance and Use

of a foot.

4.1 The materials and construction methods used in the

2.1.4 footwear, n—wearing apparel for feet (such as shoes,

manufacture of footwear play a significant role in the “breath-

boots, slippers).

ability” of the footwear. This test method provides a means to

measure moisture vapor permeability, expressed as MVTR,

2.1.5 gusset, n—the part of the vamp that extends over the

which is one aspect of comfort of the footwear.

instep of the foot between the eyestays and allows expansions

of the opening at the top of the footwear.

5. Interferences

2.1.5.1 Discussion—For slip-on footwear this may include

an elastic gusset that allows expansion at the opening at the top

5.1 Temperature, humidity or air movement fluctuations.

of the footwear.

6. Apparatus

1

This test method is under the jurisdiction of ASTM Committee D31 on Leather

6.1 The external test environment control system shall be

and is the direct responsibility of Subcommittee D31.03 on Footwear.

capable of maintaining 73 6 2 °F [23.0 6 1.0 °C] and 50 6 2

Current edition approved Sept. 1, 2016. Published November 2016. DOI:

10.1520/D8041_D8041M-16. % relative humidity throughout the test duration.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8041/D8041M − 16

6.2 The weight scale shall be capable of determining weight 6.11 The wind speed shall be 250 6 30 ft/min [1.3 60.15

of boot, plus foot form assembly and WHBI filled with water m/s] at the heel edge of the boot (S) as measured with a 2.8-in.

to an accuracy of 60.1 g. [7.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.